Patents

Literature

38results about How to "High voltage gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc oxide piezoresistor material and preparing method thereof

The present invention discloses a zinc oxide piezoresistor material comprising the following raw materials: ZnO, Bi2O3, Sb2O3, Co2O3, Cr2O3, MnCO3, NiO, Al2O3 and oxides of boron, wherein, calculating according to B2O3, the weight ratio of the oxide of boron to ZnO is 2.1-20:100; the percentages by mole of ZnO, Bi2O3, Sb2O3, Co2O3, Cr2O3, MnCO3, NiO and Al2O3 are respectively 90.5%-96.5%, 0.3%-5%, 0.1%-3%, 0.1-2%, 0.1%-1%, 0.2%-2%, 0.1%-1% and 0.005%-0.05%; and voltage-dependent combination performance of the material is good. The present invention further discloses a preparing method of the material; the method has the advantages of simple technology and low cost, and the method is suitable for industrialized production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing electrical property-controllable zinc oxide (ZnO) piezoresistor material at low temperature

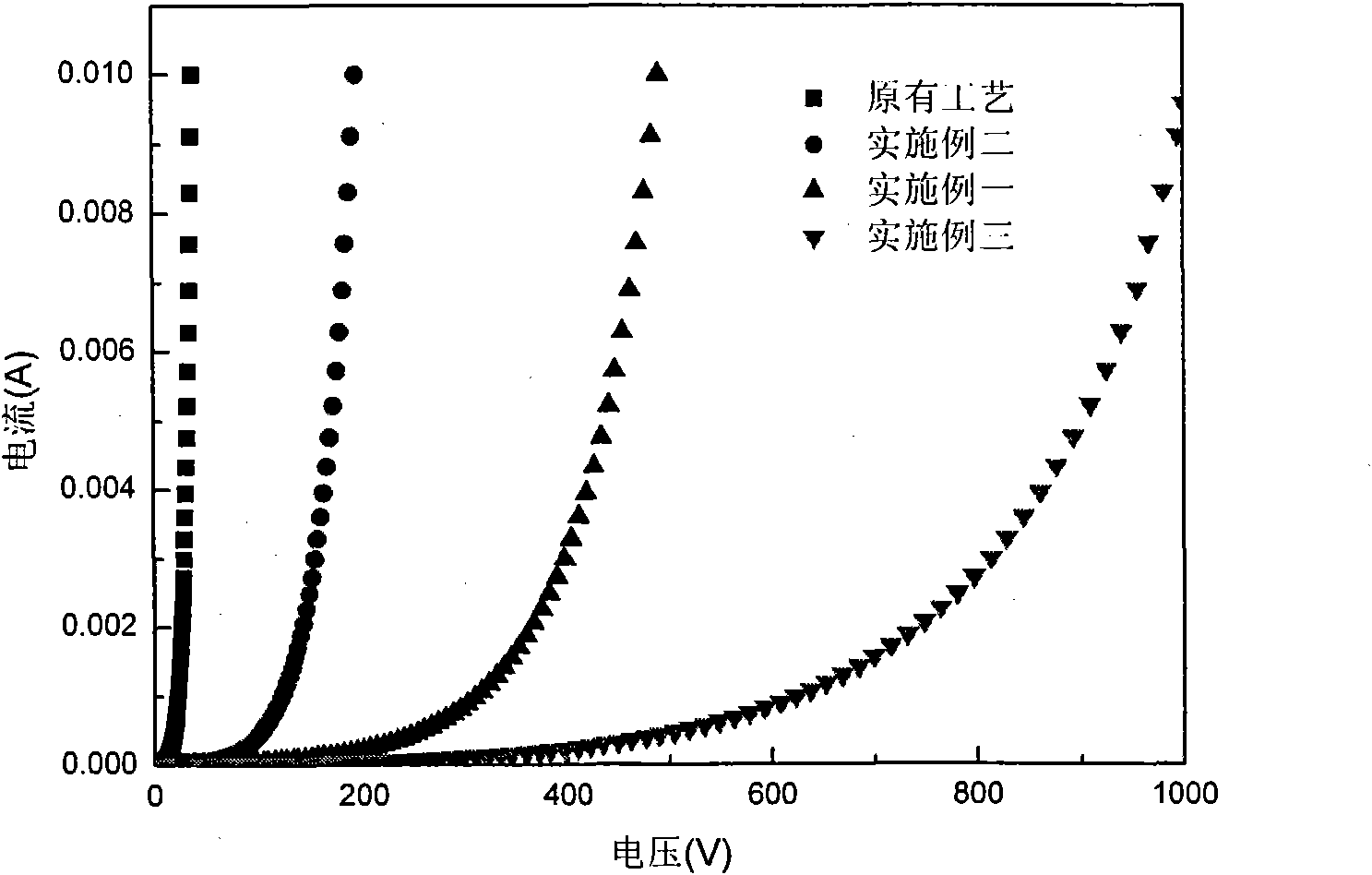

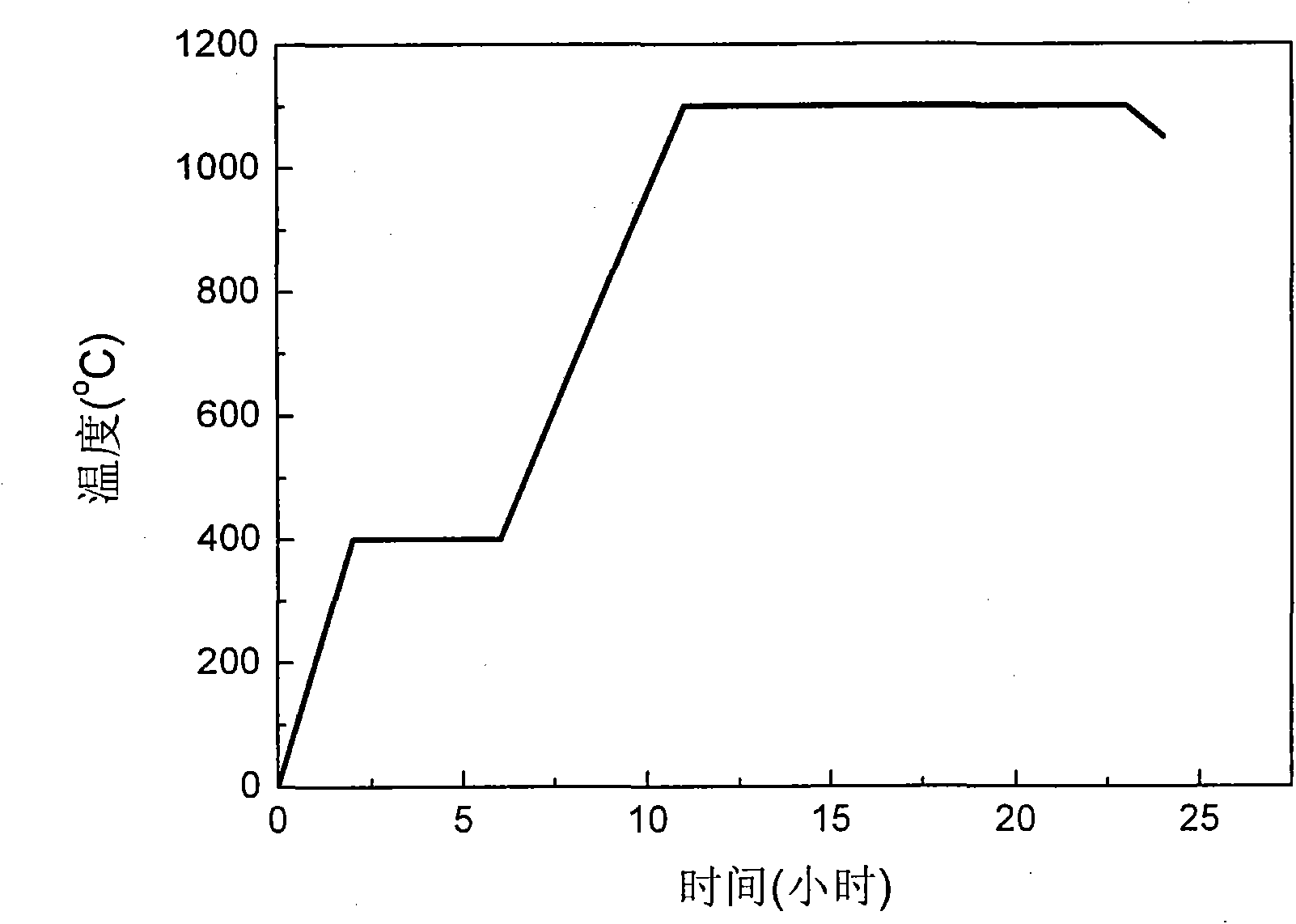

A method for preparing an electrical property-controllable zinc oxide (ZnO) piezoresistor material at a low temperature comprises preparing a high-impedance sintered nanomaterial composed of one or more oxides by solid-phase sintering; subjecting micron-scale ZnO, said high-impedance sintered nanomaterial and at least one nano-scale doped oxide at a given proportion to uniform ball milling by a high-energy ball milling process; sintering at 800-1,100 DEG C.; and adjusting the proportion between the high-impedance sintered material and the doped oxide to obtain a ZnO piezoresistor material with excellent comprehensive electric properties and controllable properties, thus improving the electric potential gradient and the nonlinear property of a ZnO piezoresistor. The inventive method is simple, has highly controllable process, low energy consumption and high yield, and is suitable for industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

