Patents

Literature

82 results about "Varistor ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc oxide base high potential gradient pressure-sensitive ceramic material and its preparation method and uses

The invention discloses a zinc oxide base high-potential gradient voltage-sensitive ceramic material and preparing method and application, which comprises the following parts: 100mol ZnO as main component, first accessory ingredient within Bi2O3, Co2O3, MnO2, Cr2O3, Ni2O3 with molar quantity at 0.5-1.2mol respectively, second accessory ingredient with 0.8-1.5mol Sb2O3, third accessory ingredient with 0.2-1.2mol Ho2O3 and or Er2O3, forth accessory ingredient with 0.002-0.005mol Al2O3. The preparing method comprises the following steps: blending each component together to make spraying slurry; spraying; drying; graining; proceeding dry pressing; moulding; sintering. The potential gradient of voltage-sensitive ceramic material is 300-500V / mm with non-linear coefficient is more than 50, which can be applied in the electric lightning arrester or other lightning protection overvoltage protection of electric electronic circuit due to strong pulse attack resistance ability.

Owner:山东鸿荣电子有限公司

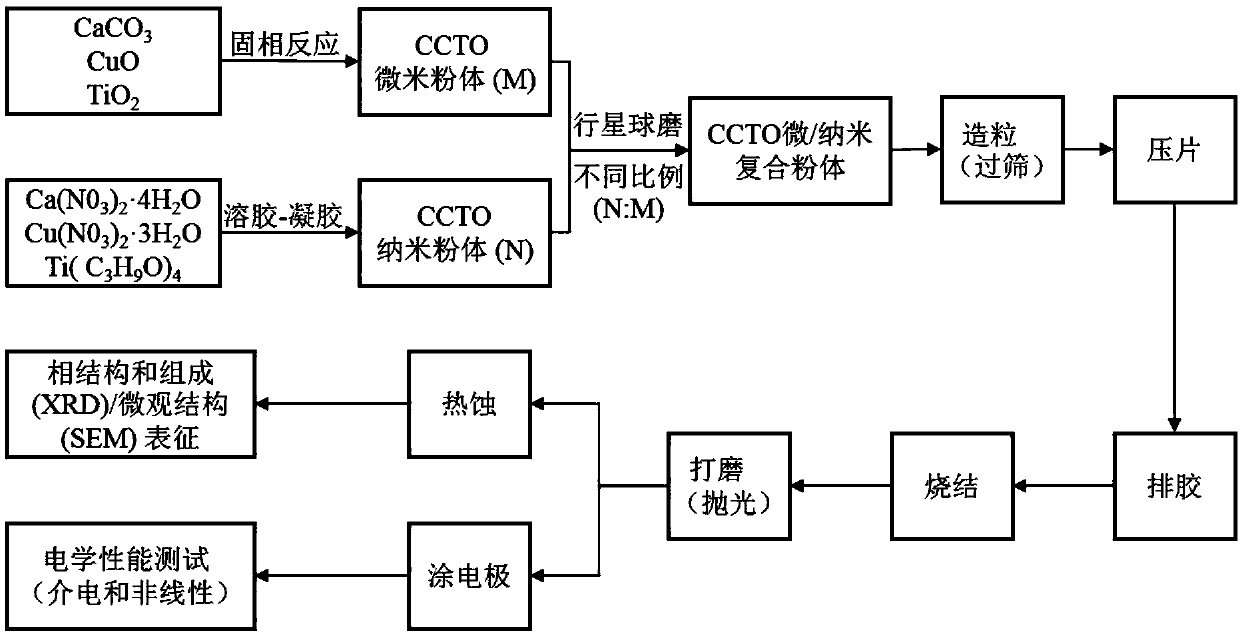

Preparation method of perovskite-like varistor ceramic material CaCu3Ti4O12 with high dielectric constant

ActiveCN102432062AOvercome energy consumptionOvercome granularityTitanium compoundsNitrateVaristor ceramics

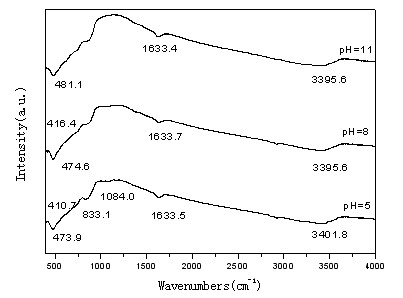

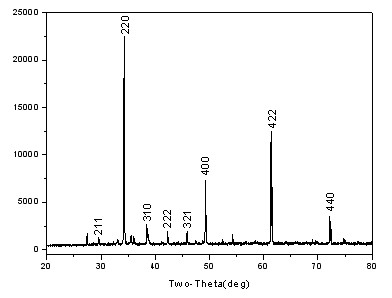

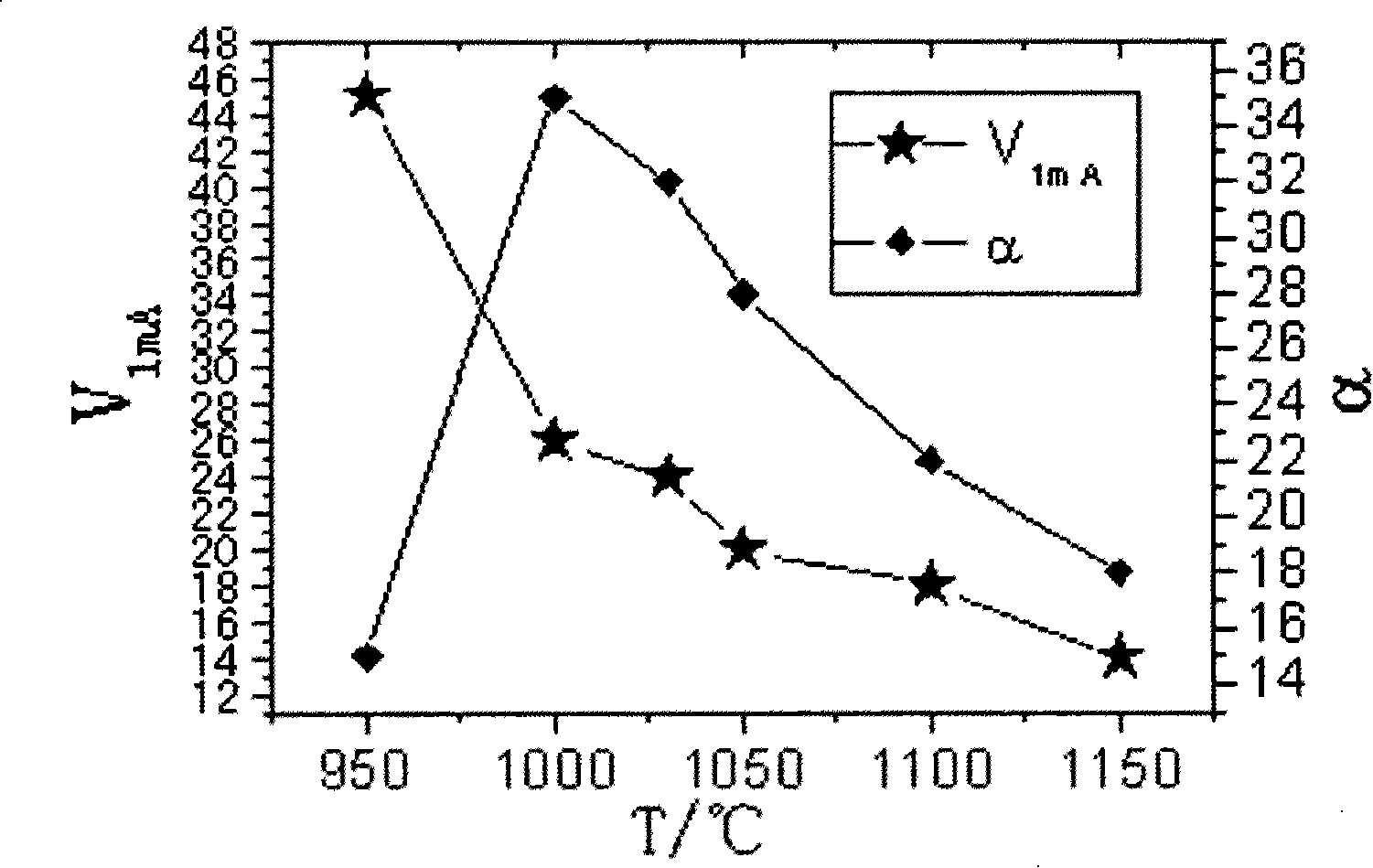

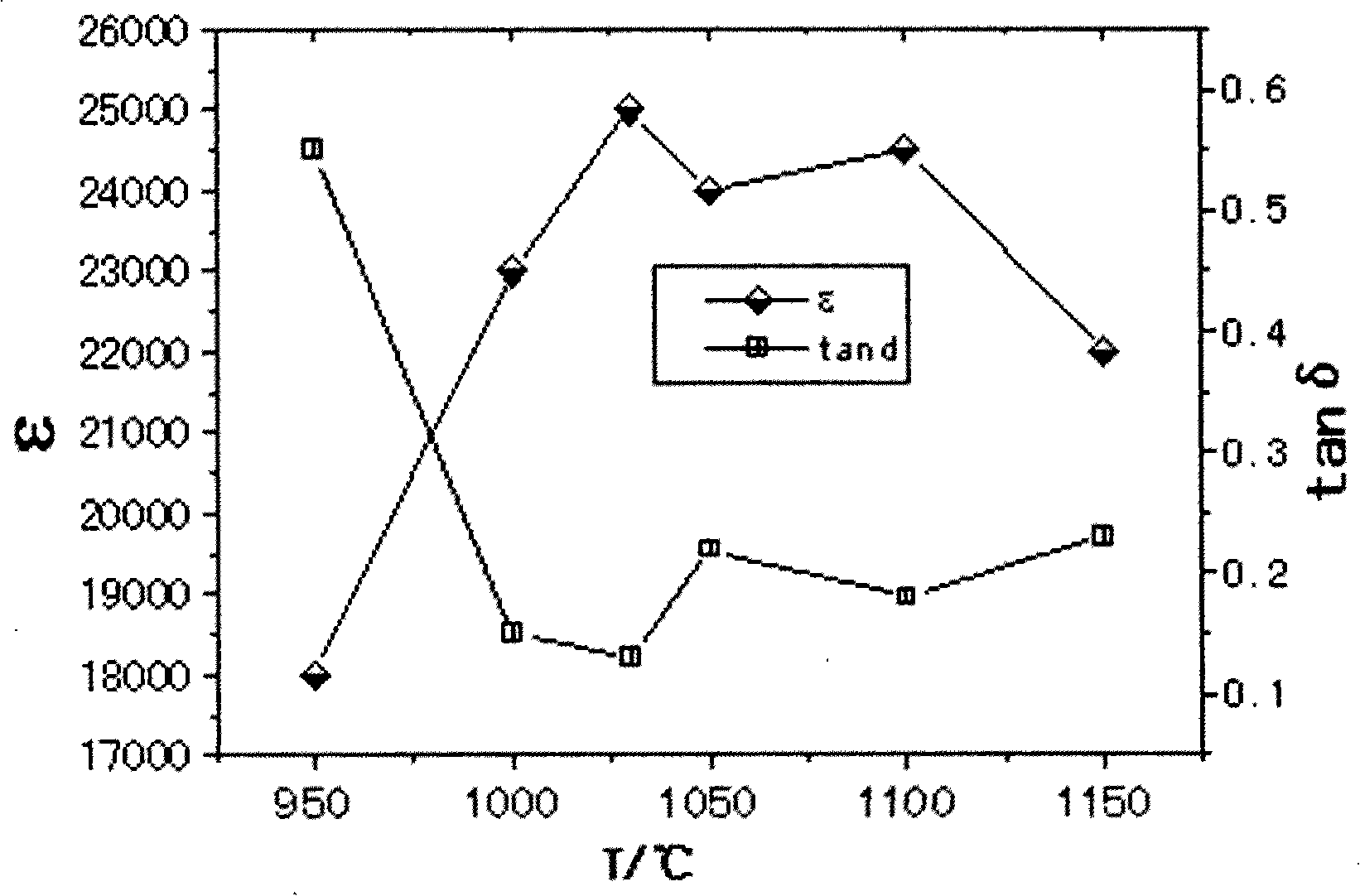

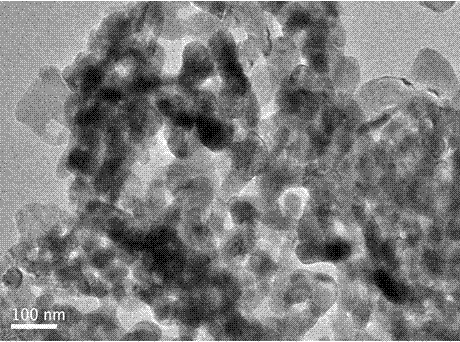

Belonging to the technical field of preparation and application of electronic ceramics, the invention relates to a preparation method of a perovskite-like varistor ceramic material CaCu3Ti4O12 (CCTO) with a high dielectric constant. With nitrates of Cu and Ca as well as Ti (OC4H9)4 as starting materials, the method of the invention combines a hydrothermal method for preparing nanometer CCTO powder so as to prepare high performance CCTO varistor ceramics, thus realizing the purposes of lowering temperature, and improving varistor as well as dielectric properties.

