A kind of titanium dioxide high-voltage varistor and its preparation method

A technology of varistors and titanium dioxide, which is applied in the direction of varistor cores, varistors, resistors, etc., can solve the problems of low potential gradient of unsuitable varistors and titanium dioxide varistors, and achieve Improved square wave flow capacity, short sintering time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

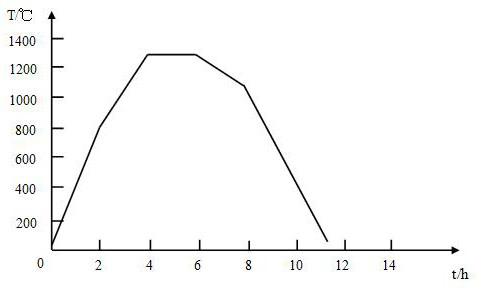

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below.

[0027] The formula of the titanium dioxide high-voltage varistor of the present invention is proportioned according to weight percentage: 75-79.1% of titanium dioxide, 10-14.1% of zinc oxide, 2.2-2.226% of bismuth oxide, 0.3-0.369% of manganese dioxide, antimony trioxide 0.5-0.569%, nickelous oxide 2.1-2.133%, cobalt oxide 1.2-1.268%, silicon carbide 1.2-1.263%, chromium oxide 0.4-0.439%, boron glass powder 3-3.2%. The titanium dioxide high-voltage varistor of the present invention improves the nonlinear coefficient and dielectric constant of the varistor by using titanium dioxide as the main raw material, reduces the dielectric loss, and improves the varistor by adding zinc oxide and bismuth oxide auxiliary materials. Potential gradient, and add manganese dioxide, antimony trioxide, nickel oxide, cobalt oxide, silicon carbide, chromium oxide, boron glass powder and other auxiliary materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com