Patents

Literature

63results about How to "Raise the potential gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

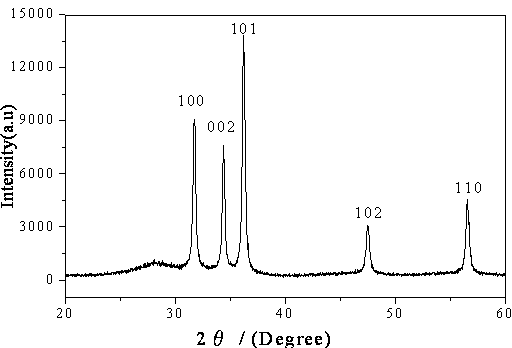

Method for preparing high-potential gradient zinc oxide piezoresistive material by low-temperature sintering

InactiveCN1801409AHigh nonlinear indexRaise the potential gradientResistor manufactureVaristor coresManufacturing technologyHigh energy

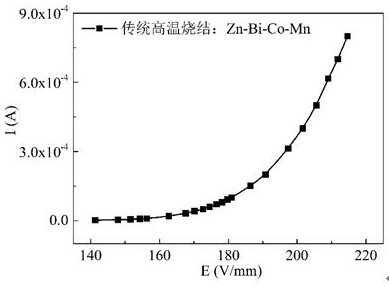

The preparation method for high-potential gradient ZnO piezoresistor material comprises: with high-energy ball grinding technology, adding rare earth oxides included Bi2O3, Sb2O3, Cr2O3, Co2O3, MnO2, and Y2O3; sintering at 800Deg, and obtaining the product. The advantages of this invention comprises: simple process technology, low sintering temperature, fit to traditional device, well properties of the product, 5.50~5.64g / cm3 density, 1845.66~2233.33V / mm voltage-sensitive potential gradient, 21.3~25.8 nonlinear index, and 1.55~10.2ª–A drain current (given 0.75V1mA).

Owner:EAST CHINA NORMAL UNIV

High-performance Pr series ZnO voltage sensitive ceramic material and preparation method thereof

The invention relates to a high-performance Pr series ZnO voltage sensitive ceramic material and a preparation method thereof, and belongs to the technical field of preparation and application of electronic ceramics. Nano composite ZnO ceramic powder is prepared by wrapping the surface of nano ZnO by a liquid phase deposition method, so that the doped components are mixed uniformly, the micro structure of a product is uniform, the performance of the Pr series ZnO voltage sensitive ceramic material is improved and the sintering temperature of the ceramic material is effectively reduced and the energy consumption is reduced. The Pr series ZnO voltage sensitive ceramic material with high electric potential gradient, a large nonlinear coefficient, and small leakage current is prepared by optimizing the reasonable ratio of all doped components and combining a liquid phase wrapping process, and meets the requirements of high-voltage and supervoltage high-quality arresters and other devices; and the variety of the doped elements for preparing the high-voltage ZnO voltage sensitive ceramic is few, the source of the doped elements is abundant, and the method is simple, so that production cost is lowered.

Owner:溧阳常大技术转移中心有限公司

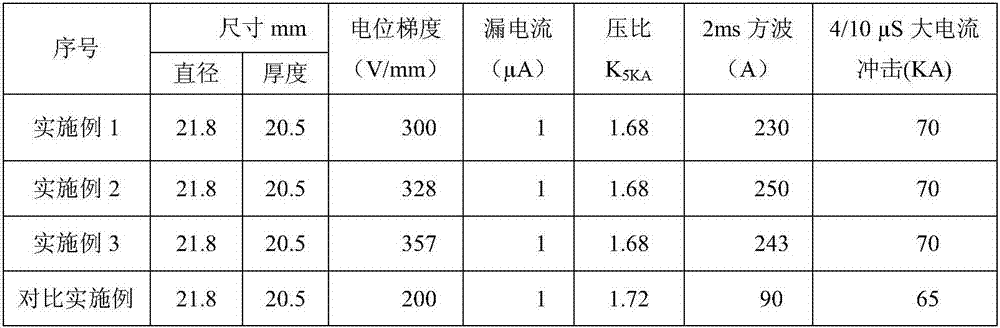

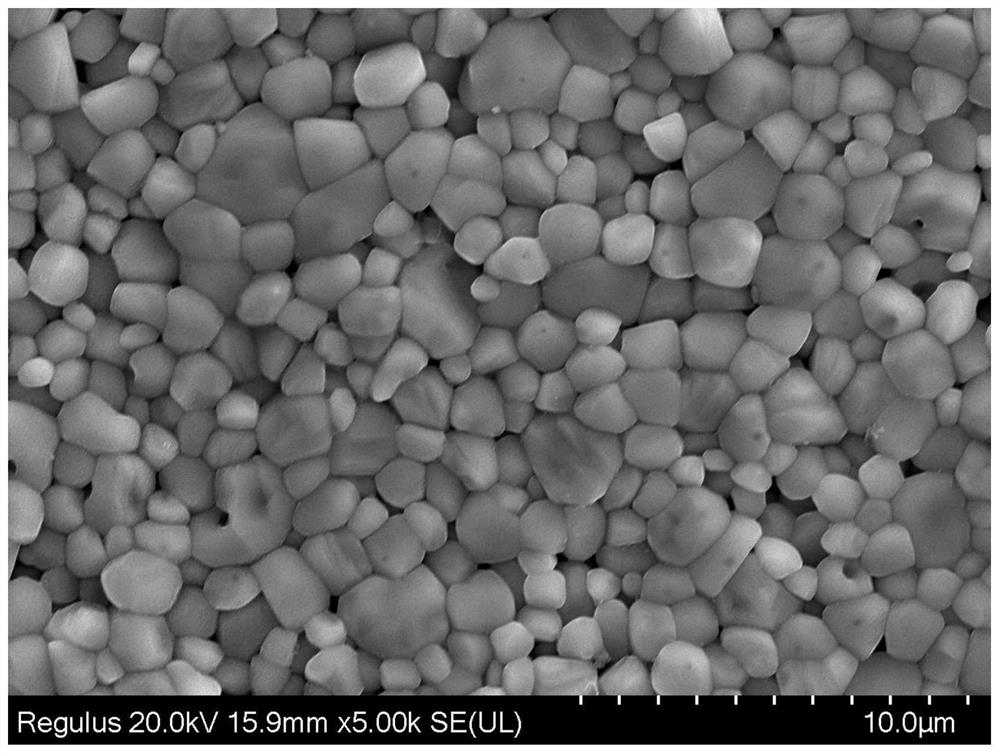

Zinc oxide resistor disc and manufacturing method thereof

ActiveCN105110786ARaise the potential gradientInhibit growthVaristor coresElectrical resistance and conductanceMetallurgy

The invention discloses a zinc oxide resistor disc and a manufacturing method thereof. The zinc oxide resistor disc comprises, by the molar fraction, 95.5% to 99% of zinc oxide base materials, 0.5% to 1.9% of yttrium oxide and 0.5% to 2.6% of zirconium oxide in a sintered mode. The manufacturing method includes the following steps: 1, material dosing; 2, wet grinding pelleting; 3, hydraulic disc forming; 4, segmented sintering. The zinc oxide resistor disc has the advantages of being high in electric potential gradient and large in current flowing capacity; compared with a zinc oxide resistor disc manufactured with a conventional method, the zinc oxide resistor disc manufactured with the manufacturing method has the advantages that the electric potential gradient is increased by near 1 / 4, and the current flowing capacity is improved by 1 / 3.