Owner:江苏津沂菊源生物健康产业研究院有限公司

Low-temperature sintering method of high potential gradient voltage-sensitive ceramic material

InactiveCN103073302AImprove performanceRaise the potential gradientManufactured materialVaristor ceramics

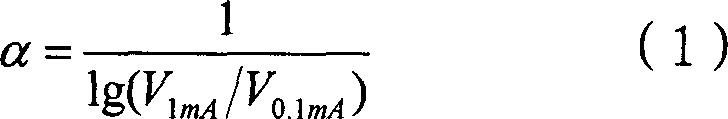

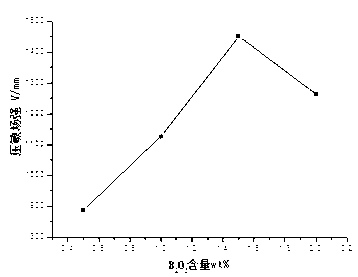

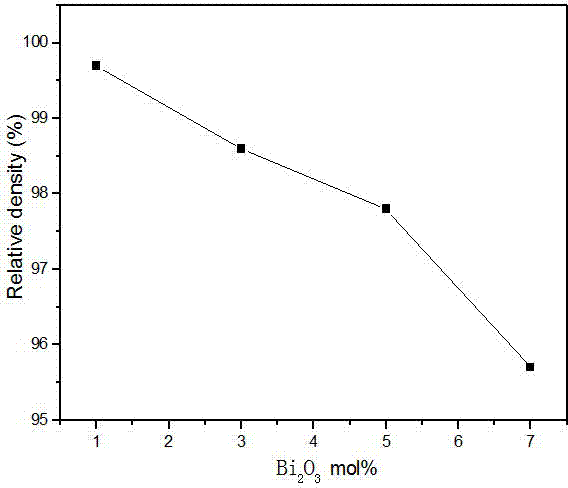

The invention discloses a ZnO-Bi2O3-based piezoresistor material with adjustable potential gradient of 600 V / mm to 1,450V / mm and a low-temperature sintering method thereof. The material consists of 92 to 98.5mol% of zinc oxide, 0.3 to 2mol% of bismuth trioxide Bi2O3 and the balance of additives such as Sb, Co,Mn, Cr, B elements and the like. According to a formula, the corresponding raw materials are weighed; and after heat is preserved for 2 to 5 hours at a temperature of 830 to 870 DEG C by utilizing a solid-phase sintering method, a corresponding voltage-sensitive ceramic material is obtained. The ZnO-Bi2O3-based piezoresistor material obtained by the invention has voltage-sensitive field intensity of 600V / mm to 1,450V / mm, nonlinear coefficient alpha of over 40 and leakage current IL of more than or equal to 0.1muA and has low sintering temperature and excellent comprehensive performance; and moreover, the preparation method disclosed by the invention has the advantages of simple process, low energy consumption, green, environmental-friendliness and the like and has wide application prospect.

Owner:LIAOCHENG UNIV

Non-bismuth additive ZnO Low-voltage Varistor Ceramics and method for making same

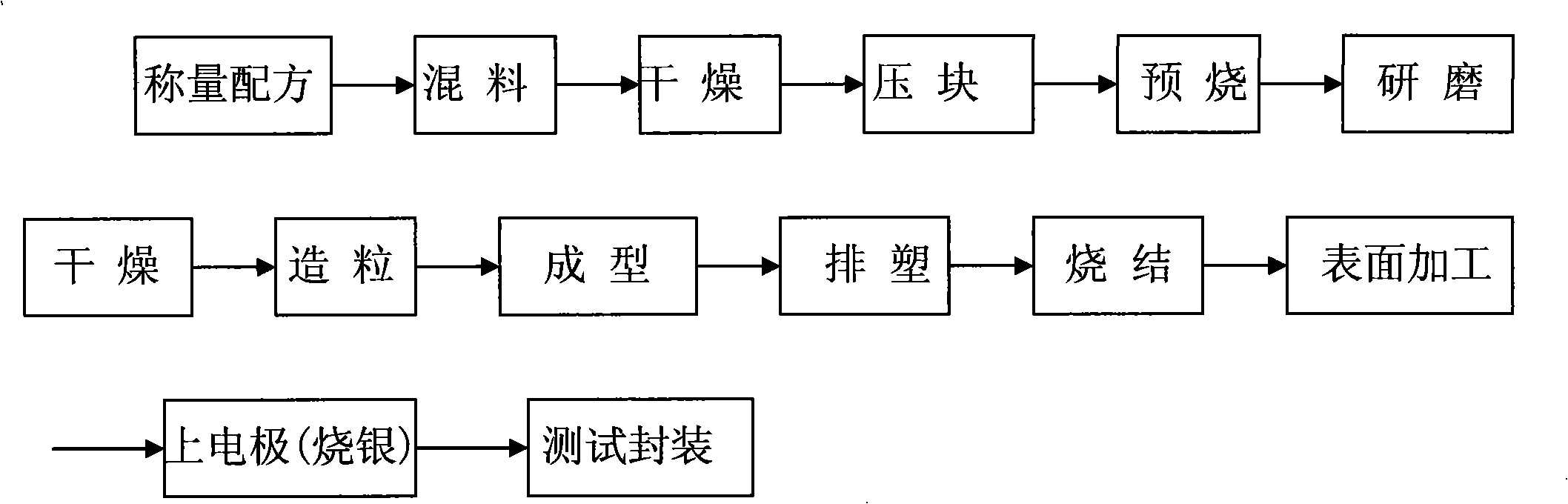

The invention relates to a method for manufacturing non-Bi low-voltage ZnO varistor ceramic materials, and belongs to the technology field of an electric component as well as the material manufacture thereof. Zinc oxide is added with the oxide powder of any one from doping elements such as Al, Fe, Eu, Pr, La, Ce, Nd, B, Si, Mn, Cr, Co, Pb, Ti and nanometer ZnO to compose mixed raw materials, the raw materials are mixed, ground, dried, pressed into blocks and pre-sintered at 600 DEG C to 750 DEG C, and then are put into a ball milling pot for being milled, granules are made after the milled material is dried and screened, the powder material is pressed into small round slices which are then heated to 600 DEG C to 720 DEG C for thermal latex exuding, and the low-voltage ZnO varistor ceramic materials can be obtained after the round slices are further sintered and cooled to the room temperature; furthermore, the surface processing and the silver plating are carried out, and the products are encapsulated after being tested, thereby obtaining low-voltage ZnO varistors. The method has the advantages that the manufacturing process is simple; the cost is lower; the performance is good; the application range is wide; the repeatability, the stability and the consistency of the produced varistors are good; the electrical parameter values have obvious improvements and so on.

Owner:KUNMING UNIV OF SCI & TECH

A kind of direct current zinc oxide varistor sheet and preparation method thereof

InactiveCN102290176AGood electrical propertiesEliminate volatilizationResistor manufactureOvervoltage protection resistorsSlurryVaristor ceramics

The invention relates to a direct-current zinc oxide varistor sheet and a preparation method thereof, and belongs to the technical field of varistor ceramic material manufacturing for lightning arresters. Its characteristic is that ZnO is used as the main material, supplemented with additives such as nano-Bi2O3, nickel nitrate, Co2O3, etc., and the nano-Bi2O3 and nickel nitrate are firstly prepared into a coated nano-powder in the solution. The main ingredient ZnO in the formula and other trace raw materials except nano-Bi2O3 and nickel nitrate are mixed evenly and then sintered, and the upper and lower surfaces of the resistance sheet prepared by sintering are coated with the coated Bi2O3 powder slurry prepared in advance, heated and sintered, and the electrode is coated , coating a high-resistance layer to produce a DC zinc oxide resistor. During the preparation process of the method, the ratio change and environmental pollution caused by the volatilization and splashing of Bi2O3 are avoided, and the prepared resistive sheet has uniform composition and excellent comprehensive electrical properties.

Owner:SHANGHAI UNIV

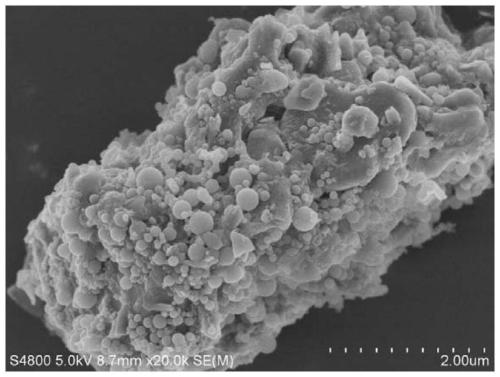

Preparation method of ZnO/Bi2O3 composite powder

The invention relates to a preparation method of ZnO / Bi2O3 composite powder. The method comprises the following steps: reacting a zinc nitrate solution with a certain concentration with an ammonium bicarbonate solution to obtain basic zinc carbonate, filtering and washing the basic zinc carbonate, dispersing into a slurry, adding the ammonium bicarbonate solution to continue the reaction for some time, slowly adding a bismuth nitrate solution, and completely reacting until the bismuth precipitate is completely coated on the zinc precipitate surface, thereby finally obtaining the simultaneous core-shell structure ZnO / Bi2O3 nano powder. The technique saves a plurality of drying and roasting links, and more importantly, can implement uniform coating by controlling the state of the precursor and enhance the combination compactness between the coating and base. The ZnO / Bi2O3 composite powder prepared by the method has the advantages of uniform particles and small particle size; and the sintered ZnO pressure-sensitive ceramic has high compactness.

Owner:佛山市顺德区杰盈实业有限公司

Preparation method of composite nano ZnO voltage-sensitive ceramic powder

The invention relates to a ZnO voltage-sensitive ceramic material and particularly relates to a preparation method of composite nano ZnO voltage-sensitive ceramic powder. The preparation method comprises the following steps: preparing soluble zinc salt, bismuth salt, cobalt salt and manganese salt which are used as raw materials, respectively preparing into aqueous liquor, mixing 95% (in mole percentage) of ZnO, 3% of Bi2O3, 1% of CoO and 1% of MnO, and uniformly stirring; slowly adding ammonia water into mixed liquor obtained in the step (1), regulating the pH to 8-8.5 to obtain mixed liquor, continuously stirring until mixing uniformly; carrying out suction filtration onto precipitates obtained in the step (2), sufficiently washing to remove impurities by using deionized water and alcohol, placing obtained precursor in water or alcohol medium for refluxing for 2-8 hours, and controlling a refluxing temperature to 70 DEG C-80 DEG C; finally, carrying out suction filtration on the powder obtained by refluxing, sufficiently washing to remove impurities by using deionized water and alcohol, finally drying in a vacuum drying box, and grinding to obtain nano composite ZnO powder.

Owner:颍上县祥盛建设管理有限公司

Method for improving electrical property of zinc-oxide-based low voltage varister ceramic film

InactiveCN102219499AHigh nonlinear coefficientLow varistor voltageLeakage current densityLow voltage

The invention relates to varistor ceramics, and specifically relates to a method for improving the electrical property of a zinc-oxide-based low voltage varister ceramic film. The method is characterized in that: an aluminum foil, which is used as an absorption layer, is attached to the surface of a zinc-oxide-based low voltage varister ceramic film sample; a confinement medium is painted, stuck or covered on the aluminum foil; the ceramic film sample is then embedded on a mold; and laser impact is applied to the ceramic film sample, such that the electrical property of the zinc-oxide-based low voltage varister ceramic film is improved. According to the present invention, a laser impact treatment technology is employed in the surface treatment upon the zinc-oxide-based low voltage varister ceramic film. With the liquid confinement medium, non-linear coefficient of the zinc-oxide-based ceramic film is raised by 24% or above comparing to that before the laser impact treatment, varister voltage of the zinc-oxide-based ceramic film is reduced by 30% or above comparing to that before the laser impact treatment, and leakage current density of the zinc-oxide-based ceramic film is reducedby 35% or above comparing to that before the laser impact treatment. The advantage of the method is that: non-linear coefficient of the film is improved while the leakage current density of the film is reduced.