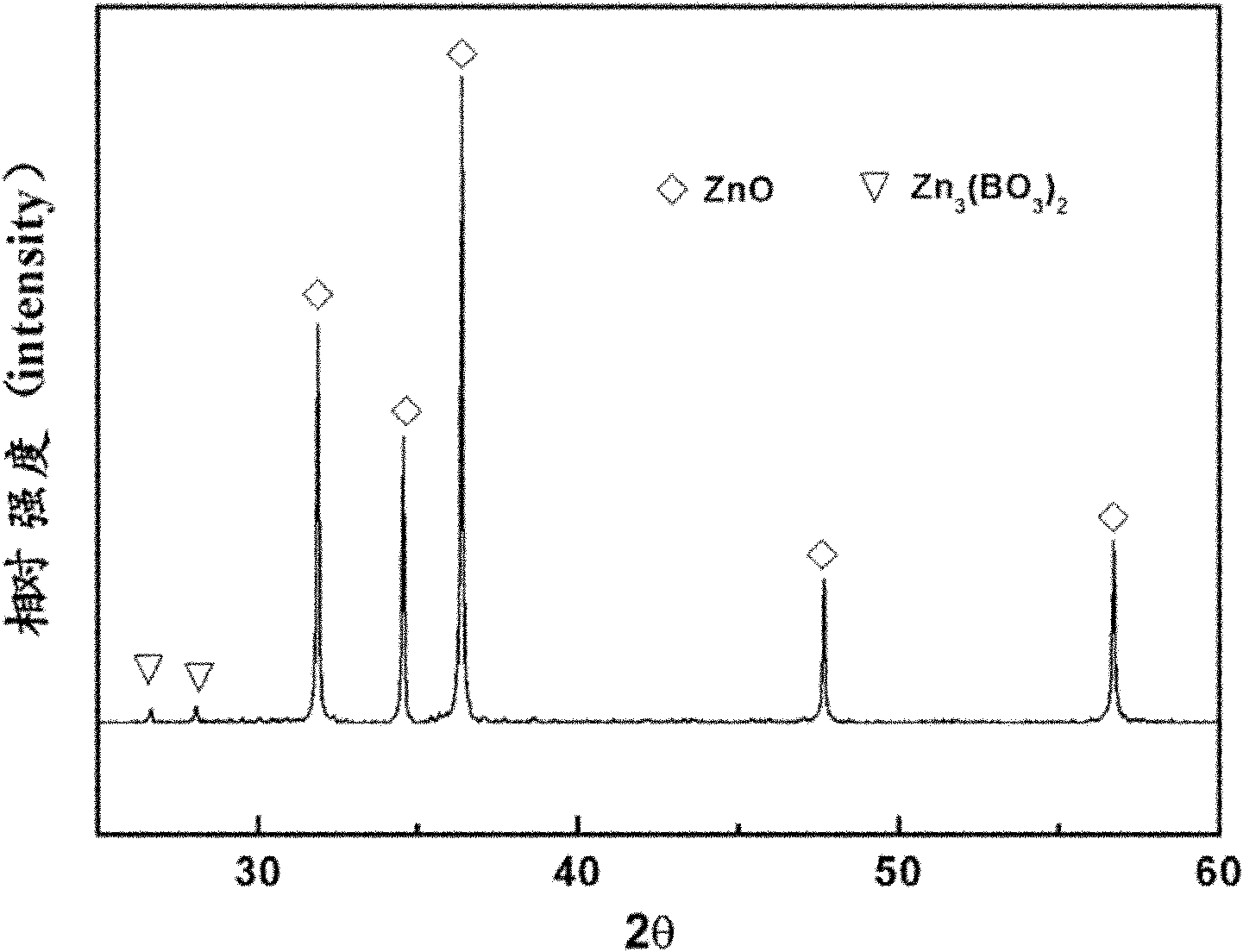

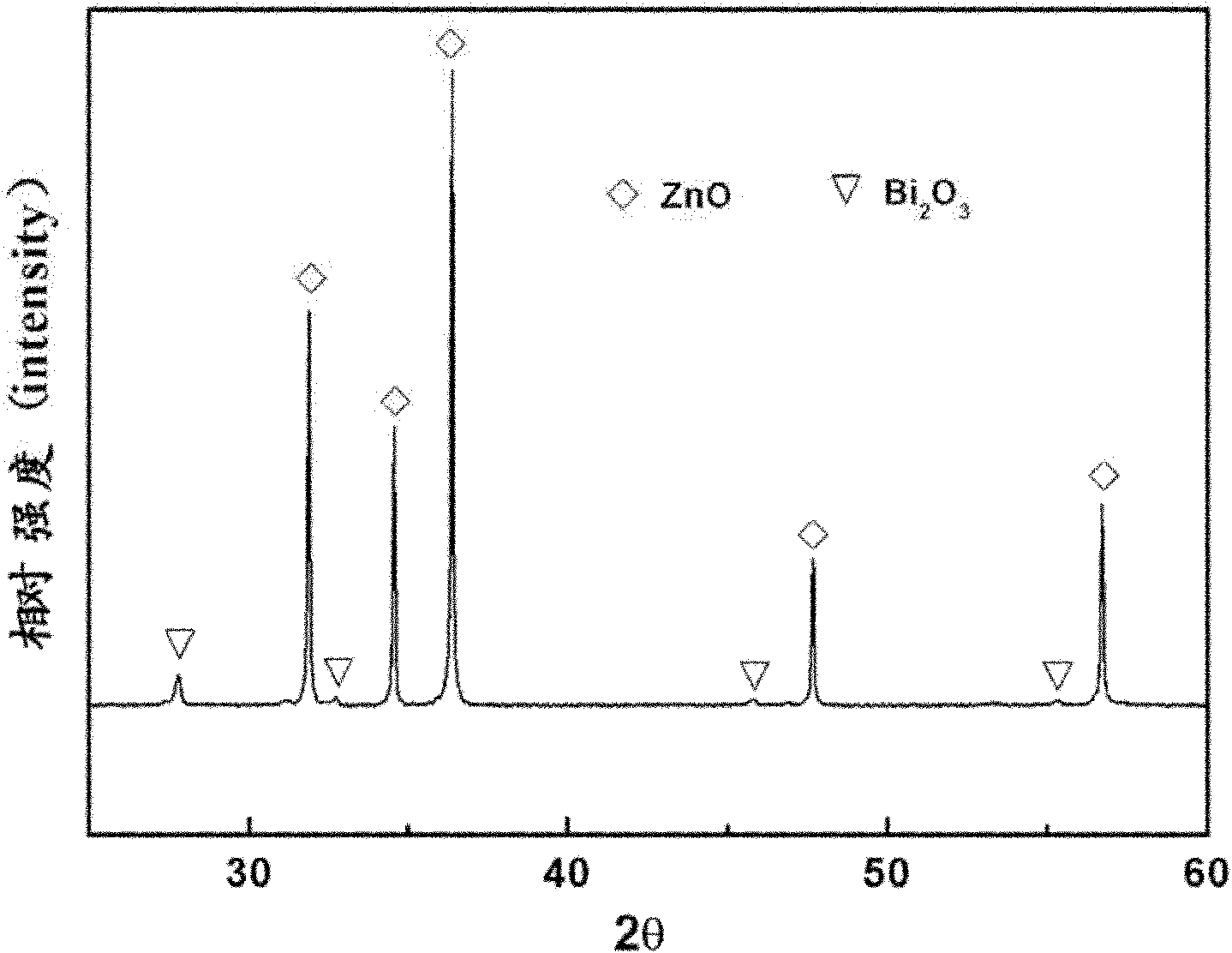

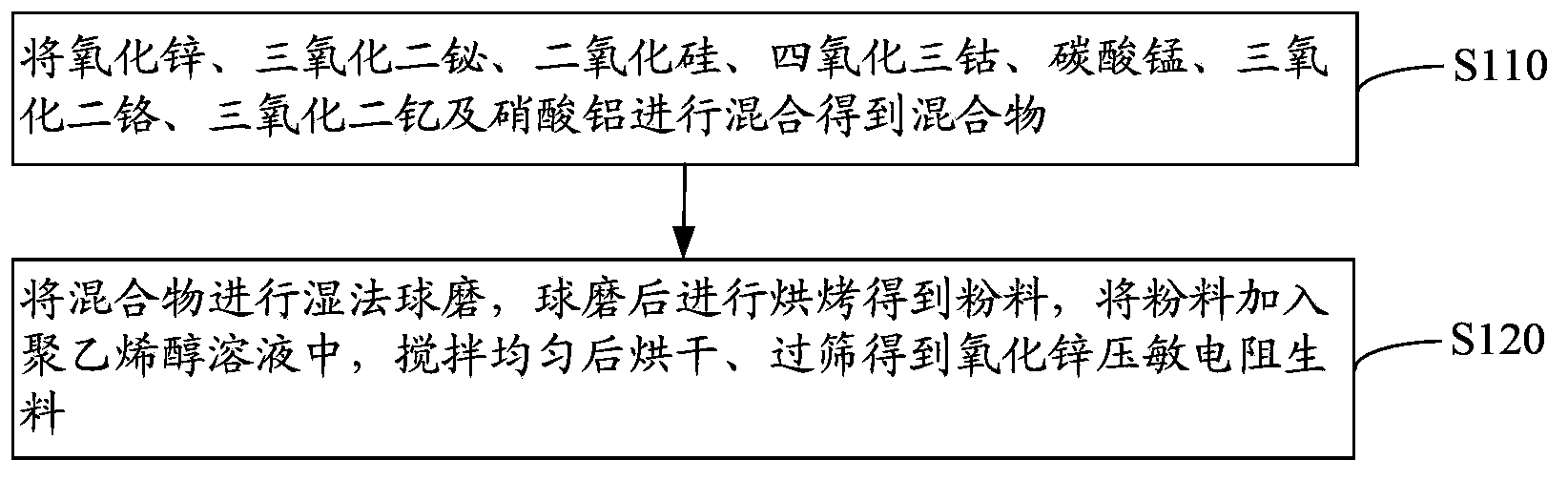

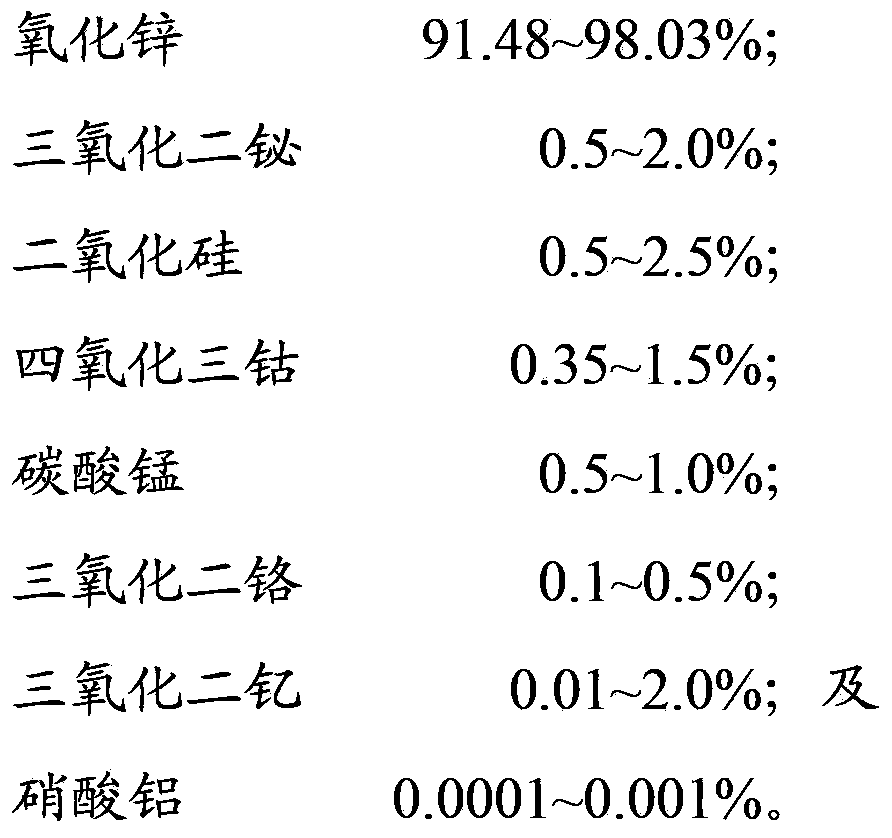

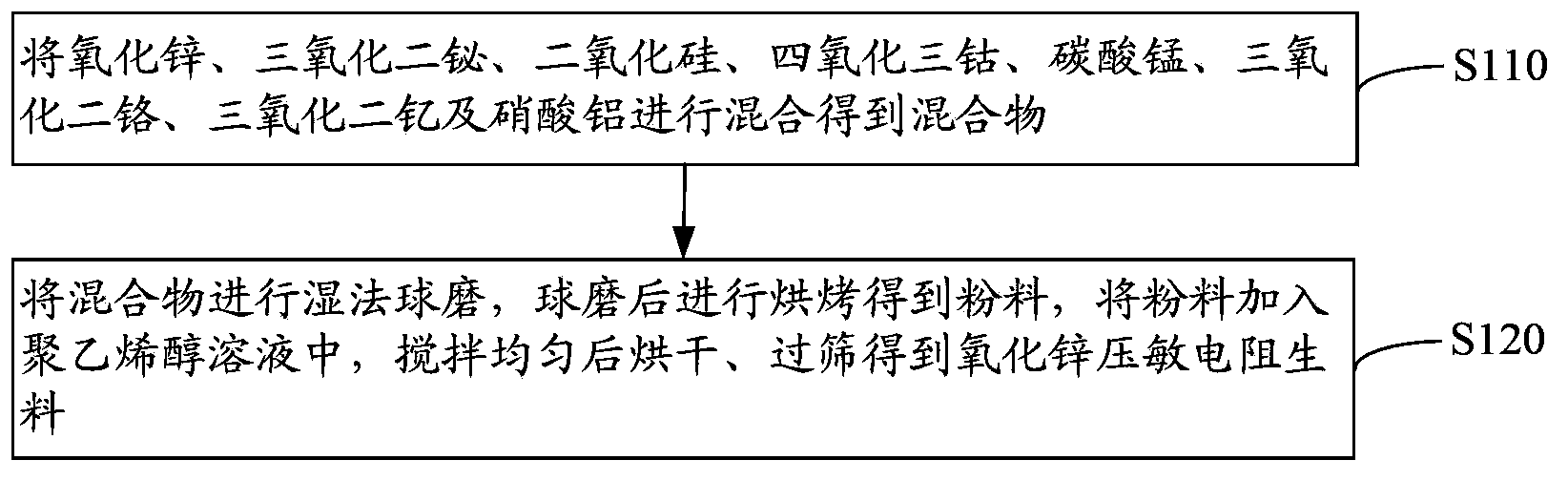

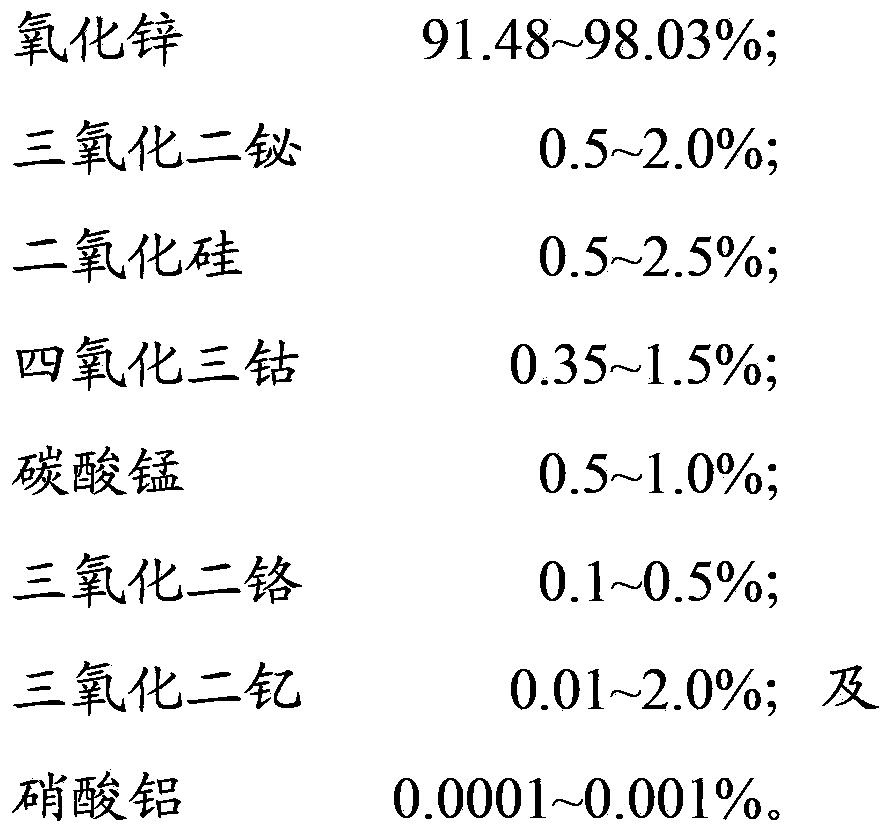

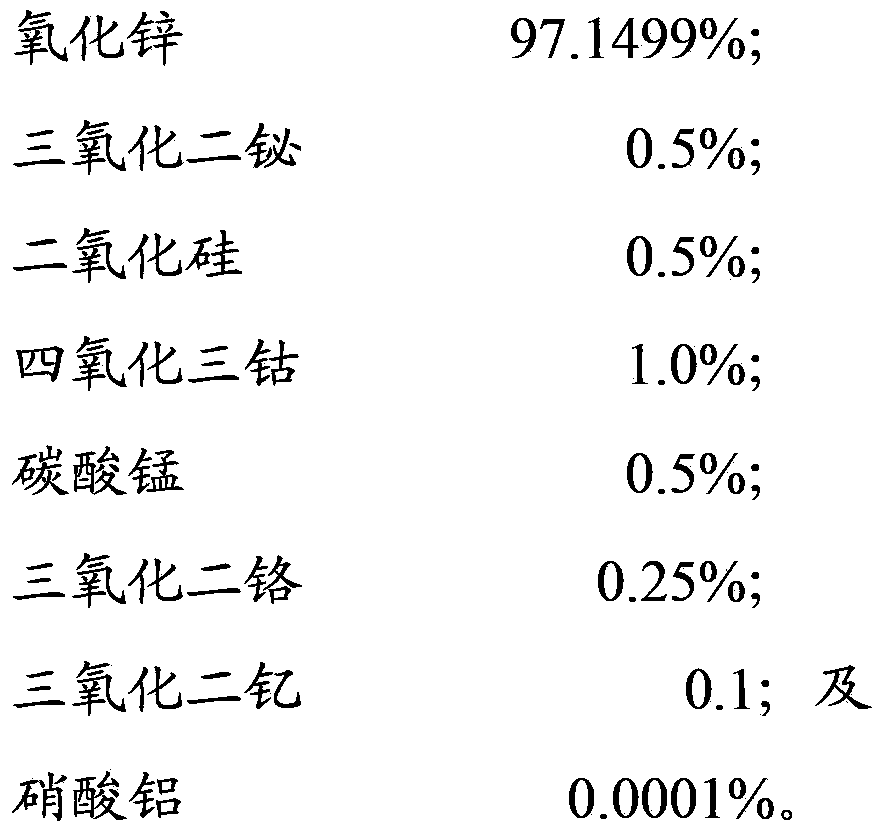

Zinc-oxide piezoresistor raw material, preparation method thereof and piezoresistor

ActiveCN103396116AImprove uniformityIncreased surface state densityVaristor coresOvervoltage protection resistorsManganeseVoltage gradient

The invention relates to a zinc-oxide piezoresistor raw material, a preparation method thereof and a piezoresistor. The zinc-oxide piezoresistor raw material comprises the following components by mole percent: 91.48-98.03% of zinc oxide, 0.5-2.0% of bismuth trioxide, 0.5-2.5% of silicon dioxide, 0.35-1.5% of cobaltosic oxide, 0.5-1.0% of manganese carbonate, 0.1-0.5% of chromium oxide, 0.01-2.0% of yttria and 0.0001-0.001% of aluminium nitrate. The zinc-oxide piezoresistor raw material does not antimony, and due to the silicon dioxide, the characteristic of the piezoresistor is improved, the surface state density is increased, the voltage gradient, the barrier height and the nonlinear coefficient are improved, the leakage current is reduced and the current impact resistance is enhanced; due to the yttria, the conductivity, the current impact resistance, the nonlinear coefficient and the voltage gradient are improved, the limiting voltage rate and the leakage current are reduced, the grain growth is inhibited and the zinc-oxide piezoresistor has higher voltage gradient and excellent electrical property.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Lightning arrester zinc oxide varistor and preparation method thereof

InactiveCN108154983AInhibit growthSmall particle sizeResistor manufactureVaristor coresManganeseAntimony trioxide

The invention discloses a lightning arrester zinc oxide varistor and a preparation method thereof. The lightning arrester zinc oxide varistor is prepared by sintering the raw materials of 85-90% of zinc oxide, 0.1-0.5% of calcium oxide, 4-7% of bismuth trioxide, 4-7% of antimony trioxide, 0.1-1% of manganese carbonate and 0.1-1% of aluminum nitrate. According to the lightning arrester zinc oxide varistor, the added calcium oxide can be effectively wrapped outside zinc oxide grains during sintering to inhibit grain growth, reduce the size of the grains and further improve the voltage gradient and the flow capacity of the grains. The lightning arrester zinc oxide varistor is a system prepared from the zinc oxide, the calcium oxide, the bismuth trioxide, the antimony trioxide, the manganese carbonate and the aluminum nitrate, thereby being low in raw material cost; the prepared lightning arrester zinc oxide varistor is uniform and stable in internal structure high in large current impactresistance.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

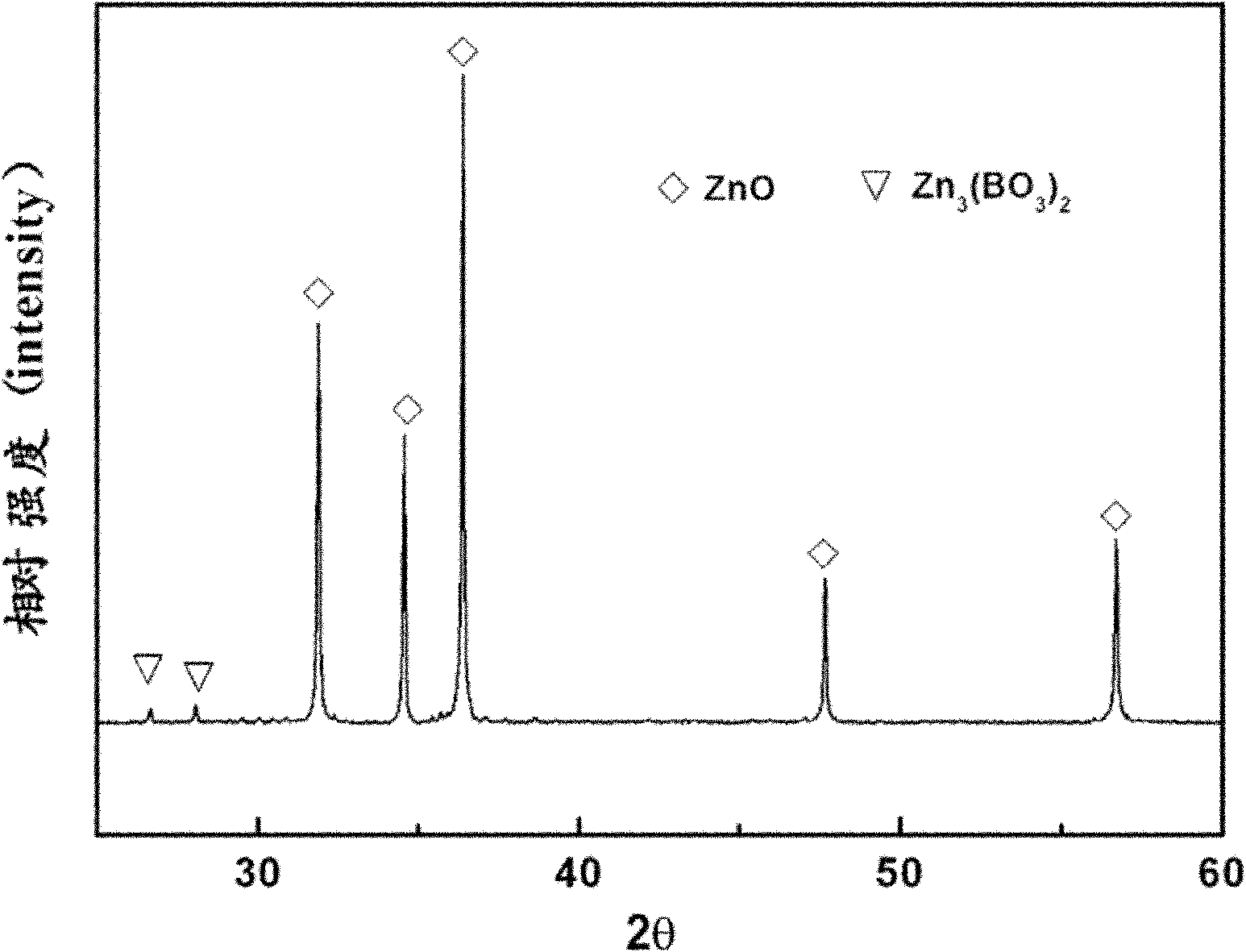

ZnO-Bi2O3-B2O3 series voltage-sensitive material sintered at lower temperature and preparation method thereof

ActiveCN102167579AOptimizing voltage-sensitive comprehensive performancePromote growthBoronMaterials science

The invention discloses a ZnO-Bi2O3-B2O3 series voltage-sensitive material sintered at lower temperature, which is prepared from the following raw materials, such as ZnO, Bi2O3, TiO2, Co2O3, Cr2O3, MnCO3, NiO, Al2O3 and oxides of boron. In B2O3 terms, the additive amount of the oxides of boron is 2.2-20 parts by weight as comparison with 100 parts by weight of ZnO. The material contains no Sb2O3,has lower sintering temperature and favorable voltage-sensitive comprehensive properties. The invention also discloses a preparation method of the material, which is simple in process and easy to operate.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

