Method for preparing boron carbide ceramic

A technology of boron carbide ceramics and boron powder, which is applied in the field of preparation of boron carbide ceramics, can solve the problems of high hardness and light weight of boron carbide ceramics, difficulty in meeting the requirements of purity, and unsuitability for industrial production, and achieve short sintering time and low boron-carbon ratio Variety, small grain size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention prepares the method embodiment 1 of boron carbide ceramics, concrete steps comprise:

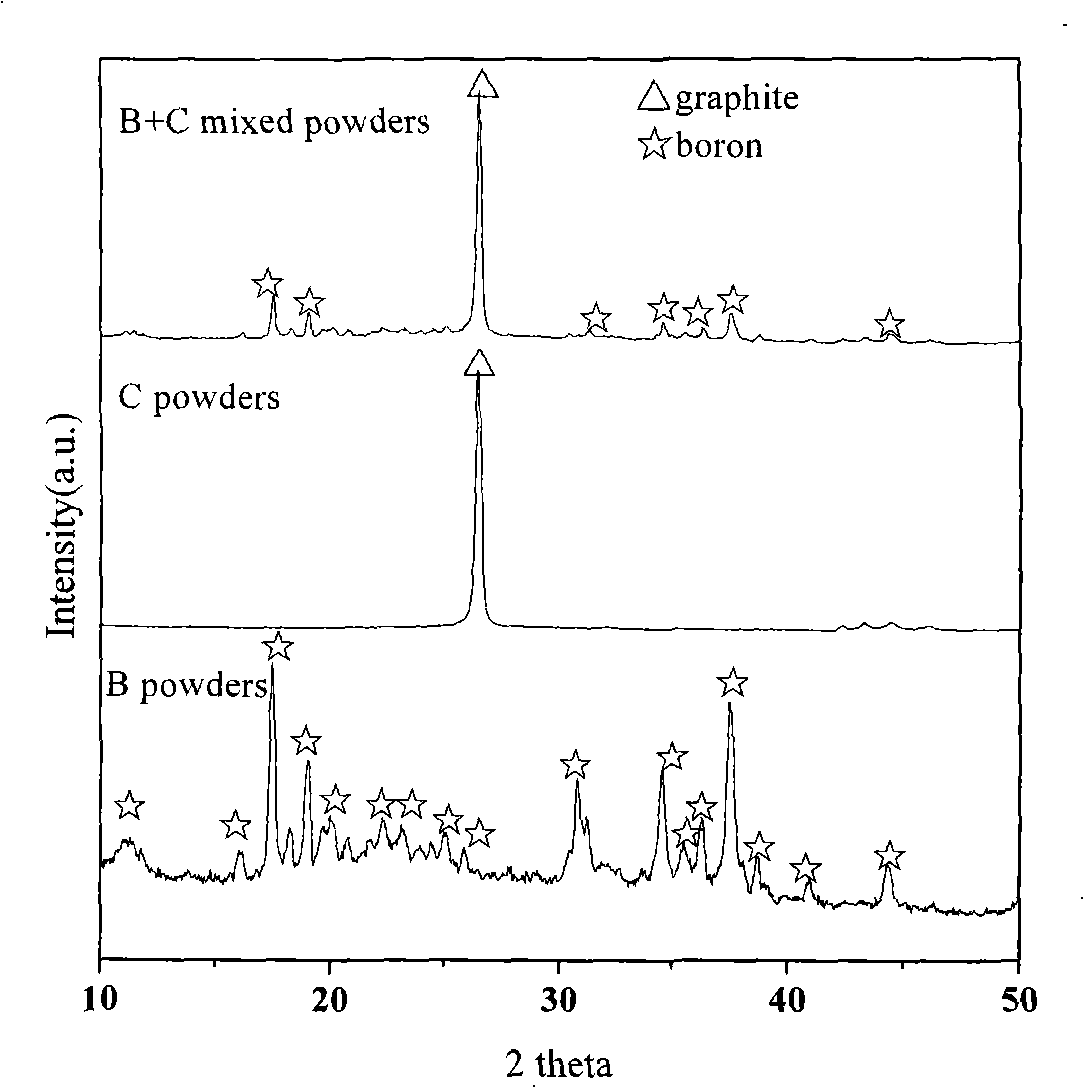

[0030] The first step, taking by weighing elemental boron powder and graphite powder with a purity of 98% and an average particle size of 0.001 μm, the molar ratio of boron to carbon in the above raw materials is 0.5, and mixed uniformly in an agate mortar;

[0031] In the second step, put the powder prepared in the first step into a high-strength graphite mold with a maximum working pressure of 60MPa. There is graphite paper between the powder and the mold, and then send it into a spark plasma sintering equipment (Dr.Sinter1050 SPS, Sumitomo Coal MiningCo ., Tokyo, Japan), and heated to 1300°C at a heating rate of 50°C / min under vacuum conditions with a vacuum degree of 1Pa;

[0032] The third step is to take the mold out of the spark plasma sintering equipment, cool down to room temperature naturally, remove the mold, and finish the product.

