A kind of preparation method of high-performance zinc oxide resistor sheet

A high-performance technology for zinc oxide resistors, applied in the manufacture of resistors, manufacturing resistor chips, resistors, etc., can solve the problem of low potential gradient, energy absorption capacity and current shock resistance, which cannot meet the requirements of ultra-high voltage arresters Devices, unfavorable miniaturization of zinc oxide resistors, etc., to avoid macroscopic uneven shrinkage, improve comprehensive electrical performance, and achieve volume miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

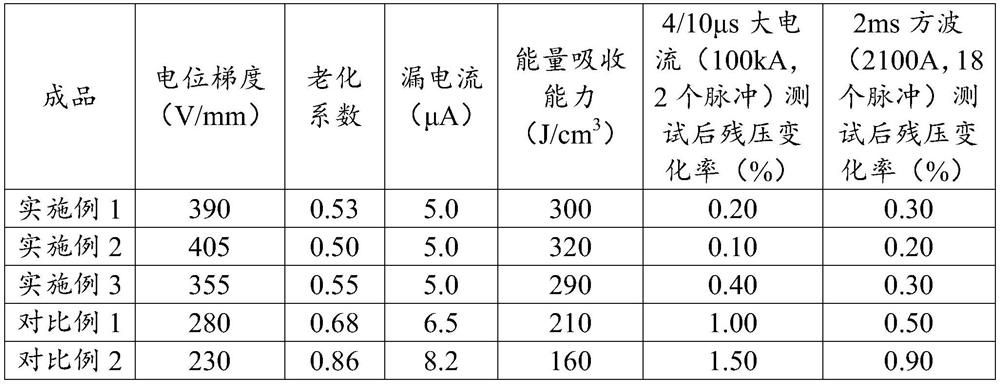

Examples

Embodiment 1

[0025] A method for preparing a high-performance zinc oxide resistance sheet, comprising the following steps:

[0026] (a) Take the raw material of zinc oxide resistor by weighing the raw material formula of zinc oxide resistor, mix the materials evenly after grinding, and obtain the powder mixture for subsequent use; wherein the raw material formula of zinc oxide resistor is composed of the following raw materials in mass percentage: zinc oxide 92%, bismuth oxide 1.5%, chromium oxide 1.2%, cobalt oxide 0.8%, silver oxide 1.1%, antimony oxide 1.2%, nickel oxide 0.8%, manganese oxide 0.6%, silicon oxide 0.8%;

[0027] (b) adding polyacrylic acid ammonium dispersant and polyvinyl alcohol binder solution to the powder mixture, then granulating, and pressing it into a zinc oxide resistor sheet green body;

[0028] (c) Place the green zinc oxide resistor sheet in the debinding chamber, control the temperature in the debinding chamber to be 350°C, and make the atmosphere pressure in...

Embodiment 2

[0032] A method for preparing a high-performance zinc oxide resistance sheet, comprising the following steps:

[0033] (a) take the raw material of zinc oxide resistor by weighing the raw material of zinc oxide resistor raw material formula, after grinding, mix evenly, obtain powder mixture for subsequent use; wherein said zinc oxide resistor raw material formula is the same as embodiment 1;

[0034] (b) adding polyacrylic acid ammonium dispersant and polyvinyl alcohol binder solution to the powder mixture, then granulating, and pressing it into a zinc oxide resistor sheet green body;

[0035] (c) Place the green zinc oxide resistor sheet in the debinding chamber, control the temperature in the debinding chamber to 380°C, and make the atmosphere pressure in the debinding chamber 40Mpa by introducing air into the debinding chamber. Degumming to obtain zinc oxide resistor blanks;

[0036] (d) placing the zinc oxide resistor sheet blank in a firing chamber, controlling the tempe...

Embodiment 3

[0039] A method for preparing a high-performance zinc oxide resistance sheet, comprising the following steps:

[0040] (a) take the raw material of zinc oxide resistor by weighing the raw material of zinc oxide resistor raw material formula, after grinding, mix evenly, obtain powder mixture for subsequent use; wherein said zinc oxide resistor raw material formula is the same as embodiment 1;

[0041] (b) adding polyacrylic acid ammonium dispersant and polyvinyl alcohol binder solution to the powder mixture, then granulating, and pressing it into a zinc oxide resistor sheet green body;

[0042] (c) Place the green zinc oxide resistor sheet in the debinding chamber, control the temperature in the debinding chamber to 400°C, and make the atmosphere pressure in the debinding chamber 50Mpa by feeding air into the debinding chamber. Degumming to obtain zinc oxide resistor blanks;

[0043] (d) placing the zinc oxide resistance sheet blank in a firing chamber, controlling the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com