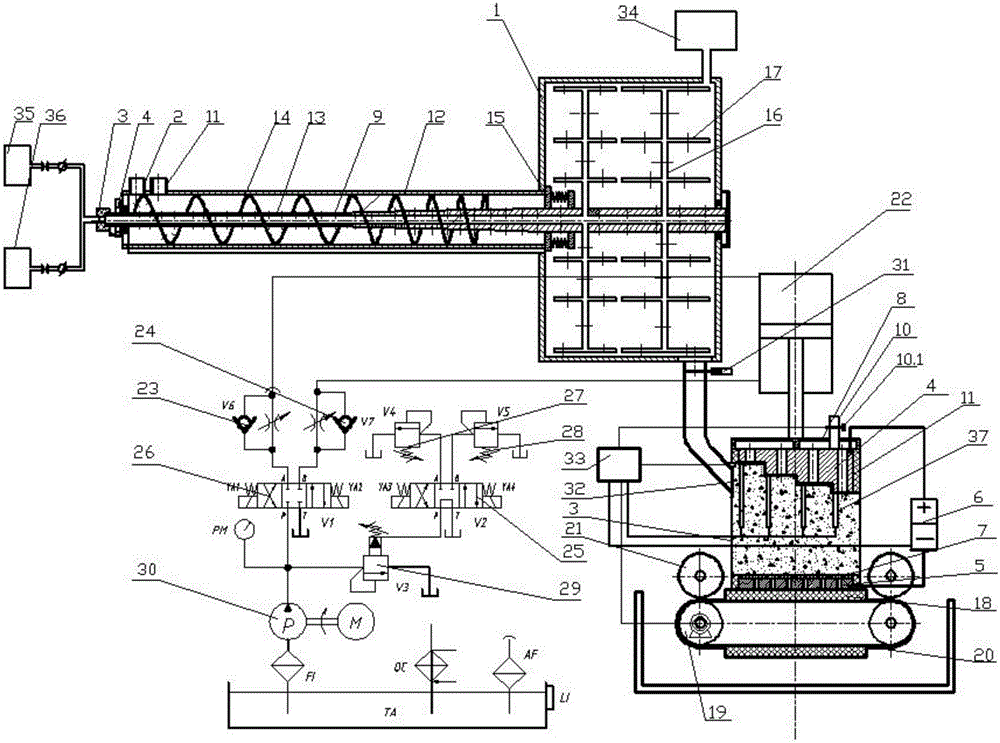

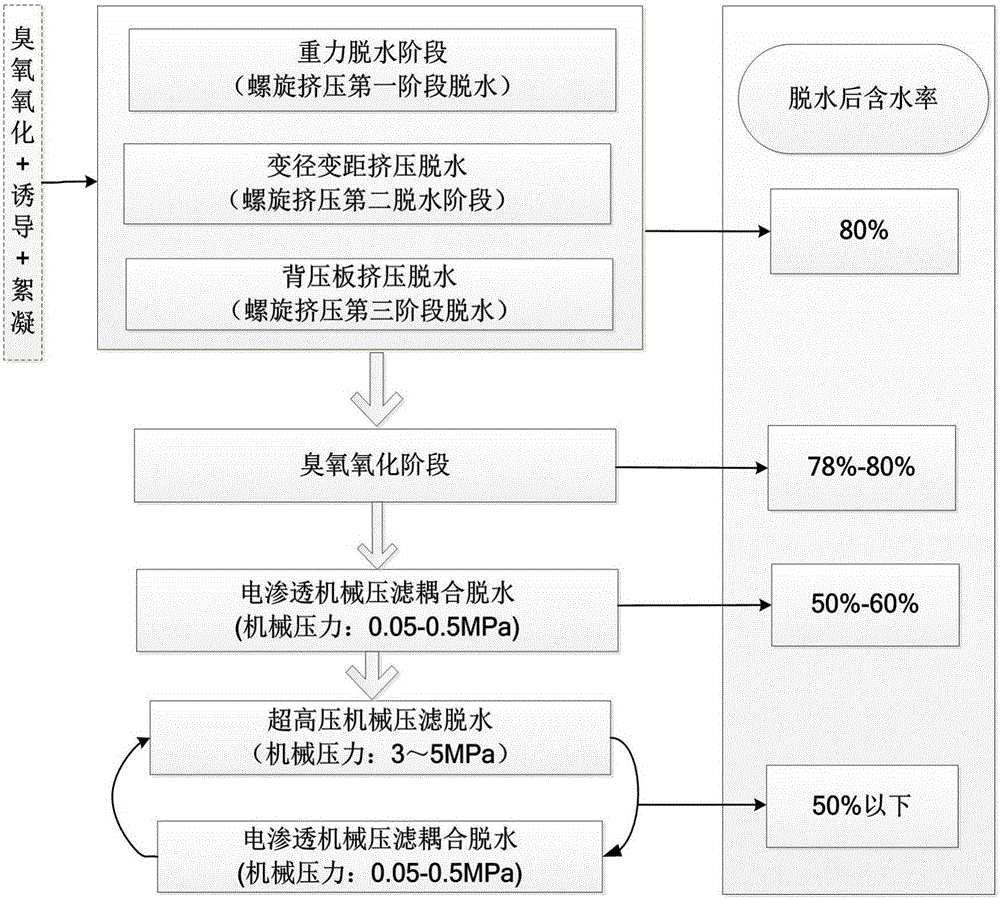

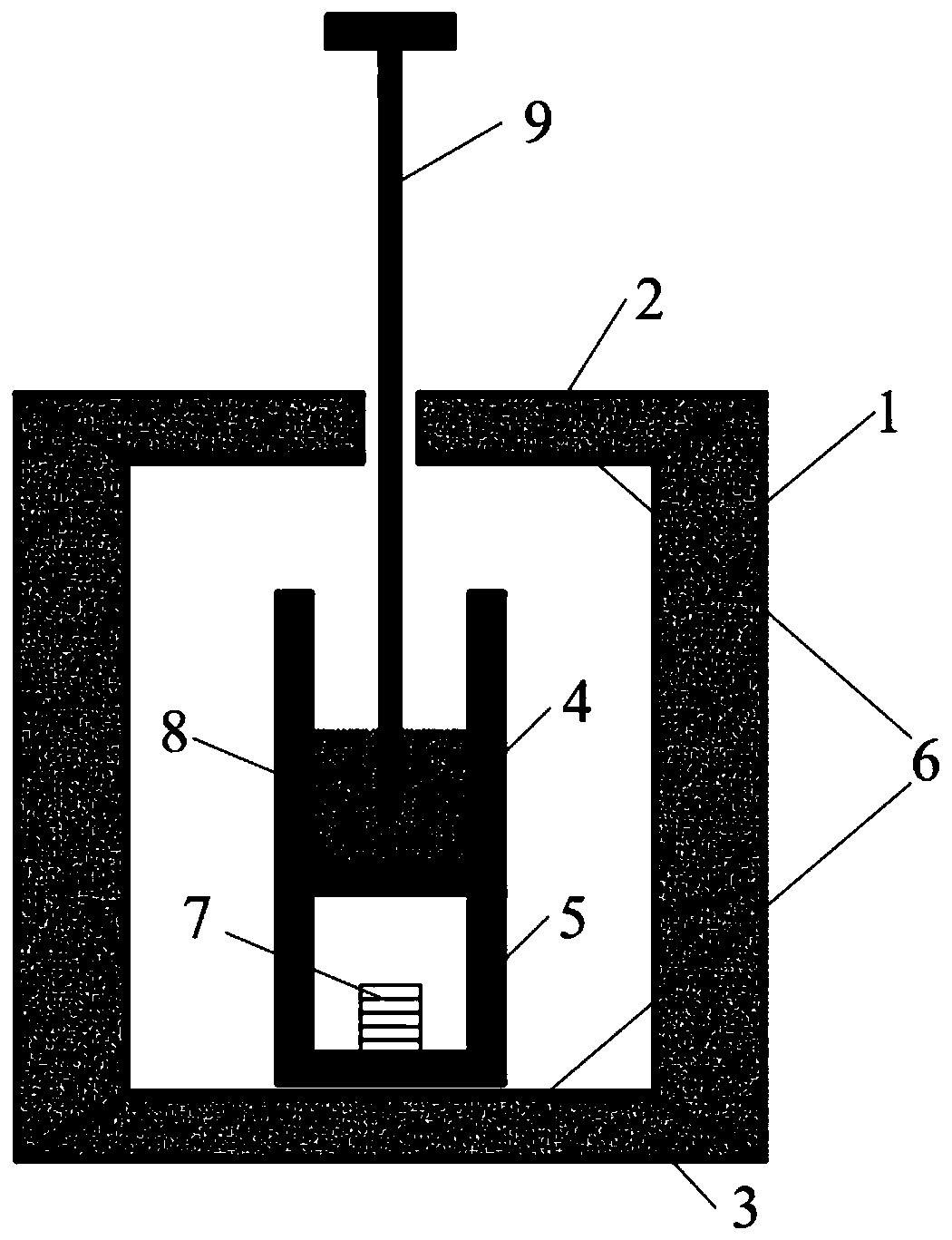

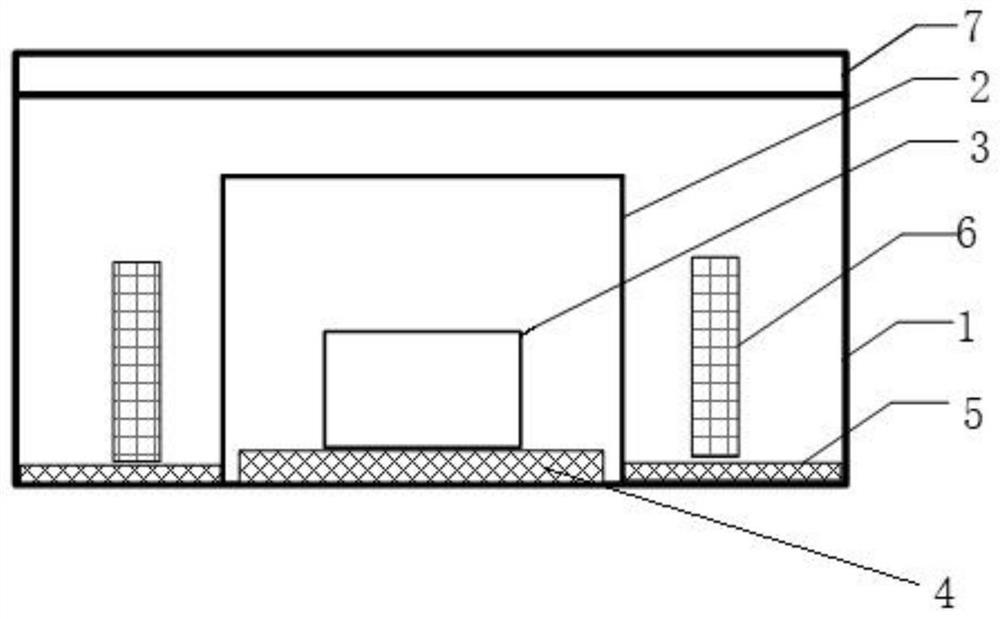

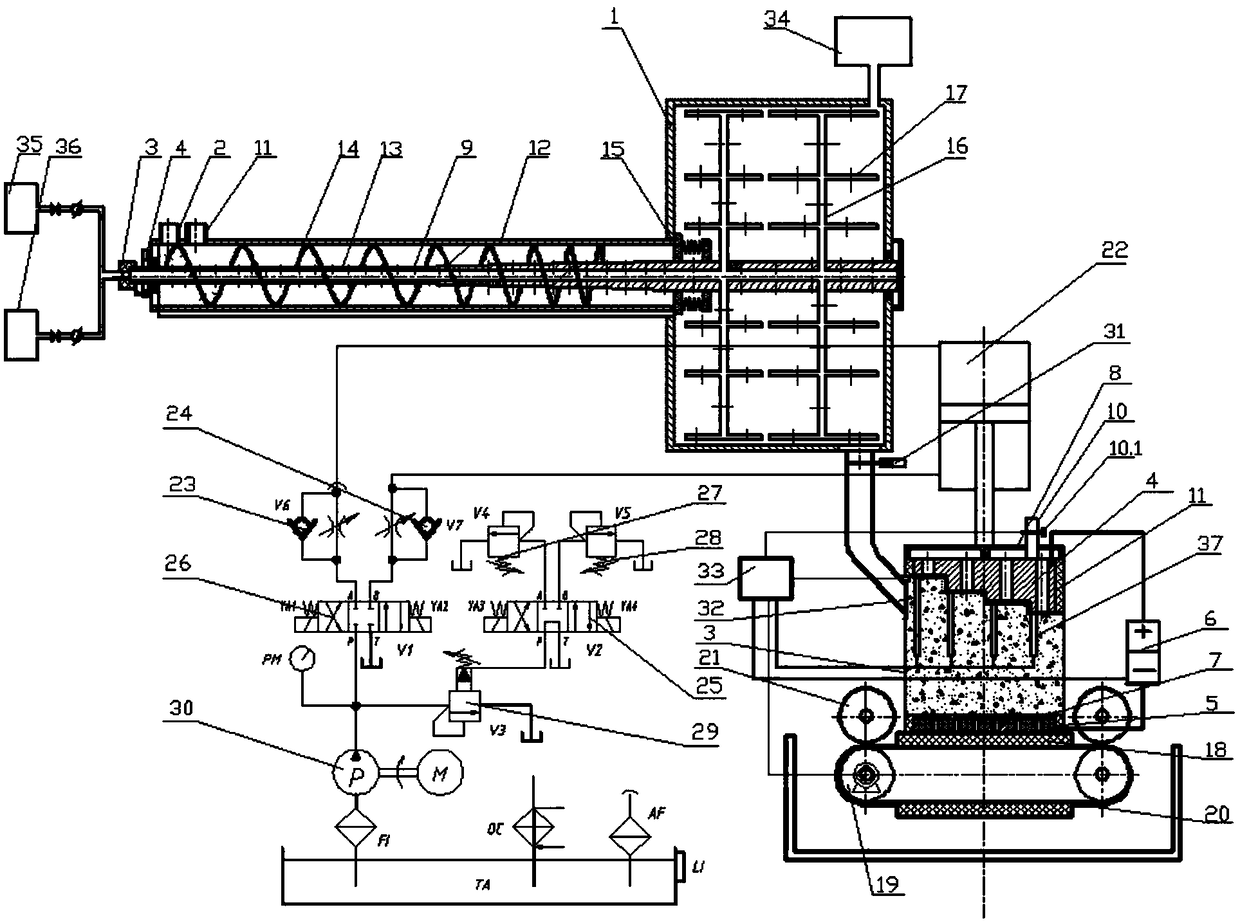

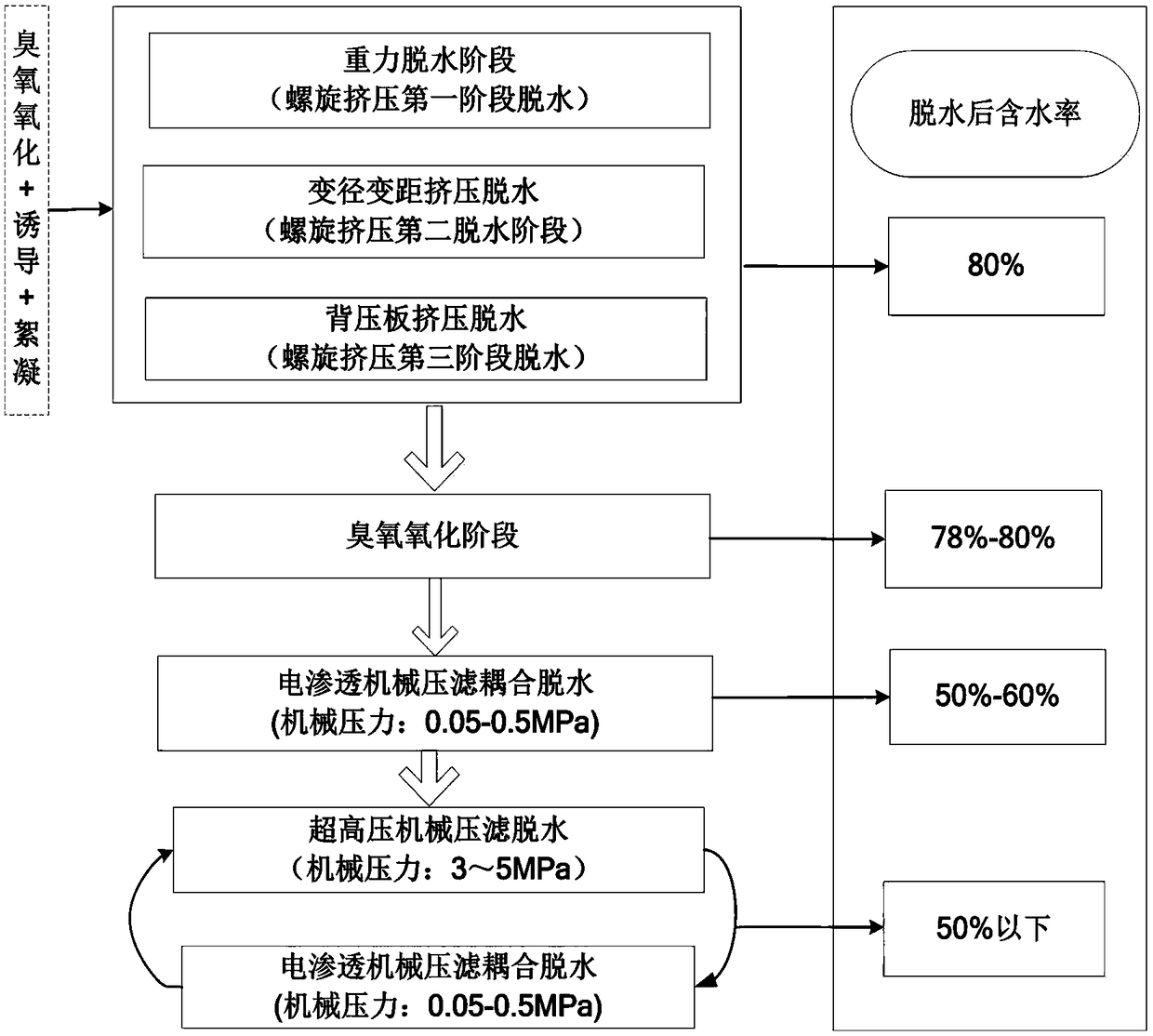

Electric osmosis filter pressing based sewage sludge co-dehydration device

ActiveCN105923952AImprove contact tightnessReduce moisture contentSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentUltra high pressureSludge

The invention discloses an electric osmosis filter pressing based sewage sludge co-dehydration device, comprising an electric osmosis squeezing container (3), an anode plate (4) and a cathode plate (5), wherein the anode plate (4) and the cathode plate (5) are arranged in the electric osmosis squeezing container (3), sludge particulates move towards the anode plate and water molecules move towards the cathode plate under the influence of an electric field force, and a pressure is exerted between the anode plate and the cathode plate such that electrically osmosed water flows out of an electric osmosis squeezing dehydration device. After the above electric osmosis dehydration is completed, a low water content of sludge of the anode plate (4) is realized, when the sludge becomes dry, the electric osmosis dehydration is stopped, and the pressure between the anode plate (4) and the cathode plate (5) is increased to realize an ultra-high pressure mechanical filter pressing dehydration, so that the water content between the anode plate and the cathode plate is uniform. According to the electric osmosis filter pressing based sewage sludge co-dehydration device disclosed by the invention, as a co-dehydration means in the combination of an electric osmosis coupling dehydration and an ultra-high pressure mechanical dehydration is employed, energy consumption for the dehydration is reduced greatly, and a lower water content of the sludge treated according to the invention is realized.