Embodiment 2

[0033] The present invention prepares the method embodiment 2 of boron carbide ceramics, concrete steps comprise:

[0034] The first step, taking by weighing boric acid powder and carbon black powder with a purity of 99% and an average particle size of 0.01 μm, the molar ratio of boron to carbon in the above-mentioned raw materials is 3.0, and is uniformly mixed with a mixer;

[0035] The second step is to put the powder prepared in the first step into a high-strength graphite mold with a maximum working pressure of 80MPa. There is graphite paper between the powder and the mold, and send it to a discharge plasma sintering equipment for sintering. 1. Under the condition of pre-pressure 10MPa, the temperature is raised to 1500°C at a heating rate of 100°C / min, and the temperature is kept for 3min;

[0036] The third step is to take the mold out of the spark plasma sintering equipment, cool down to room temperature naturally, remove the mold, and finish the product.

Embodiment 3

[0037] The present invention prepares the method embodiment 3 of boron carbide ceramics, concrete steps comprise:

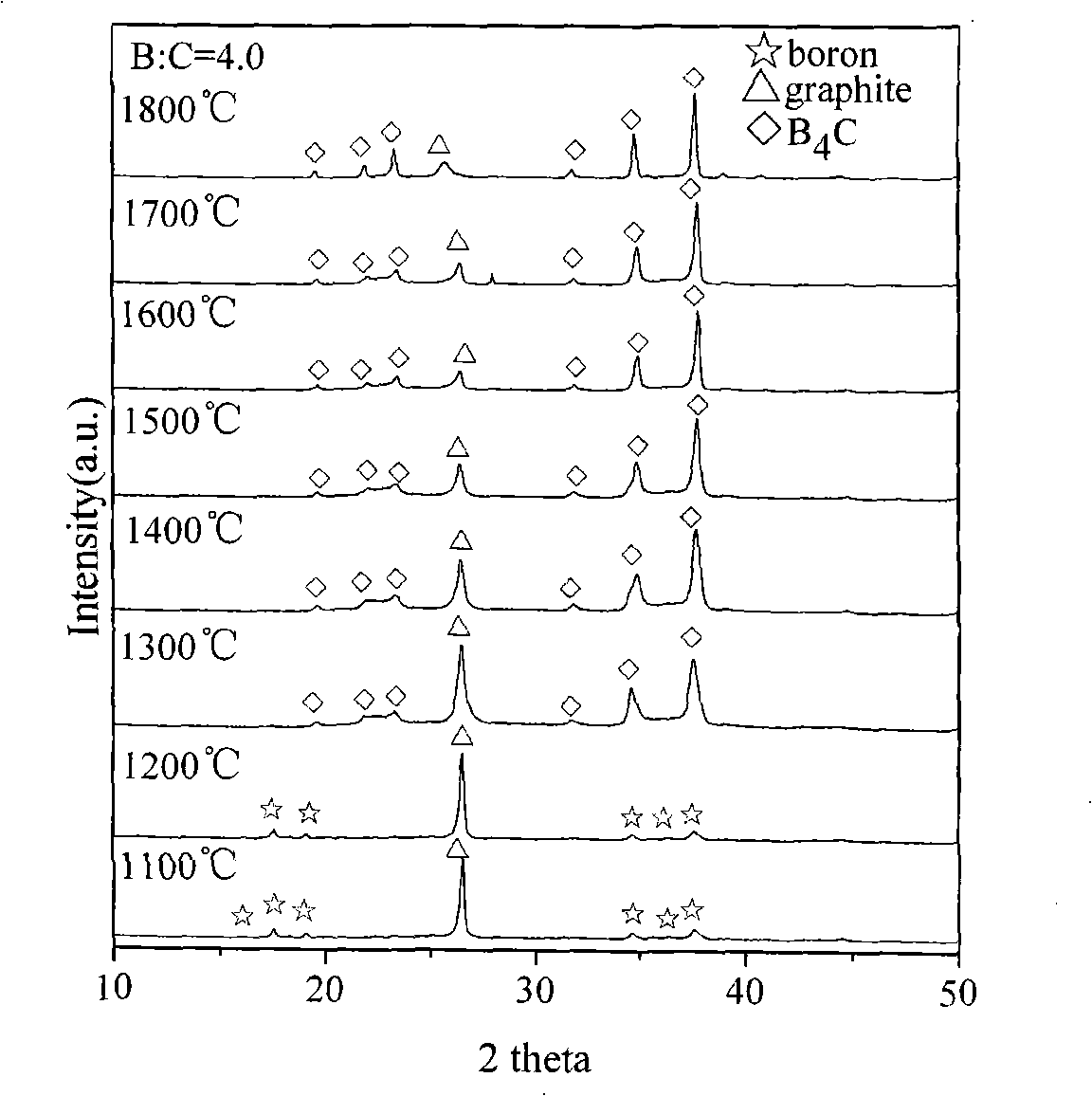

[0038] The first step, taking by weighing boric anhydride powder and petroleum coke powder with a purity of 99.9% and an average particle size of 0.1 μm, the boron-carbon mol ratio in the above-mentioned raw materials is 4.0, and they are uniformly mixed in an agate mortar;