Owner:STATE GRID CORP OF CHINA +2

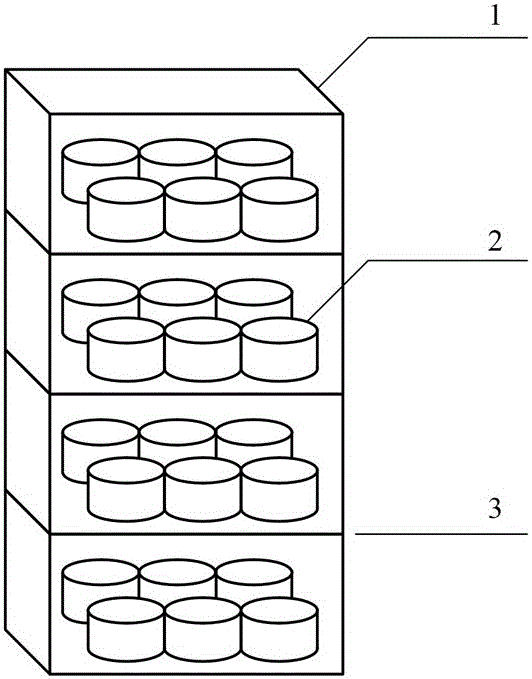

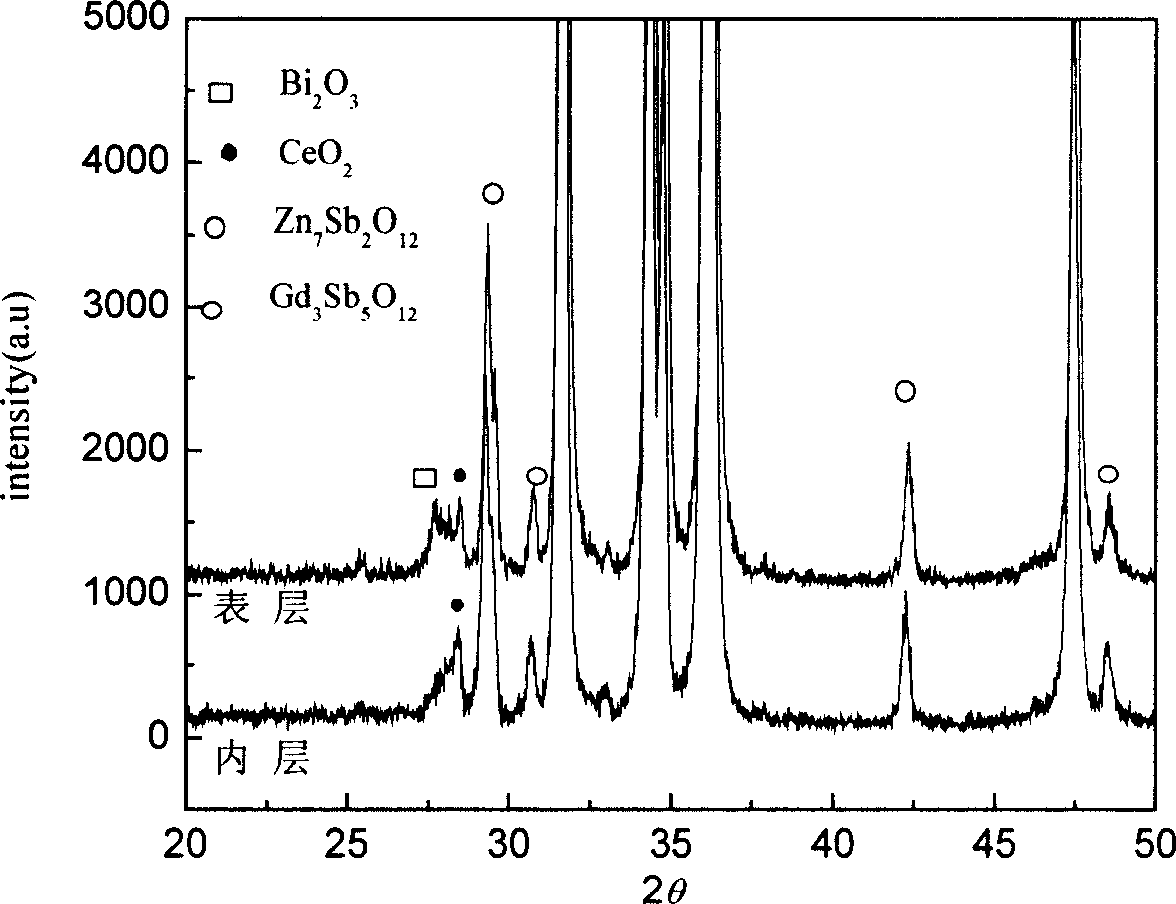

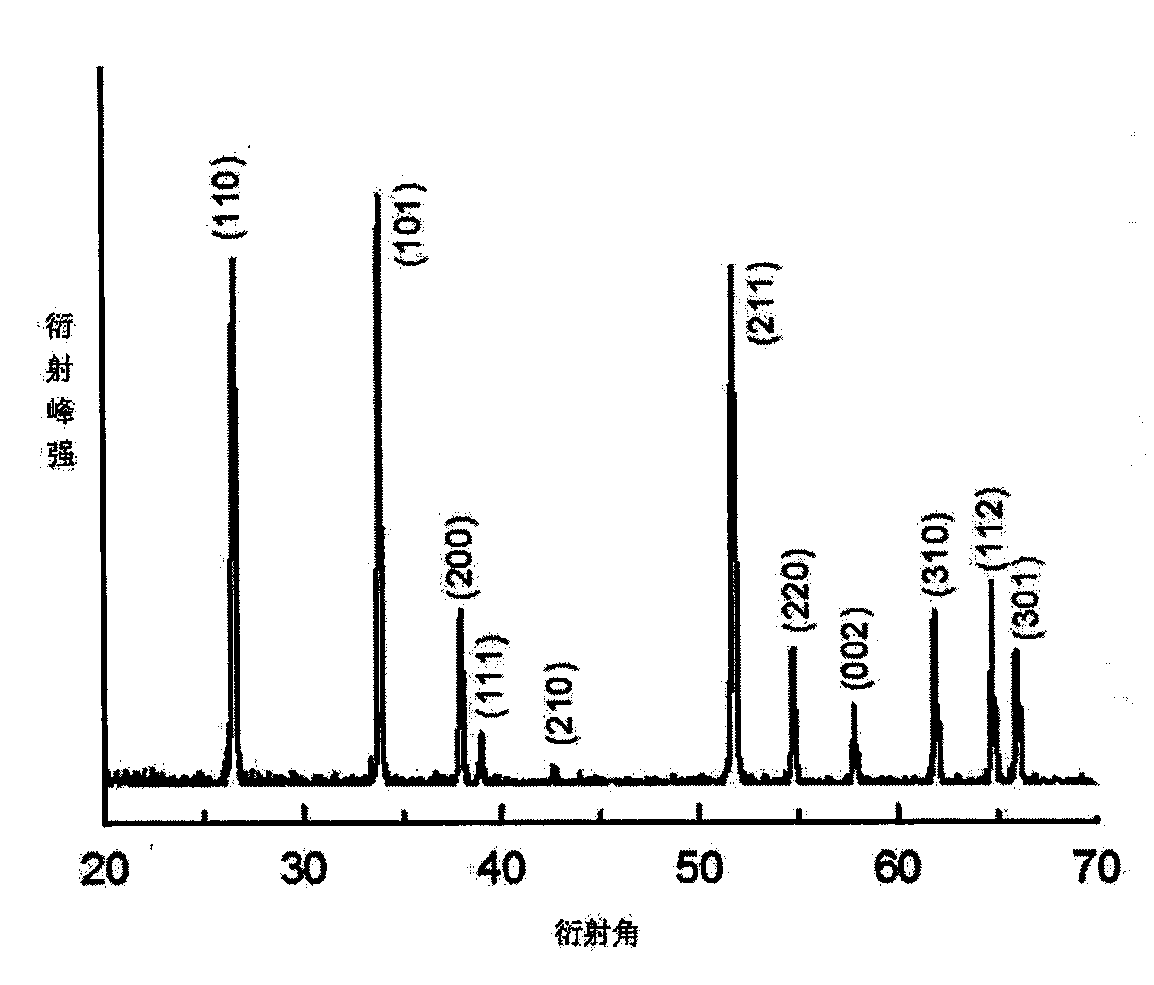

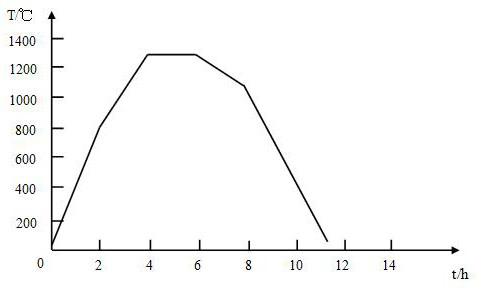

Process for preparing ZnO-Bi2O3 series pressure-sensitive ceramic chamotte doped with rare-earth oxide

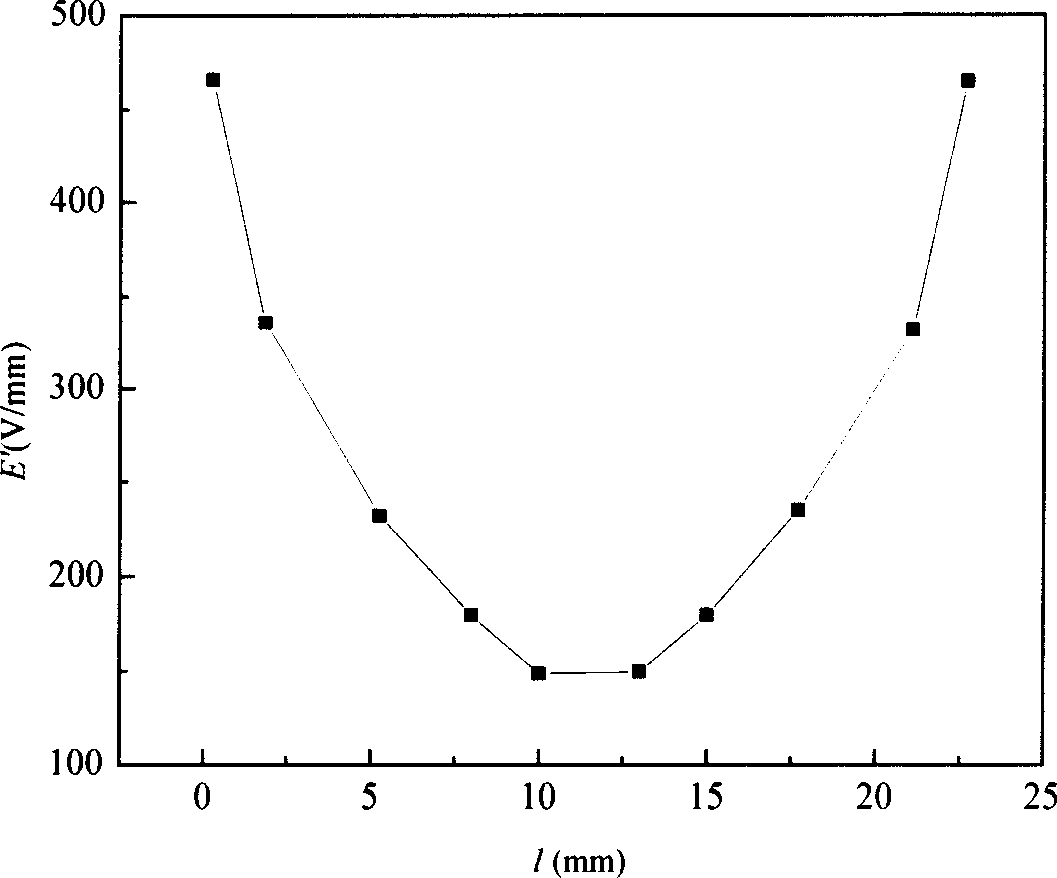

InactiveCN1844043AInhibit "soft heart" phenomenonRaise the potential gradientVaristorsPressure sensitiveElectric properties