Owner:浙江诺曼环保工程技术有限公司

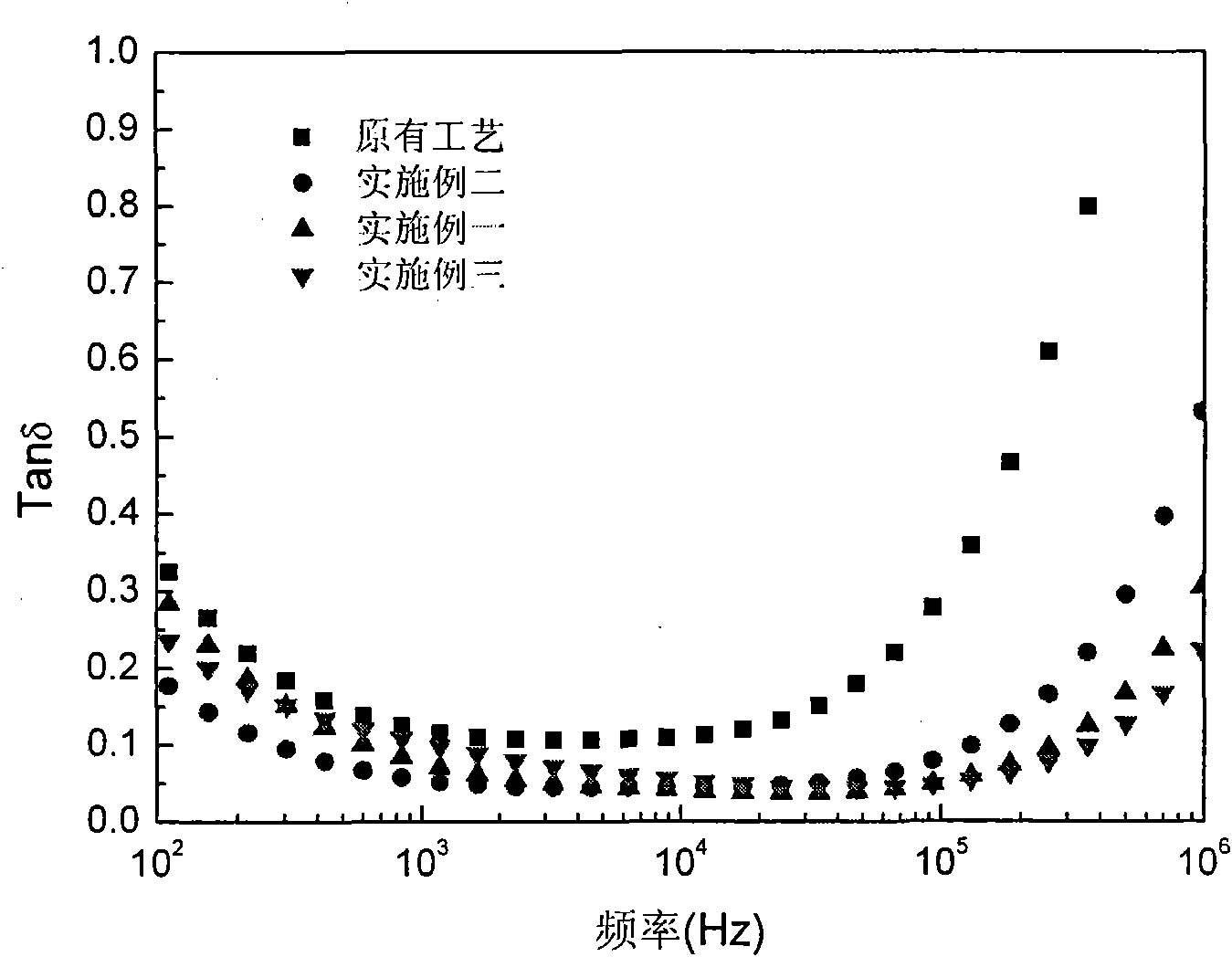

Method for preparing high-gradient, high-dielectric and low-loss pressure-sensitive material

The invention relates to a method for preparing a high-gradient, high-dielectric and low-loss pressure-sensitive material, belonging to the technical field of a high dielectric ceramic material. The method utilizing CaCO3 or CaO, CuO, TiO2 and PbO as raw materials comprises the following steps: weighting and placing the raw materials in a ball milling pot for mixed milling; presintering the mixedly-milled materials and then cooling along with a furnace; scraping the presintered materials, placing in the ball milling pot, grinding by utilizing alcohol as a grinding medium, drying, and adopting a tabletting and forming process to prepare the powder material into a green body with required shape and strength; and sintering the green body under the air atmosphere to compact the sintered ceramics. In the method, PbO is distributed on the grain boundary of CCTO, crystal grain size is effectively reduced, and grain boundary resistance is increased, thus lowering dielectric loss and improving voltage gradient.

Owner:TSINGHUA UNIV

Method for preparing nano-added zinc oxide varistor

InactiveCN1832059AReduce production processHigh voltage gradientNanostructure manufactureResistor manufactureSilver plateNanometre

A method for preparing piezoresistance with nano-additive and nano-grade of zinc oxide includes forming multiple compositions to be nano-additive, setting 5% of zinc oxide material to be nanograde and 95% of zinc oxide material to be micron grade, adding nano-additive into said zinc oxide material and mixing as well as grinding them, sintering mixed and ground material at temperature of 1000 ¿C 1050 deg.c for obtaining silver plate of piezoresistance with nano-additive and nanograde of zinc oxide.

Owner:广东省佛山科星电子有限公司

Safe environment-friendly nonlinear piezoresistor and application thereof

InactiveCN106630998AImprove conductivityIncrease the carrier concentrationVaristor coresOvervoltageSilicon dioxide

The invention discloses a safe environment-friendly nonlinear piezoresistor and application thereof. The safe environment-friendly nonlinear piezoresistor is composed of a piezoresistor ceramic wafer and a conductive electrode. The piezoresistor ceramic wafer is composed of zinc oxide, manganese dioxide, silicon dioxide, titanium dioxide, nonacobalt octasulfate, dinickel trisulfate, silicon carbide, zirconium nitride, zirconium titanate and copper calcium titanate. The surface density of the piezoresistor ceramic wafer is increased, the characteristics of the piezoresistor are improved, and the current impact resistance and nonlinear coefficient of the resistor are enhanced, so that the piezoresistor has higher voltage gradient and favorable electric properties. The overvoltage response speed reaches the nanosecond level; and the piezoresistor can quickly restore without after flow after overvoltage. The piezoresistive material is safe and nontoxic, and is harmless to the human body and environment.