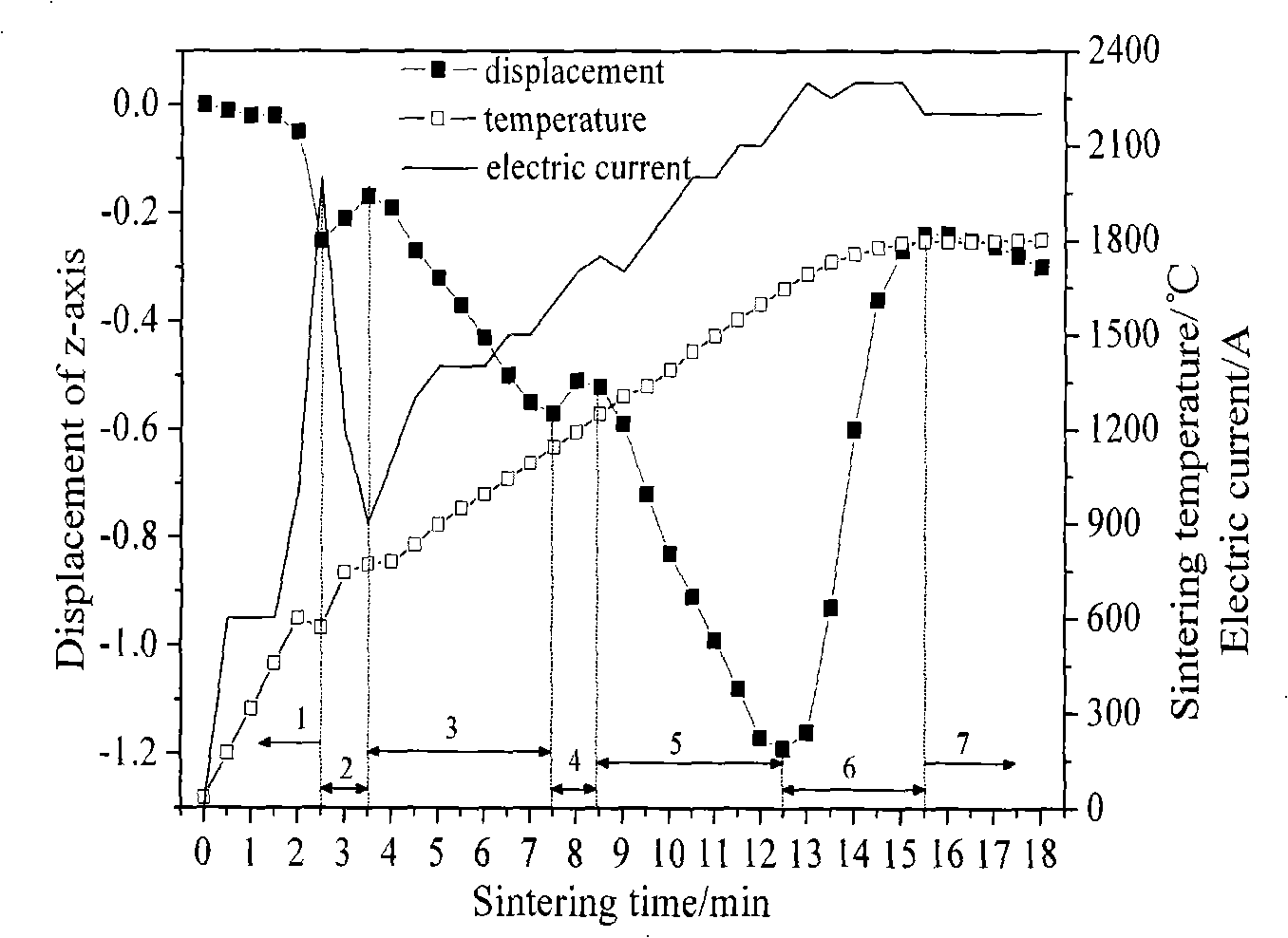

[0039] The second step is to put the powder prepared in the first step into a high-strength graphite mold with a maximum working pressure of 90MPa. There is graphite paper between the powder and the mold, and send it to the discharge plasma sintering equipment for sintering. , Under the condition of pre-pressure 20MPa, the temperature is raised to 1800°C at a heating rate of 150°C / min, and the temperature is kept for 5min;

[0040] The third step is to take the mold out of the spark plasma sintering equipment, cool down to room temperature naturally, remove the mold, and finish the product. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com