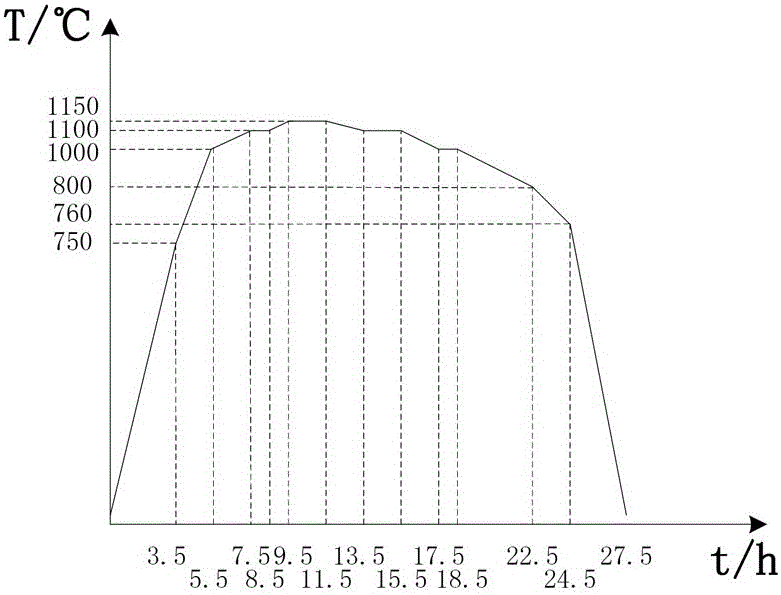

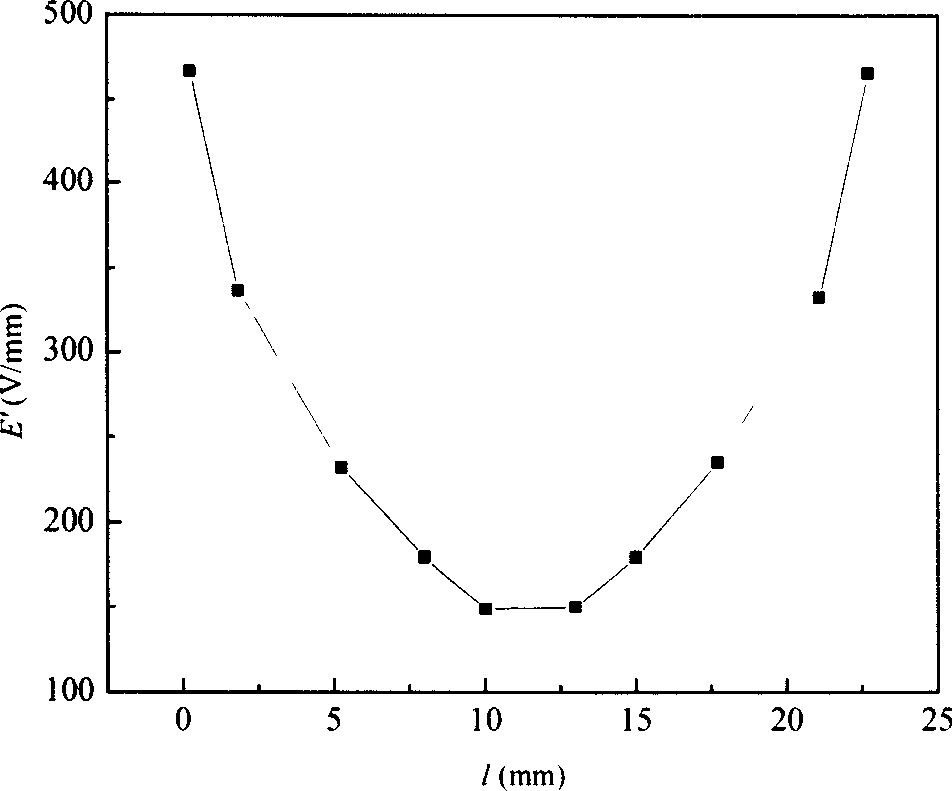

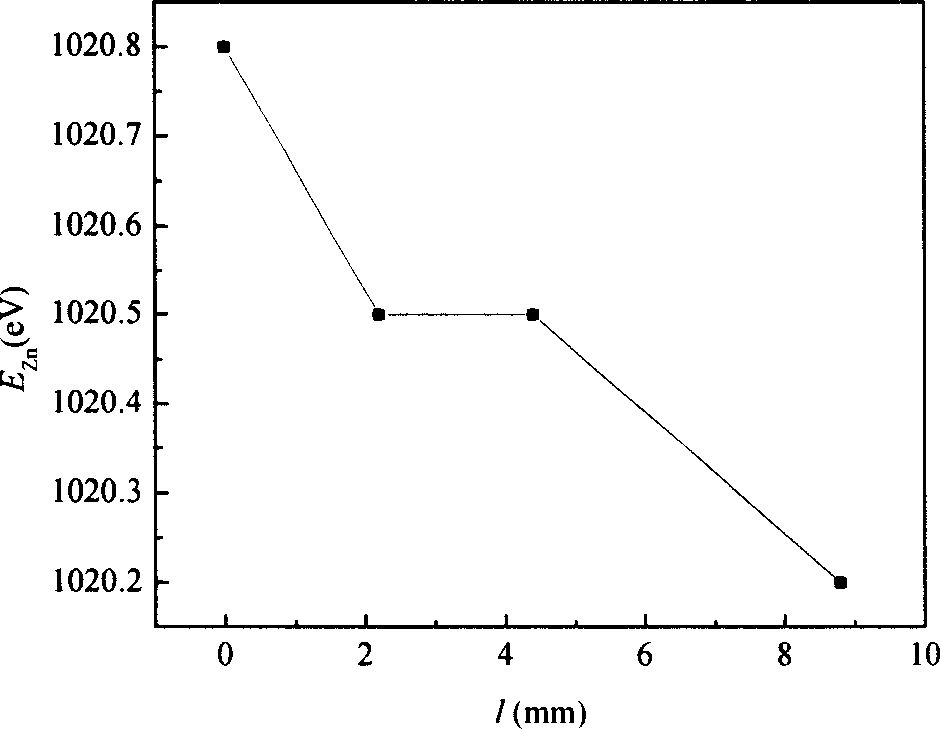

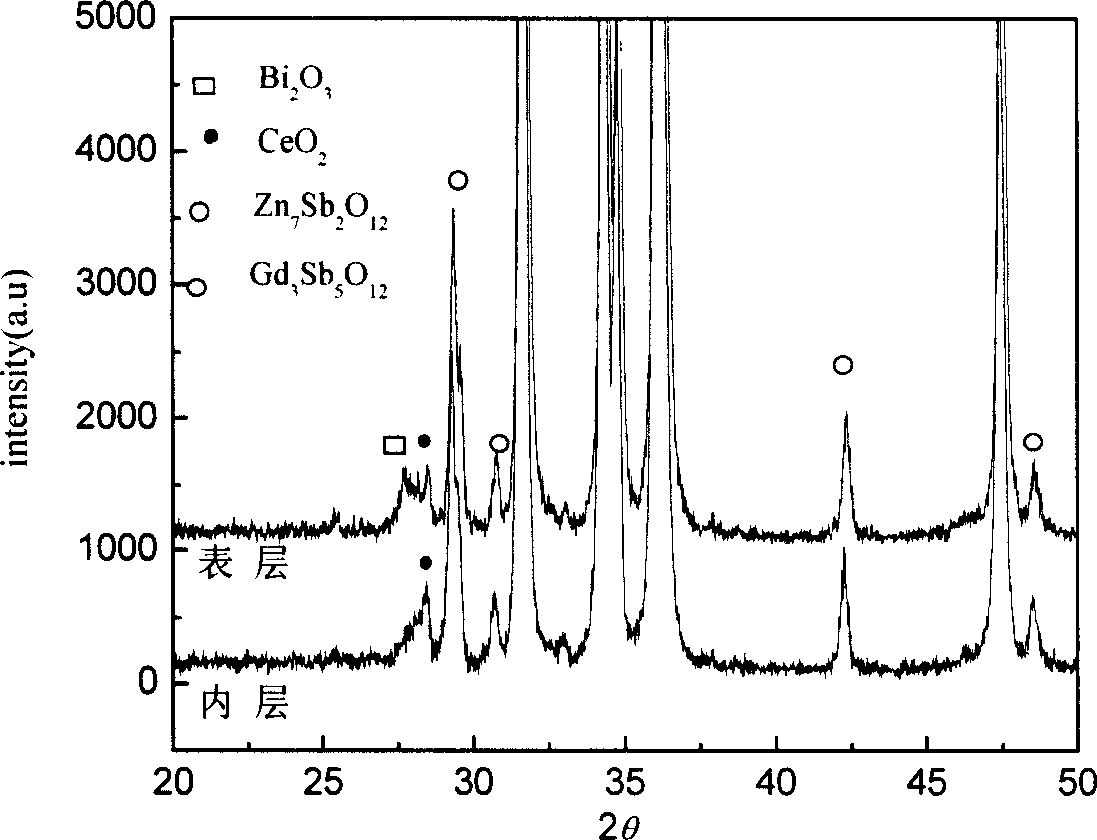

This invention discloses a preparation technology of rare-earth oxide doped ZnO-Bi2O3 group pressure sensitive ceramic, prefireing components except Al(NO3)3 9H2O in 900deg C for 30min, and then mixing ball milling granulating with Al(NO3)3 9H2O and residual ZnO, pressing to shape green compact, heating from room temperature to 1180deg C by the rate of 100-200deg C / h and preserving heat for 4h after discharging rubber, lowing temperature to room temperature by the rate of 60-200deg C / h; Annealing sintered body by 600-800deg C for 2h, the getted rare-earth oxide doping ZnO-Bi2O3 group pressure sensitive ceramic sample after detemperature rate 0.1-2deg C / min, the homogeneity of electric property is improved obviously, moreover, extenuating center soft+-phenomenon in high extent, can be used to make lightning protection arrester products of super / extra-high voltage electric transmission system.

Owner:XI AN JIAOTONG UNIV

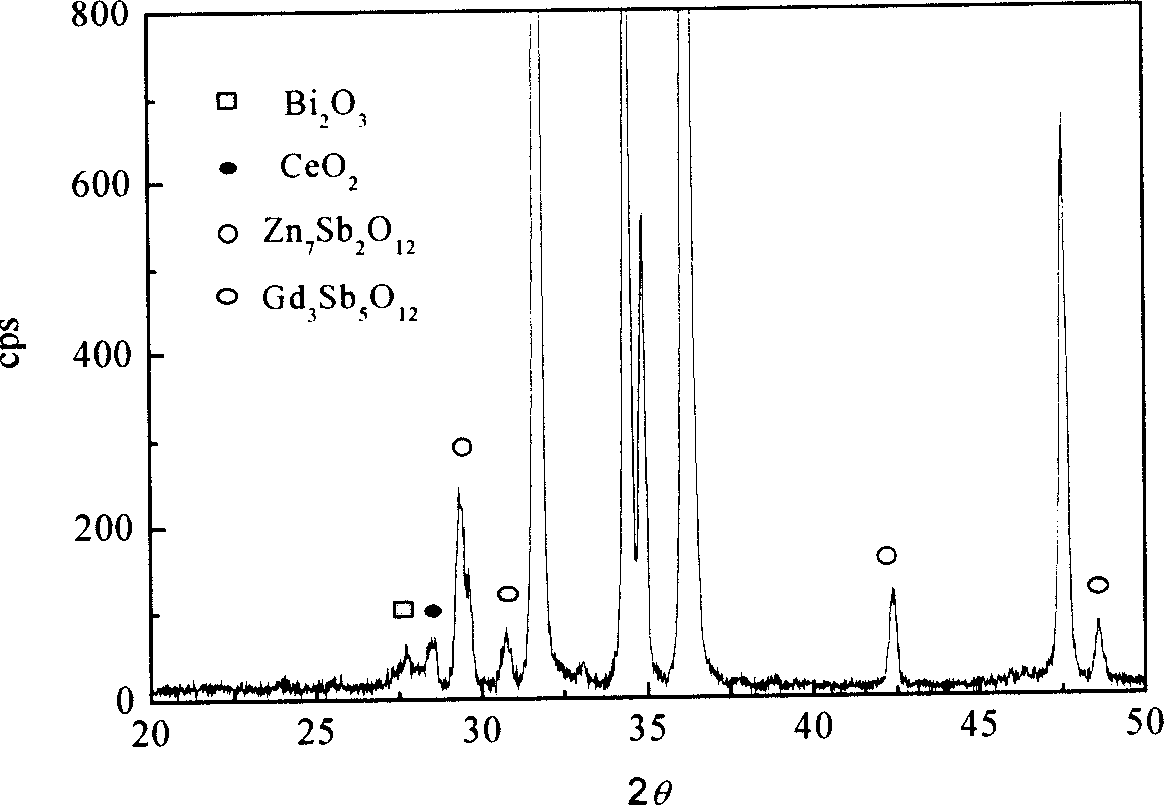

Process for preparing ZnO-Bi2O3 series pressure-sensitive raw material doped with rare-earth oxide

InactiveCN1844045ANonlinear Exponential DeclineNonlinear Exponential ImprovementVaristorsRare earthSlurry

The invention discloses a process for preparing rare earth oxide doped ZnO-Bi2O3 family pressure-sensitive ceramic slurry, which comprises mixing all the addition constituents with main ingredient ZnO directly, ball grinding and granulating, compacting into blanks, discharging glue and heating, cooling down, subjecting the sintered body to heat treatment and cooling down again.

Owner:XI AN JIAOTONG UNIV

High-performance direct-current zinc oxide varistor and preparation process thereof

ActiveCN105427977ARaise the potential gradientReduce leakage currentResistor manufactureVaristor coresVaristorBismuth preparation

The invention provides a high-performance direct-current zinc oxide varistor and a preparation process thereof. The varistor is prepared from the following components in parts by mol: 90 to 98 parts of ZnO, 0.5 to 7 parts of Bi2O3, 0.1 to 10 parts of Sb2O3, 0.1 to 2 parts of Co2O3, 0.1 to 5 parts of SiO2, 0.1 to 5 parts of MnO2, 0.1 to 5 parts of Cr2O3, 0.1 to 4 parts of NiO, 0.1 to 1 part of B2O3, 0.01 to 0.6 part of Al(NO3) 3.9HO, 0.01 to 0.5 part of V2O5, 0.01 to 0.5 part of CeO2 and 0.05 to 0.5 part of silver glass powder. According to the varistor and the preparation method thereof, by adding B2O3, V2O5, CeO2 and silver glass powder in a traditional varistor, and by coating a varistor blank surface with bismuth-containing oxide during high-temperature firing and by carrying out direct-current coating and diffusion treatment on the varistor obtained by high-temperature firing according to the preparation process, various performances, such as aging resistance, rectangular wave current impact tolerance stability and large current impact tolerance stability of the varistor can be greatly improved, and the preparation process has the advantages of low cost, high efficiency and the like.

Owner:STATE GRID CORP OF CHINA +2

Rare earth oxide composite additive for zinc oxide varistor and preparation method thereof

InactiveCN102515779AImprove electrical performanceImprove dispersion uniformityRare-earth elementMaterials preparation

The invention relates to a rare earth oxide composite additive for a zinc oxide varistor and a preparation method thereof and belongs to the technical field of varistor material preparation. The preparation method comprises the following steps of: precipitating two or more rare earth element salts, filtering to obtain a precipitate, washing, drying, and calcining to obtain the rare earth oxide composite additive for the zinc oxide varistor. Components of the rare earth oxide composite additive prepared are uniformly mixed. Particle distribution range is narrow. Hydrogen chloride in mother liquor after precipitation can be recovered and reused. There is no discharge of harmful gases such as nitrogen oxide and the like during the calcining process, the whole process is environmentally friendly and has no pollution. In the meanwhile, in comparison with a plurality of rare earth oxide respectively added in a zinc oxide varistor, the rare earth oxide composite additive prepared by the preparation method can be used to make various rare earth elements added to be uniformly distributed, substantially improve the microstructure of the zinc oxide varistor and greatly raise its comprehensive electric properties.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

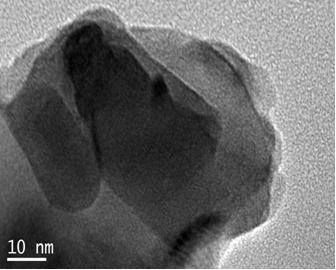

Preparation method of composite nano ZnO voltage-sensitive ceramic powder

The invention relates to a ZnO voltage-sensitive ceramic material and particularly relates to a preparation method of composite nano ZnO voltage-sensitive ceramic powder. The preparation method comprises the following steps: preparing soluble zinc salt, bismuth salt, cobalt salt and manganese salt which are used as raw materials, respectively preparing into aqueous liquor, mixing 95% (in mole percentage) of ZnO, 3% of Bi2O3, 1% of CoO and 1% of MnO, and uniformly stirring; slowly adding ammonia water into mixed liquor obtained in the step (1), regulating the pH to 8-8.5 to obtain mixed liquor, continuously stirring until mixing uniformly; carrying out suction filtration onto precipitates obtained in the step (2), sufficiently washing to remove impurities by using deionized water and alcohol, placing obtained precursor in water or alcohol medium for refluxing for 2-8 hours, and controlling a refluxing temperature to 70 DEG C-80 DEG C; finally, carrying out suction filtration on the powder obtained by refluxing, sufficiently washing to remove impurities by using deionized water and alcohol, finally drying in a vacuum drying box, and grinding to obtain nano composite ZnO powder.