Owner:NORTH CHINA INST OF SCI & TECH

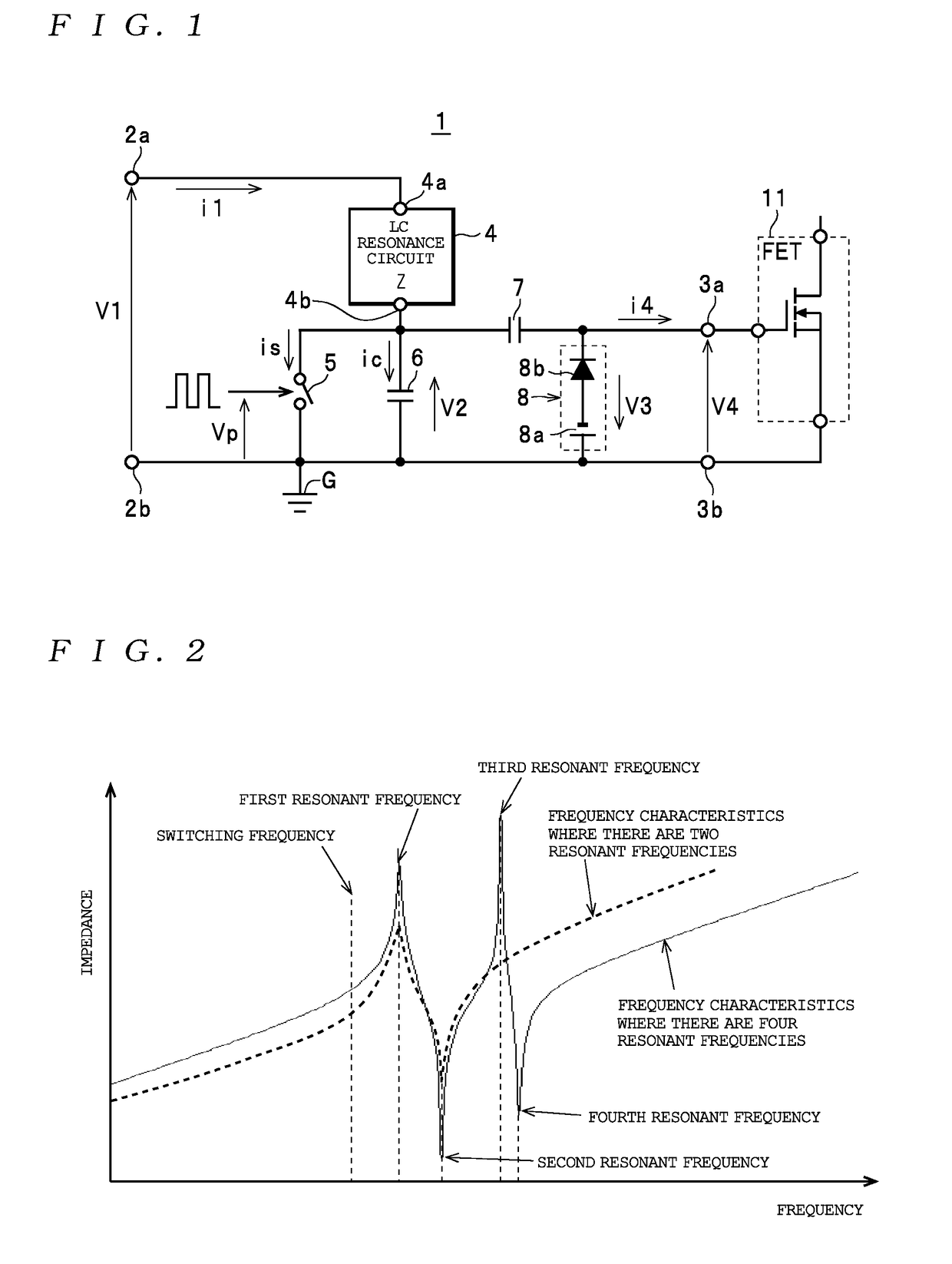

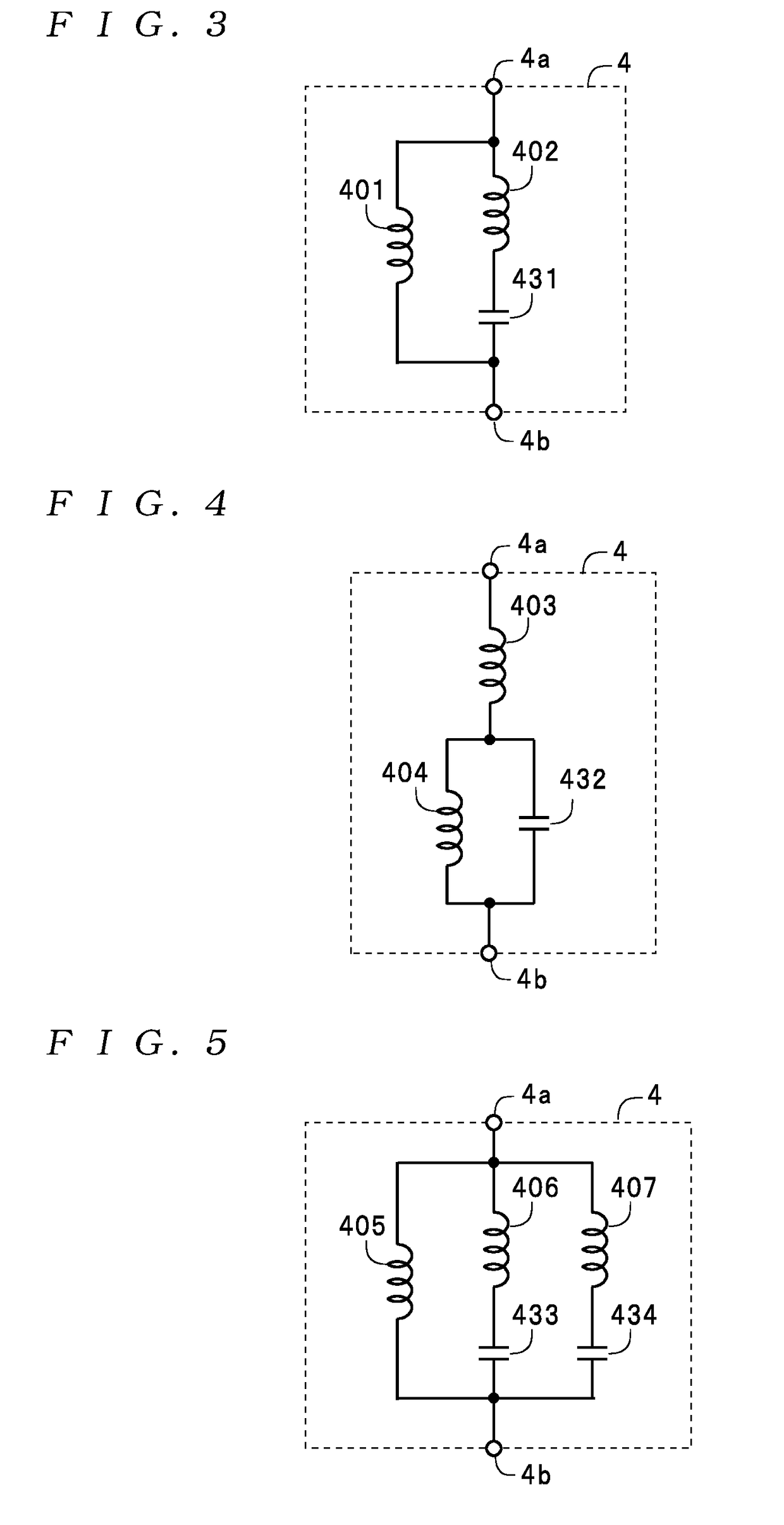

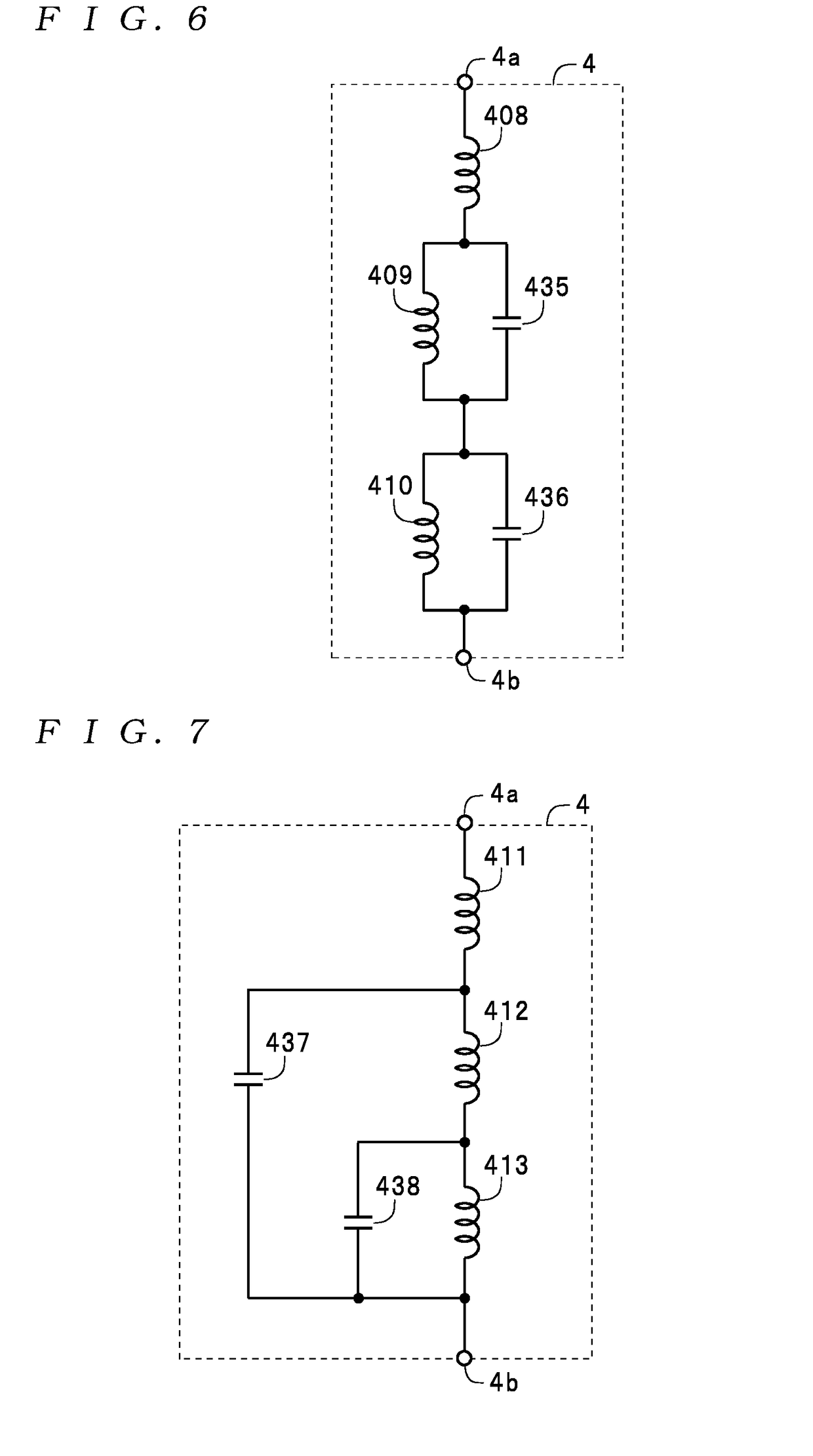

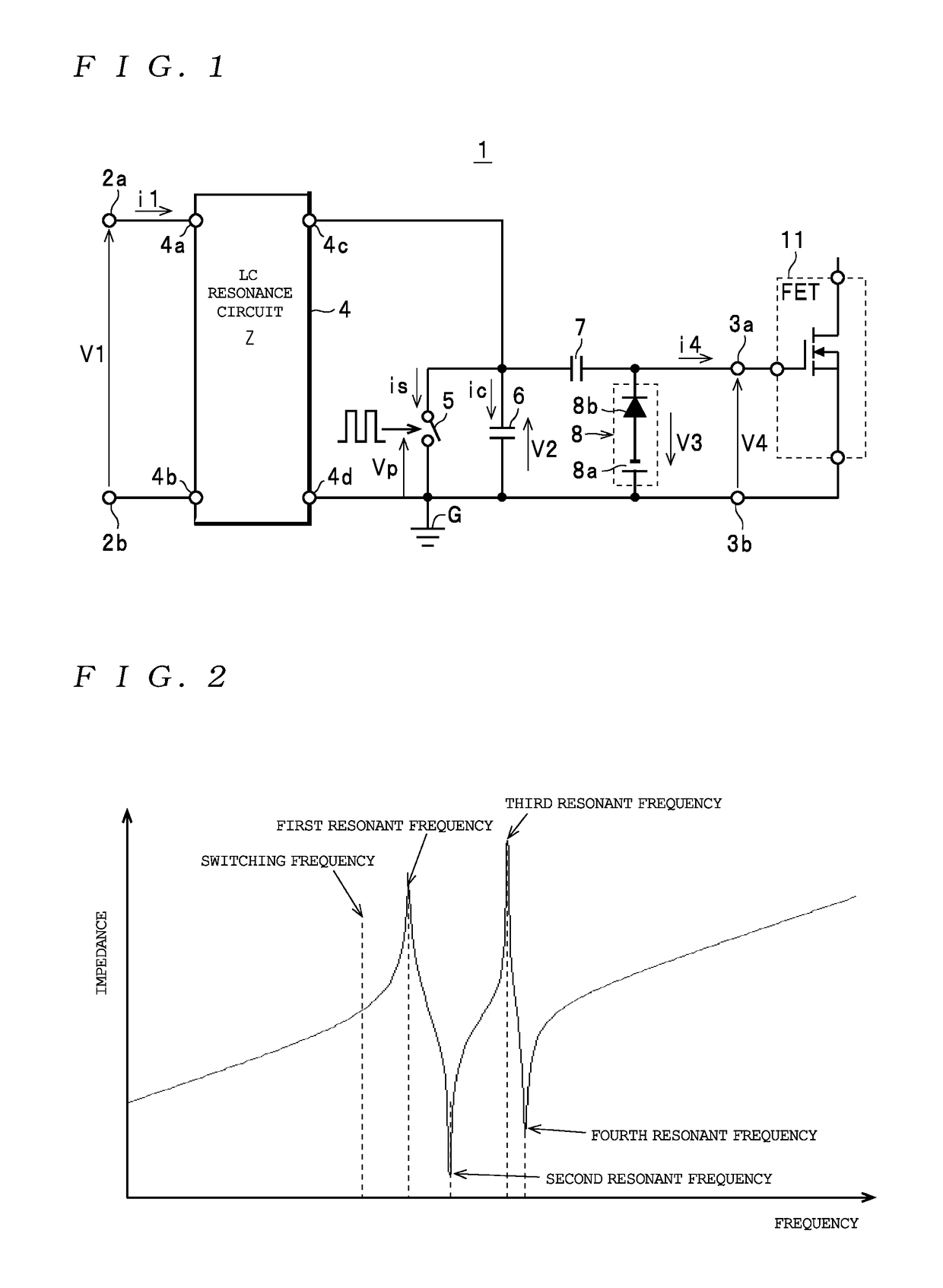

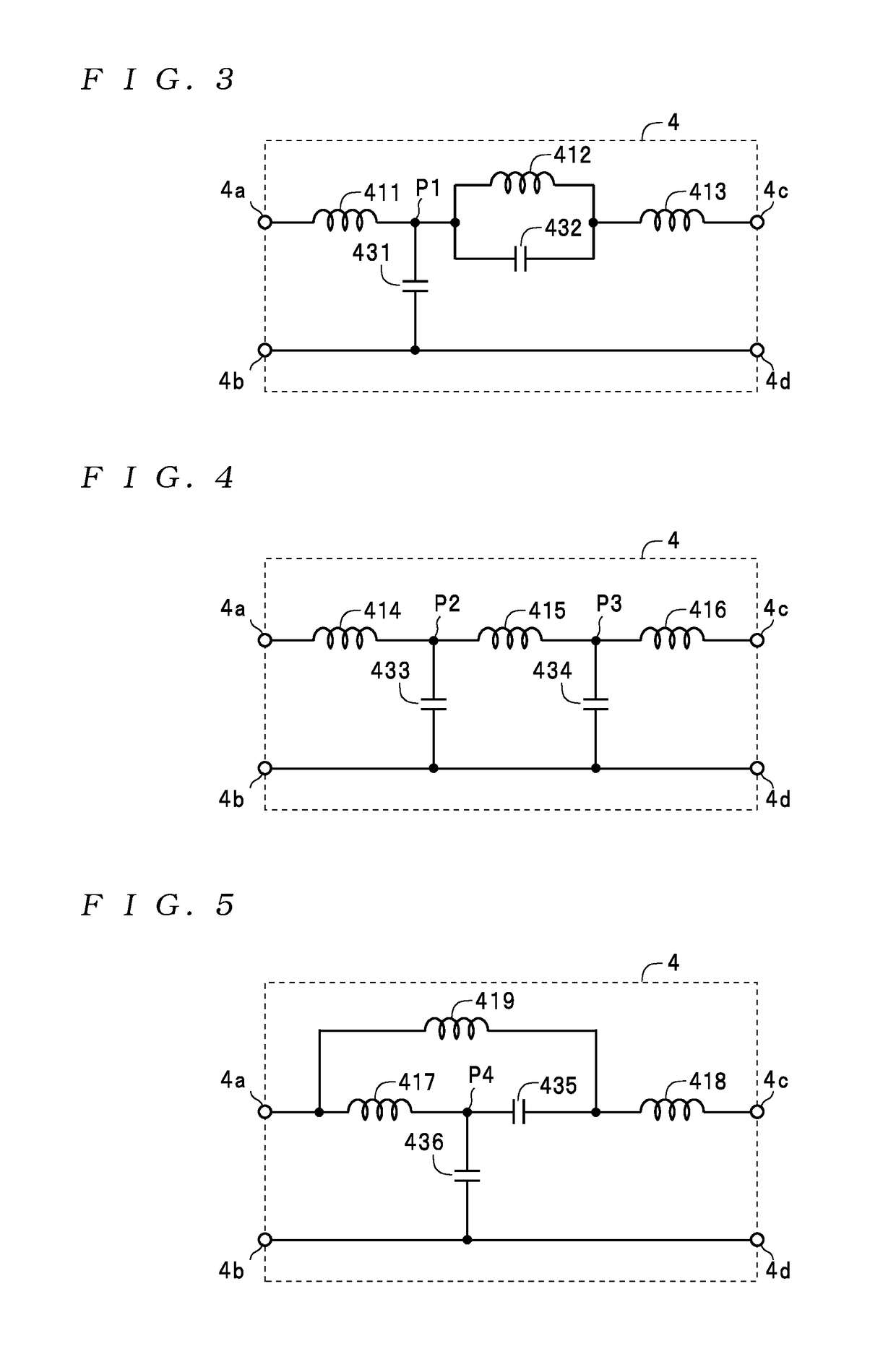

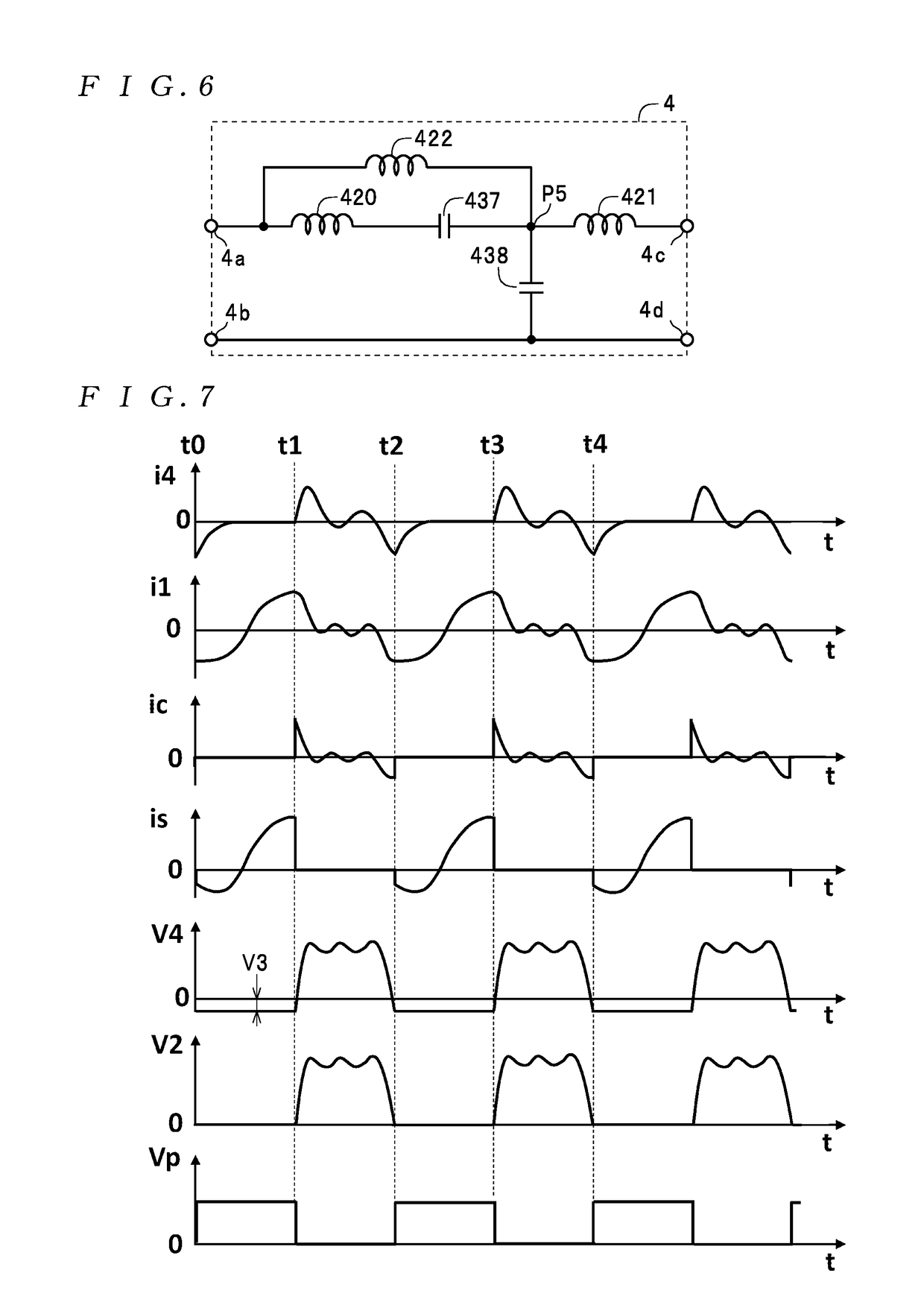

Fet driving circuit

ActiveUS20180375504A1High voltage gradientShorten the timeTransistorElectronic switchingCapacitanceResonance

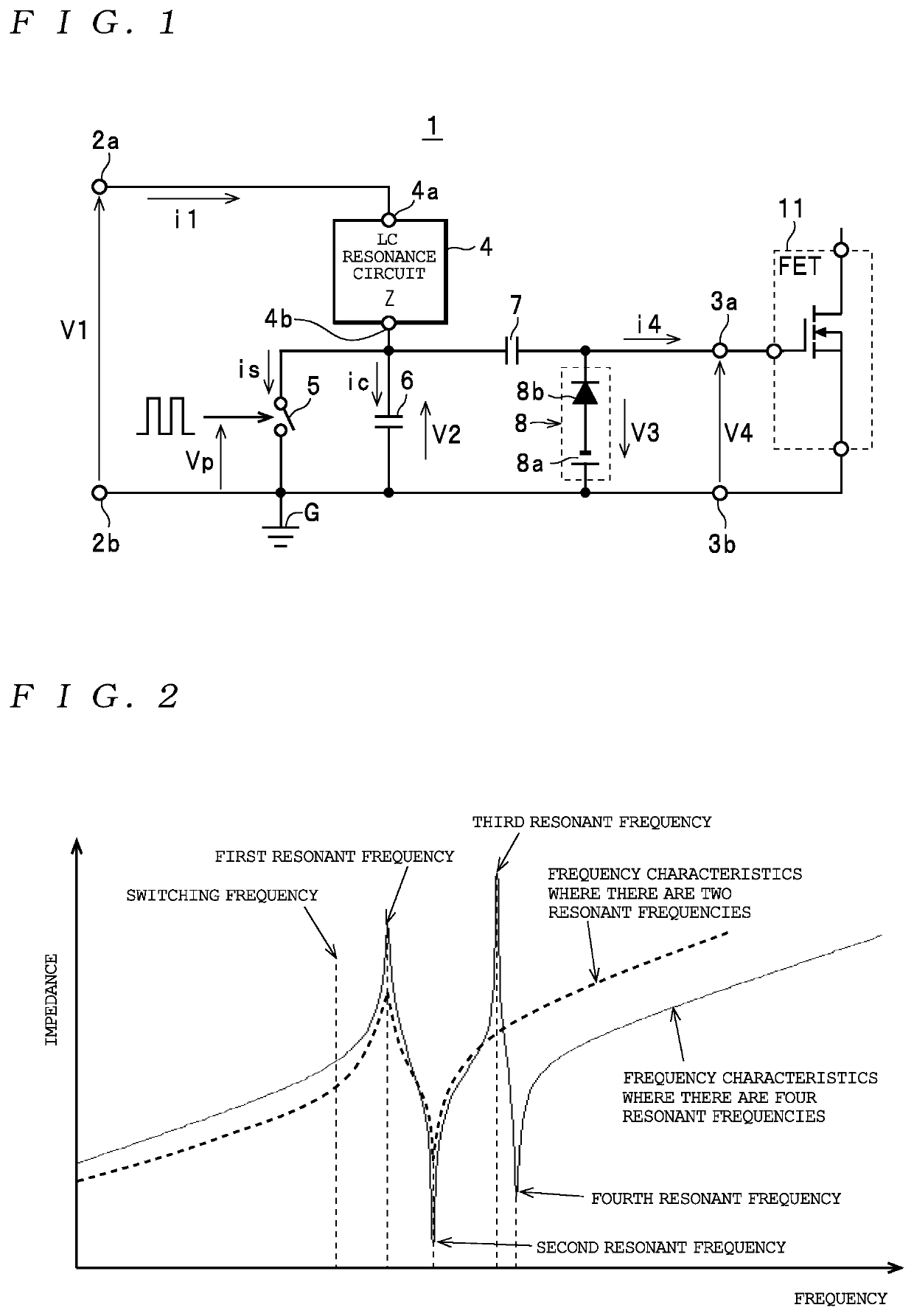

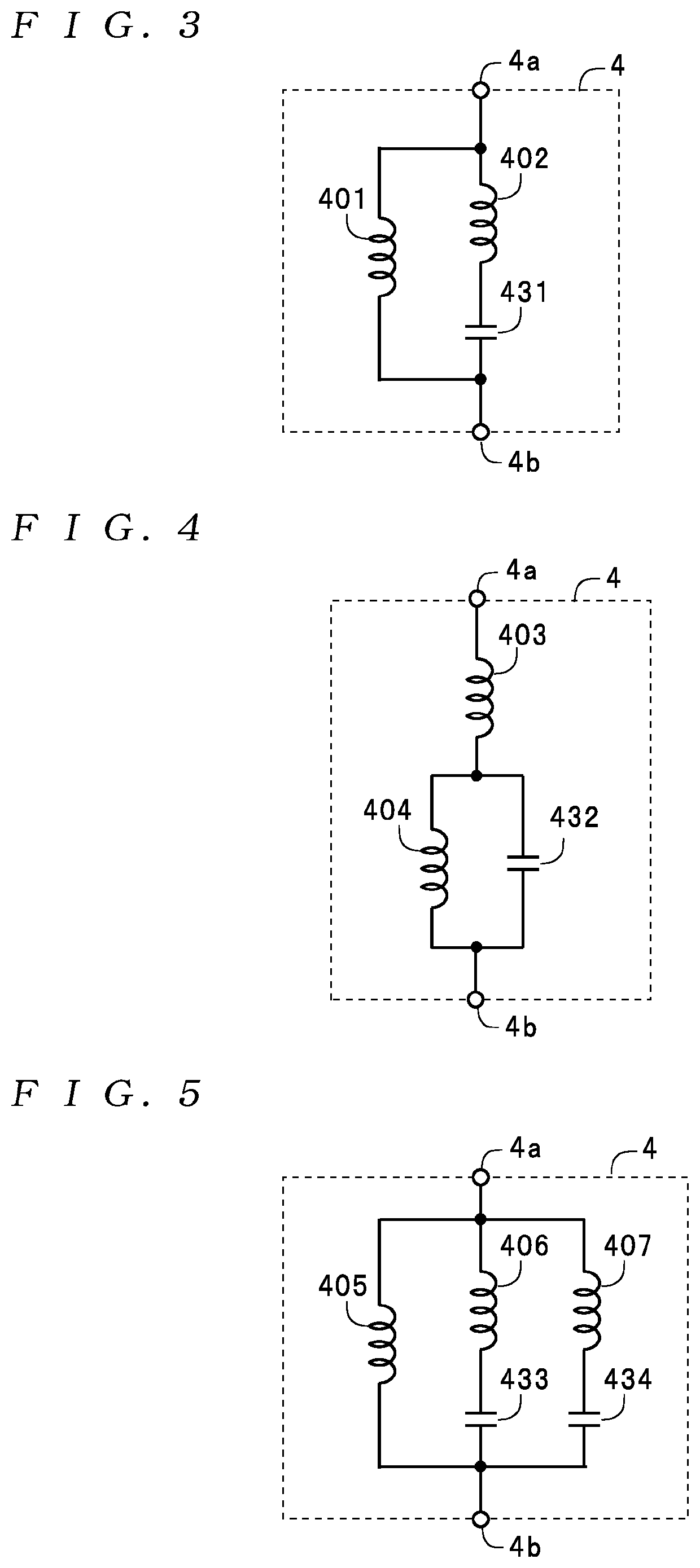

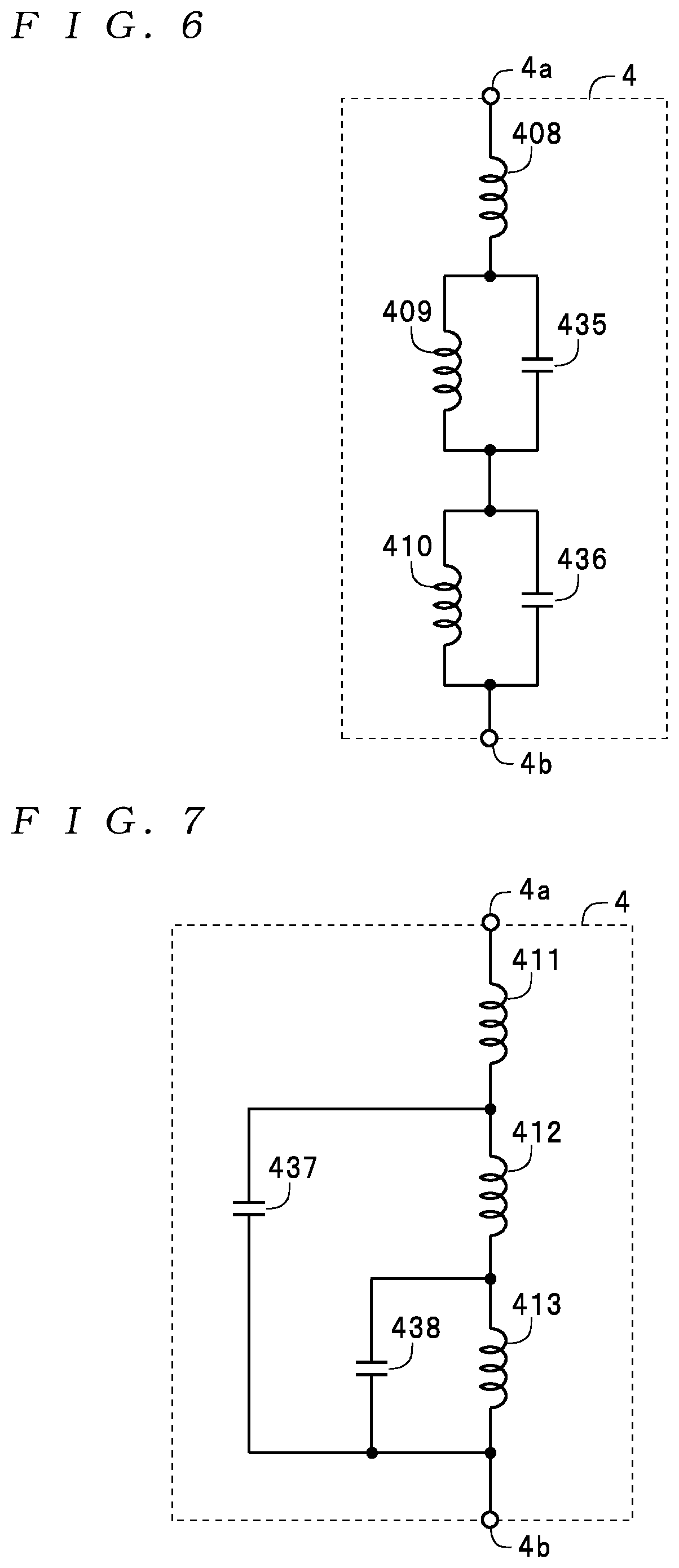

A FET driving circuit includes: inputs into which a DC voltage is inputted; outputs connected to gate and source electrodes of a FET; a switch; a capacitance connected across the switch; and an LC resonance circuit connected in series with the switch across the inputs. A voltage generated across the switch during switching is outputted to drive the FET. The LC resonance circuit has a first connector connected to one input and a second connector connected to the switch, and is configured with a path including an inductance and a path including an inductance and a capacitance. An impedance between the first and second connectors has two resonant frequencies. The impedance has a local maximum at the lower resonant frequency, which is higher than a switching frequency, and a local minimum at the higher resonant frequency, which is around double the switching frequency.