Owner:JIANGSU UNIV

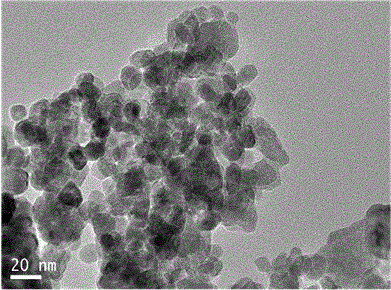

Preparation method for monodisperse nanometer ZnO pressure-sensitive ceramic powder

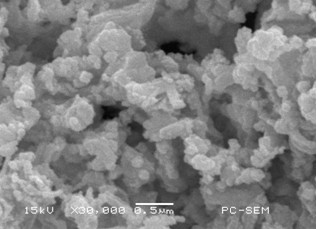

InactiveCN104402038ASmall sizeUniform shapeZinc oxides/hydroxidesPhysical chemistryVaristor ceramics

The invention relates to nanometer zinc oxide, especially relates to a preparation method for a monodisperse nanometer ZnO pressure-sensitive ceramic powder, and belongs to the technical field of preparation and application of electronic ceramic. According to the preparation method, sodium dodecanesulphonate (SDS) is mainly employed as a dispersant for synthesizing the nanometer composite ZnO powder so as to prepare the high-performance ZnO pressure-sensitive ceramic powder. By employing sodium dodecanesulphonate (SDS) as a dispersant for synthesizing nanometer composite ZnO, the obtained powder is relatively small in dimension, homogeneous in morphology, uniform in phase dispersion and high in powder purity, and helps to effectively improve the electric performances of the ZnO pressure-sensitive ceramic.

Owner:CHANGZHOU CHUANGJIE LIGHTNING PROTECTION

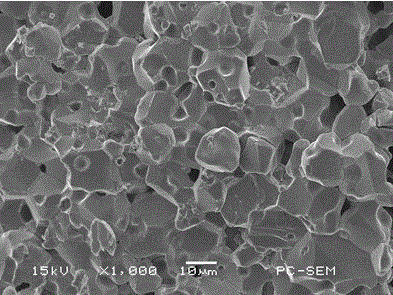

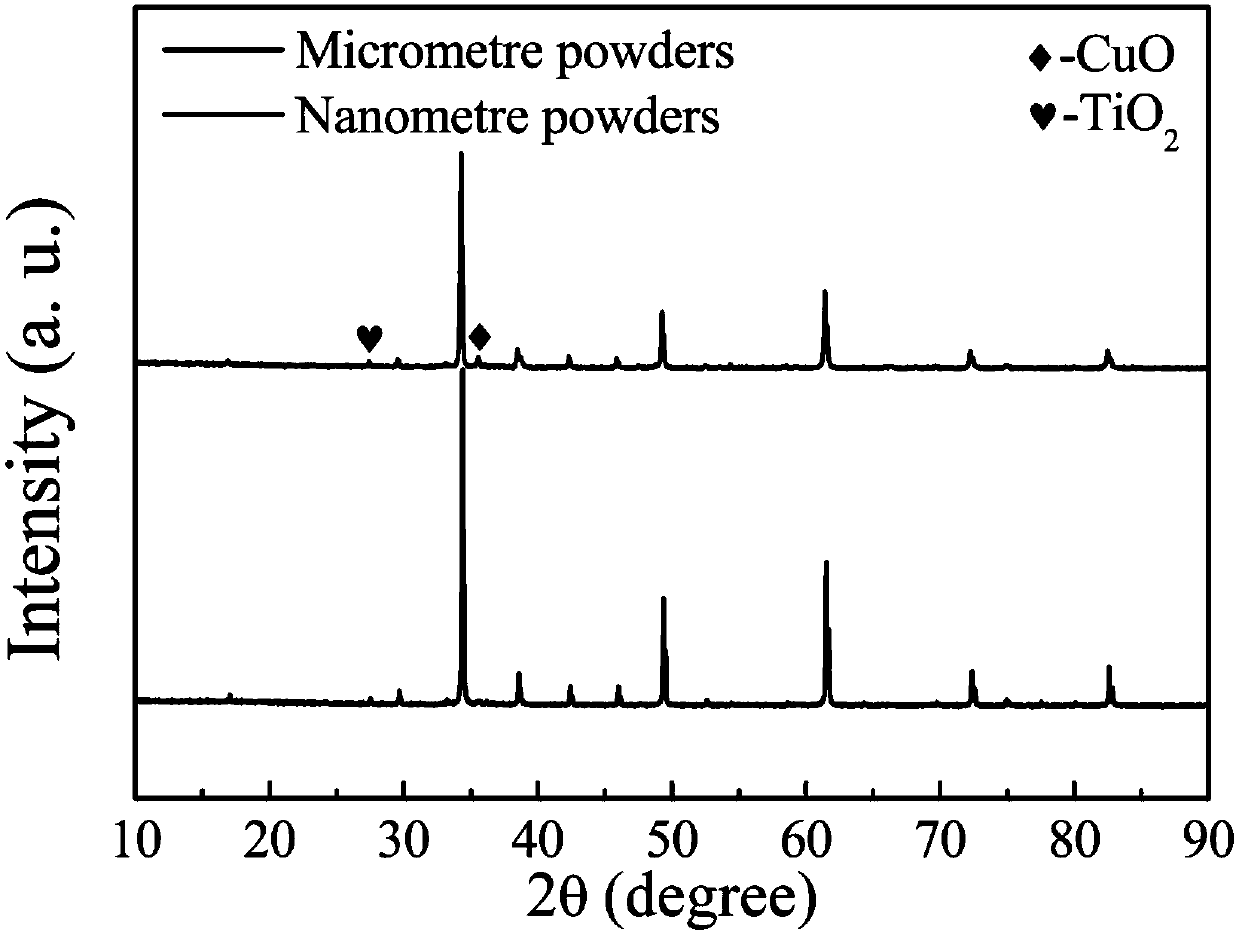

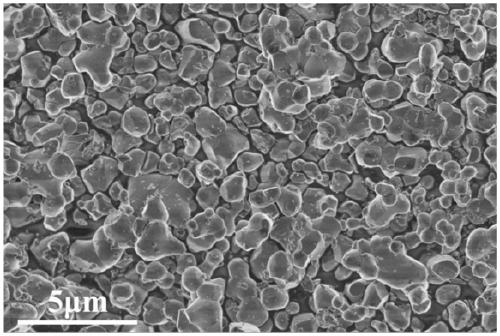

Giant dielectric composite ceramic copper calcium titanate material and preparation method and application thereof

ActiveCN109650875AThe preparation process is simple and controllableImprove yieldFixed capacitor dielectricStacked capacitorsHigh energyComposite ceramic

The invention discloses a giant dielectric composite ceramic copper calcium titanate material and a preparation method and application thereof and belongs to the technical field of electronic ceramicmaterial preparation. According to the method, micro powder and nano powder which are synthesized by a solid-phase method and a sol-gel method are mixed for preparing the composite ceramic copper calcium titanate material, and the preparation process is simple, controllable and high in repeatability and yield. Moreover, by changing the composite ratio of the micro and nano powder, the crystal grain size and range of the composite ceramic copper calcium titanate material can be regulated and controlled, and therefore, the compact composite ceramic copper calcium titanate material with a high dielectric constant (5*104), low loss (0.051), high breakdown field strength (2,374V / cm) and high energy storage density (20kJ / m<3>) is obtained, wherein the energy storage density of the composite ceramic material is 12.7 times higher than that of ceramics prepared from micro powder and 12.1 times higher than that of ceramics prepared from nano powder. The composite ceramic copper calcium titanatematerial prepared by the method has high practicability, can be used as a dielectric material for preparing high-dielectric multilayer ceramic capacitors and dynamic random access memories, and can also serve as a pressure-sensitive ceramic material in the fields of electric power, electronic systems and the like.

