Voltage-sensitive ceramic resistor

A technology of varistor ceramics and resistors, which is applied in the field of electronic components, can solve the problems of complicated preparation methods, difficult preparation of oxide-based varistor ceramics, and difficulty in industrialization, and achieve simple preparation process, improvement of electrical varistor performance, and promotion of crystallization. The effect of boundary barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

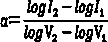

Method used

Image

Examples

Embodiment 1

[0020] 1) Formula according to raw material components: (balance) ZnO+0.5mol%V 2 o 5 +0.1mol%TiO 2 +0.5mol% MnCO 3 +0.4mol%Co 2 o 3 Weighed analytically pure zinc oxide (ZnO), vanadium oxide (V 2 o 5 ), titanium oxide (TiO 2 ), manganese carbonate (MnCO 3 ) and cobalt oxide (Co 2 o 3)raw material. After weighing, the raw materials were ball-milled on a planetary ball mill for 12 hours, and the grinding medium was absolute ethanol and zirconium balls. After ball milling, remove the zirconium balls in the slurry, dry the slurry in an oven at about 80°C; get the required ceramics. The sintering temperature was 775°C, the holding time was 4 hours, and the heating rate was 4°C / min. After sintering, the upper and lower surfaces of the sample are ground, burnt into silver electrodes, welded leads and necessary packaging to make the required varistor. Its voltage-current nonlinear coefficient is 20, the varistor voltage is 2145V / mm, and the leakage current density is 0.4...

Embodiment 2

[0022] Formula according to raw material components: (balance) ZnO+0.5mol%V 2 o 5 +0.5mol%TiO 2 +0.5mol% MnCO 3 +0.5mol%Co 2 o 3 + 0.01mol%Bi 2 O 3 Weighed analytically pure zinc oxide (ZnO), vanadium oxide (V 2 o 5 ), titanium oxide (TiO 2 ), manganese carbonate (MnCO 3 ) and cobalt oxide (Co 2 o 3 )raw material. After weighing, the raw materials were ball-milled on a planetary ball mill for 12 hours, and the grinding medium was absolute ethanol and zirconium balls. After ball milling, the zirconium balls in the slurry are removed, and the slurry is dried in an oven at about 80°C; then the traditional mixed oxide ceramic preparation method consisting of granulation, unidirectional pressure molding, debinding and sintering is used to produce Prepare the required ceramics. The sintering temperature is 800°C, and the holding time is 4 hours , the heating rate is 4°C / min. After sintering, the upper and lower surfaces of the sample are ground, burnt into silver ...

Embodiment 3

[0024] Formula according to raw material components: (balance) ZnO+0.5mol%V 2 o 5 +0.5mol%TiO 2 +0.5mol% MnO 2 +0.5mol%Co 2 o 3 + 0.2mol%Bi 2 O 3 Weighed analytically pure zinc oxide (ZnO), vanadium oxide (V 2 o 5 ), titanium oxide (TiO 2 ), manganese carbonate (MnCO 3 ) and cobalt oxide (Co 2 o 3 )raw material. After weighing, the raw materials were ball-milled on a planetary ball mill for 12 hours, and the grinding medium was absolute ethanol and zirconium balls. After ball milling, the zirconium balls in the slurry are removed, and the slurry is dried in an oven at about 80°C; then the traditional mixed oxide ceramic preparation method consisting of granulation, unidirectional pressure molding, debinding and sintering is used to produce Prepare the required ceramics. The sintering temperature is 800°C, and the holding time is 4 hours , the heating rate is 4°C / min. After sintering, the upper and lower surfaces of the sample are ground, burnt into silver e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com