Owner:颍上县祥盛建设管理有限公司

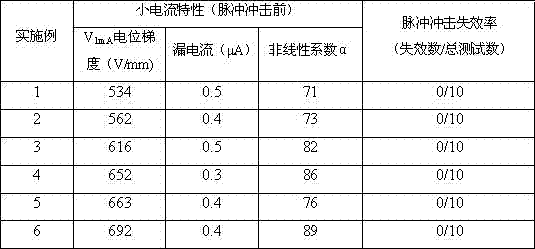

Preparation method of nonlinear resistance piece for miniaturization GIS lightning arrestor

ActiveCN101140821AInhibit growthRaise the potential gradientResistor manufactureOvervoltage protection resistorsNonlinear resistorMiniaturization

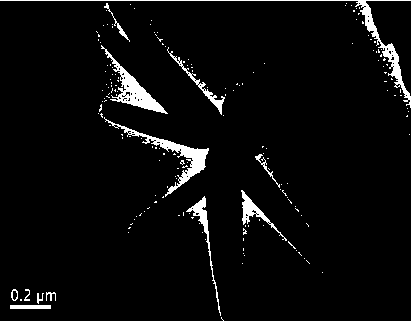

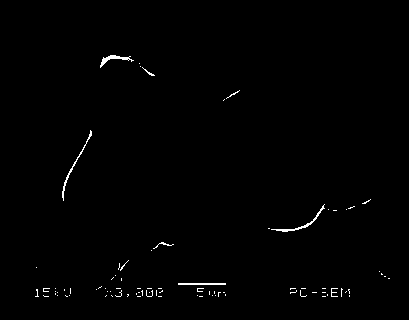

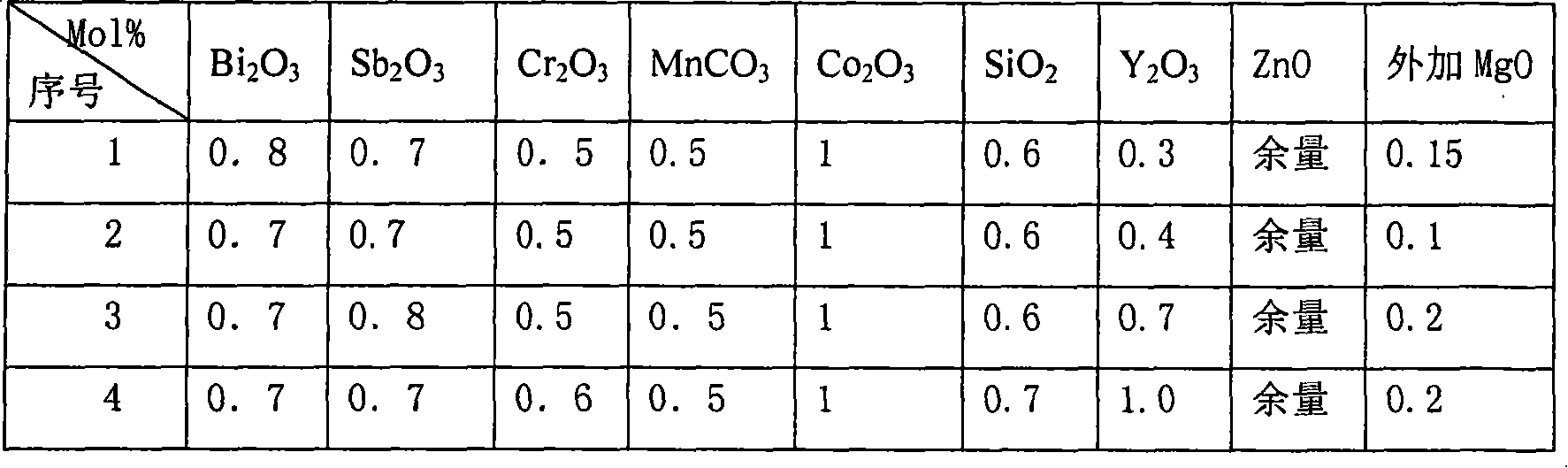

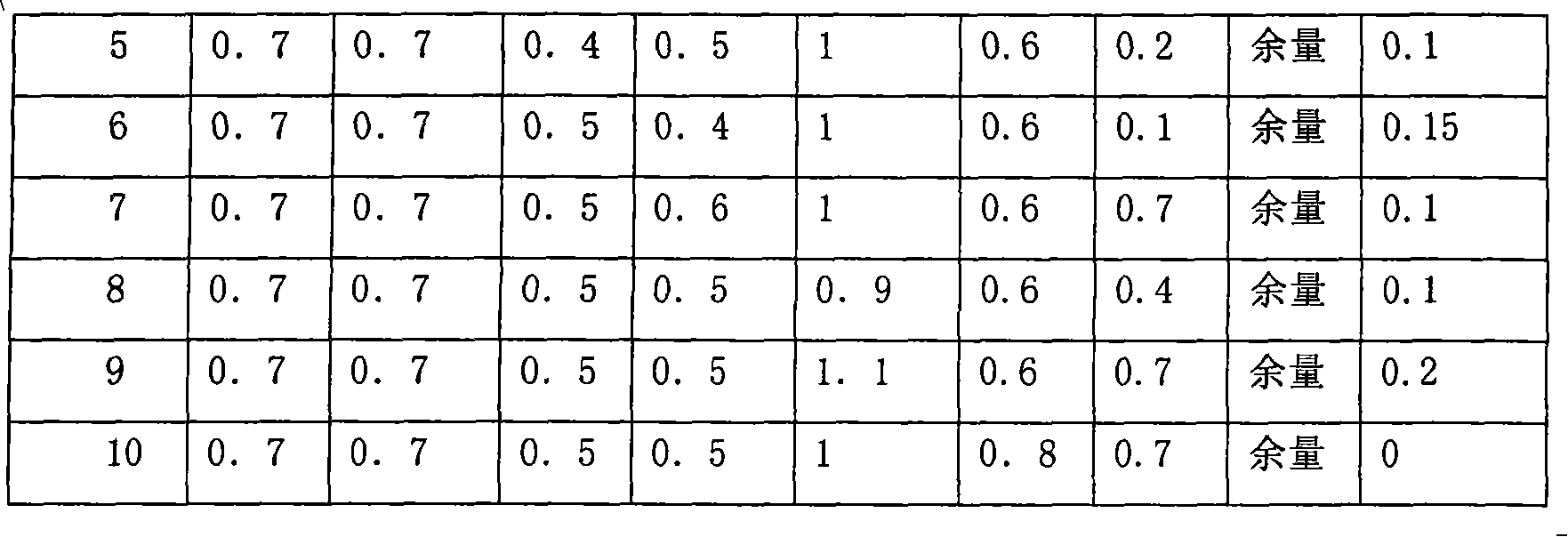

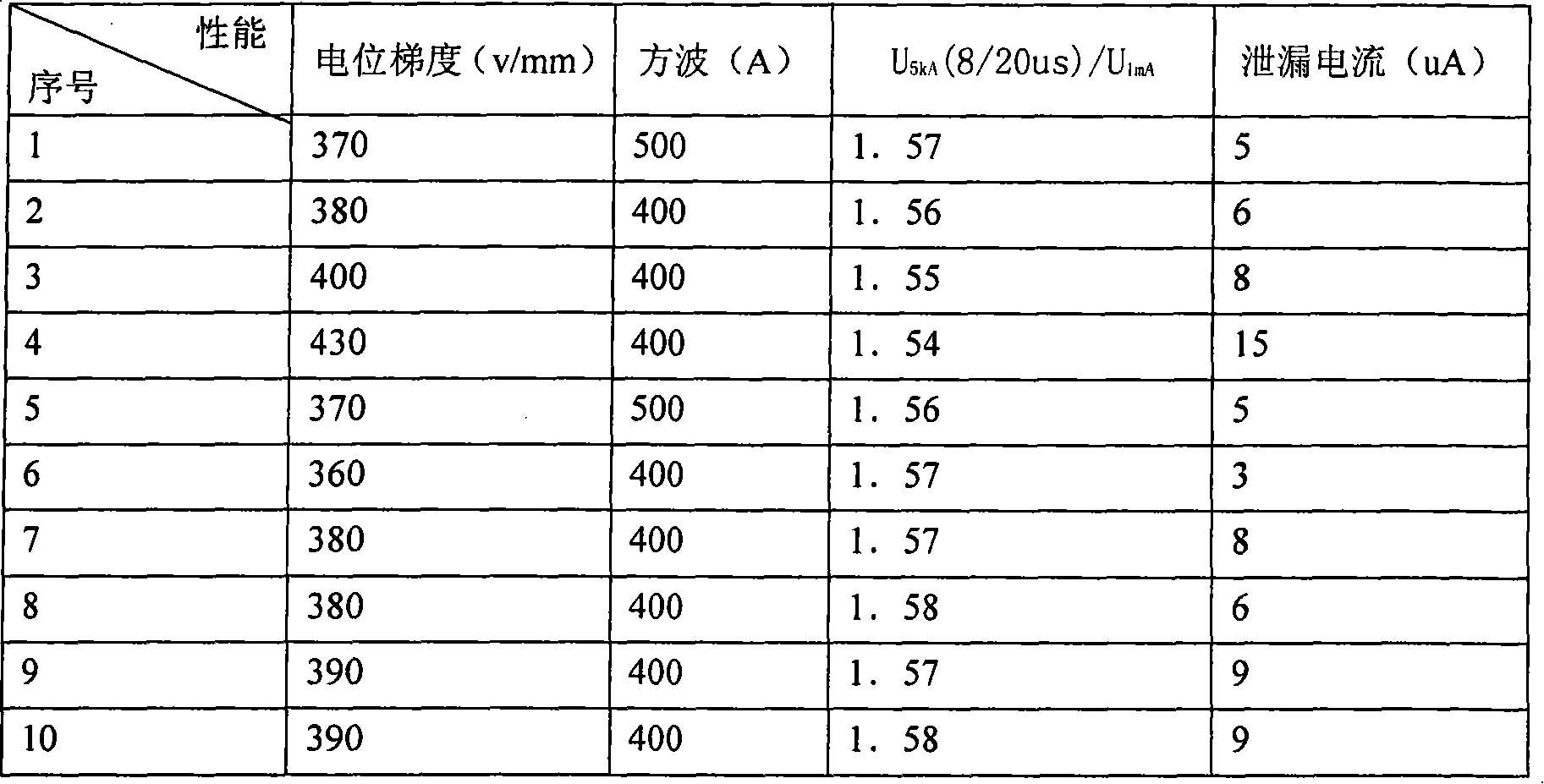

The invention discloses a preparation method for the non-linear resistors of high-potential gracient, strong square wave tolerance and good pressure ratio aging performance used for mini-type GIS lightning arrester, which comprises steps as follows: to weight the following additive constituents after mixture making with ZnO as the major ingredient: Bi2O3 of 0.7-0.8 percent , Sb2O3 of 0.7-0.8 percent , Cr2O3 of 0.4-0.6 percent , MnCo3 of 0.4-0.6 percent , Co2O3 of 0.9-1.1 percent , SiO2 of 0.6-0.8 percent and Y2O3 of 0.1-1 percent ; after mixed calcining, the additive constituents are required to have waterproof pulverization mix with ZnO; firing them to form ceramic chip under 1100 degrees centigrade for four hours after granulation mechanism, molding and batching out and making heat treatment after grinding; jet cutting the Al electrodes onto both ends of the ceramic chip and coating the insulating barrier on the circumference surface of the ceramic chip, by which the resistors are produced.