Owner:TDK CORPARATION

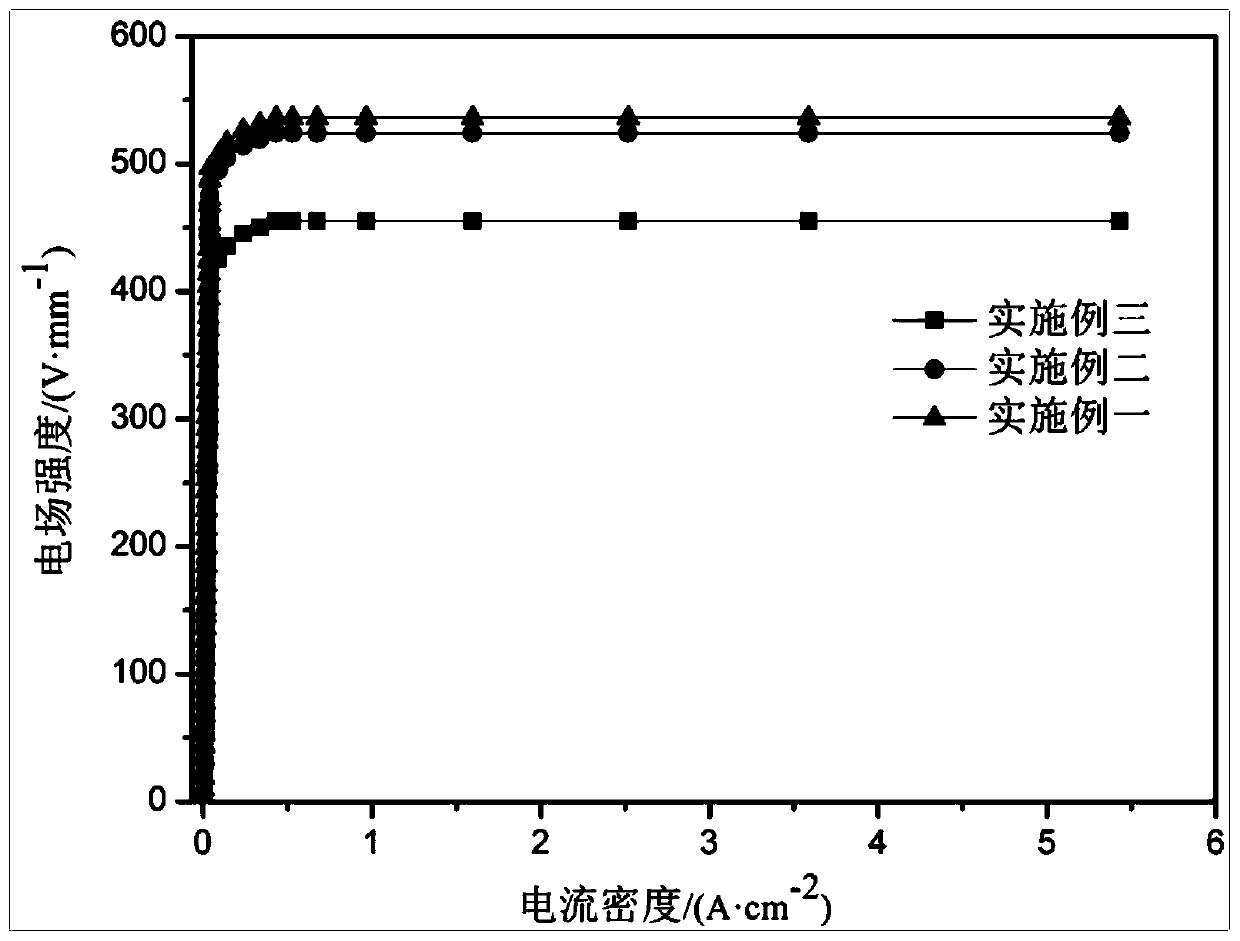

SnO2 metal oxide varistor and preparation method thereof

ActiveCN109704752ASmall grain sizeReduce the voltage gradientResistor manufactureVaristor coresManganeseSlurry

The invention discloses a SnO2 metal oxide varistor and a preparation method thereof, and belongs to the field of materials. The preparation method comprises the following steps: mixing stannic oxideSnO2, manganese carbonate MnCO3, chromium sesquioxide Cr2O3, vanadium pentoxide V2O5 and holmium trioxide Ho2O3 powder, adding acid radical ions and deionized water to prepare a first mixed solution,adding a binder into the first mixed solution to prepare a second mixed solution, then carrying out high-frequency vibration on the prepared second mixed solution, calcinating slurry obtianed after vibration, and carrying out tabletting, glue discharging, sintering and heat treatment. A metal oxide varistor sheet prepared by the method has the characteristics of small leakage current, high voltagegradient, good nonlinearity and high heat conductivity is achieved, and is more suitable for application requirements of the SnO2 metal oxide varistor valve sheets in the field of strong electricity.

Owner:XINJIANG UNIVERSITY +1

Pressure sensor material and preparation method thereof

InactiveCN107089808AHigh nonlinear coefficientReduce leakage currentFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsStrontium titanatePolyvinyl alcohol

The invention discloses a pressure sensor material. The pressure sensor material is characterized by being prepared from, by weight, 5-10 parts of bismuth trioxide, 5-10 parts of sodium carbonate, 10-20 parts of titanium dioxide, 55-65 parts of zinc oxide, 0.5-1 part of cobaltic oxide, 4-6 parts of strontium titanate, 5-10 parts of rare-earth oxide, 2-5 parts of aluminium nitrate, 3-6 parts of silicon dioxide and 10-20 parts of polyvinyl alcohol. The pressure sensor material has relatively high nonlinear coefficients, relatively low leakage currents and relatively high large-current resistance capacity and voltage gradients, at the same time, the pressure sensor material is low in density, high in strength, excellent in passivation resistance property and good in heat resistance property, the preparation method of the pressure sensor material is simple, the raw materials are easy to obtain, the production cost is low, and the pressure sensor material has good application prospects.

Owner:合肥羿振电力设备有限公司

Fet driving circuit

ActiveUS20180375503A1Low voltage appliedReduce lossesTransistorElectronic switchingCapacitanceLc resonant circuit

A FET driving circuit includes: two inputs for inputting a DC voltage; two outputs respectively connected to gate and source electrodes of a FET; a switch; a resonant capacitance connected between both ends of the switch; and an LC resonance circuit connected between the inputs and both ends of the switch. When the two inputs are shorted, frequency characteristics of an impedance of the LC resonance circuit include, in order from a low to a high-frequency side, first to fourth resonant frequencies. The first resonant frequency is higher than a switching frequency of the switch, the second resonant frequency is around double the switching frequency, the fourth resonant frequency is around four times the switching frequency, and the impedance has local maxima at the first resonant frequency and the third resonant frequency and local minima at the second resonant frequency and the fourth resonant frequency.

Owner:TDK CORPARATION

Resistor disc and preparation process thereof, and zinc oxide lightning arrester

PendingCN114373591ASimple processLow cost of preparation processEnvelope/housing resistor manufactureVaristor coresPhysicsComposite material

The invention relates to a resistor disc and a preparation process thereof as well as a zinc oxide arrester. The resistor disc is prepared from the following powdery components in percentage by mole: 88 to 95 percent of ZnO, 0.01 to 4.0 percent of Bi2O3, 0.01 to 2.0 percent of Sb2O3, 0.05 to 2.0 percent of Co3O4, 0.01 to 2.0 percent of MnO2, 0.01 to 2.0 percent of NiO, 0.05 to 3.0 percent of SiO2 and 0.01 to 1.0 percent of Y2O3, wherein the purity of the components is more than 99.5 percent. Wherein the particle size of ZnO is 50 + / -10 nm, the particle size of NiO is smaller than 30 nm, and the particle size of SiO2 is 100-150 nm. The resistor disc provided by the invention has excellent performance such as high potential gradient, low residual voltage, high square wave and large current impact resistance, small leakage current and the like, and excellent comprehensive performance indexes enable the resistor disc to meet the performance requirements of the piezoresistor disc for the lightning arrester of the ultra-high-voltage and extra-high-voltage direct-current power transmission line.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +4

Method for preparing voltage dependent resistor

InactiveCN104310987AImprove electrical nonlinearityHigh voltage gradientResistor manufactureVaristor coresVoltage gradientPolyester

The invention discloses a method for preparing a voltage dependent resistor, belonging to the field of electronic element preparation. The method comprises the following steps: (1) mixing MgO with the purity of 99.5% and SiO2 with the purity of 99% in a mole ratio of 1:1, ball-milling, and drying after ball-milling; (2) pressing the components into round pieces at 60MPa, synthesizing at 750 DEG C, naturally cooling, and crushing for later use; (3) adopting 90.4% of ZnO, 5.18% of Bi2O3, 1.84% of Sb2O3, 0.97% of Co2O3, 0.84% of Ni2O3, 0.64% of Cr2O3 and 0.13% of MnO2 as base components, further adding 0.04% of MgSiO3, so as to prepare a mixed raw material; and (4) putting the mixed raw material, water and balls into a polyester tank at a ratio of 1:1:2.5, stirring and grinding for 1 hour, drying the slurry, adding 8% of an adhesive, pressing into square pieces of 40*40mm in width and length at 240MPa, and sintering. By adjusting the proportions of the raw materials and doping 0.04% of MgSiO3, not only is the electric nonlinearity property of a ZnO anti-lightning voltage dependent resistor greatly improved, but also the voltage gradient of the ZnO voltage dependent resistor is improved, the through-current capability of the ZnO voltage dependent resistor is greatly improved, and the residual pressure ratio and leakage current of the ZnO voltage dependent resistor are reduced.

Owner:SHAANXI EYOUNG TECH

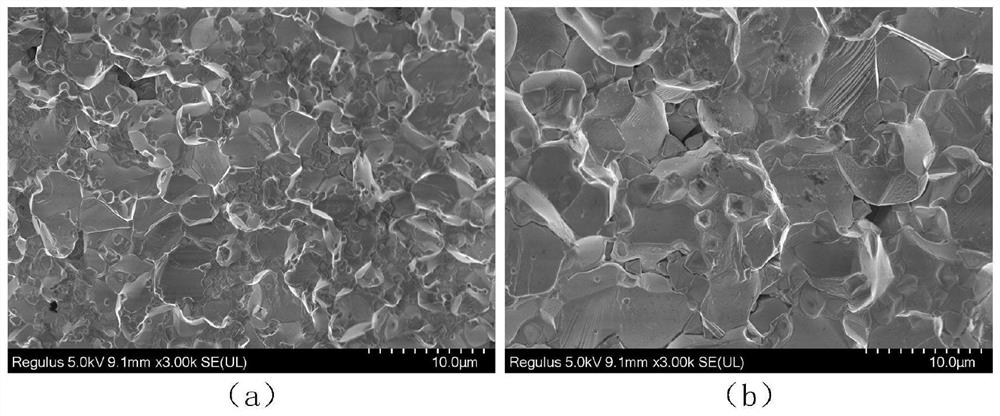

Heat preservation device for microwave sintering and microwave sintering method of zinc oxide pressure-sensitive ceramic

ActiveCN111548142AImprove performanceImprove featuresThermometers using electric/magnetic elementsUsing electrical meansCrazingNickel sesquioxide

The invention discloses a heat preservation device for microwave sintering and a microwave sintering method of zinc oxide pressure-sensitive ceramic. The method comprises the following steps: carryingout ball milling on zinc oxide, bismuth oxide, cobaltosic oxide, manganese carbonate, antimony oxide, nickel sesquioxide, titanium dioxide, an aluminum nitrate nonahydrate solution, a dispersing agent and the like, granulating, carrying out dry pressing molding, discharging glue, putting into a heat preservation device, and carrying out microwave sintering to obtain the zinc oxide pressure-sensitive ceramic. The heat preservation device comprises a box body, a high crucible, a short crucible, powder for pressing a ceramic chip green body, an end cover and a thermocouple; the high crucible isstacked on the short crucible; end covers are arranged on the top surface and the bottom surface in the box body; the thermocouple and the high crucible are in connection. The heat preservation deviceis adopted for microwave sintering, the temperature difference between materials and the surrounding environment is reduced, and the phenomena of cracks, deformation and uneven colors are eliminated.Compared with a traditional method, the method of the invention has the advantages that the sintering time is shortened by 50%, volatilization of low-melting-point substances and abnormal growth of crystal grains are reduced, and the performance of the obtained product is better than that of the traditional method.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation method of large-discharge-current-capacity and low-residual-voltage voltage-sensitive ceramic used for ultrahigh voltage power transmission system

The invention provides a preparation method of large-discharge-current-capacity and low-residual-voltage voltage-sensitive ceramic used for an ultrahigh voltage power transmission system. The ceramic is prepared from zinc oxide ZnO, bismuth oxide Bi2O3, antimonous oxide Sb2O3, manganese dioxide MnO2, chromic oxide Cr2O3, cobalt oxide Co2O3, silicon dioxide SiO2, silver oxide Ag2O, Ga(NO3)3 and aluminium nitrate Al(NO3)3. The method has the advantages that the leakage current is restrained, the ageing performance of a ZnO voltage-sensitive resistor manufactured according to the formula is more stable by adding elements Al and Ga together, and the defect that when only Ag ions are added, the ageing performance of the voltage-sensitive resistor is not stable is overcome.

