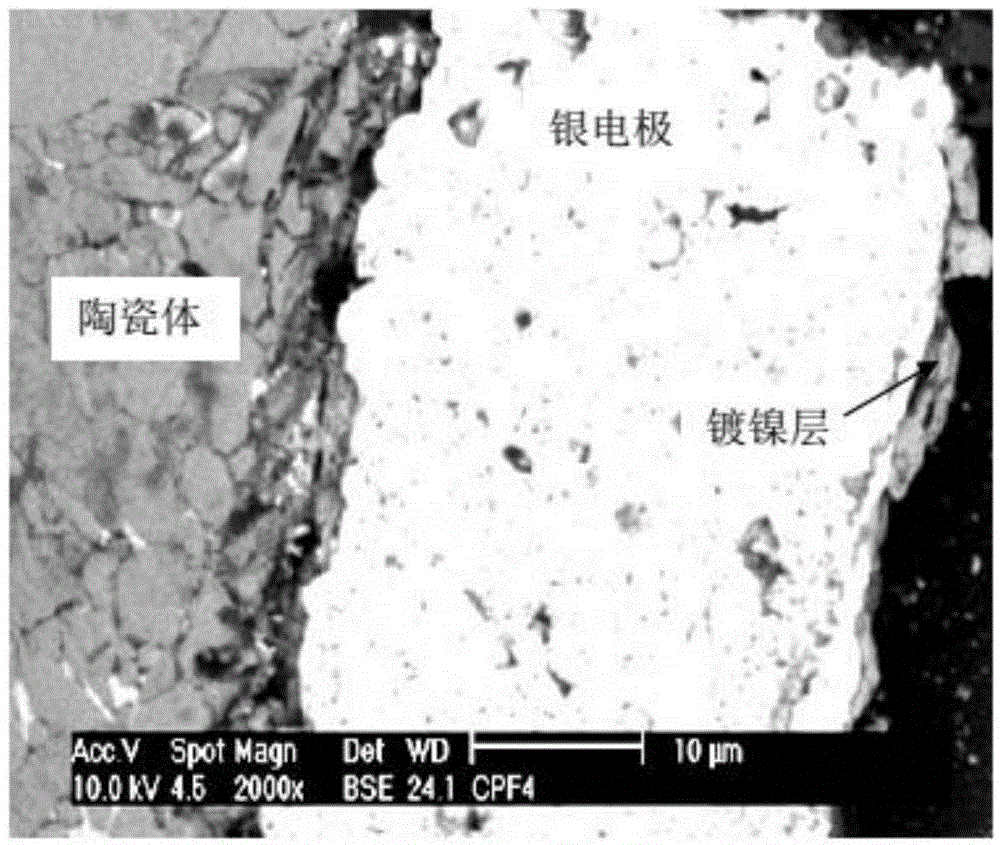

Method for electroplating laminated ZnO pressure-sensitive ceramic resistor chip

A pressure-sensitive ceramic and electroplating technology, applied in resistors, resistor manufacturing, circuits, etc., can solve problems such as damage to the organic insulating protective layer, organic insulating layer failure, device disconnection, etc., to achieve good moisture and dust resistance, The effect of avoiding the phenomenon of creeping plating and preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Take the laminated ZnO ceramic sheet with a rectangular cross section for sintering treatment to obtain the sintered laminated ZnO ceramic sheet; put the corundum and the sintered laminated ZnO ceramic sheet in the drum together, and the corundum The mass ratio to the sintered laminated ZnO ceramic sheet is 2:1; start the drum to rotate, so that the emery in the drum and the sintered laminated ZnO ceramic sheet are mixed and tumbled, and the mixed tumbler is controlled The time is: 20min, in the process of mixing and tumbling, use emery to polish the outer surface of the sintered laminated ZnO ceramic sheet to obtain a laminated ZnO ceramic sheet with a smooth outer surface;

[0110] Place the laminated ZnO ceramic sheet with a smooth outer surface in an ultrasonic cleaner, and add deionized water to the ultrasonic cleaner; turn on the ultrasonic cleaner, and use the ultrasonic cleaner to clean the laminated ZnO ceramic sheet for 10 minutes; The cleaned laminated ZnO ce...

Embodiment 2

[0115] Take the laminated ZnO ceramic sheet with a rectangular cross section for sintering treatment to obtain the sintered laminated ZnO ceramic sheet; put the corundum and the sintered laminated ZnO ceramic sheet in the drum together, and the corundum The mass ratio to the sintered laminated ZnO ceramic sheet is 2.5:1; start the drum to rotate, so that the emery in the drum and the sintered laminated ZnO ceramic sheet are mixed and tumbled, and the mixed tumbler is controlled The time is: 25min, in the process of mixing and tumbling, use emery to polish the outer surface of the sintered laminated ZnO ceramic sheet to obtain a laminated ZnO ceramic sheet with a smooth outer surface;

[0116] The laminated ZnO ceramic sheet with a smooth outer surface is placed in an ultrasonic cleaner, and deionized water is added to the ultrasonic cleaner; the ultrasonic cleaner is turned on, and the laminated ZnO ceramic sheet is cleaned by the ultrasonic cleaner for 20 minutes; The cleaned...

Embodiment 3

[0121] Take the laminated ZnO ceramic sheet with a rectangular cross section for sintering treatment to obtain the sintered laminated ZnO ceramic sheet; put the corundum and the sintered laminated ZnO ceramic sheet in the drum together, and the corundum The mass ratio to the sintered laminated ZnO ceramic sheet is 3:1; start the drum to rotate, so that the emery in the drum and the sintered laminated ZnO ceramic sheet are mixed and tumbled, and the mixed tumbler is controlled The time is: 30min, in the process of mixing and tumbling, use emery to polish the outer surface of the sintered laminated ZnO ceramic sheet to obtain a laminated ZnO ceramic sheet with a smooth outer surface;

[0122] The laminated ZnO ceramic sheet with a smooth outer surface is placed in an ultrasonic cleaner, and deionized water is added to the ultrasonic cleaner; the ultrasonic cleaner is turned on, and the laminated ZnO ceramic sheet is cleaned by the ultrasonic cleaner for 30 minutes; The cleaned l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com