Owner:CHINA XD ELECTRIC CO LTD

Nano-ZnO varistor composite powder material and preparation method thereof

InactiveCN104193320AImprove stabilityRaise the potential gradientAqueous solutionParticle-size distribution

The invention relates to a nano-ZnO varistor composite powder material and a preparation method thereof. The material is composed of ZnO, Co2O3, Bi2O3, Sb2O3 and Y2O3. The preparation method adopts a chemical coprecipitation method and particularly comprises the following steps: adding ZnO, Bi2O3, Co2O3, Sb2O3 and Y2O3 in dilute hydrochloric acid serving as a solvent, dissolving to form a transparent solution in a constant-temperature water bath environment; dropwise adding an ammonia solution serving as a precipitant into the transparent solution at a constant speed; and precipitating, filtrating, washing, drying, grinding and calcinating, thus obtaining the nano-ZnO varistor composite powder material. The preparation of nano-ZnO composite powder with excellent performances is a key of manufacture of a high-performance varistor. The ZnO composite powder prepared by using the method disclosed by the invention has the advantages of small particle size, uniform modified oxide distribution and narrow particle size distribution; and the preparation method disclosed by the invention is simple, and precisely controllable in component, and products have the characteristics of good morphology consistency, excellent electrical properties and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Zinc oxide resistor disc and preparation method and application thereof

ActiveCN111606703AThe content is easy to controlRaise the potential gradientResistor manufactureVaristor coresElectrical resistance and conductanceElectrical current

The invention relates to the technical field of piezoresistor discs for lightning arresters, in particular to a zinc oxide resistor disc and a preparation method and application thereof. The zinc oxide resistor disc provided by the invention is prepared from the following raw materials in percentage by mole: 85-95% of ZnO, 0.01-4.0% of Bi2O3, 0.01-4.0% of Sb2O3, 0.05-3.0% of Co2O3, 0.01-2.0% of MnO2, 0.01-3.0% of NiO, 0.01-2.0% of Fe2O3, 0.01-2.0% of A12O3, and 0.01-2.0% of Dy2O3. According to the zinc oxide resistor disc provided by the invention, a toxic substance Cr2O3 does not need to be added, various components including ZnO, Bi2O3, Sb2O3, Co2O3, MnO2, NiO, Fe2O3, Al2O3 and Dy2O3 cooperate with each other, such that the zinc oxide resistor disc has the excellent performances of highpotential gradient, high square wave through-flow capacity, low residual voltage, high square wave current and large current impact resistance, good aging resistance and the like.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +6

Horizontally arranged cathode vacuum electroosmosis sludge dehydration device and method

InactiveCN110550848AImprove the blocking effectReduce the phenomenon of resistance increaseSludge treatment by de-watering/drying/thickeningContaminated waterways/lakes/ponds/rivers treatmentElectricitySludge

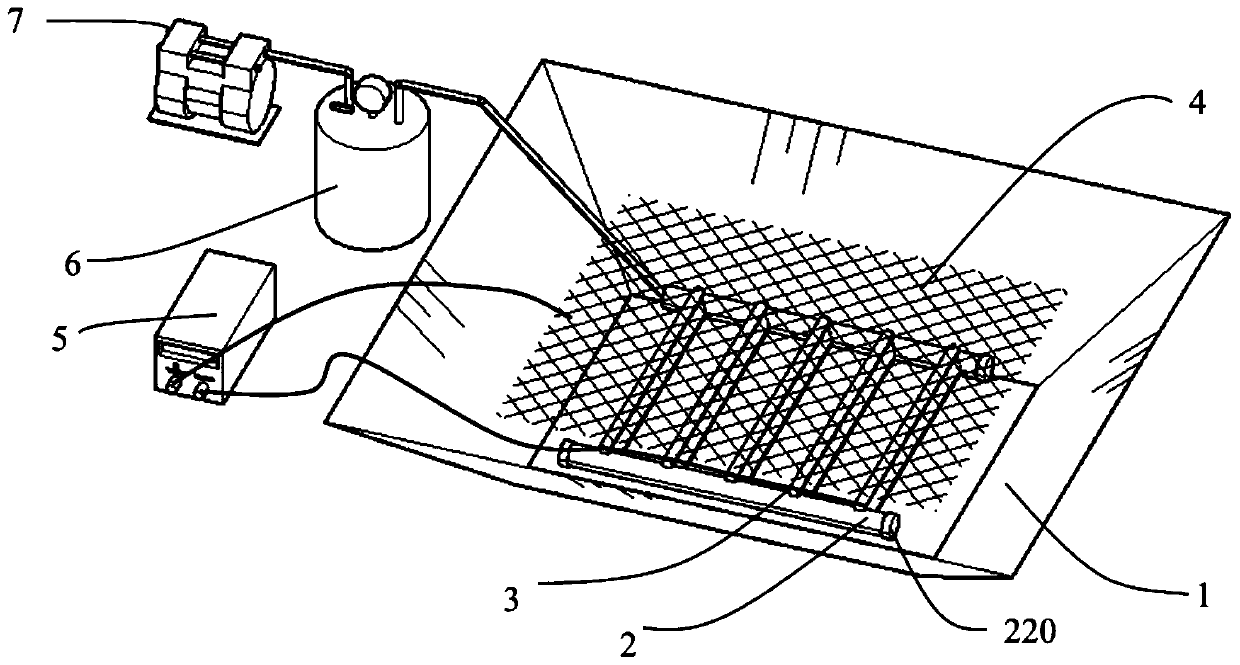

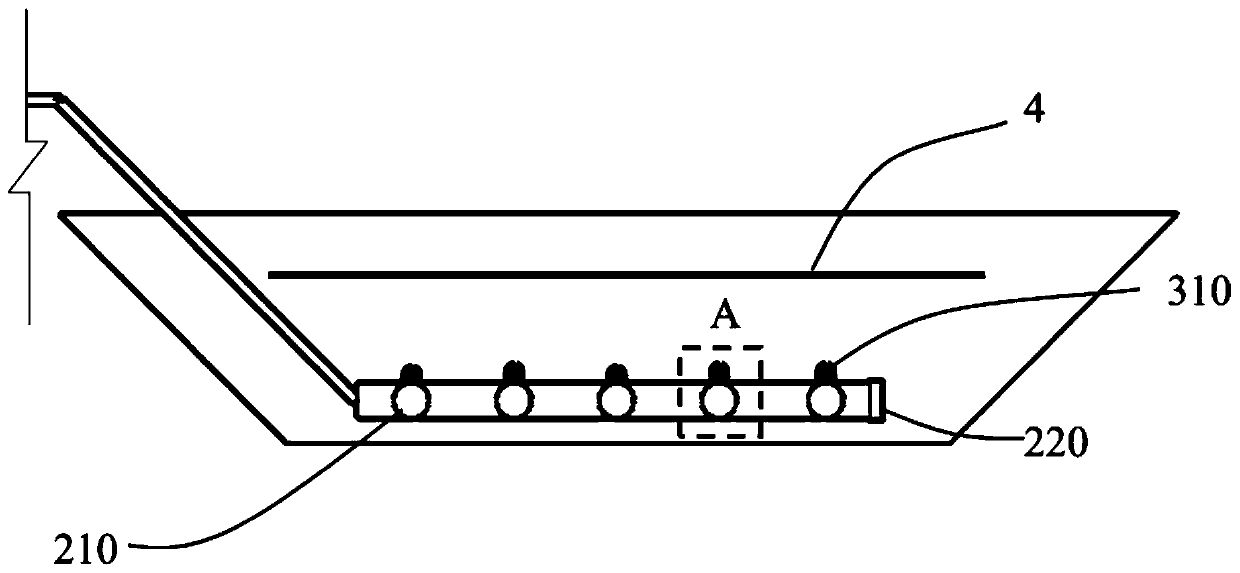

The invention provides a horizontally arranged cathode vacuum electroosmosis sludge dehydration device and method. The horizontally arranged cathode vacuum electroosmosis sludge dehydration device comprises a sludge pond, a filter pipe net is horizontally paved in the sludge pond, plane cathode is horizontally and closely paved on the upper part of the filter pipe net, the plane cathode and the filter pipe net are both buried into the sludge in the sludge pond, plane anode is arranged on the upper surface of the sludge in the sludge pond, the plane anode is electrically connected with the positive pole of a direct-current power supply, and the plane cathode is electrically connected with the negative pole of the direct-current power supply; and a water-gas separation device is arranged onthe edge of the sludge pond, one end of the water-gas separation device communicates with a vacuum pump, and the other end of the water-gas separation device communicates with the filter pipe net. According to the horizontally arranged cathode vacuum electroosmosis sludge dehydration device and method, the filter pipe net and the plane cathode are sequentially arranged at the bottom of the sludgepond from bottom to top, the plane anode is paved on the surface of the sludge, the gravity field and the electric field can be fully and effectively utilized, and thus water in the sludge is separated from the sludge under the joint action of the electric field and the gravity field.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Heavy aromatic electrical insulation oil with high breakdown voltage

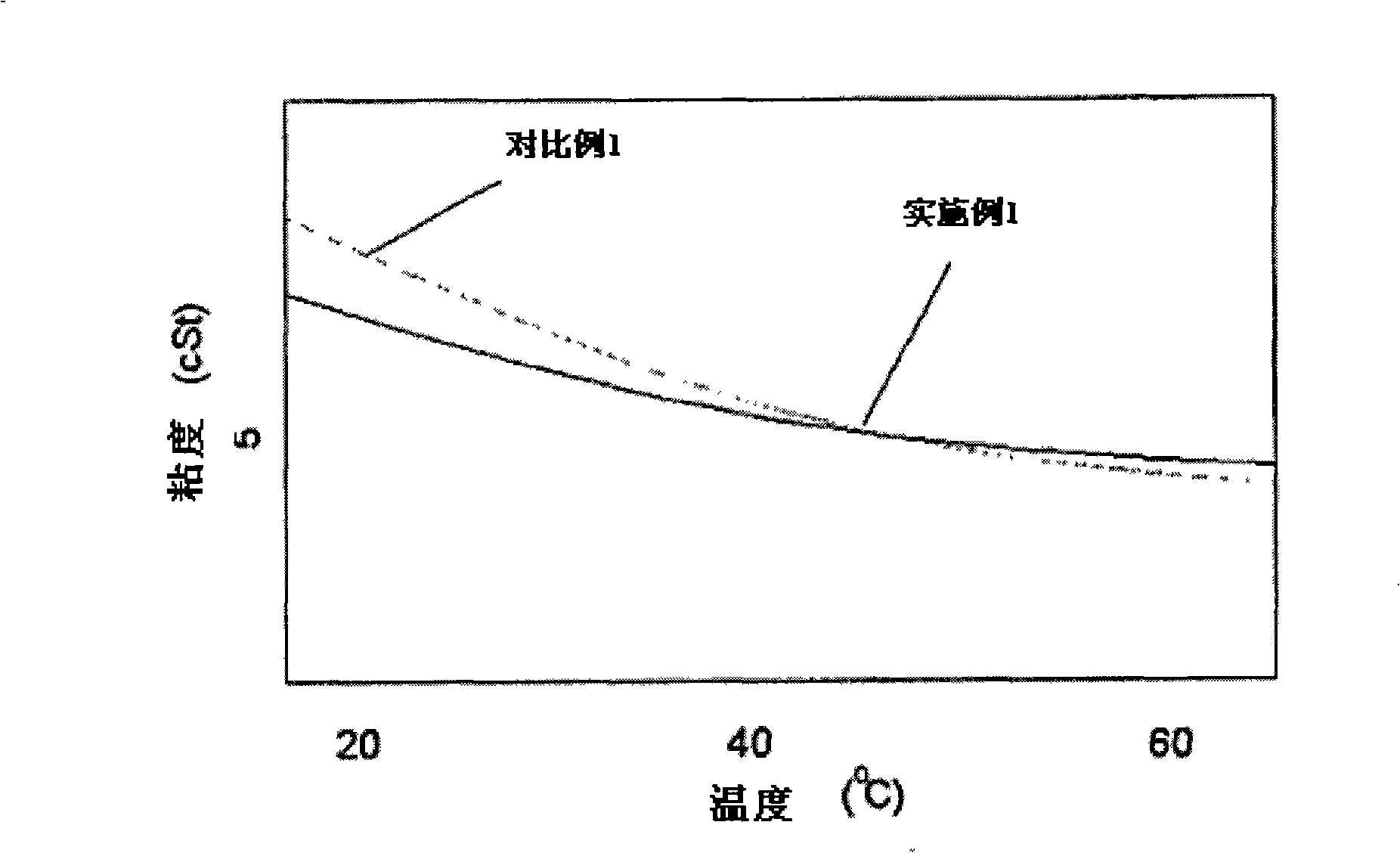

InactiveCN101356590AImprove stabilityHigh dielectric breakdown voltageLiquid organic insulatorsCatalytic naphtha reformingElectricityDistillation

Disclosed herein is an electrical insulating oil composition using a high-boiling-point aromatic fraction. The oil composition comprises a component having a distillation range of 280-330 DEG C, obtained by continuously distilling an aromatic hydrocarbon fraction from a platforming or aromatizing process. According to the disclosed invention, an electrical insulating oil composition having excellent voltage-withstand capability and excellent gas absorption capability can be obtained from an aromatic fraction. Also, the electrical insulating oil contains no unstable components, resulting in an increase in electrical properties, and thus has advantages of high stability and high potential gradient.

