Method for preparing silicon-based surface plasma waveguide having stepped structure

A surface plasmon, stepped structure technology, applied in the directions of light guide, optics, instrument, etc., can solve the problems of increased loss, limited efficiency and rate of third-order nonlinear effect, low speed of two-photon absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

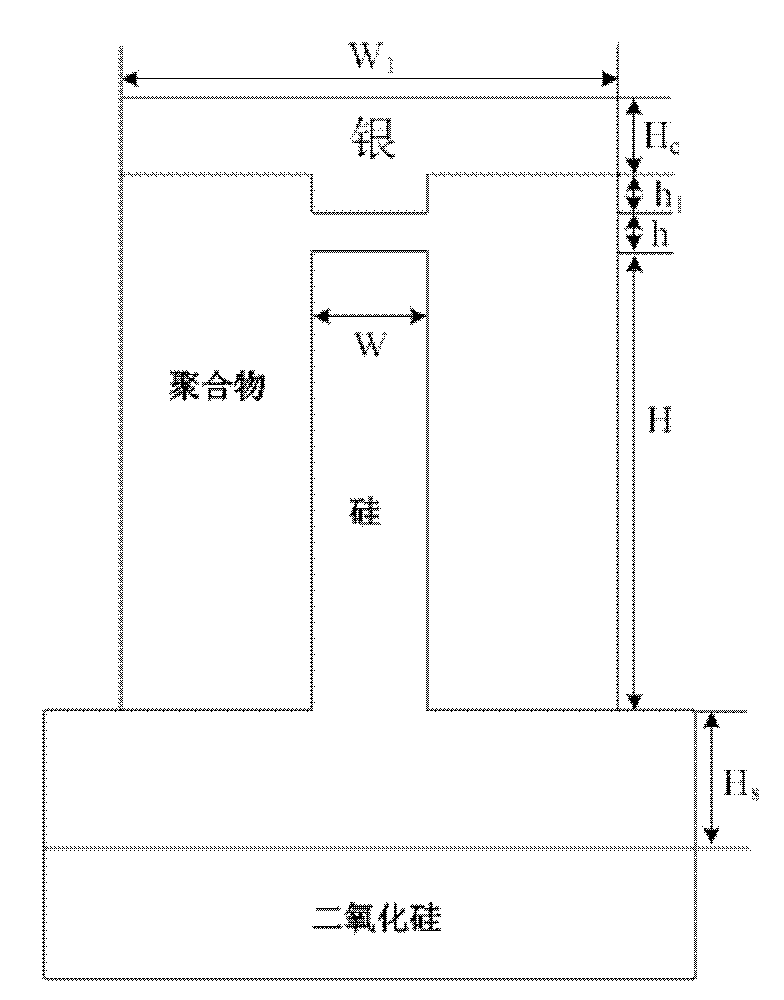

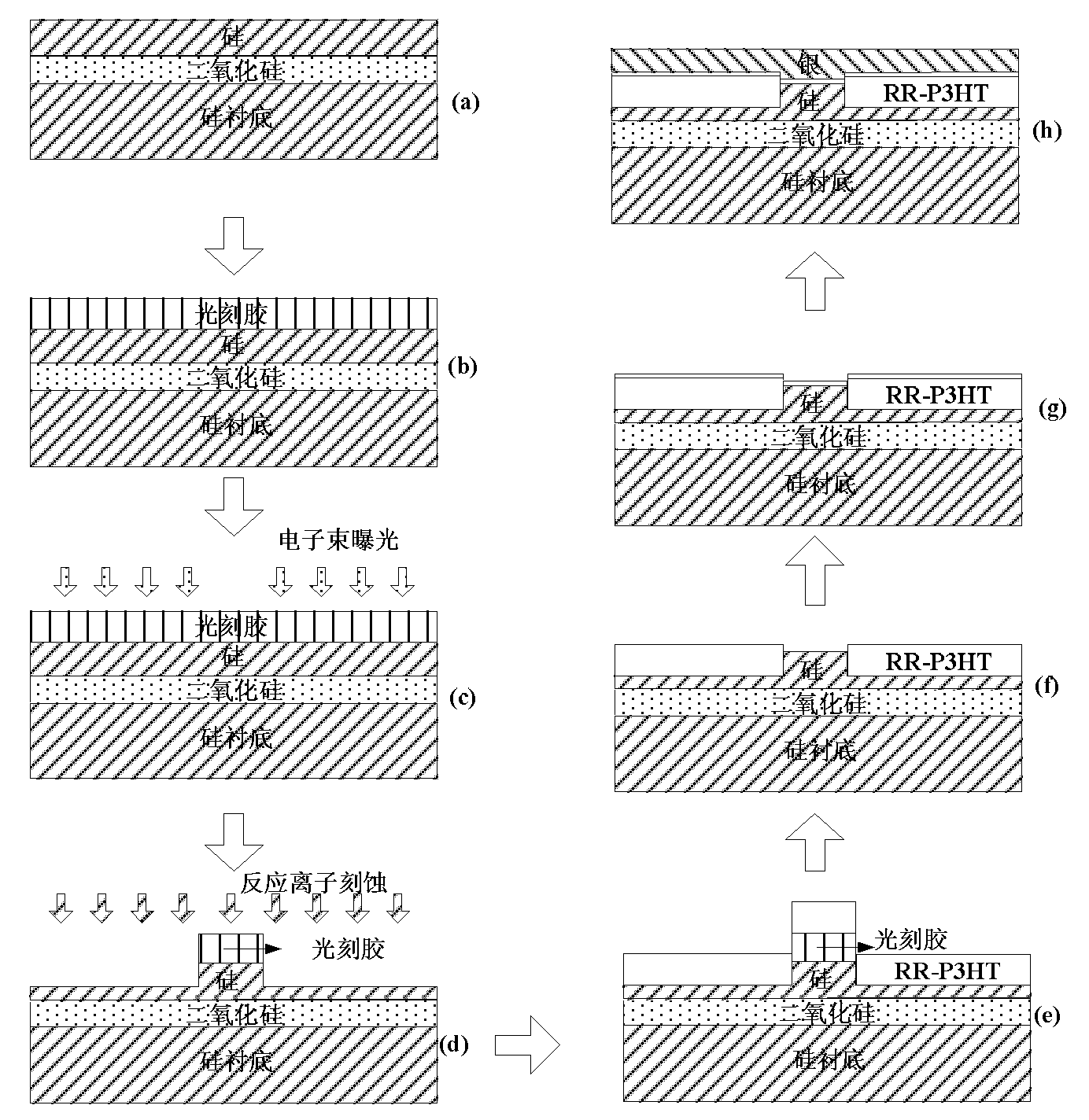

[0025] This embodiment includes the following steps:

[0026] The first step is to coat an electron beam photoresist on the SOI wafer, and then form a waveguide pattern on the silicon layer through an electron beam exposure (E-beam lithograph) system and a reactive ion etching (RIE) system;

[0027] The second step is to deposit a highly nonlinear polymer-regioregular poly-3-hexylthiophene (RR-P3HT) on the SOI ridge waveguide;

[0028] The deposition refers to: using the remaining electron beam photoresist after electron beam exposure as a mask to deposit RR-P3HT by molecular beam deposition;

[0029] The difference between the deposited thickness and the height of the SOI ridge waveguide is the step height of silver.

[0030] The third step is to remove the electron beam photoresist and RR-P3HT on it, and deposit RR-P3HT for the second time by molecular beam deposition

[0031] The thickness of the second deposition is 5nm.

[0032] The fourth step is to use the radio freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com