Owner:TSINGHUA UNIV

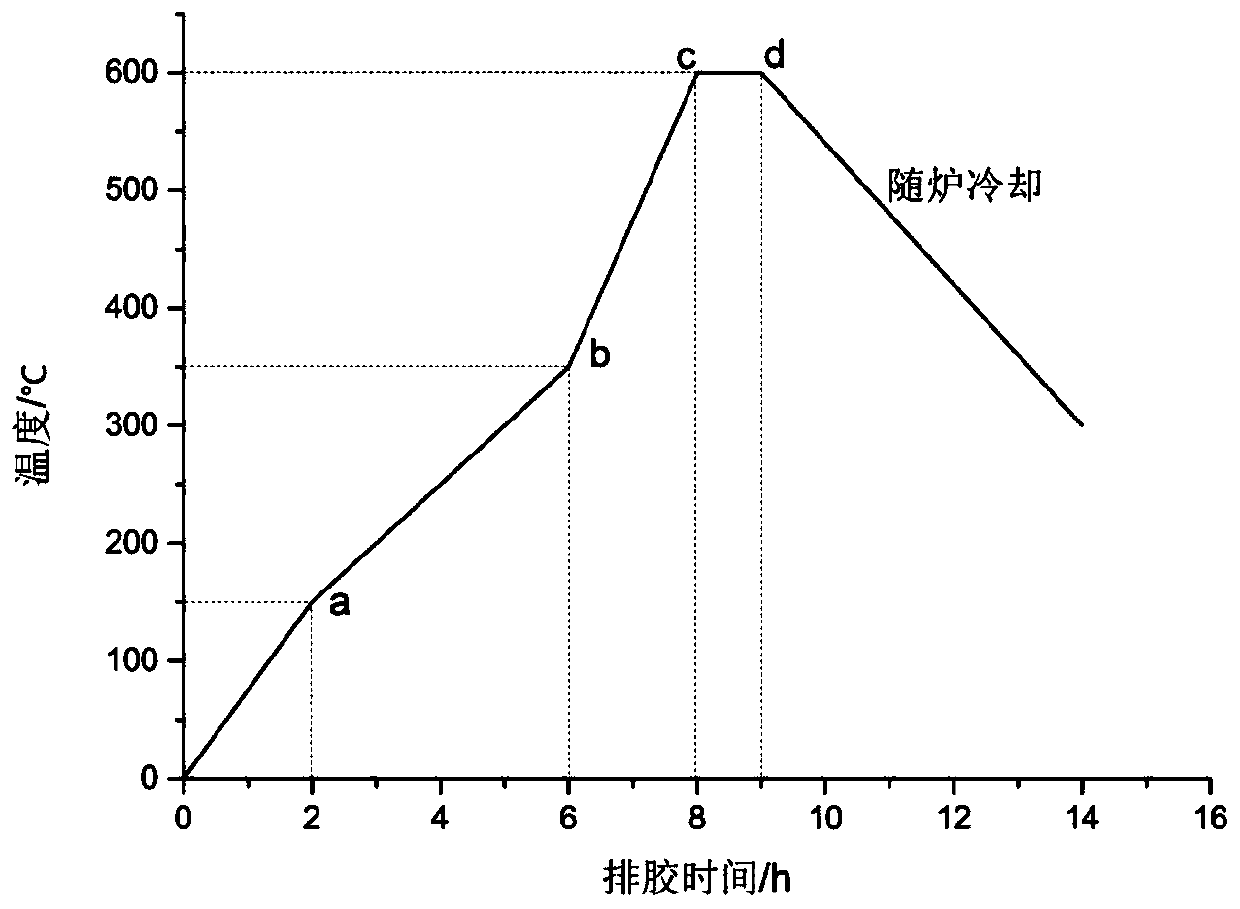

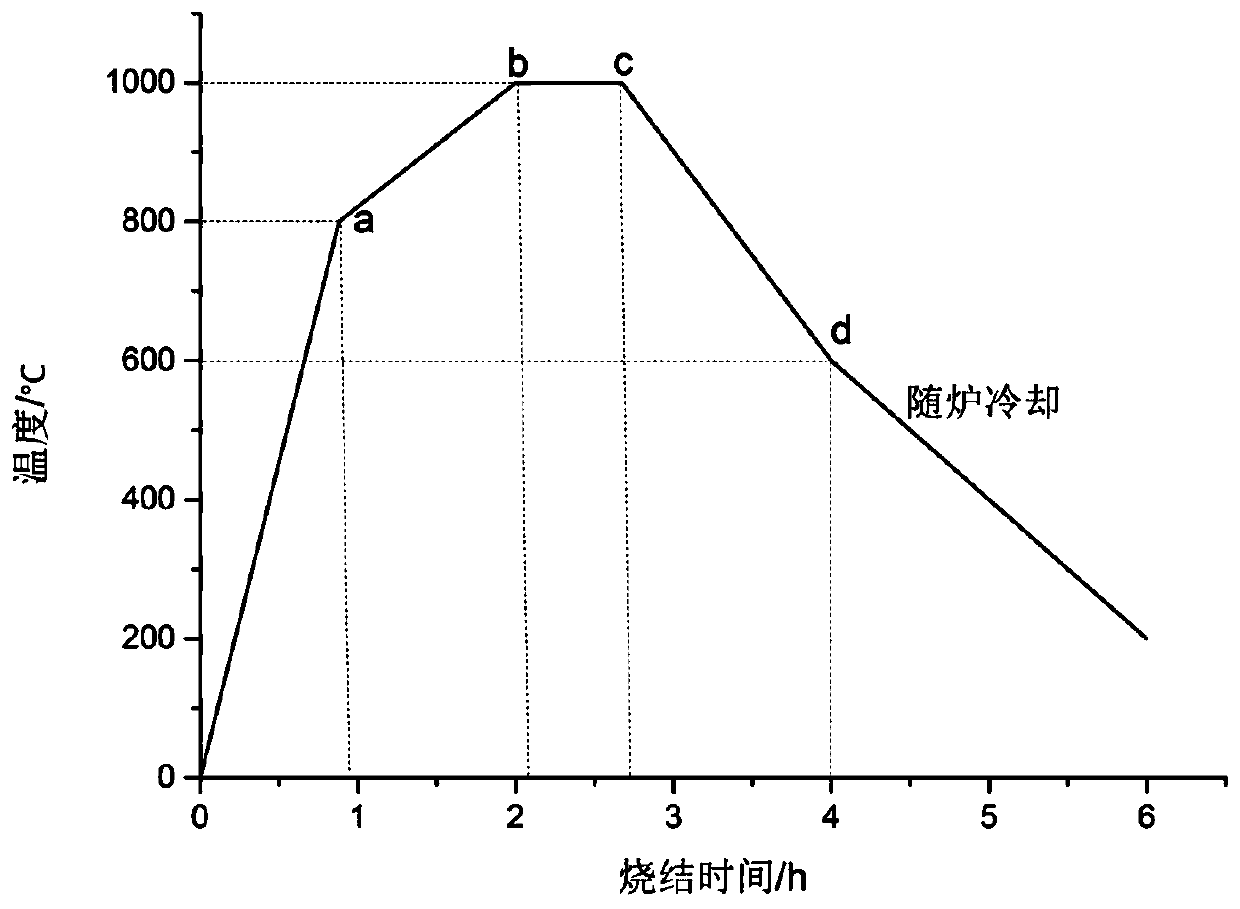

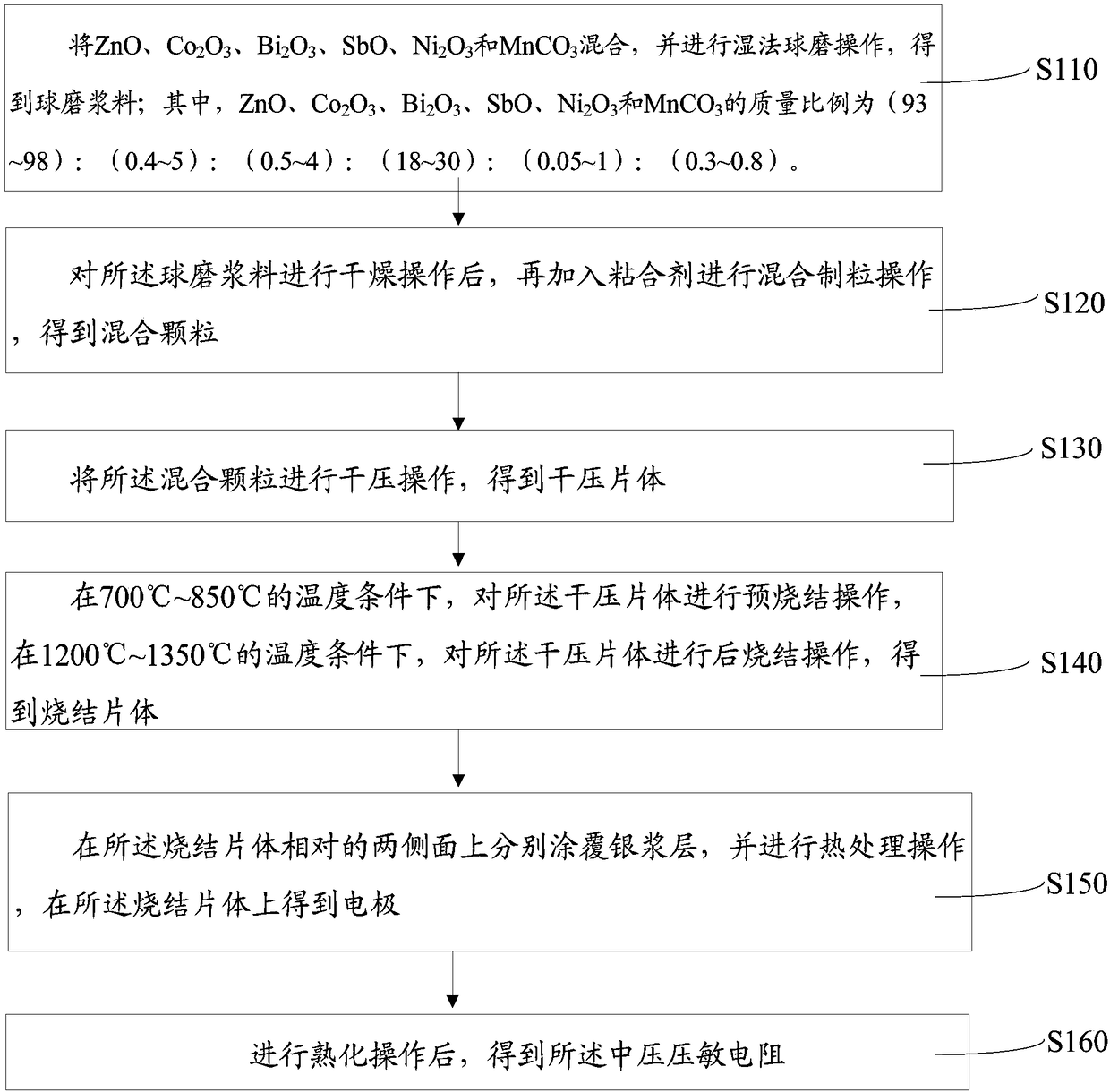

Medium voltage varistor and preparation method thereof

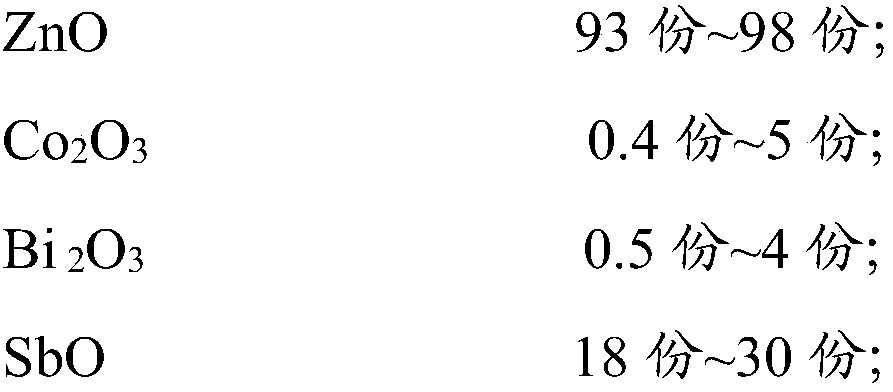

A medium voltage varistor comprises the following components by mass: 93-98 parts of ZnO, 0.4-5 parts of Co2O3, 0.5-4 parts of Bi2O3, 18-30 parts of SbO, 0.05-1 part of Ni2O3 and 0.3-0.8 part of MnCO3. The components of the medium voltage varistor are subjected to mixing operation, wet ball milling operation, mixing granulation operation, dry pressing operation, pre-sintering operation, post-sintering operation, silver layer coating operation, heat treatment operation and curing operation to obtain the medium voltage varistor. According to experimental test results, the voltage gradient of themedium voltage varistor is 220-280 (V / mm), so that the varistor has the advantages of good stability and high voltage gradient.

Owner:惠州嘉科实业有限公司

A preparation method of large flow capacity and low residual pressure varistor ceramics for UHV power transmission system

ActiveCN105622087BLower Die ResistanceLow residual pressure levelPiezoelectric/electrostrictive/magnetostrictive devicesSilicon dioxideMaterials science

A method for preparing pressure-sensitive ceramics with large flow capacity and low residual voltage for ultra-high voltage transmission systems. The raw materials include zinc oxide ZnO, bismuth oxide Bi2O3, antimony trioxide Sb2O3, manganese dioxide MnO2, chromium oxide Cr2O3, and cobalt trioxide. Co2O3, silicon dioxide SiO2, silver oxide Ag2O, Ga(NO3)3, aluminum nitrate Al(NO3)3. The beneficial effects are: the leakage current is suppressed; the joint addition of Al and Ga elements makes the aging performance of the ZnO varistor produced by this formula more stable, eliminating the disadvantage of unstable aging performance of the varistor caused by simply adding Ag ions. place.

Owner:TSINGHUA UNIV

FET driving circuit

ActiveUS10630277B2High voltage gradientShorten the timeTransistorElectronic switchingCapacitanceHemt circuits

A FET driving circuit includes: inputs into which a DC voltage is inputted; outputs connected to gate and source electrodes of a FET; a switch; a capacitance connected across the switch; and an LC resonance circuit connected in series with the switch across the inputs. A voltage generated across the switch during switching is outputted to drive the FET. The LC resonance circuit has a first connector connected to one input and a second connector connected to the switch, and is configured with a path including an inductance and a path including an inductance and a capacitance. An impedance between the first and second connectors has two resonant frequencies. The impedance has a local maximum at the lower resonant frequency, which is higher than a switching frequency, and a local minimum at the higher resonant frequency, which is around double the switching frequency.

Owner:TDK CORPARATION

A large flow capacity, low residual voltage, high gradient zinc oxide varistor ceramics

ActiveCN105481363BLower Die ResistanceLow residual pressure levelPiezoelectric/electrostrictive/magnetostrictive devicesManganeseAntimony trioxide

A method for preparing zinc oxide varistor ceramics with large flow capacity, low residual voltage and high gradient, which is characterized in that the formula ingredients include zinc oxide ZnO, bismuth oxide Bi2O3, antimony trioxide Sb2O3, manganese dioxide MnO2, chromium oxide Cr2O3, cobalt trioxide Co2O3, silicon dioxide SiO2, silver nitrate oxide Ag2O, gallium nitrate Ga(NO3)3, yttrium nitrate Y(NO3)3. The beneficial effects are: the leakage current is suppressed; the joint addition of Y and Ga elements makes the aging performance of the ZnO varistor produced by this formula more stable, eliminating the problem that the leakage current cannot be suppressed due to the simple addition of Ag ions. at.

Owner:TSINGHUA UNIV

Zinc oxide varistor raw material, its preparation method and varistor

ActiveCN103396116BImprove uniformityIncreased surface state densityVaristor coresOvervoltage protection resistorsManganeseSilicon dioxide

The invention relates to a zinc-oxide piezoresistor raw material, a preparation method thereof and a piezoresistor. The zinc-oxide piezoresistor raw material comprises the following components by mole percent: 91.48-98.03% of zinc oxide, 0.5-2.0% of bismuth trioxide, 0.5-2.5% of silicon dioxide, 0.35-1.5% of cobaltosic oxide, 0.5-1.0% of manganese carbonate, 0.1-0.5% of chromium oxide, 0.01-2.0% of yttria and 0.0001-0.001% of aluminium nitrate. The zinc-oxide piezoresistor raw material does not antimony, and due to the silicon dioxide, the characteristic of the piezoresistor is improved, the surface state density is increased, the voltage gradient, the barrier height and the nonlinear coefficient are improved, the leakage current is reduced and the current impact resistance is enhanced; due to the yttria, the conductivity, the current impact resistance, the nonlinear coefficient and the voltage gradient are improved, the limiting voltage rate and the leakage current are reduced, the grain growth is inhibited and the zinc-oxide piezoresistor has higher voltage gradient and excellent electrical property.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

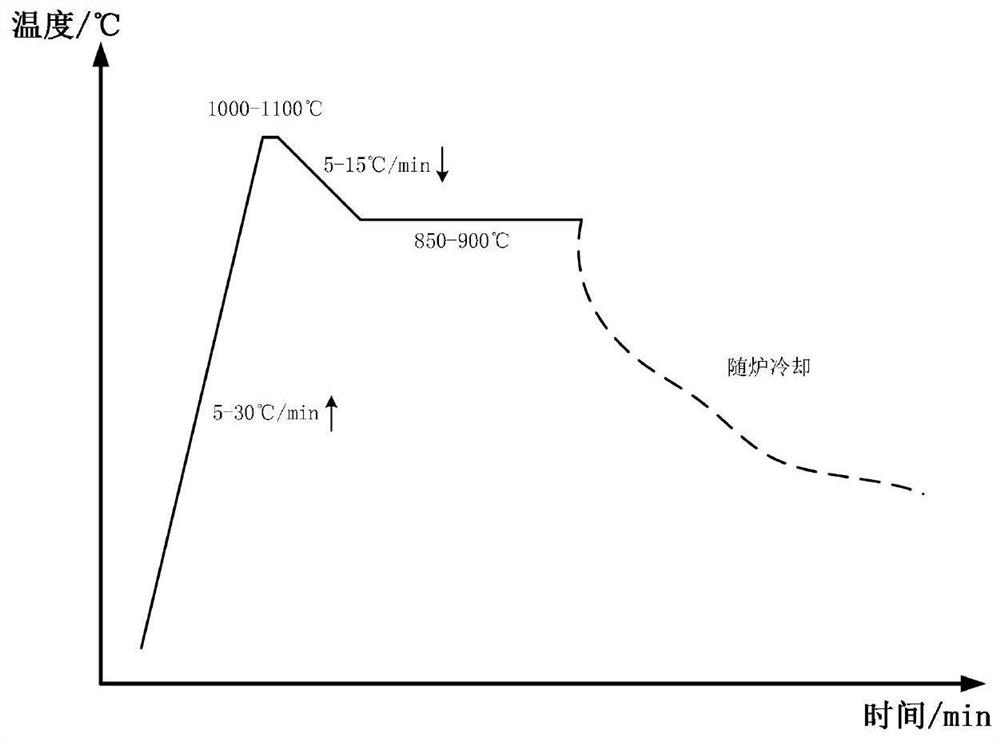

Preparation method of zinc oxide varistor sheet

ActiveCN110156454BImprove efficiencyHigh voltage gradientResistor chip manufactureVaristor coresMetallurgyElectrical performance

The invention relates to a preparation method of a zinc oxide varistor sheet. The method includes the steps of: preparing a green body by using zinc oxide as the main material and auxiliary materials including bismuth oxide as raw materials, sealing the green body and then performing microwave sintering, and the microwave sintering process is as follows: heating to 1000-1100° C., Heat preservation for 1-10min; then cool down to 850-900°C, heat-retain for 1-3h, and finally cool to room temperature to obtain a zinc oxide varistor sheet. The method proposed by the invention greatly shortens the sintering time, reduces the energy consumption in the sintering process, and improves the electrical properties such as the voltage gradient and energy tolerance of the zinc oxide varistor sheet.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