Owner:SK INNOVATION CO LTD +1

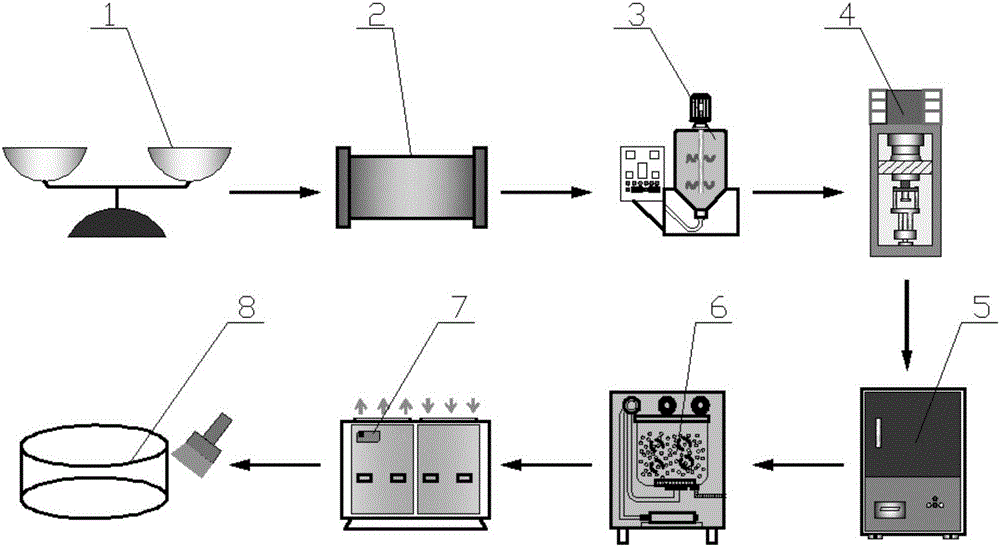

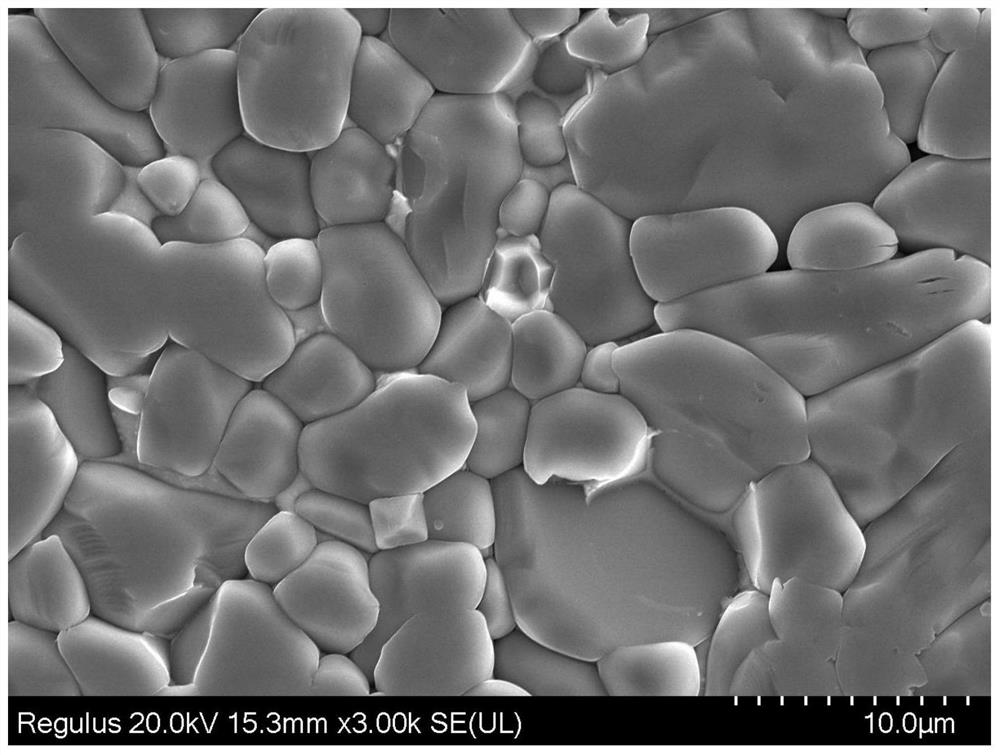

Production process of zinc oxide resistance chip with high electric potential gradient and strong through-current capability

The invention discloses a production process of a zinc oxide resistance chip with high electric potential gradient and strong through-current capability. The zinc oxide resistance chip comprises the following raw materials: a main ingredient zinc oxide and a dopant, wherein the dopant comprises bismuth sesquioxide, cobalt sesquioxide, nickel sesquioxide, chromium sesquioxide, stibium sesquioxide, silica, yttrium sesquioxide and zirconia; the mass percent of zinc oxide is not less than 90%. The production process comprises the following steps: (1) ball-milling mixing; (2) drying granulation; (3) dry pressing; (4) sintering; and (5) silver electrode coating. By virtue of the production process, the zinc oxide resistance chip with high electric potential gradient and strong through-current capability can be prepared based on a solid-phase synthesis method.

Owner:STATE GRID CORP OF CHINA +2

Zinc oxide varistor and preparation method thereof

InactiveCN106298121AUniform particle sizeSmooth appearanceResistor manufactureVaristor coresSesquioxideRare earth

The invention provides a zinc oxide varistor which comprises the following raw materials: 68-92 parts of zinc oxide, 2-18 parts of bismuth trioxide, 0.4-19 parts of cobaltosic oxide, 0.3-11 parts of cobalt sesquioxide, 3-24 parts of stannic oxide, 0.2-11 parts of manganese dioxide, 0.05-5.4 parts of oxyde de nickel, 3-16 parts of silicon dioxide, 0.2-6.9 parts of boron oxide, 0.003 to 0.06 part of aluminium nitrate, 0.006 to 0.07 part of glass dust, 0.02 to 0.4 part of rare earth, 0.02-0.4 part of praseodymium system oxide, 0.3-10 parts of chromium sesquioxide, 0.5-4 parts of boric acid and 0.8-3.5 parts of silver nitrate. The invention also provides a preparation method of the zinc oxide varistor. Compared with the prior art, the preparation method provided by the invention has the advantage that procedures of pulp drying, calcining inside a kiln and grinding for an auxiliary additive are omitted; the pulp of the auxiliary additive is directly mixed with zinc oxide to form a raw material under high-speed stirring, procedures are reduced, energy is saved, moreover, secondary pollution caused by the auxiliary additive can be avoided.

Owner:陆川县华鑫电子厂

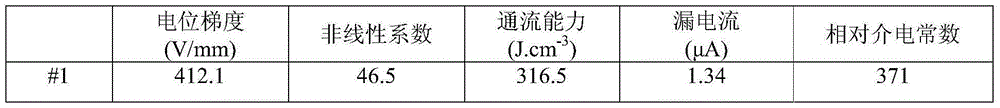

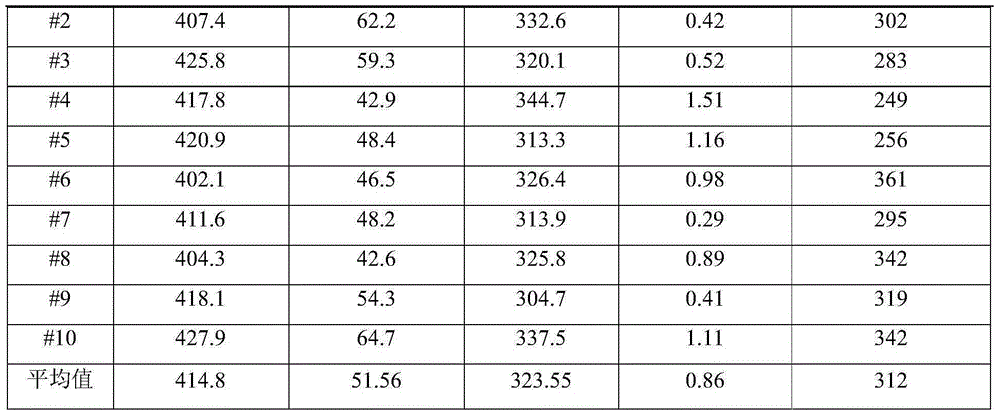

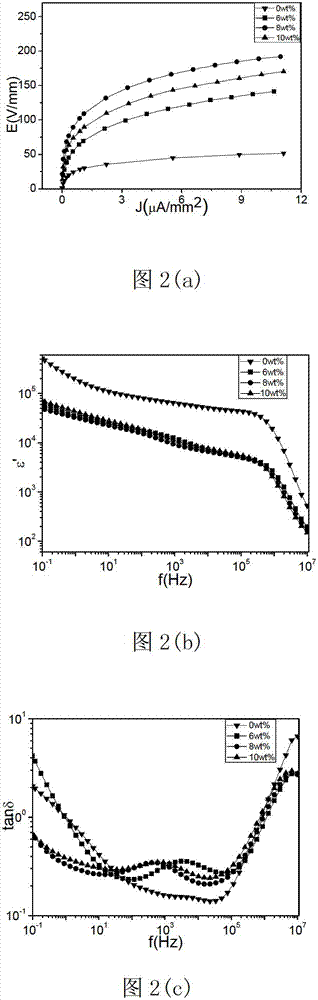

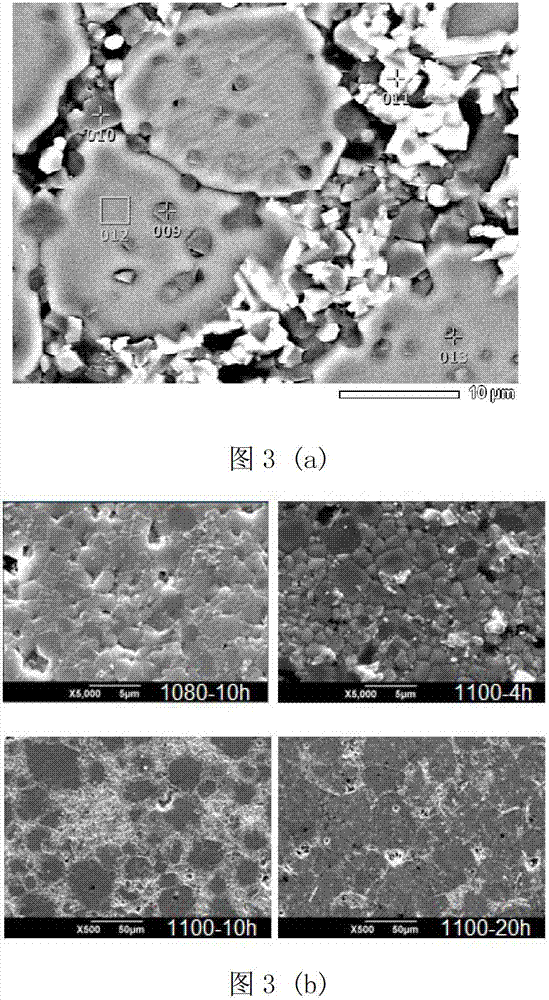

Preparation method for copper calcium titanate multiphase ceramic with high potential gradient