Owner:XI AN JIAOTONG UNIV

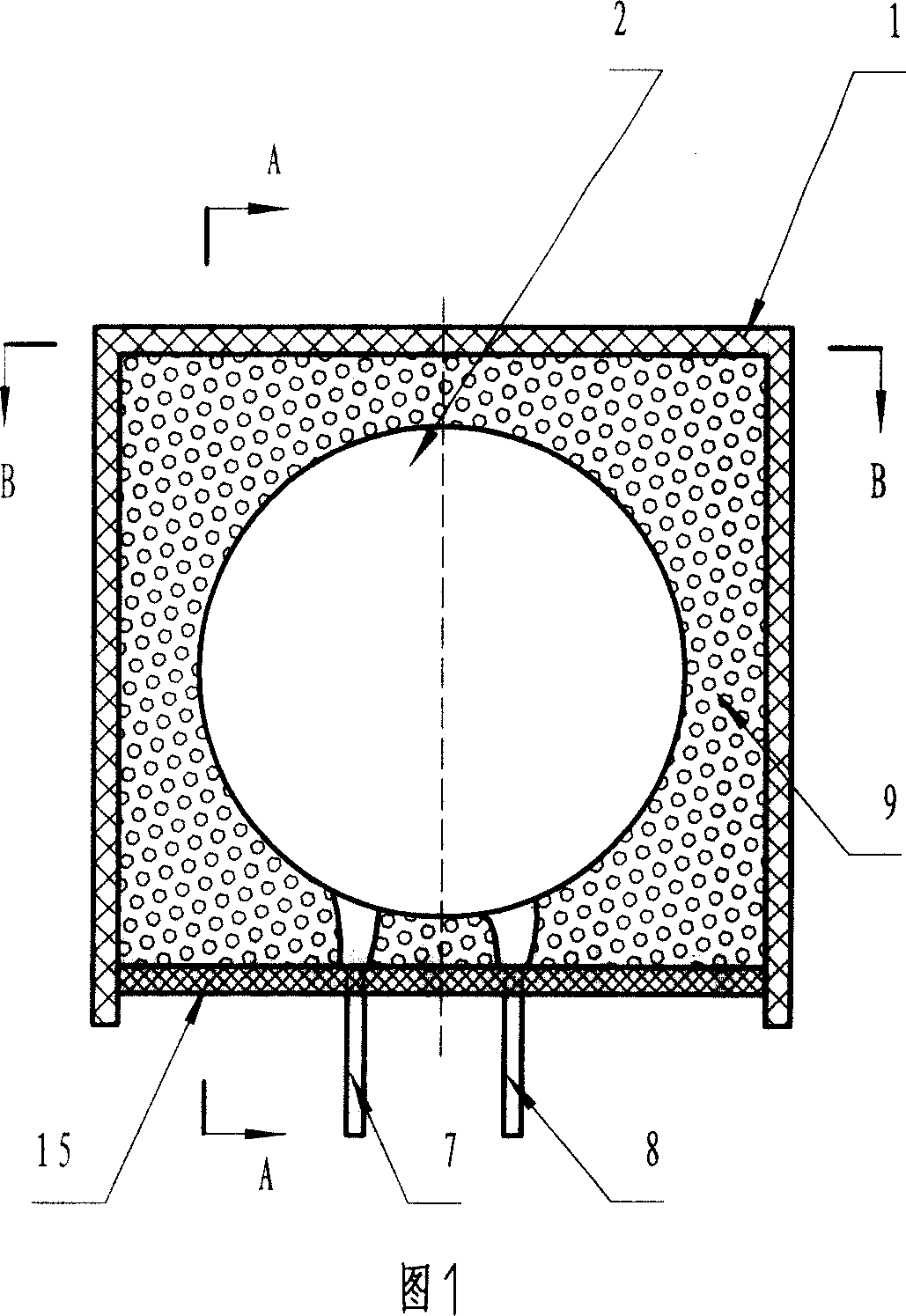

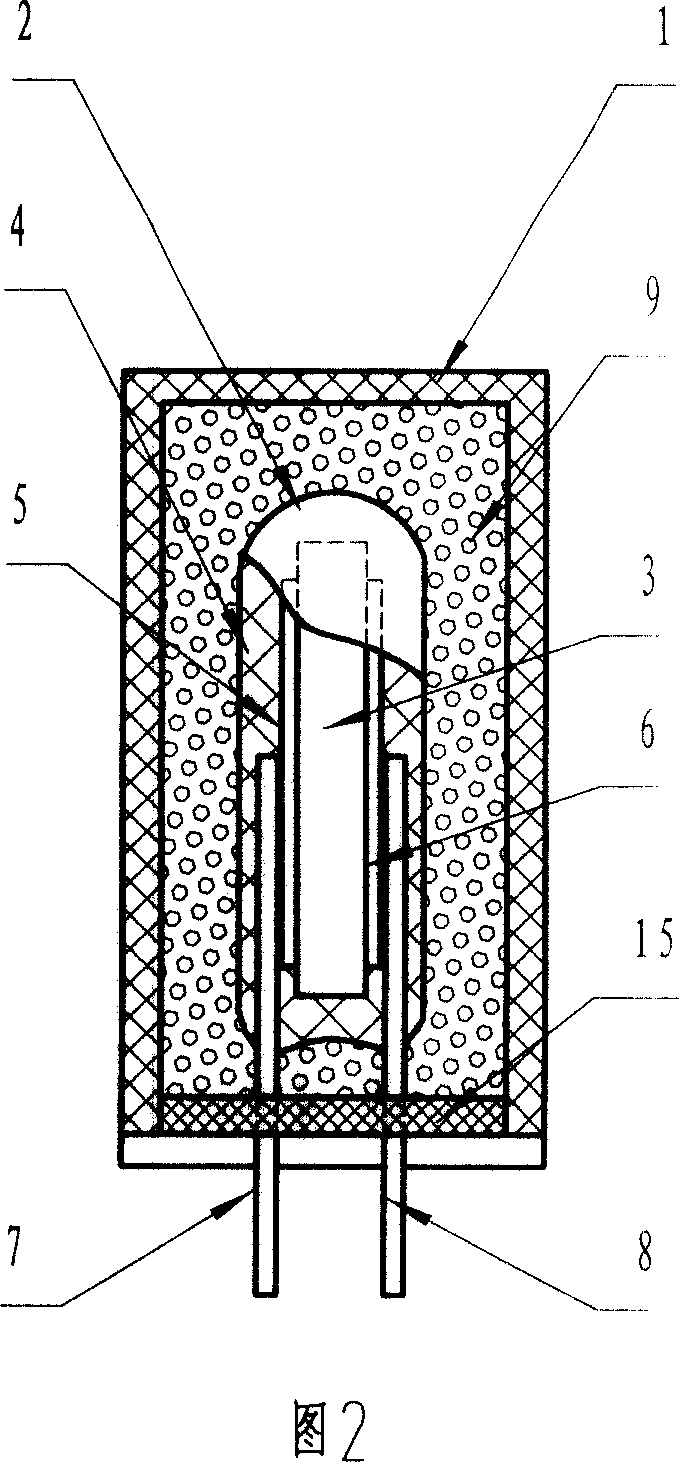

Easy-to-produce antiexplosive voltage-dependent resister

InactiveCN1933040AImprove sealingPrevent leakageResistor terminals/electrodesResistor housing/enclosing/embeddingVaristor ceramicsBiomedical engineering

A varistor uses to produce explosion-protected varistor. It relates to shell and varistors main body inside of shell. The main body is made up of varistor ceramics group piece and insulating layer enveloping the varistor ceramics group piece and there are two detached inner electrodes on surface of varistor ceramics group piece. There are first and second derivation electrode on varistors main body, and the inner wall of shell and the outside wall of varistors main body make up of a hold cavity. Insulated non-burn material fills in the cavity and makes up of the insulated non-burn material layer warped the varistors main body. The bottom is glue-sealed layer and the other ends of the first and second derivation electrodes cross the insulated layer and glue-sealed layer to out of shell. It can effectively enhance the production speed and reduce the production technology to improve the closed ability of shell bottom.

Owner:CHENGDU TIEDA ELECTRONICS CORP

Voltage sensitive ceramic and alumina ceramic composite insulation structure and preparation

The invention discloses a composite insulation structure with voltage-sensitive ceramics and alumina ceramics, as well as a preparation method thereof, in order to raise the along-surface flashover voltage of insulation media in vacuum. The composite insulation structure is characterized in that two end faces of an alumina ceramic matrix are in plane connection with voltage-sensitive ceramic sheets through insulating-bonding layers. The preparation method for the composite insulation structure comprises the following steps: (1) the voltage-sensitive ceramics and the alumina ceramics are respectively polished and leveled; (2) the alumina ceramics are bonded between the voltage-sensitive ceramics, low-temperature bonding can use epoxy, silicone rubber, and so on, and high-temperature bonding can use low-temperature glass; and (3) heating and solidification are performed, and then the insulation structure of variable dielectric constant or resistivity is obtained. As the voltage-sensitive ceramics have nonlinear V-I characteristics, the field intensity of a vacuum-electrode-insulator combination area is greatly weakened, thereby inhibiting initial electron emission. The insulation structure disclosed by the invention can remarkably improve vacuum along-surface flashover performance.

Owner:XI AN JIAOTONG UNIV

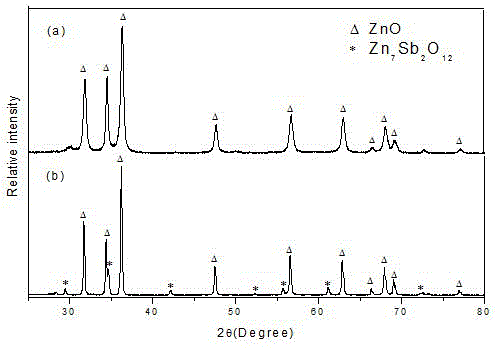

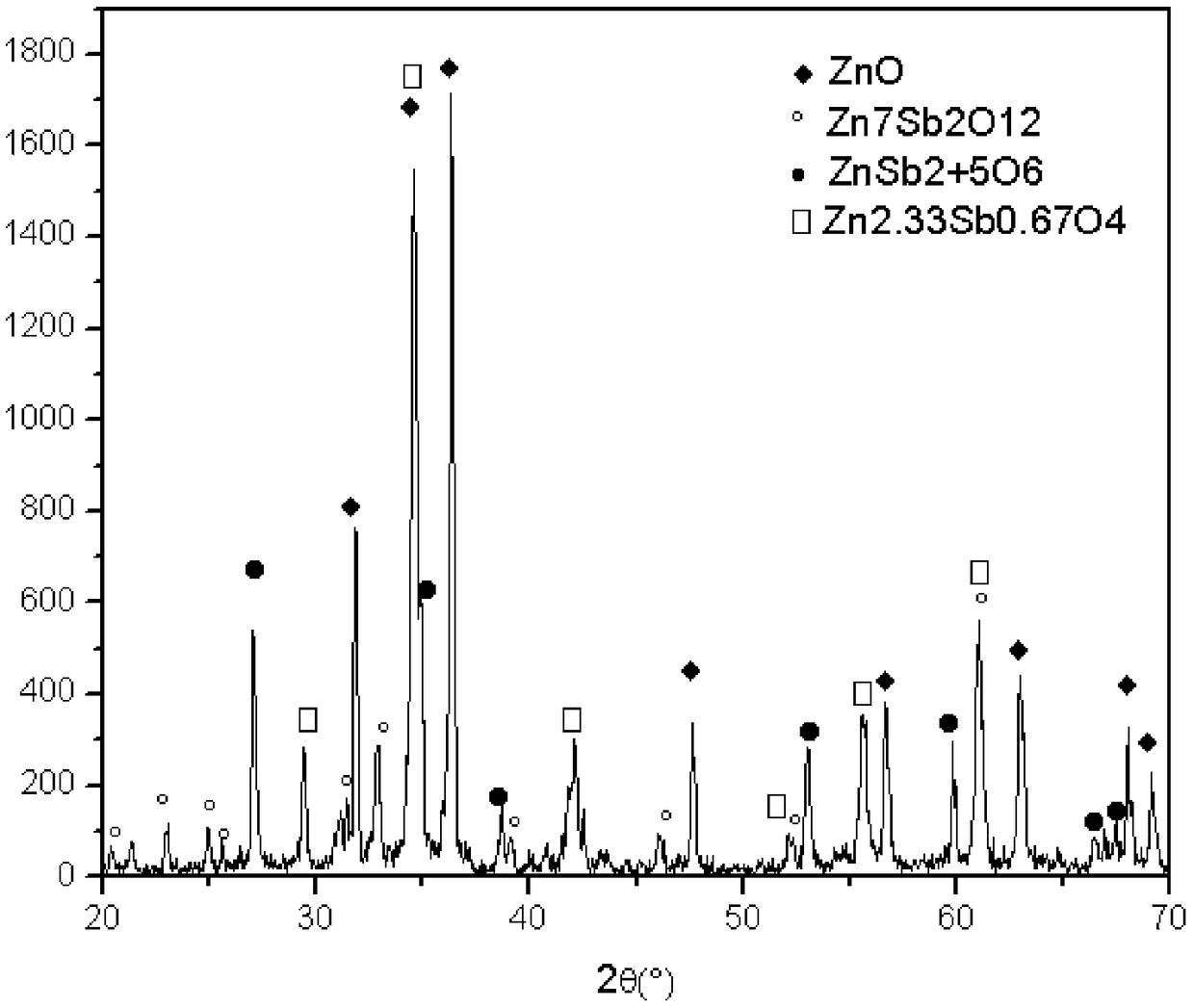

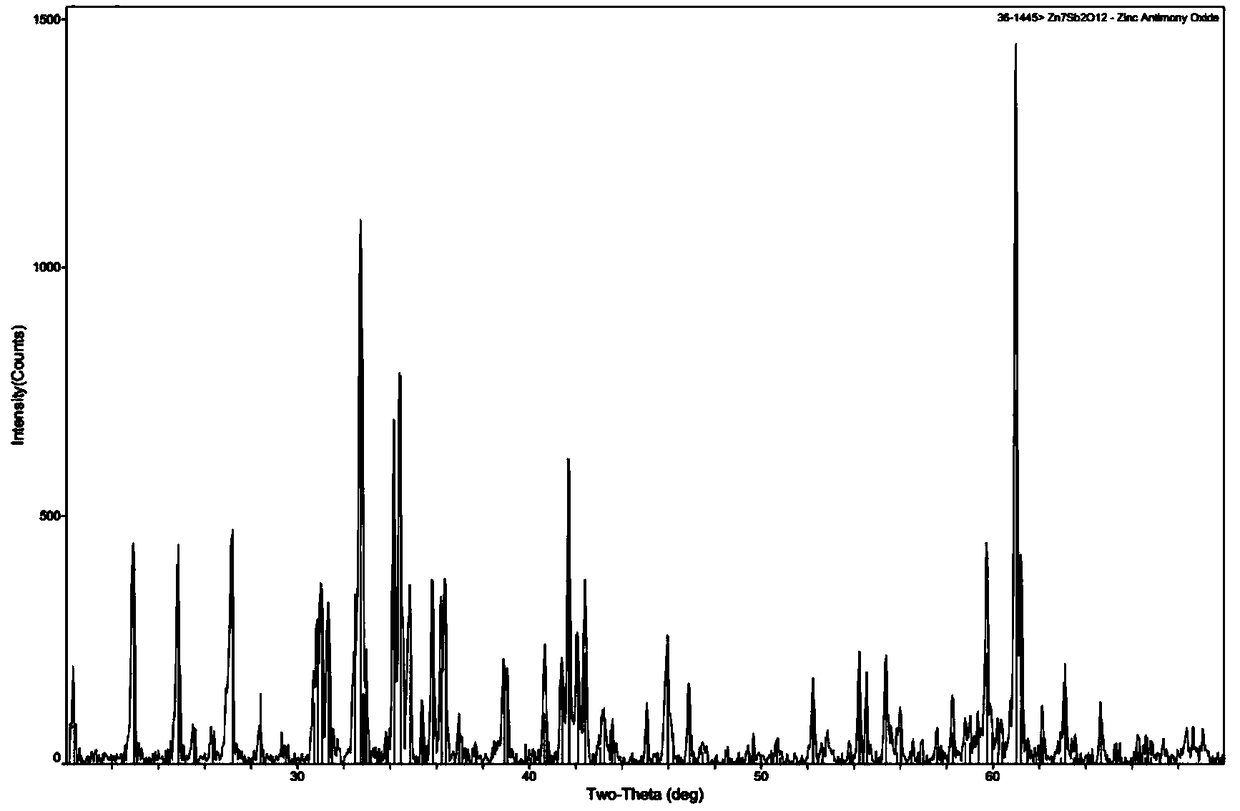

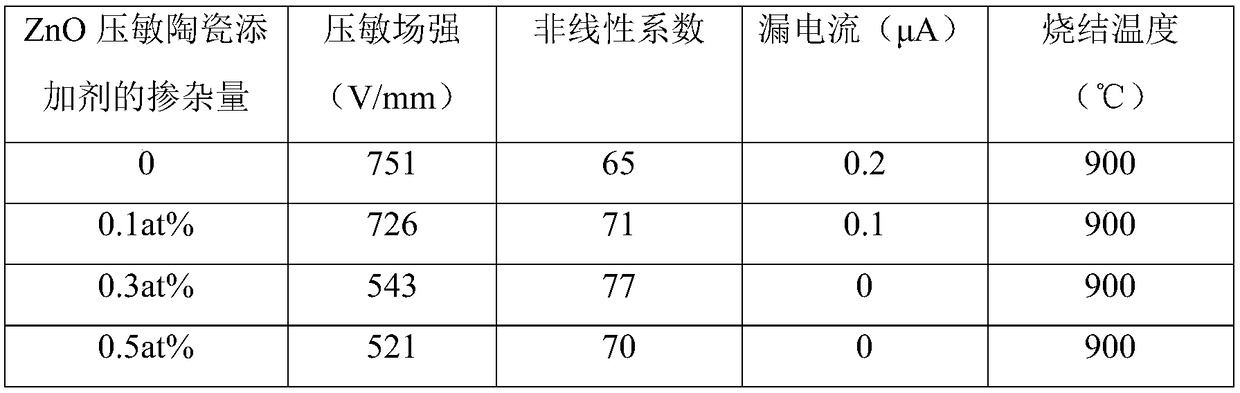

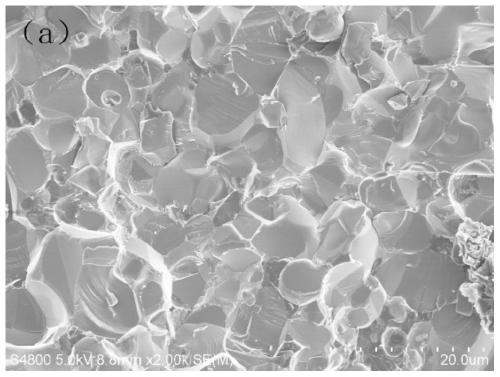

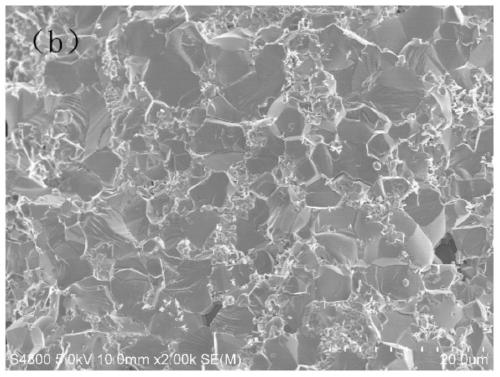

ZnO varistor ceramic additive as well as preparation method and application thereof