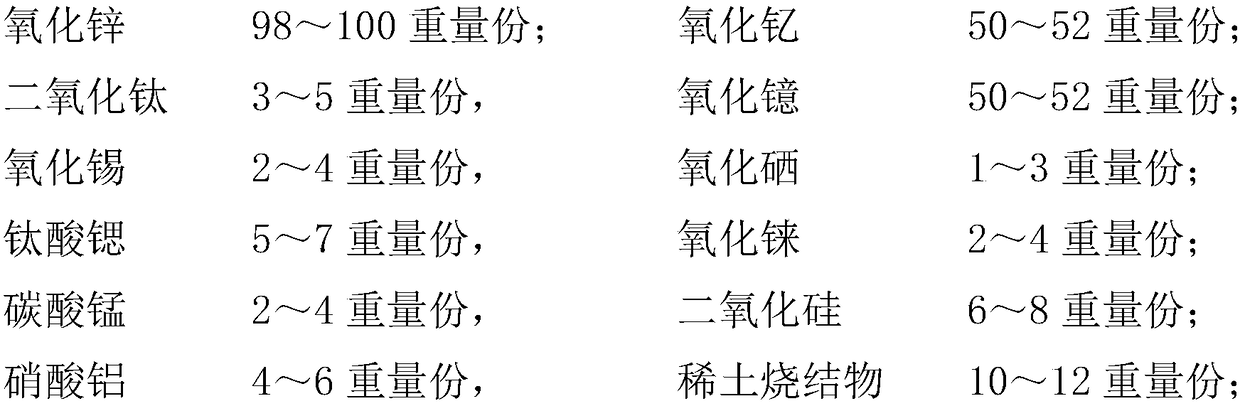

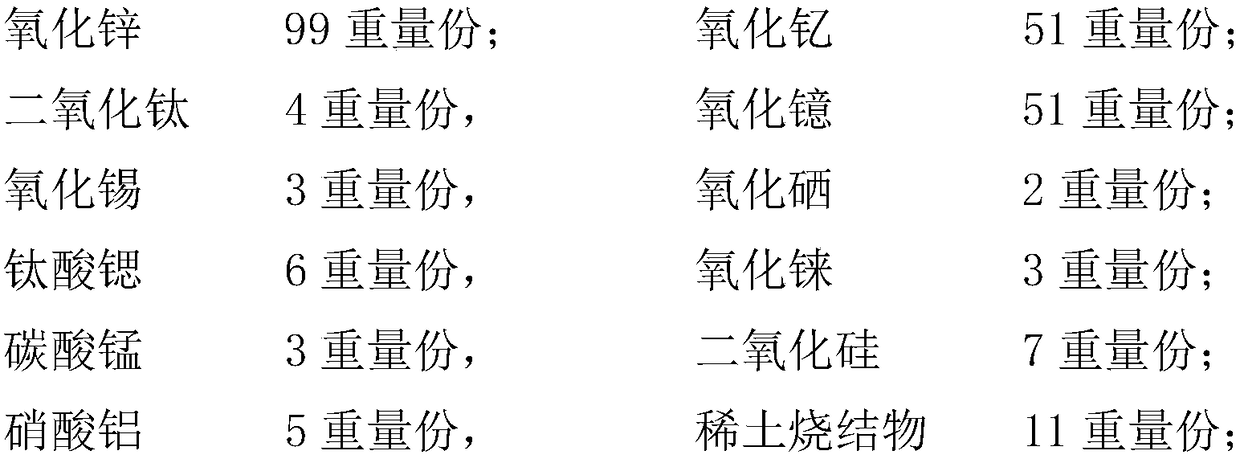

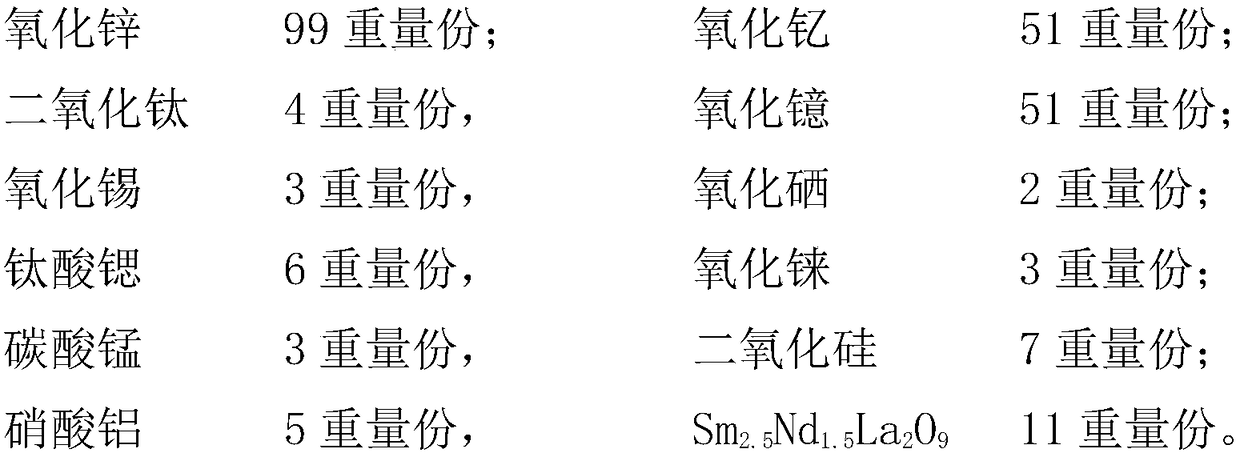

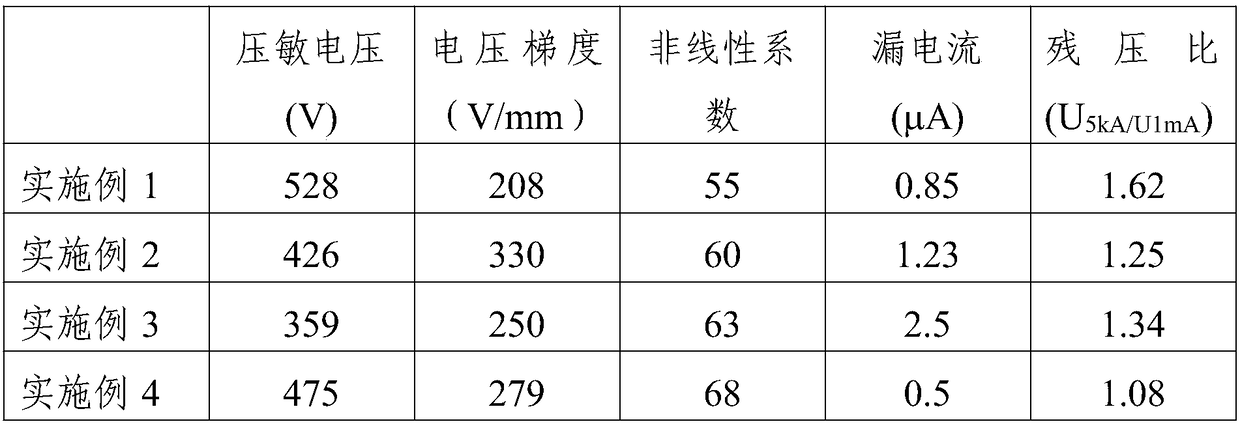

A varistor material

ActiveCN106316384BHigh nonlinear coefficientReduce leakage currentVaristor coresStrontium titanateManganese

The invention discloses a piezoresistor material. The piezoresistor material is prepared from the following raw materials in parts by weight: 98-100 parts of zinc oxide, 50-52 parts of yttria, 3-5 parts of titanium dioxide, 50-52 parts of ytterbia, 2-4 parts of stannic oxide, 1-3 parts of selenium oxide, 5-7 parts of strontium titanate, 2-4 parts of rhenium oxide, 2-4 parts of manganese carbonate, 6-8 parts of silicon dioxide, 4-6 parts of aluminum nitrate and 10-12 parts of rare earth sinter. Yttrium ions and ytterbium ions, with radii close to those of zinc ions, are introduced, so that a traditional formula with zinc oxide as the main component is replaced with a new formula with zinc oxide, yttria and ytterbia as main components. In combination with various additives in the new formula, the prepared piezoresistor material has higher nonlinear coefficients, lower leakage currents, higher heavy current resistance capacity and higher voltage gradient.

Owner:张颖

Sewage sludge electro-osmotic filter press collaborative dehydration device

ActiveCN105923952BImprove contact tightnessReduce moisture contentSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentUltra high pressureFiltration

The invention discloses an electric osmosis filter pressing based sewage sludge co-dehydration device, comprising an electric osmosis squeezing container (3), an anode plate (4) and a cathode plate (5), wherein the anode plate (4) and the cathode plate (5) are arranged in the electric osmosis squeezing container (3), sludge particulates move towards the anode plate and water molecules move towards the cathode plate under the influence of an electric field force, and a pressure is exerted between the anode plate and the cathode plate such that electrically osmosed water flows out of an electric osmosis squeezing dehydration device. After the above electric osmosis dehydration is completed, a low water content of sludge of the anode plate (4) is realized, when the sludge becomes dry, the electric osmosis dehydration is stopped, and the pressure between the anode plate (4) and the cathode plate (5) is increased to realize an ultra-high pressure mechanical filter pressing dehydration, so that the water content between the anode plate and the cathode plate is uniform. According to the electric osmosis filter pressing based sewage sludge co-dehydration device disclosed by the invention, as a co-dehydration means in the combination of an electric osmosis coupling dehydration and an ultra-high pressure mechanical dehydration is employed, energy consumption for the dehydration is reduced greatly, and a lower water content of the sludge treated according to the invention is realized.

Owner:浙江诺曼环保工程技术有限公司

Zinc oxide resistance sheet and preparation method thereof

The invention relates to a zinc oxide resistance sheet and a preparation method thereof. The zinc oxide resistance sheet is sintered from the following molar percentages of raw materials: 94.5% to 99% of zinc oxide base material, 0.2% to 1.6% of tungsten oxide, 0.7% to 3.6% of calcium oxide; 94.5% to 99% of the The zinc oxide base material includes raw materials with the following molar percentages: 91%-94% of zinc oxide, 1%-1.5% of cobalt oxide, 1.5%-2.5% of bismuth oxide and 0.6%-1% of manganese oxide. The zinc oxide resistance sheet proposed by the present invention can improve its electrical properties such as voltage gradient on the basis of reducing sintering energy consumption, wherein the voltage gradient can be as high as 547V / mm, and the flow capacity can reach 350J / cm 3 . The invention also proposes a preparation method of the zinc oxide resistor, including granulation, tablet pressing, pre-sintering and sintering. The method improves the performance of the zinc oxide resistor and is also beneficial to reduce energy consumption.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

A Nonlinear Cylindrical Varistor and Its Application

ActiveCN107134332BImprove propertiesIncrease heightVaristor coresSilicon-controlled rectifierVoltage response

The invention discloses a nonlinear cylindrical pressure sensitive resistor and application thereof. The nonlinear cylindrical pressure sensitive resistor is composed of a pressure sensitive resistor ceramic wafer and a non-continuous electrode. Due to doping of a zinc oxide material in the pressure sensitive resistor ceramic wafer, grains of the zinc oxide are refined, the surface density of the pressure sensitive resistor ceramic wafer is increased, the characteristics of the pressure sensitive resistor are improved, and the current-force impact resistance and nonlinear coefficient of the resistor are improved, so that the pressure sensitive resistor has high voltage gradient and beneficial electrical properties, reaches a nanosecond over-voltage response speed and is fast in over-voltage recovery and zero in follow current. The pressure sensitive resistor disclosed by the invention is safe and non-toxic in material and harmless to the human body and environment and can be widely applied to over-voltage protection of power diodes, silicon stacks, medium / low-power silicon controlled rectifiers and the like.

Owner:VOCATIONAL SKILLS TRAINING BASE OF STATE GRID JIANGSU ELECTRIC POWER CO

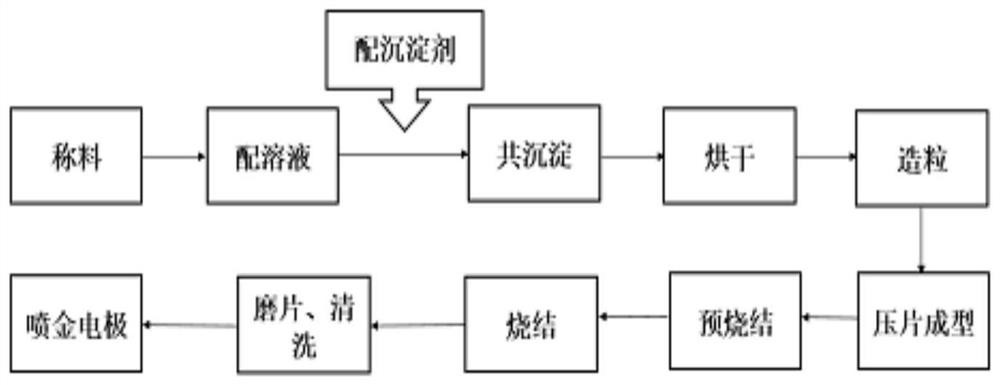

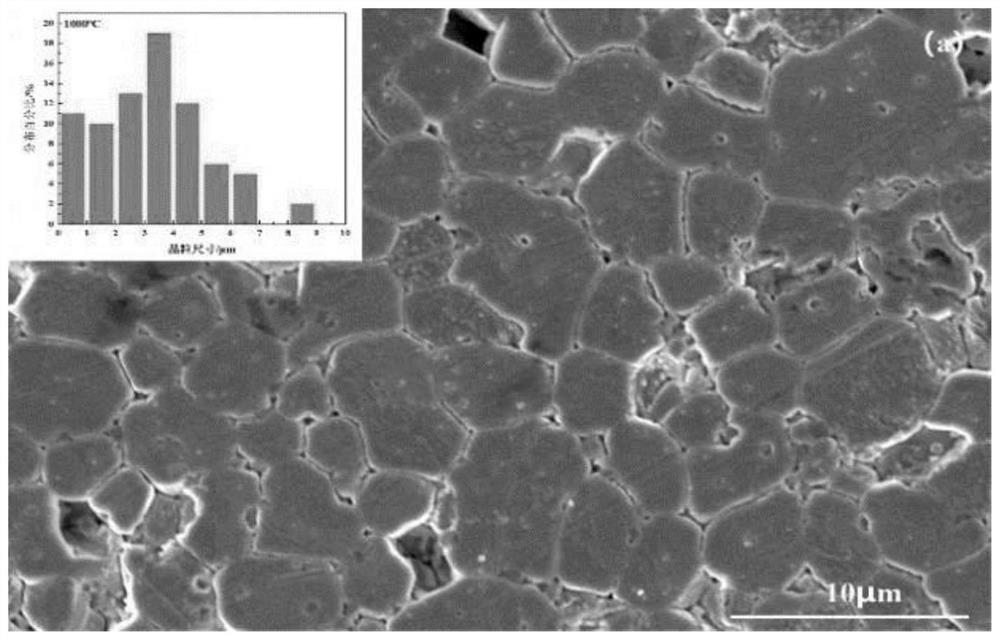

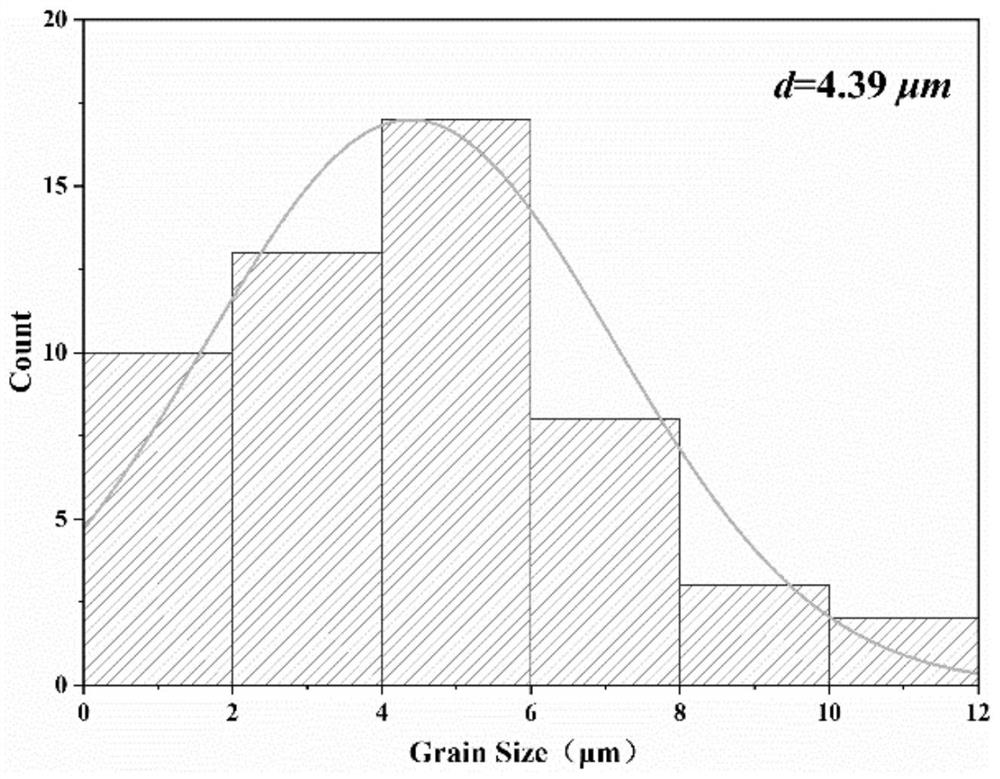

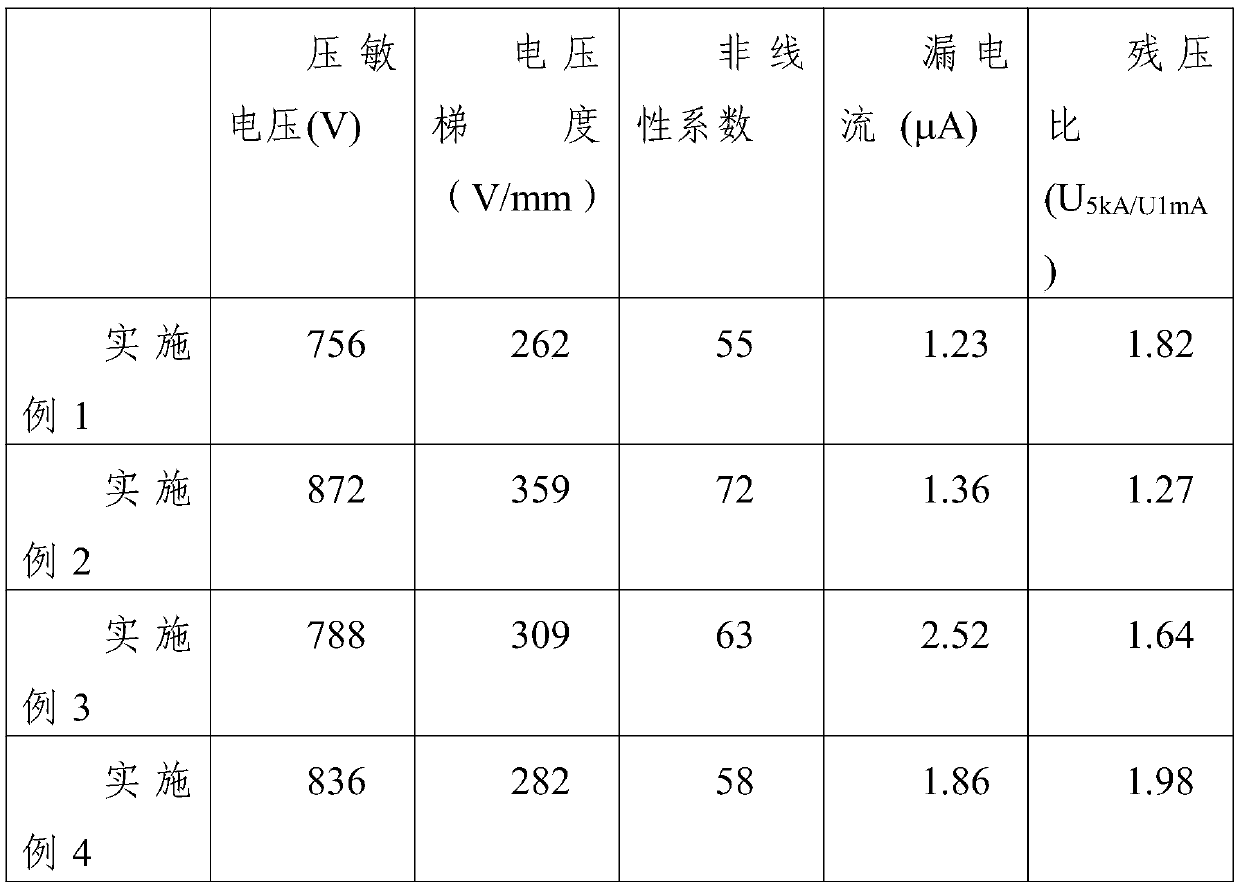

Zinc oxide piezoresistor preparation method based on chemical deposition method

PendingCN114133236ADiffusion fastImprove electrical performanceVaristor coresResistors adapted for applying terminalsPolyvinyl alcoholGlycol synthesis

The invention discloses a zinc oxide piezoresistor preparation method based on a chemical deposition method, which comprises the following steps: S1, dissolving weighed raw materials with ethylene glycol to form a mixed solution, dropwise adding a NaOH solution into the mixed solution to obtain a precipitate, and filtering and washing the precipitate; s2, drying the precipitate in a drying machine, grinding after drying, and sieving with a 60-mesh sieve; s3, adding a polyvinyl alcohol aqueous solution into the precipitate, mixing, drying, grinding, sieving with a 60-mesh sieve, and granulating; s4, spraying deionized water into the granulated powder, uniformly shaking, standing and tabletting; s5, sintering the tablet, and cooling to room temperature to obtain a sample; s6, performing fine grinding on the sample, performing ultrasonic cleaning on the sample in an ultrasonic cleaning machine, and drying; and S7, coating the surface of the dried sample with a gold electrode to obtain the zinc oxide varistor. According to the preparation method disclosed by the invention, uniform mixing of the ZnO powder and the doped metal oxide is effectively realized, so that the ZnO varistor is more uniform in microscopic grain structure and more excellent in electrical property, and can meet the development requirements of an extra-high voltage power grid.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

A safe and environmentally friendly non-linear piezoresistor and its application

InactiveCN106630998BImprove conductivityIncrease the carrier concentrationVaristor coresOvervoltageVoltage gradient

Owner:NORTH CHINA INST OF SCI & TECH

A Varistor with Low Residual Voltage Ratio and Its Application

InactiveCN107082635BImprove conductivityIncrease the carrier concentrationVaristor coresEngineeringVoltage gradient

The invention discloses a piezoresistor with a low residual voltage ratio and application of the piezoresistor. The piezoresistor with the low residual voltage ratio consists of a piezoresistor chip, a silicone rubber sealing layer, an insulated sealing layer, an electrode and an electrode lead wire. A zinc oxide material is doped, so that grain sizes of zinc oxide are refined, and surface density of a piezoresistor is increased, and therefore, the purpose of reducing the residual voltage ratio of the piezoresistor is achieved, current power impact resistance and a nonlinear coefficient of the piezoresistor are improved, so that the piezoresistor has relatively high voltage gradient.

Owner:新昌县恩喜电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com