Production process of zinc oxide resistance chip with high electric potential gradient and strong through-current capability

A zinc oxide resistor sheet and production process technology, applied in the field of high-voltage electrical sensitive ceramic materials, can solve the problem of not meeting the construction requirements of ultra-high voltage transmission lines, affecting the operating life and lightning protection effect of arresters, and not forming independent intellectual property rights. Production process, etc. problem, to achieve the effect of improving lightning protection effect, good effect and increasing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

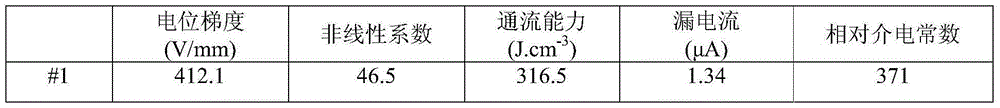

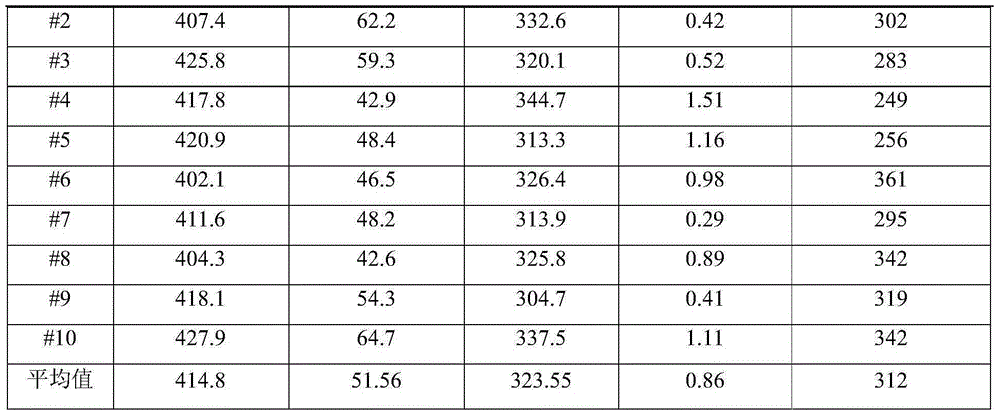

Examples

Embodiment 1

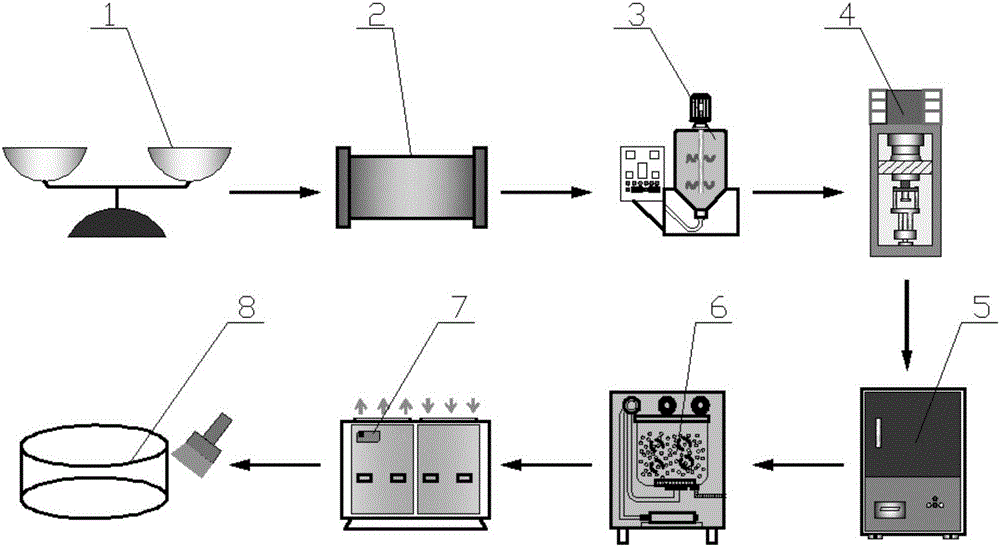

[0030] A kind of production process of the zinc oxide resistor sheet of the present invention with high potential gradient and strong flow capacity, see figure 1 , including the following steps:

[0031] 1. Weighing of ingredients: Use a commercially available ME-type Mettler precision balance (accuracy 0.1mg, range 200g) to weigh the raw material of the zinc oxide resistor. The raw materials of the zinc oxide resistance chip of this embodiment include the main material zinc oxide and dopant, and the dopant includes bismuth trioxide, cobalt trioxide, manganese carbonate, nickel trioxide, chromium trioxide, dichromium trioxide Antimony, silica, yttria, zirconia, aluminum nitrate, and silver oxide. Weigh the material of the zinc oxide resistor according to the following ratio:

[0032] Zinc Oxide 91%, Bismuth Trioxide 1.2%, Cobalt Trioxide 1.2%, Nickel Trioxide 0.8%, Chromium Trioxide 1.3%, Antimony Trioxide 1.4%, Silicon Dioxide 1%, Diyttrium Trioxide 1.3%, zirconia 0.8%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com