The invention belongs to the field of varistor materials, and provides a ZnO varistor ceramic additive as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) carrying out ball milling on ZnO and Sb2O3 by taking a solvent as a medium to obtain slurry, wherein a molar ratio of the ZnO to the Sb2O3 is equal to 1-(14 to 1); (2) drying and calcining the slurry obtained in the step (1) to obtain the ZnO varistor ceramic additive. The invention also provides the ZnO varistor ceramic additive and application thereof. After the ZnO varistor ceramic additive is added into raw materials for preparing ZnO varistor ceramics, ZnO grain growth is promoted, the varistor voltage is reduced, the low temperature sintering of a varistor is maintained, and the nonlinear coefficient of the varistor ceramics can be increased; the sintering temperature of the ZnO varistor ceramics is reduced to 850-900DEG C, the nonlinear coefficient alpha value of the material can reach 91, and the varistor field strength is as low as 500-760V / mm.

Owner:LIAOCHENG UNIV

Voltage-sensitive ceramic material and preparation method thereof

InactiveCN103496970AExcellent pressure sensitive performanceNo pollution in the processVaristor ceramicsBall mill

The invention relates to a voltage-sensitive ceramic material and a preparation method thereof, belonging to the field of ceramic process technologies. The voltage-sensitive ceramic material comprises the following components: 93-95 parts of ZnO, 0.6-0.8 part of Bi2O3, 0.9-1.3 parts of Sb2O3, 1.0-1.3 parts of CoO, 0.5-0.8 part of MnCO3, 0.5-0.8 part of Cr2O3, 0.5-0.8 part of NiO, and 1.0-1.5 parts of Pr6O11. The preparation method comprises the following steps of pouring the components into a stirring ball mill according to proportion, adding pure water of 85-93% of the total weight of additives, ball milling for 2-4 hours till the grain size is less than 1.3mu m, then heating the obtained mixed solution up to 85-100 DEG C, keeping warm and stirring continuously till the solvent is evaporated and becomes paste, drying the paste, keeping warm for 6-8 hours at 500-580 DEG C, finally ball milling, and obtaining the zinc oxide voltage-sensitive ceramic compound powder. The ceramic material has excellent voltage-sensitive property, has a simple preparation method, has no toxicity and no environment contamination, and is beneficial to industrial large scale production.

Owner:陈锐群

Zinc oxide pressure-sensitive ceramic material and preparation method thereof

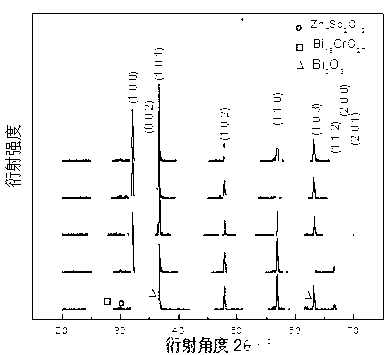

The invention provides a zinc oxide pressure-sensitive ceramic material and a preparation method thereof. The method comprises the following steps: 1) preparing a ZnO / Al2O3 composite material by usinga hydrothermal method; 2) selecting raw materials of ZnO, the ZnO / Al2O3 composite material, Co2O3, MnO2, Cr2O3, Bi2O3, Sb2O3, SiO2, Y2O3 and Sc2O3, uniformly mixing the raw materials, and then carrying out ball milling on the mixture; and 3) carrying out spark plasma sintering on the ball-milled mixture to obtain the zinc oxide pressure-sensitive ceramic material. Zinc oxide prepared by the method is good in binding property with aluminum oxide, the uniform distribution uniformity of aluminum oxide is high, the sintering temperature of the pressure-sensitive ceramic is low, and a sintered body has a grain structure with high uniformity, so that the zinc oxide pressure-sensitive ceramic material has excellent nonlinear electrical properties.

Owner:WUHAN UNIV OF TECH

Voltage-sensitive ceramic interface state response measurement method based on frequency domain dielectric response

ActiveCN112180174AEffective detection of interface state responseResistance/reactance/impedenceElectrical field strengthVaristor ceramics

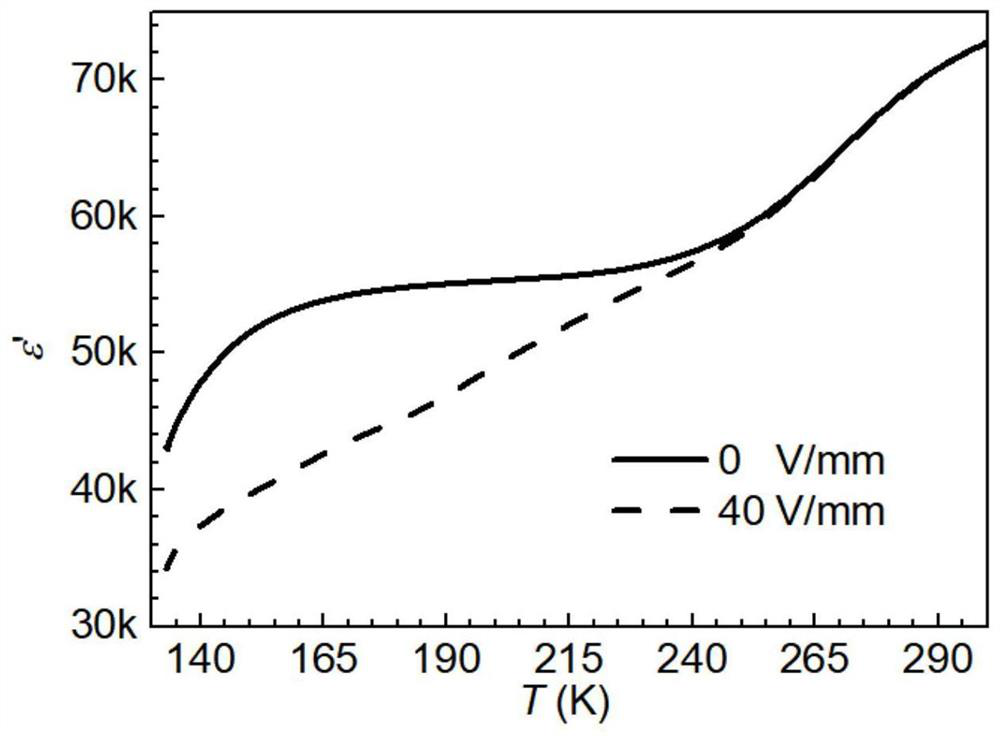

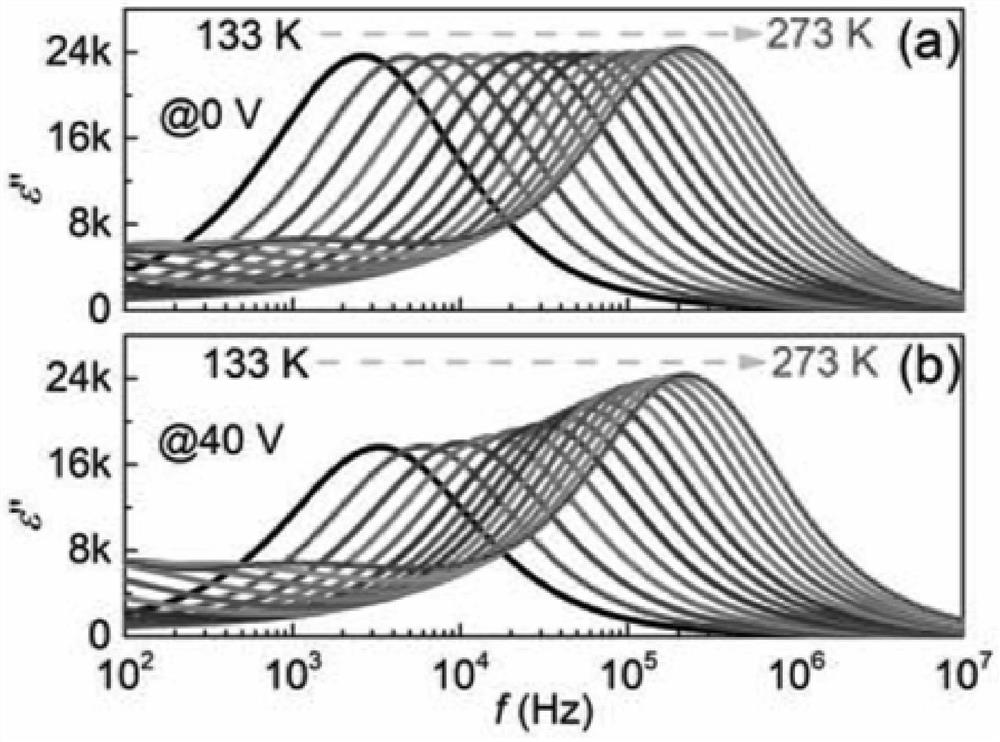

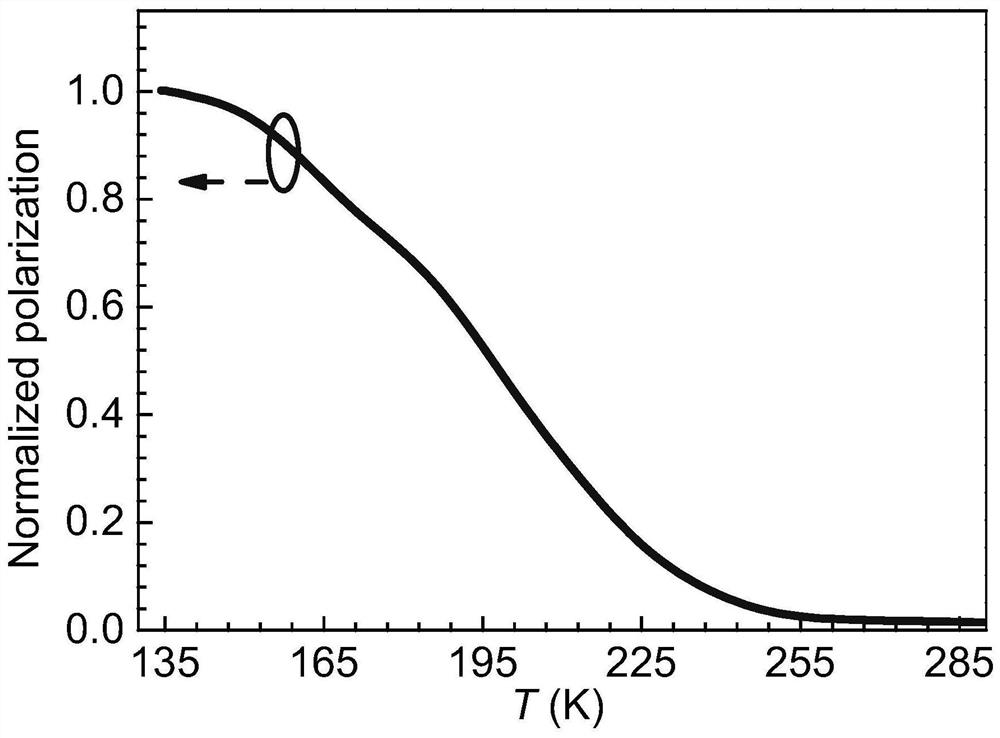

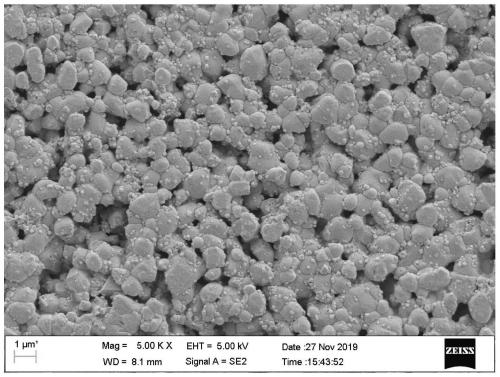

The invention discloses a voltage-sensitive ceramic interface state response measurement method based on frequency domain dielectric response. The method comprises the steps of 1) heating or cooling asample to an initial test temperature, setting a direct current bias voltage to enable the electric field intensity of the sample to be 0V / mm, keeping the electric field intensity for a first set time, removing the direct current bias voltage, measuring the frequency domain dielectric spectrum of the sample under a set alternating current signal, heating according to a set heating rate, continuously measuring the frequency domain dielectric spectrum of the sample until the temperature of the sample reaches a preset test ending temperature, and obtaining a first frequency domain dielectric spectrum of the sample; 2) repeating the step 1) to modulate the electric field intensity to n V / mm to obtain a second frequency domain dielectric spectrum of the sample; and 3) subtracting the first frequency domain dielectric spectrum from the second frequency domain dielectric spectrum to obtain a voltage-sensitive ceramic interface state response curve, wherein n is less than the breakdown fieldintensity of the sample. The test result can well represent the characteristics of the interface state response of the sample. The method is an effective method for testing the interface state response of a back-to-back barrier.

