A varistor material

A varistor, general technology, applied in the direction of varistor, varistor core, etc., to achieve the effect of strong resistance to large current, high voltage gradient, high nonlinear coefficient

Active Publication Date: 2019-03-12

张颖

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, with the development and progress of science and technology, especially the rapid development of large-scale intelligent circuits, the requirements for components, especially resistors, are getting higher and higher. The current varistors can no longer meet the needs of development. Resistors and resistive materials with high performance and high capacity have been extensively studied, and varistor materials and varistors are one of the important research directions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

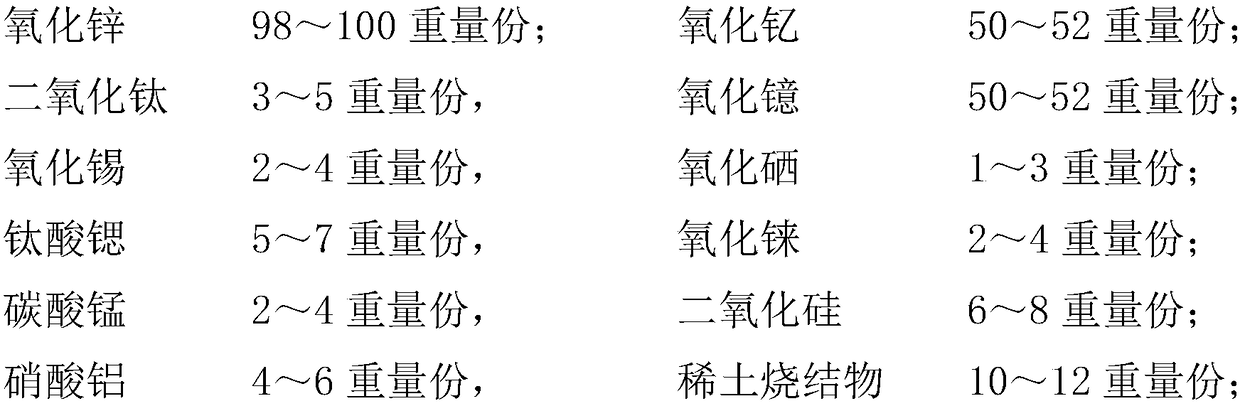

[0040] A varistor material, consisting of the following materials in parts by weight:

[0041]

Embodiment 2

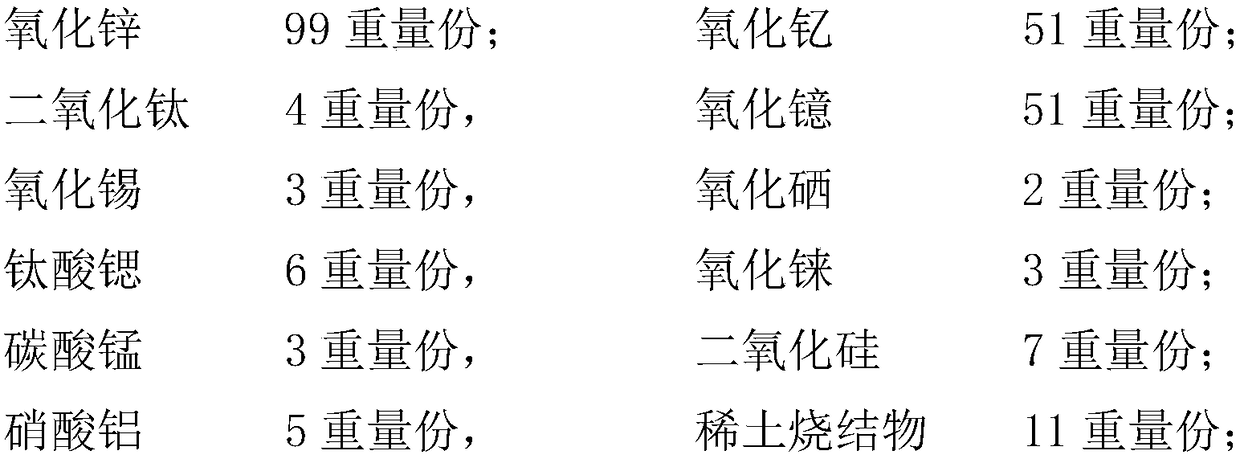

[0043] A varistor material, consisting of the following materials in parts by weight:

