Method of preparing zinc oxide product by adding nano antimony oxide

A nano antimony oxide and zinc oxide technology, which is applied in the installation of cables, conductor discharge/power consumption, installation of lighting conductors, etc., can solve the problems of unsatisfactory energy absorption density, low potential gradient, and large volume, and achieve economical production Effects of cost, increase in potential gradient, and increase in energy absorption density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

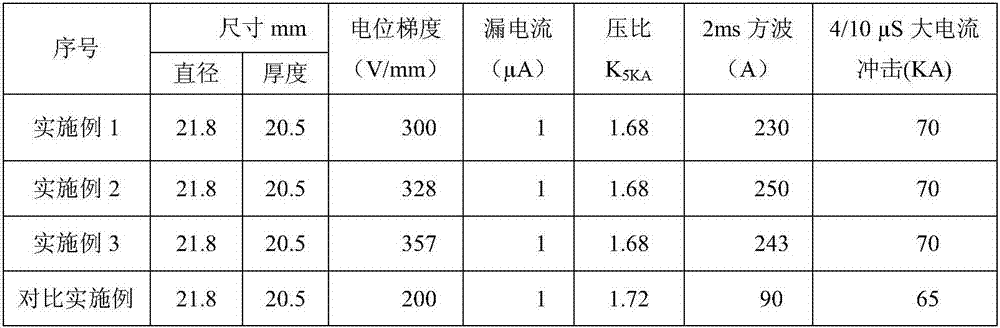

Embodiment 1

[0019] Using the formula in the present invention, the main components are: bismuth oxide 3.7wt%, nano antimony oxide 2.7wt%, cobalt oxide 1.5wt%, silicon oxide 0.9wt%, manganese oxide 0.6wt%, chromium oxide 0.9wt%, nickel oxide 0.10wt%, 0.9wt% yttrium oxide and 1.0wt% ytterbium oxide, and the rest is mainly zinc oxide.

[0020] After preparing the above formula, ball mill all raw materials except nano antimony oxide, and add 1.8wt% dispersant, 2.2wt% adhesive solution, 0.8wt% defoamer, and add a certain amount of pure water , with a solid content ratio of 65%, after ball milling for 3 hours, adding nano antimony oxide, and continuing ball milling for 1.5 hours to obtain a mixed slurry for later use; the mixed slurry was spray-dried to obtain dry powder, and pressed into a resistor blank. The main technical parameters are as follows: spray drying temperature is 150°C, humidify the dried powder to a humidity of 1.2%, and let it stand for 24 hours; then press the powder into a r...

Embodiment 2

[0022] Using the formula in the present invention, the main components are: bismuth oxide 3.7wt%, nano antimony oxide 3.2wt%, cobalt oxide 1.5wt%, silicon oxide 0.9wt%, manganese oxide 0.6wt%, chromium oxide 0.9wt%, nickel oxide 0.10wt%, 0.9wt% yttrium oxide and 1.0wt% ytterbium oxide, and the rest is mainly zinc oxide.

[0023] After preparing the above formula, ball mill all raw materials except nano antimony oxide, and add 1.8wt% dispersant, 2.2wt% adhesive solution, 0.8wt% defoamer, and add a certain amount of pure water , with a solid content ratio of 65%, after ball milling for 3 hours, adding nano antimony oxide, and continuing ball milling for 1.5 hours to obtain a mixed slurry for later use; the mixed slurry was spray-dried to obtain dry powder, and pressed into a resistor blank. The main technical parameters are as follows: spray drying temperature is 150°C, humidify the dried powder to a humidity of 1.2%, and let it stand for 24 hours; then press the powder into a r...

Embodiment 3

[0025] Using the formula in the present invention, the main components are: bismuth oxide 3.7wt%, nano antimony oxide 3.7wt%, cobalt oxide 1.5wt%, silicon oxide 0.9wt%, manganese oxide 0.6wt%, chromium oxide 0.9wt%, nickel oxide 0.10wt%, 0.9wt% yttrium oxide and 1.0wt% ytterbium oxide, and the rest is mainly zinc oxide. After preparing the above formula, ball mill all raw materials except nano antimony oxide, and add 1.8wt% dispersant, 2.2wt% adhesive solution, 0.8wt% defoamer, and add a certain amount of pure water , the solid content ratio is 65%. After ball milling for 3 hours, add nano antimony oxide and continue ball milling for 1.5 hours to obtain a mixed slurry for later use; the mixed slurry is spray-dried to obtain dry powder, which is pressed into a resistor blank. The main technical parameters are as follows: spray drying temperature is 150°C, humidify the dried powder to a humidity of 1.2%, and let it stand for 24 hours; then press the powder into a resistor blank;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com