Owner:XI AN JIAOTONG UNIV

Low-temperature sintered zinc oxide pressure-sensitive ceramic and preparation method thereof

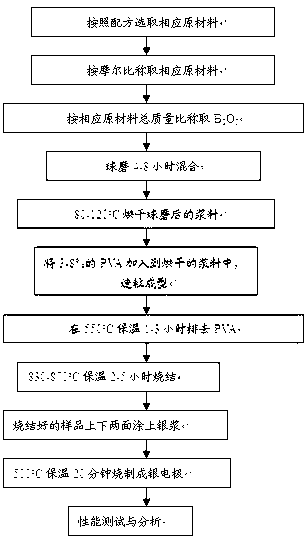

The invention discloses low-temperature sintered zinc oxide pressure-sensitive ceramic and a preparation method thereof. The method comprises steps: mixing, ball milling, and drying zinc oxide, a sintering aid B4C and a modification additive to obtain a powder, wherein the modification additive contains Bi2O3, Sb2O3, Co3O4, an oxide of manganese and Ni2O3; adding PVA glue into the obtained powder,granulating, sieving, tabletting and discharging glue; sintering for 2 to 3h at 900 to 950 DEG C to obtain a black and compact pressure-sensitive ceramic chip; and respectively coating the two surfaces of the pressure-sensitive ceramic chip with silver paste, heating to 500-550 DEG C, carrying out heat preservation for 20-30 minutes, and cooling to obtain the pressure-sensitive ceramic with electrodes printed on the two surfaces. According to the preparation method, B4C is adopted as a sintering aid, the sintering temperature is reduced to 950 DEG C or below from traditional 1100-1200 DEG C,meanwhile, it is guaranteed that the pressure-sensitive ceramic has good comprehensive electrical properties, and the whole process is energy-saving, consumption-reducing, environmentally friendly, simple, convenient and easy to implement and capable of being industrially popularized.

Owner:SOUTH CHINA UNIV OF TECH

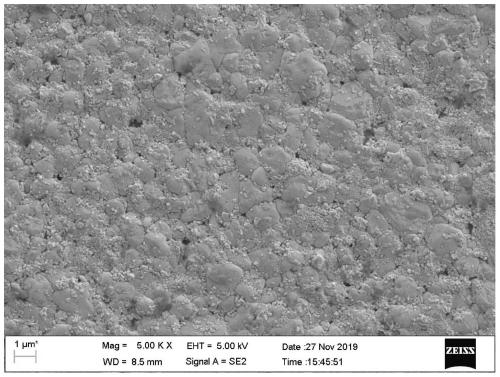

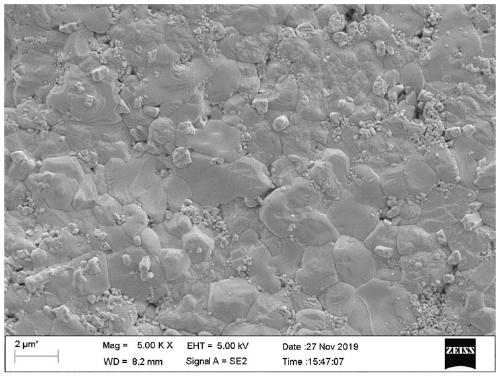

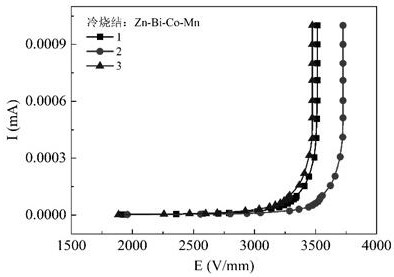

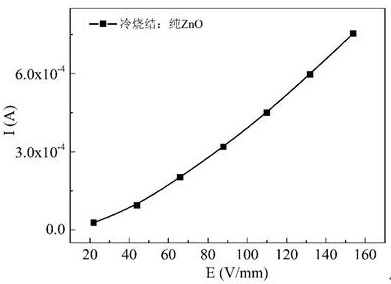

High-potential-gradient ZnO voltage-sensitive ceramic based on cold sintering and preparation method thereof

InactiveCN111848152AHigh nonlinear coefficientLower sintering temperatureCeramic sinteringVaristor ceramics

The invention relates to a high-potential-gradient ZnO voltage-sensitive ceramic based on cold sintering and a preparation method thereof. The method comprises the following steps of: mixing ZnO, Bi2O3, CoO and Mn2O3 according to a molar ratio of 95-100%:0-5%:0-5%:0-5%; and then carrying out wet ball milling for 12h, drying the mixed powder for 12h at a temperature of 80DEG C, putting the mixed material into a metal mold, performing sintering for 1-3h at a temperature of 200-300DEG C by adopting a cold sintering technology, and conducting natural cooling to obtain the target voltage-sensitiveceramic. According to the method, the voltage-sensitive ceramic is prepared by adopting a cold sintering technology, the sintering temperature and the heat preservation time are greatly reduced, the method is more energy-saving and environment-friendly, the potential gradient of the obtained ZnO voltage-sensitive ceramic reaches up to 3300V / mm or above, and the nonlinear coefficient reaches up toabout 40.

Owner:CHONGQING UNIV

Voltage-sensitive ceramic resistor

InactiveCN103964837AImprove electrical varistor performanceHigh nonlinear coefficientOxide ceramicManganese(II) carbonate

The invention relates to a voltage-sensitive ceramic resistor, particularly to a voltage-sensitive ceramic resistor sintered at the temperature of 800 DEG C by adopting a traditional ceramic technology, and belongs to the field of electronic components. According to the voltage-sensitive resistor, 0.25%-2.0% mole of vanadium oxide and 0.2%-0.7% mole of titanium oxide are doped simultaneously to ensure the low temperature sintering property, and on the basis of that, manganese carbonate or manganese oxide, cobaltous oxide, cobaltous oxide, bismuth oxide and the like are continuously added to ensure the excellent voltage-sensitive property. When the voltage-sensitive ceramic resistor is prepared by adopting the traditional oxide ceramic technology, the ceramic body can be sintered at the temperature of about 800 DEG C, the highest nonlinear coefficient can up to more than 40, the leakage current is about 0.3 mA / cm<2>, the voltage-sensitive voltage is 300-2000 V / mm. The voltage-sensitive ceramic resistor is simple in preparation technology and excellent in performance, and is an excellent candidate material for the low-cost voltage-sensitive resistor and the plate voltage-sensitive resistor; rare earth oxides are not required to be added.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

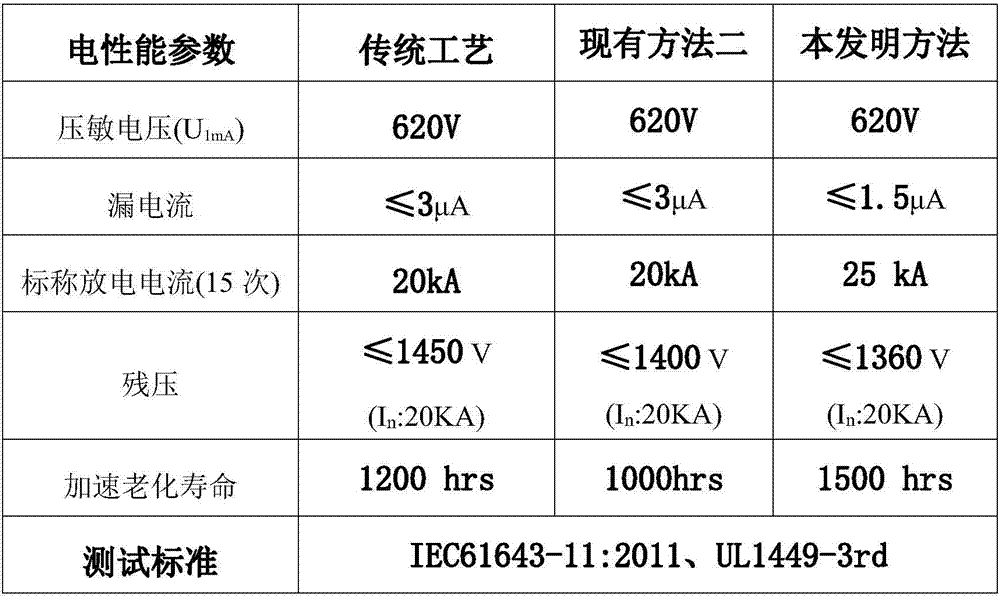

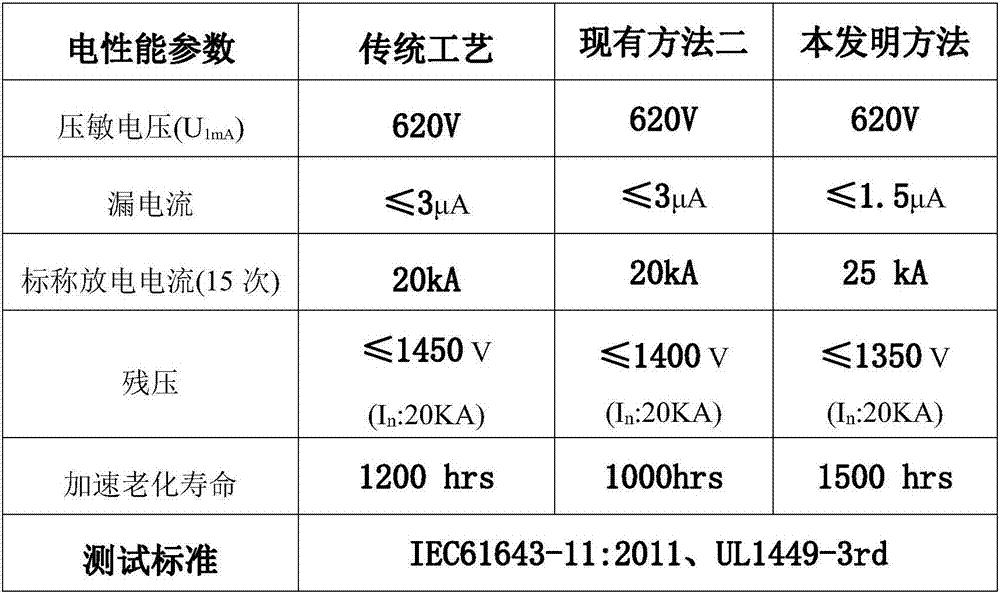

A large flow capacity, low residual voltage, high gradient zinc oxide varistor ceramics