[0044]

Embodiment 3

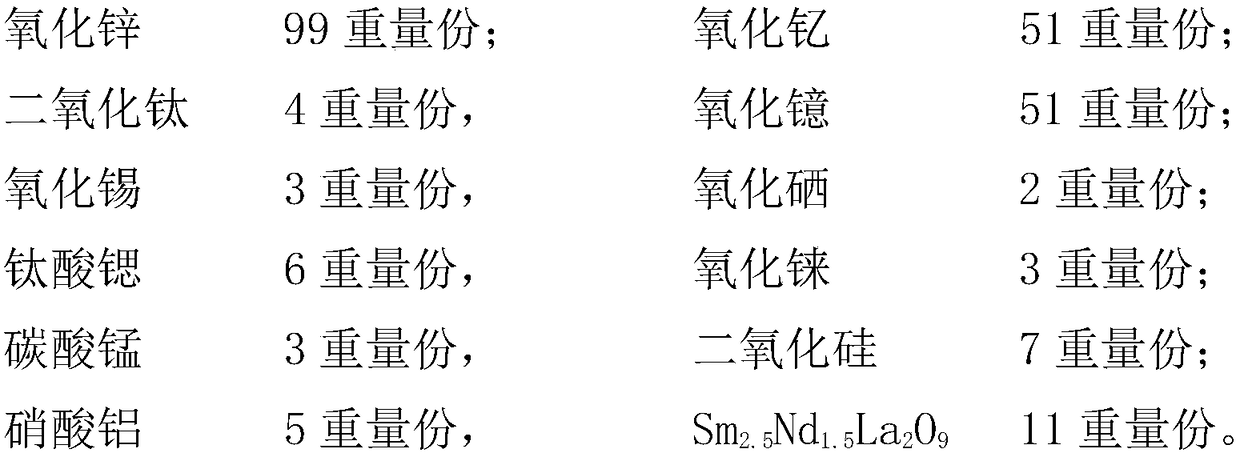

[0046] A varistor material, consisting of the following materials in parts by weight:

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a piezoresistor material. The piezoresistor material is prepared from the following raw materials in parts by weight: 98-100 parts of zinc oxide, 50-52 parts of yttria, 3-5 parts of titanium dioxide, 50-52 parts of ytterbia, 2-4 parts of stannic oxide, 1-3 parts of selenium oxide, 5-7 parts of strontium titanate, 2-4 parts of rhenium oxide, 2-4 parts of manganese carbonate, 6-8 parts of silicon dioxide, 4-6 parts of aluminum nitrate and 10-12 parts of rare earth sinter. Yttrium ions and ytterbium ions, with radii close to those of zinc ions, are introduced, so that a traditional formula with zinc oxide as the main component is replaced with a new formula with zinc oxide, yttria and ytterbia as main components. In combination with various additives in the new formula, the prepared piezoresistor material has higher nonlinear coefficients, lower leakage currents, higher heavy current resistance capacity and higher voltage gradient.

Description

technical field [0001] The invention relates to the field of varistor materials, in particular to a varistor material mainly composed of zinc oxide, yttrium oxide and ytterbium oxide. Background technique [0002] Varistor is a resistive device with nonlinear volt-ampere characteristics. It is mainly used for voltage clamping when the circuit is subjected to overvoltage, and absorbs excess current to protect sensitive devices. The English name is "Voltage Dependent Resistor" abbreviated as "VDR", or "Varistor". The resistor material of the varistor is a semiconductor, so it is a variety of semiconductor resistors. The varistor is a voltage limiting protection device. Utilizing the nonlinear characteristics of the varistor, when an overvoltage occurs between the two poles of the varistor, the varistor can clamp the voltage to a relatively fixed voltage value, thereby realizing the protection of the subsequent circuit. The main parameters of varistors are: varistor voltage,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/453C04B35/622H01C7/112H01C7/115

CPCC04B35/453C04B35/622C04B2235/3224C04B2235/3225C04B2235/3227C04B2235/3232C04B2235/3236C04B2235/3262C04B2235/3268C04B2235/3293C04B2235/34C04B2235/3418C04B2235/443H01C7/112H01C7/115

Inventor 张颖

Owner 张颖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com