The invention provides a preparation method for a copper calcium titanate multiphase ceramic with high potential gradient. The method comprises the following steps: preparing uniformly mixed powder of aluminum hydroxide and copper calcium titanate by using a liquid phase precipitation method, controlling the pH value of a reaction to be in a range of 8 to 9 by using an aluminum nitrate solution as a titrant and an ammonia water solution as a precipitating agent and stirring copper calcium titanate suspension with an electromagnetic mixer so as to allow aluminum hydroxide to be uniformly distributed; filtering the suspension, carrying out washing with distilled water, carrying out drying in a baking oven at a temperature of 120 DEG C and then successively carrying out grinding, sieving and calcining so as to obtain uniformly mixed powder; and preparing a ceramic sample by using a traditional solid phase method so as to obtain a multiphase ceramic composed of cupric aluminate and copper calcium titanate, wherein a copper calcium titanate multiphase ceramic sample which contains 8 wt% of alumina and is sintered at a temperature of 1100 DEG C for 4 h has a potential gradient as high as 2063 V / mm, more than 9 times higher than that of a pure copper calcium titanate sample. The preparation method provided by the invention is simple; and the prepared multiphase ceramic has the characteristics of high potential gradient, great energy storage density and small low-frequency loss.

Owner:XI AN JIAOTONG UNIV

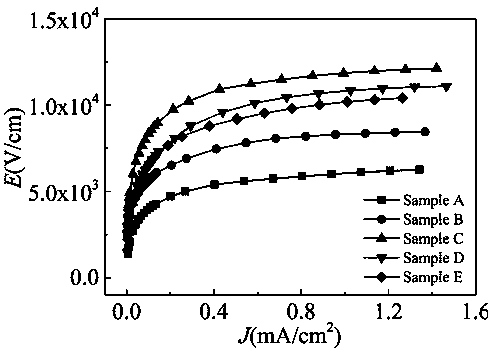

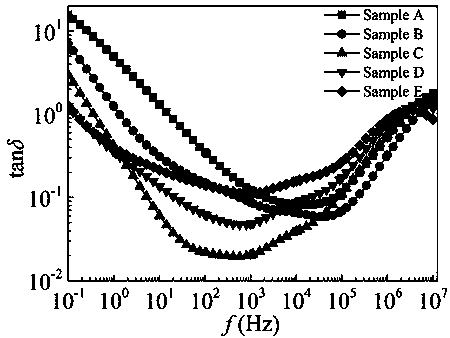

CaCu3Ti4O12 voltage-sensitive ceramic with high potential gradient and low dielectric loss and preparation method thereof

The invention relates to a CaCu3Ti4O12 voltage-sensitive ceramic with high potential gradient and low dielectric loss and a preparation method thereof. The method comprises the following steps: mixingCaCO3, CuO, TiO2, ZnO and Al2O3 according to a molar ratio of 1:3:4:(0-5%):(0-5%); carrying out wet ball milling for 12h, drying mixed powder at 80 DEG C for 12h; putting the mixture into a graphitemold and placing the mold in a discharge plasma sintering furnace for sintering at 750 DEG C for 10min; and placing a sintered sample in a muffle furnace for annealing at 1000 DEG C for 3 hours, and then naturally cooling the sample to obtain a target voltage-sensitive ceramic. The method adopts a discharge plasma sintering technology to prepare the voltage-sensitive ceramic, the sintering temperature and the heat preservation time are greatly reduced, the method is more energy-saving and more environment-friendly, the potential gradient of the obtained CaCu3Ti4O12 voltage-sensitive ceramic isreaches 1200V / mm or more, and the dielectric loss is reduced to about 0.02 at 1kHz.

Owner:CHONGQING UNIV

Stannic oxide pressure sensitive resistor composite powder material and preparation method thereof

The invention relates to a stannic oxide pressure sensitive resistor composite powder material with excellent properties, and a preparation method thereof. The powder material is prepared from SnO2, Co2O3, Bi2O3, Pr2O3 and Y2O3. The preparation method comprises the following steps: by adopting a chemical coprecipitation method and by taking absolute ethyl alcohol as an organic solvent and polyethylene glycol as a dispersing agent, adding stannic chloride, tribismuth chloride, tricobalt chloride, praseodymium nitrate and yttrium nitrate, dissolving the components into a transparent solution in a constant temperatue water bath environment, dropwise adding an ammonia water solution used as a precipitator into the transparent solution at a uniform speed, precipitating, filtering, washing, drying, grinding and calcining, thereby obtaining the stannic oxide pressure sensitive resistor composite powder material. The stannic oxide composite powder with excellent properties is essential to manufacturing of high-performance pressure sensitive resistors. The stannic oxide composite powder prepared by using the method disclosed by the invention has the advantages of small particle size, uniform modified oxide distribution and narrow particle size distribution. The stannic oxide pressure sensitive resistor composite powder material disclosed by the invention is simple in preparation method, precise and controllable in component, relatively good in product morphology consistence and excellent in electric property.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

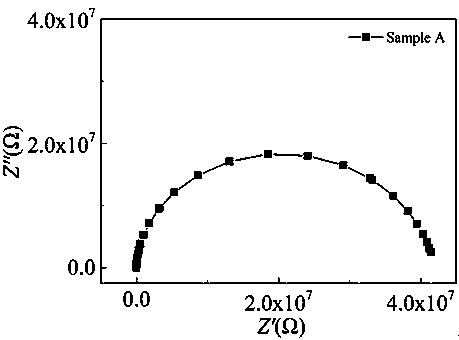

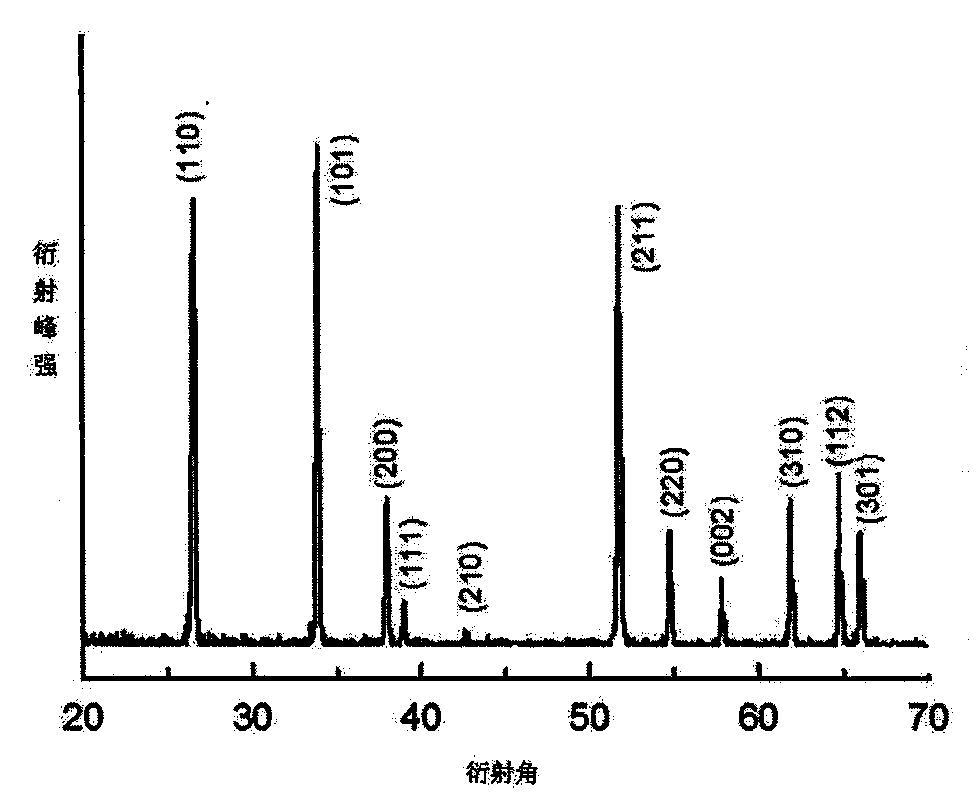

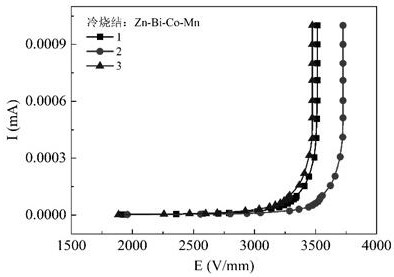

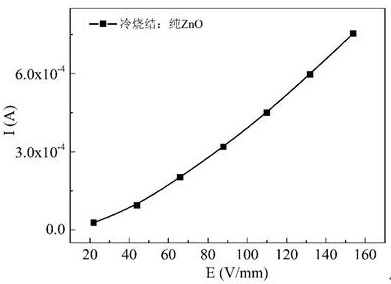

High-potential-gradient ZnO voltage-sensitive ceramic based on cold sintering and preparation method thereof

InactiveCN111848152AHigh nonlinear coefficientLower sintering temperatureCeramic sinteringVaristor ceramics

The invention relates to a high-potential-gradient ZnO voltage-sensitive ceramic based on cold sintering and a preparation method thereof. The method comprises the following steps of: mixing ZnO, Bi2O3, CoO and Mn2O3 according to a molar ratio of 95-100%:0-5%:0-5%:0-5%; and then carrying out wet ball milling for 12h, drying the mixed powder for 12h at a temperature of 80DEG C, putting the mixed material into a metal mold, performing sintering for 1-3h at a temperature of 200-300DEG C by adopting a cold sintering technology, and conducting natural cooling to obtain the target voltage-sensitiveceramic. According to the method, the voltage-sensitive ceramic is prepared by adopting a cold sintering technology, the sintering temperature and the heat preservation time are greatly reduced, the method is more energy-saving and environment-friendly, the potential gradient of the obtained ZnO voltage-sensitive ceramic reaches up to 3300V / mm or above, and the nonlinear coefficient reaches up toabout 40.

Owner:CHONGQING UNIV

Method for preparing high-potential gradient zinc oxide piezoresistance by low-temperature sintering

InactiveCN100485827CHigh nonlinear indexRaise the potential gradientResistor manufactureVaristor coresHigh energyRare earth

The preparation method for high-potential gradient ZnO piezoresistor material comprises: with high-energy ball grinding technology, adding rare earth oxides included Bi2O3, Sb2O3, Cr2O3, Co2O3, MnO2, and Y2O3; sintering at 800Deg, and obtaining the product. The advantages of this invention comprises: simple process technology, low sintering temperature, fit to traditional device, well properties of the product, 5.50-5.64g / cm3 density, 1845.66-2233.33V / mm voltage-sensitive potential gradient, 21.3-25.8 nonlinear index, and 1.55-10.2muA drain current (given 0.75V1mA).