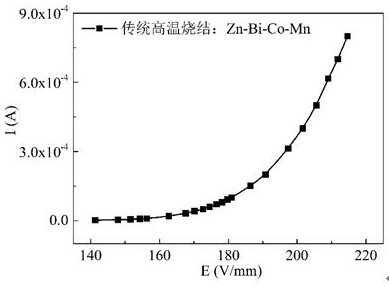

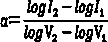

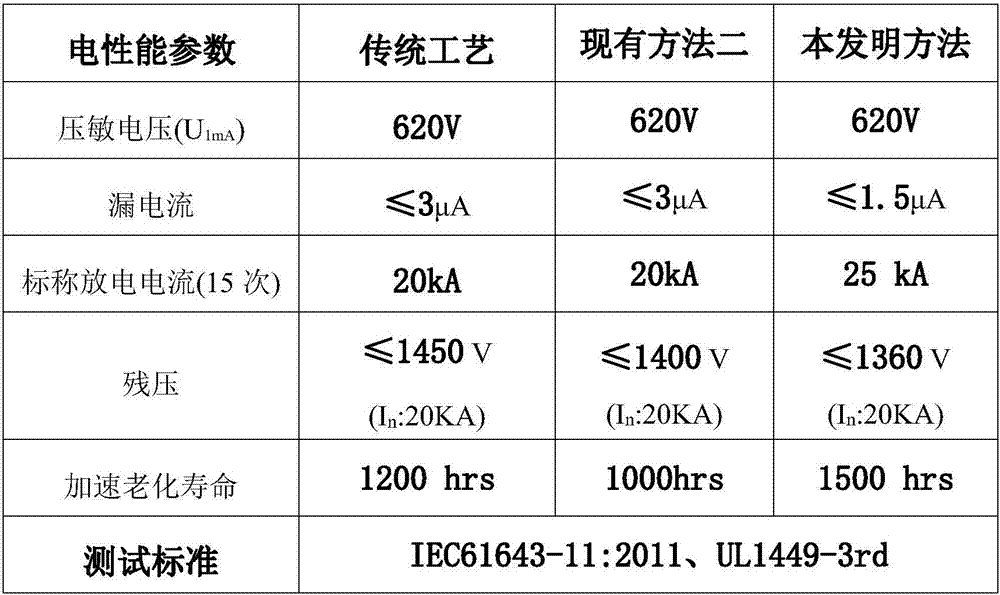

ActiveCN105481363BLower Die ResistanceLow residual pressure levelPiezoelectric/electrostrictive/magnetostrictive devicesManganeseAntimony trioxide

A method for preparing zinc oxide varistor ceramics with large flow capacity, low residual voltage and high gradient, which is characterized in that the formula ingredients include zinc oxide ZnO, bismuth oxide Bi2O3, antimony trioxide Sb2O3, manganese dioxide MnO2, chromium oxide Cr2O3, cobalt trioxide Co2O3, silicon dioxide SiO2, silver nitrate oxide Ag2O, gallium nitrate Ga(NO3)3, yttrium nitrate Y(NO3)3. The beneficial effects are: the leakage current is suppressed; the joint addition of Y and Ga elements makes the aging performance of the ZnO varistor produced by this formula more stable, eliminating the problem that the leakage current cannot be suppressed due to the simple addition of Ag ions. at.

Owner:TSINGHUA UNIV

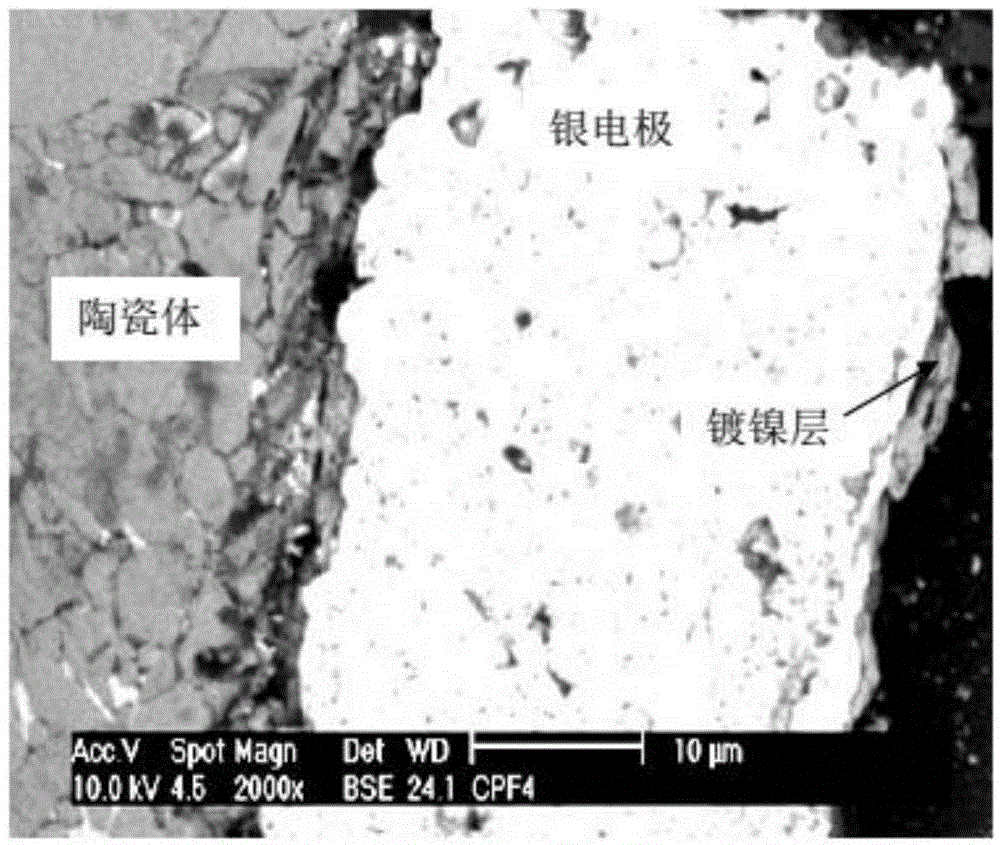

Method for electroplating laminated ZnO pressure-sensitive ceramic resistor chip

InactiveCN104947163AAvoid plating phenomenonInhibit deteriorationResistor manufacturePressure sensitiveElectroplating

The invention discloses a method for electroplating a laminated ZnO pressure-sensitive ceramic resistor chip, which comprises the following steps: putting a sintered laminated ZnO ceramic chip and corundum into a rotating roller, and carrying mixing and barreling to obtain a laminated ZnO ceramic chip with smooth external surface; cleaning the laminated ZnO ceramic chip with smooth external surface to obtain a cleaned laminated ZnO ceramic chip; carrying out insulation treatment on the cleaned laminated ZnO ceramic chip by using an insulation treatment modification solution to obtain a laminated ZnO ceramic wafer coated with a glass insulation layer on the external surface; and sequentially carrying out silver plating and barrel plating on the laminated ZnO ceramic wafer coated with a glass insulation layer on the external surface, thereby completing the electroplating on the laminated ZnO pressure-sensitive ceramic resistor chip. The method can form a firm insulation layer on the device surface, overcomes the defect of overplating in the electroplating process, and is beneficial to inhibiting property deterioration in the device operation process.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Aqueous gel tape casting method for preparing DC (direct current) zinc oxide voltage-sensitive resistor disk

InactiveCN102800452ACompact structureUniform compositionResistor manufactureVaristor coresSlurryResistor

The invention relates to the technology of the manufacturing of voltage-sensitive resistor materials, in particular to a method for preparing a DC (direct current) zinc oxide voltage-sensitive resistor disk. The conventional tape casting molding slurry contains a great amount of organic solvents served as carriers such as toluene and xylene, has certain toxicity, worsens the production conditions, causes environmental pollution and has extremely high production cost. Combined with an aqueous gel tape casting process and a preparation technology of the voltage-sensitive ceramic resistor disk, the invention provides an aqueous gel tape casting method for preparing the DC zinc oxide voltage-sensitive resistor disk. The aqueous gel tape casting method comprises the following steps of: 1, preparing raw materials; 2, preparing ceramic green bodies by a gel tape casting method; 3, cutting the resistor disk in required shapes and size, and sintering at high temperature; and 4, coating bismuth slurry at both ends of the sintered resistor disk, and heating at certain temperature to make bismuth components uniformly infiltrate into the resistor disk so as to obtain the required DC zinc oxide voltage-sensitive resistor disk. The resistor disk is compact in integral structure and uniform in the components and has comprehensive electrical performance.

Owner:JIANGSU JINLEIKAI PHOTOELECTRIC TECH

Y<3+> and Nb<5+> composite donor doped ZnO voltage-sensitive ceramic and preparation method thereof

The invention discloses Y<3+> and Nb<5+> composite donor doped ZnO voltage-sensitive ceramic and a preparation method thereof. The voltage-sensitive ceramic comprises base materials and doping materials. The base materials contain, by weight, 87-95 parts of ZnO, 2.0-4.0 parts of Bi2O3, 0.4-0.7 part of MnO2, 1.5-3.5 parts of Sb2O3, 0.5-1.5 parts of Co2O3, 0.2-1.0 part of Cr2O3, and 1-5 parts of seed crystal doping materials. The seed crystal doped materials include ZnO, Nb2O5 and Y2O3, wherein mass ratio of ZnO: Nb2O5: Y2O3 is 90-95:0.1-5: 0.1-5. The Y<3+> and Nb<5+> composite donor doped ZnO voltage-sensitive ceramic has characteristics of reducing ZnO grain resistivity and controlling ZnO lattice distortion to finally achieve low residual voltage of ZnO varistor, long aging life and strong pulse current withstand capacity.

Owner:贵阳高新益舸电子有限公司

Low-pressure pressure-sensitive ceramic material and preparation method thereof

The invention relates to a low-pressure pressure-sensitive ceramic material and a preparation method thereof. The material comprises a component A and a component B and contents thereof by mass percent are as follows: A comprises 57.4 percent of SrO, 40.7 percent of TiO2, 0.7 percent of Nb2O5, 0.8 percent of CeO2 and 0.4 percent of MnO; and B comprises 92.4 percent of Al2O3, 0.1 percent of Co2O3, 3.5 percent of MnO, 2.5 percent of Cr2O3, 0.3 percent of SiO2 and 1.5 percent of TiO2; pure reagents are taken according to a mass ratio of the component A and the component B being equal to 4:6 to 6:4, subjected to mixing, ball milling, drying, pelleting and sintering in a vacuum graphite oven at the temperature of 1305 to 1500 DEG C after being pressed and formed, and are cooled with the oven or cooled with the oven after being kept at constant temperature for 1 to 3h; surface treatment and cleaning are conducted to a sample after sintering, and the pressure-sensitive ceramic material with C=0.02 to 22muF, epsilon=1.7*10 to 1.5*10, U1mA=0.6 to 6.3V, U10mA=1.8 to 11.6V and alpha=2.1 to 5.1 is obtained after put through electrode; and the preparation method is simple, safe and reliable.

Owner:GUANGXI UNIV

Combined In3+ and Sn4+ donor doped ZnO varistor ceramic and preparation method thereof

ActiveCN106892657ASuppresses the increase in leakage currentSuppresses the decrease of the nonlinear coefficientOvervoltage protection resistorsCeramicSeed crystal

The invention discloses combined In3+ and Sn4+ donor doped ZnO varistor ceramic and a preparation method thereof; the combined In3+ and Sn4+ donor doped ZnO varistor ceramic comprises a base material and a doping material, wherein the base material comprises, by weight, 87-95 parts of ZnO, 2.0-4.0 parts of Bi2O3, 0.4-0.7 part of MnO2, 1.5-3.5 parts of Sb2O3, 0.5-1.5 parts of Co2O3, 0.1-1.0 part of Cr2O3, and 1-5 parts of seed crystal doping material; the seed crystal doping material comprises ZnO, SnO2 and In2O3 having a mass ratio of (90-95):(0.1-5):(0.1-5). The combined In3+ and Sn4+ donor doped ZnO varistor ceramic has the advantages that ZnO grain resistivity can be decreased and ZnO lattice distortion can also be controlled, and also has the advantages of low final ZnO varistor residue, long ageing life and high pulse current tolerance.

Owner:贵阳高新益舸电子有限公司

High-temperature pressurizing method for preparing direct-current zinc oxide piezoresistor sheet

The invention relates to a high-temperature pressurizing method for preparing a direct-current zinc oxide piezoresistor sheet, and belongs to the field of preparation technologies of a voltage-sensitive ceramics resistor sheet. According to the invention, the high-temperature pressurizing method is adopted to prepare the direct-current zinc oxide piezoresistor sheet at a high temperature in an oxidizing atmosphere, the environment under high pressure is used for inhibtting the volatilization of a component with a low melting point, and heat preservation and sintering are carried out in a high temperature environment, so that the overall density of the voltage-sensitive ceramics is improved, voltage-sensitive ceramics bars can be obtained after cooling and can also be cut at will to prepare the resistor sheet with the required thickness. With the adoption of the method provided by the invention, the components with a low melting point can be inhibited to violate under the high pressure during being pressurized at the high temperature, so that the conditions that the design prescription needs to be changed and the distribution of the whole component is nonuniform can be avoided, and high quality of the resistor sheet can be ensured.

Owner:JIANGSU JINLEIKAI PHOTOELECTRIC TECH

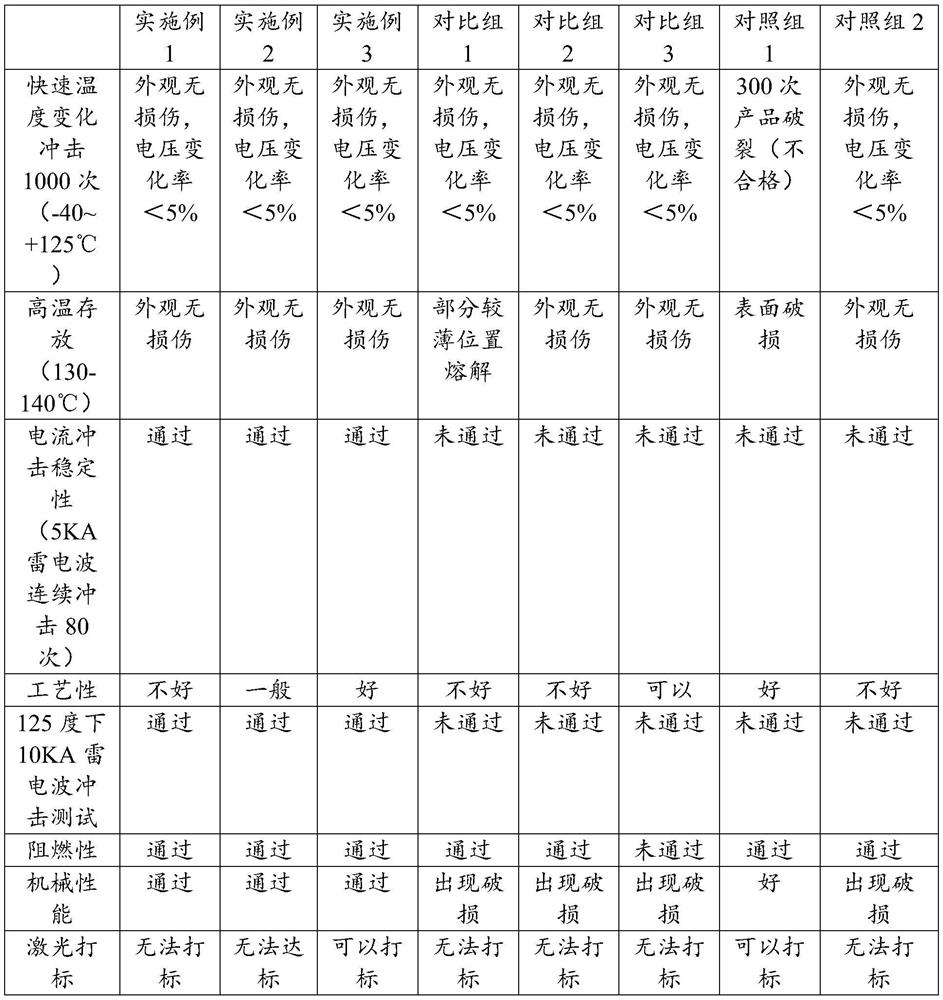

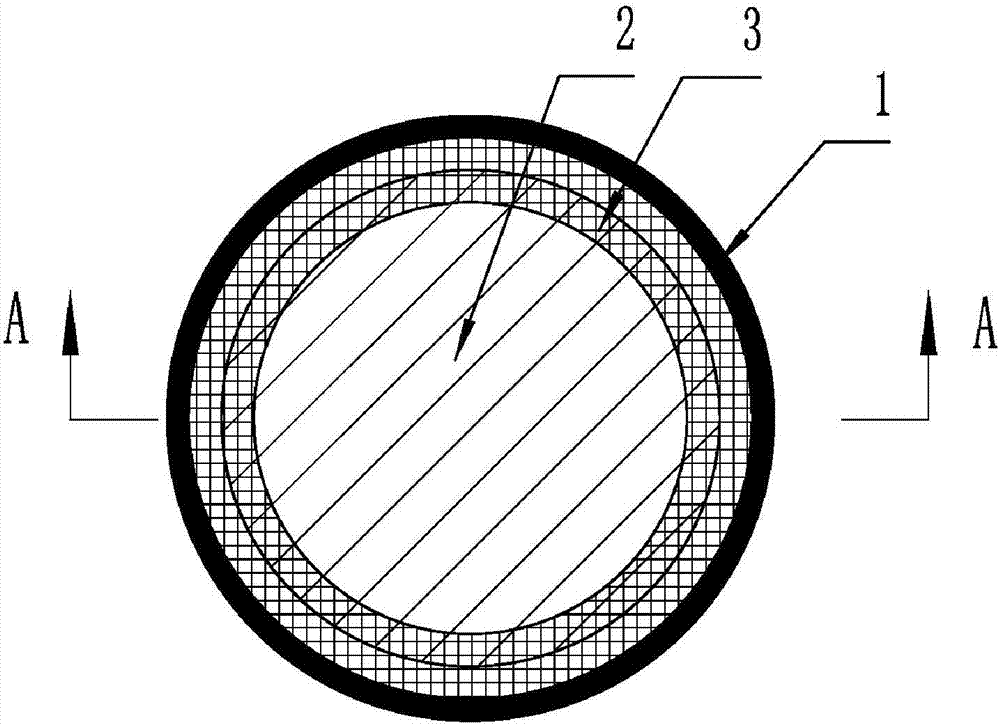

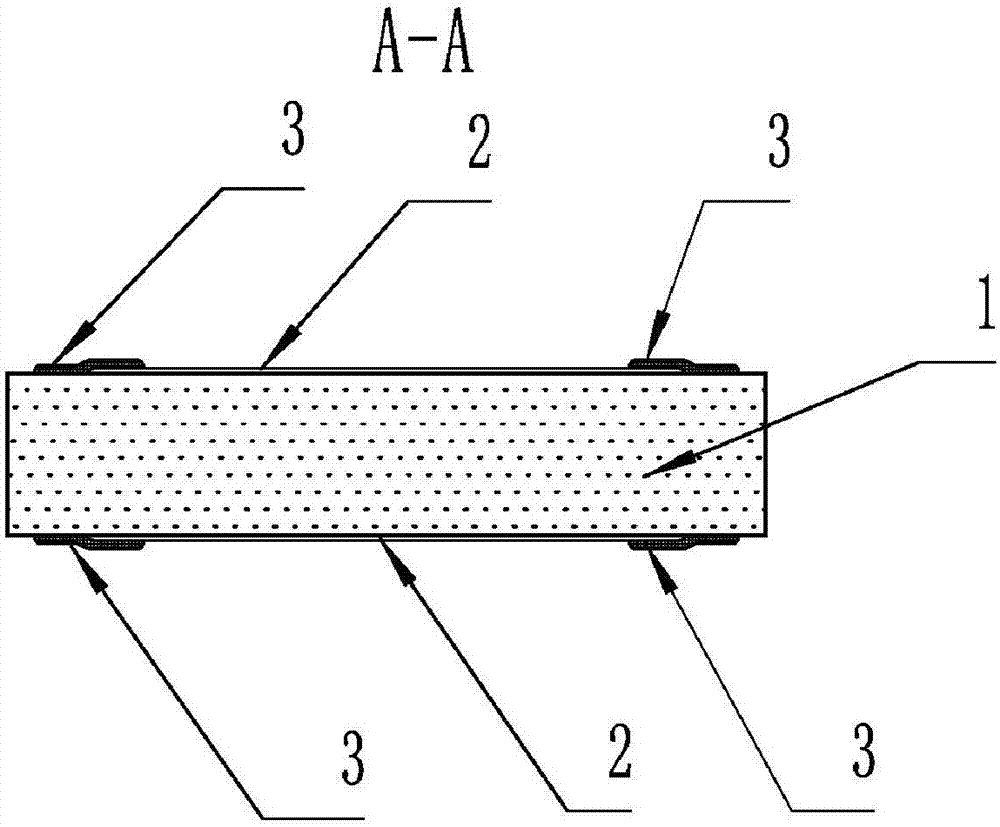

Piezoresistor adopting silicon rubber insulating layer, and manufacturing method thereof

ActiveCN111710487AImprove high temperature stabilityGood weather resistanceEnvelope/housing resistor manufactureOvervoltage protection resistorsHigh densityLiquid state

The invention discloses a piezoresistor adopting a silicone rubber insulating layer, and a manufacturing method of the piezoresistor. The piezoresistor comprises a piezoresistor porcelain body and twoend surface electrode pins of the piezoresistor porcelain body, and also comprises a soft silicone rubber layer which wraps the piezoresistor porcelain body and the pins to form insulation protection, wherein the pins penetrate out of the soft silicon rubber layer to be connected with external equipment. The invention also discloses a manufacturing method, which comprises the following steps of:arranging the two pins on the two end surfaces of the piezoresistor porcelain body respectively, soaking the piezoresistor porcelain body connected with the pins in the liquid-state raw material of the soft silicone rubber layer, taking out the piezoresistor porcelain body after dip-coating 1-3 times, curing the piezoresistor porcelain body at normal temperature, testing the performance of the piezoresistor porcelain body after curing, and obtaining a finished product after the piezoresistor porcelain body is qualified. According to the invention, the method is different from the existing silicone rubber technology, and the special formula solves the problem of binding force between the pressure-sensitive ceramic and the silica gel, and enhances the high-density lightning surge high-current impact resistance of the product, especially the high-density lightning surge high-current impact resistance at high temperature.

Owner:CHENGDU TIEDA ELECTRONICS CORP

High-energy-tolerance ZnO piezoresistor sheet and preparation method therefor

PendingCN107146667AHigh electrical breakdown strengthTightly boundVaristor coresResistive material coatingHigh energyVoltage

The invention provides a high-energy-tolerance ZnO piezoresistor sheet and a preparation method therefor. A ZnO voltage-sensitive ceramic sheet is manufactured firstly; then silver electrode slurry is printed on the two surfaces of the ZnO voltage-sensitive ceramic sheet, and is sintered to form a silver electrode to obtain a ZnO voltage-sensitive silver sheet with silver electrodes on the two surfaces; finally, an annular insulating and covering material is prepared on the edges of the silver electrodes on the two surfaces of the ZnO voltage-sensitive silver sheet to prepare the ZnO piezoresistor sheet covered with the annular insulating material; and the annular insulating material covers the edges of the silver electrodes for a range of 0.5mm or above inside and outside. No matter whether the prepared ZnO piezoresistor sheet is packaged by adopting an organic material or not or whether the prepared ZnO piezoresistor sheet suffers from a pulse current or not, flashover or arc-over does not occur on the edge and side surface, so that high reliability is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Y<3+> and Sn<4+> composite donor doped ZnO voltage-sensitive ceramic and preparation method thereof

The invention discloses Y<3+> and Sn<4+> composite donor doped ZnO voltage-sensitive ceramic and a preparation method thereof. The voltage-sensitive ceramic comprises base materials and doping materials. The base materials contain, by weight, 87-95 parts of ZnO, 2.0-4.0 parts of Bi2O3, 0.4-0.7 part of MnO2, 1.5-3.5 parts of Sb2O3, 0.5-1.5 parts of Co2O3, 0.2-1.0 part of Cr2O3, and 1-5 parts of seed crystal doping materials. The seed crystal doped materials include ZnO, SnO2 and Y2O3, wherein mass ratio of ZnO: SnO2: Y2O3 is 90-95: 0.1-5: 0.1-5. The Y<3+> and Sn<4+> composite donor doped ZnO voltage-sensitive ceramic has characteristics of reducing ZnO grain resistivity and controlling ZnO lattice distortion to finally achieve low residual voltage of ZnO varistor, long aging life and strong pulse current withstand capacity.

Owner:贵阳高新益舸电子有限公司

Pressure-sensitive ceramic membrane and preparation method thereof

InactiveCN104230327AReduce leakage current densityExcellent pressure sensitive performanceSolvent evaporationAlloy substrate

The invention relates to a pressure-sensitive ceramic membrane and a preparation method of the pressure-sensitive ceramic membrane and belongs to the technical field of ceramic processing. The pressure-sensitive ceramic membrane comprises the following components in parts by weight: 60-90 parts of ZnO, 1-10 parts of Bi2O3, 0-5 parts of Sb2O3, 0.2-1.5 parts of MnO2, and 5-10 parts of Pr6O11. The preparation method comprises the following steps: pouring the substances into a stirring ball mill according to the above ratio; adding pure water which is 75-80% of total weight of the additive; carrying out ball-milling until the particle size is 0.5-1.5 microns, and then heating the obtained mixed solution to 85-100 DEG C; carrying out heat preservation and stirring continuously, so that the solvent is evaporated into a sticky paste; spraying the sticky paste on an alloy substrate material by adopting a spray drying technology; and calcining at 200-300 DEG C for 6-10 hours, and demolding so as to obtain a pressure-sensitive ceramic membrane product. The ceramic membrane has good pressure-sensitive characteristic, is simple in preparation process, and is suitable for mass industrial production.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com