Owner:EAST CHINA NORMAL UNIV

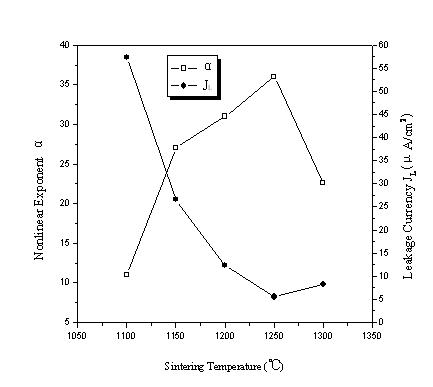

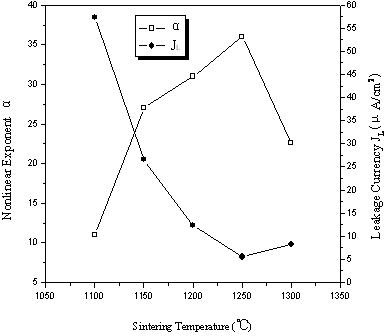

High voltage varistor and preparation method thereof

InactiveCN101702358BImprove performanceLarge resistance rangeResistor manufactureVaristor coresSpray GranulationDrain current

The invention relates to a high voltage varistor and a preparation method thereof, ZnO, Bi2O3, Sb2O3, MnCO3, Co2O3, Cr2O3, Ni2O3, SiO2 and R2O3 which account for 75-94%, 1-6%, 2-7%, 0.5-2%, 0.5-2%, 0.5-2%, 0.5-2%, 0.5-2% and 0.1-10% of the total weight of raw materials respectively are used, wherein, R2O3 is one or more of Pr6O11, Dy2O3 and Y2O3, the proportion is arbitrary, spraying, granulation, molding and sintering are sequentially carried out on the raw materials, thereby finally preparing the high voltage varistor. The preparation method is characterized by simple preparation technology, low cost and easy large-scale production, and the prepared material has good comprehensive performances of high voltage gradient, high nonlinearity and low leakage current.

Owner:SHAANXI UNIV OF SCI & TECH

CMOS (complementary metal oxide semiconductor) image sensor capable of being used in multiple working modes

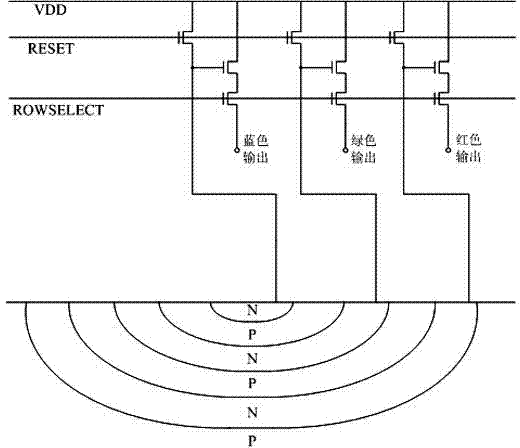

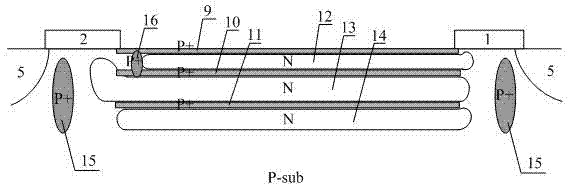

ActiveCN104241311APrevent leakageImprove transfer efficiencyTelevision system detailsColor television detailsQuantum efficiencyCMOS

The invention provides a CMOS (complementary metal oxide semiconductor) image sensor capable of being used in multiple working modes and aims to solve the problem that an CMOS image sensor in the prior art cannot take both multispectral output and high quantum efficiency into consideration. The CMOS image sensor is structured on the basis of 4T pixel of surface clamping and comprises three transmission grids, a photoelectric diode, a floating node, a resetting tube resetting grid, a source tracker and a selectron, the photoelectric diode adopts a three-N-buried-layer vertical stacked structure, each N buried layer senses illumination of different wavebands and is correspondingly connected with one transmission grid, three N buried layers share the floating node, and the CMOS image sensor can be in different working modes by differently sequencing the transmission grids, the resetting tube resetting grid and the selectron. The CMOS image sensor has the advantages that multispectral selection output of a single pixel can be realized, and high-quantum-efficiency output of pixels can be realized.

Owner:UNITED MICROELECTRONICS CENT CO LTD

Nanotin dioxide piezoresistor composite powder material and preparation method thereof

The invention relates to a nanotin dioxide piezoresistor composite powder material. The material is prepared from tin dioxide, bismuth trioxide, antimony trioxide and yttrium trioxide. The preparation method is characterized by preparing the high-performance nanotin dioxide composite powder by adopting a forced micromixing method and a colloid mill as a reaction container through a nucleating / growth isolation method. The preparation of the nanotin dioxide piezoresistor composite powder with excellent performance is a crucial to obtaining of a high-performance piezoresistor. The forced micromixing technology is adopted during nucleating / growth isolation preparation, a salt solution and an alkaline solution are fast and fully mixed at a gap between a rotor and a stator of the reactor, so that the material has the characteristics of being small in particle size and uniform in distribution; zinc element and other modification elements can be coprecipitated during the growth of crystal grains, so that the microscopic uniformity of the composite powder can be improved. Therefore, the nanotin dioxide piezoresistor composite powder which is small in grain size, uniform in the distribution of modification oxides, and narrow in the distribution of grain sizes can be obtained.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Zinc oxide piezoresistor medium with high electric potential gradient and high nonlinear coefficient and preparation method thereof

InactiveCN107324797ARaise the potential gradientHigh nonlinear coefficientVaristor coresZinc borateZinc

The invention provides a zinc oxide piezoresistor medium with high electric potential gradient and high nonlinear coefficient. The zinc oxide piezoresistor medium is prepared from the following components in parts by mol: 100 parts of ZnO, 0.03 to 1.5 parts of Sb2O3, 0.03 to 1.5 parts of Co2O3, 0.03 to 1.5 parts of Bi2O3, 0.03 to 1.5 parts of Ni2O3, 0.03 to 1.5 parts of Cr2O3, 0.03 to 1.5 parts of MnNb2O6, 0.03 to 0.8 part of Al2O3, 0.03 to 0.8 part of zinc borate, 0.03 to 0.8 part of LiNO3 and 0.03 to 0.8 part of MnSiO3. The invention further provides a preparation method of the zinc oxide piezoresistor medium with the high electric potential gradient and the high nonlinear coefficient. The zinc oxide piezoresistor medium provided by the invention has the advantages of high electric potential gradient, high nonlinear coefficient and strong pulse impact endurance capability.

Owner:汕头市瑞升电子有限公司

Method of preparing zinc oxide product by adding nano antimony oxide

InactiveCN108002823ARaise the potential gradientIncrease energy absorption densityDischarge by conduction/dissipationCobalt oxideAntimony oxide

The invention discloses a method of preparing a zinc oxide product by adding nano antimony oxide. The method comprises the following steps: weighing all components according to mass percentage: 3.5 to4.0 percent of bismuth oxide, 2.7 to 3.7 percent of nano antimony oxide, 1.0 to 1.8 percent of cobalt oxide, 0.6 to 1.3 percent of silicon oxide, 0.6 to 0.9 percent of manganese oxide, 0.8 to 1.4 percent of chromium oxide and other additives and the balance of zinc oxide; mixing all raw materials except the nano antimony oxide; then adding a dispersing agent, an adhesive solution and a defoamingagent, adding purified water to enable the solid content to be 60 to 65 percent and carrying out ball milling; then adding the nano antimony oxide, pulping, tabletting, discharging glue, carrying outhigh-temperature sintering and annealing, coating the annealed resistor disc with a side glass insulating layer and drying the insulating layer; rubbing down two end faces of the resistor disc and spraying aluminum electrodes on the two end faces of the resistor disc by using an arc spraying method, thus obtaining a zinc oxide arrester product. The zinc oxide arrester prepared by the method disclosed by the invention has high potential gradient and good energy absorption capability.

Owner:ZHENGYE ENG & INVESTMENT INC

A kind of titanium dioxide high-voltage varistor and its preparation method

ActiveCN108218420BImproved square wave flow capacityImproved high current withstand capabilityVaristor coresResistive material coatingAntimony trioxideTitanium oxide

The invention relates to a preparation method of a varistor and particularly relates to a titanium dioxide high-voltage varistor and a preparation method thereof. According to the titanium dioxide high-voltage varistor provided by the invention, the titanium dioxide serves as a main raw material, so that the non-linear coefficient and the dielectric constant of the varistor are improved and the dielectric loss is reduced; auxiliary materials such as zinc oxide and bismuth oxide are added, so that the electric potential gradient of the varistor is improved; and auxiliary materials such as manganese dioxide, antimony trioxide, nickel protoxide, cobalt oxide, silicon carbide, chromium oxide and boron glass powder are added, so that the electrical properties, such as square wave capacity, high-current resistant ability and ageing coefficient, of the varistor are improved. The titanium dioxide high-voltage varistor provided by the invention has the characteristics of high electric potentialgradient, short sintering time and low cost.

Owner:襄阳市三三电气有限公司

A kind of preparation method of high-performance zinc oxide resistor sheet

ActiveCN109192420BAvoid Macroscopically Inhomogeneous ShrinkageImprove compactnessResistor chip manufactureOvervoltage protection resistorsUltra high voltageMiniaturization

The invention relates to the technical field of manufacturing zinc oxide lightning arrester, in particular to a method for preparing a high-performance zinc oxide resistor sheet, subsequently the steps of mixing, granulating, pressing, debinding, firing, spraying aluminum and coating high resistance layer and insulating glaze. By creatively designing the technological conditions of glue drainage and firing, a synergistic effect is obtained to compensate for that volatilization of organic matter in the glue discharge stage, pore defects caused by decomposition in zinc oxide resistor sheet and volatilization of bismuth oxide in firing stage, Improving the density and uniformity of zinc oxide resistor, improving the potential gradient of zinc oxide resistor, energy absorption capacity and current shock resistance, and improving the electrical performance of zinc oxide resistor as a whole, it is easy to meet the requirements of ultra / ultra high voltage lightning arrester devices, and is conducive to the volume miniaturization of the resistor.

Owner:STATE GRID CORP OF CHINA +3

Process for preparing ZnO-Bi2O3 series pressure-sensitive ceramic chamotte doped with rare-earth oxide

InactiveCN1328212CInhibit "soft heart" phenomenonRaise the potential gradientVaristorsRare earthRoom temperature

This invention discloses a preparation technology of rare-earth oxide doped ZnO-Bi2O3 group pressure sensitive ceramic, prefireing components except Al(NO3)3 9H2O in 900deg C for 30min, and then mixing ball milling granulating with Al(NO3)3 9H2O and residual ZnO, pressing to shape green compact, heating from room temperature to 1180deg C by the rate of 100-200deg C / h and preserving heat for 4h after discharging rubber, lowing temperature to room temperature by the rate of 60-200deg C / h; Annealing sintered body by 600-800deg C for 2h, the getted rare-earth oxide doping ZnO-Bi2O3 group pressure sensitive ceramic sample after detemperature rate 0.1-2deg C / min, the homogeneity of electric property is improved obviously, moreover, extenuating center soft+-phenomenon in high extent, can be used to make lightning protection arrester products of super / extra-high voltage electric transmission system.

Owner:XI AN JIAOTONG UNIV

A kind of preparation method of zinc oxide resistor sheet

Owner:STATE GRID HUNAN ELECTRIC POWER +2

A zinc oxide resistor and its preparation method and application

ActiveCN111606703BThe content is easy to controlRaise the potential gradientResistor manufactureVaristor coresEngineeringMaterials science

The invention relates to the technical field of piezoresistors for lightning arresters, in particular to a zinc oxide resistor and its preparation method and application. The zinc oxide resistance sheet provided by the present invention comprises the following raw materials in molar percentage: 85-95% ZnO, 0.01-4.0% Bi 2 o 3 , 0.01‑4.0% Sb 2 o 3 , 0.05‑3.0% Co 2 o 3 , 0.01‑2.0% MnO 2 , 0.01‑3.0% NiO, 0.01‑2.0% Fe 2 o 3 , 0.01‑2.0% A1 2 o 3 , 0.01‑2.0% Dy 2 o 3 . The zinc oxide resistance sheet provided by the present invention does not need to add the toxic substance Cr 2 o 3 , through ZnO, Bi 2 o 3 , Sb 2 o 3 、Co 2 o 3 , MnO 2 , NiO, Fe 2 o 3 、A1 2 o 3 and Dy 2 o 3 Various components cooperate with each other, so that the zinc oxide resistor has excellent performances such as high potential gradient, high square wave flow capacity, low residual voltage, high square wave current and high current impact resistance, and good aging resistance.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +6

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com