ZnO varistor ceramic additive as well as preparation method and application thereof

A technology of varistor ceramics and additives, which is applied in the field of varistor ceramic additives and its preparation, and can solve problems such as reducing the nonlinear coefficient of varistors and increasing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 ZnO and Sb 2 o 3 The molar ratio is 14:1

[0030] 1) Combine ZnO and Sb 2 o 3 Using absolute ethanol as the medium ball mill for 4h to obtain the slurry, in which ZnO and Sb 2 o 3 The molar ratio is 14:1;

[0031] 2) After drying the slurry obtained in step 1), grind it into a crucible for calcination, wherein the drying temperature is 80°C, the drying time is 8h, the calcination temperature is 750°C, and the calcination time is 10h;

[0032] 3) Grinding the calcined powder and sieving through a 60-mesh sieve to obtain the ZnO pressure-sensitive ceramic additive.

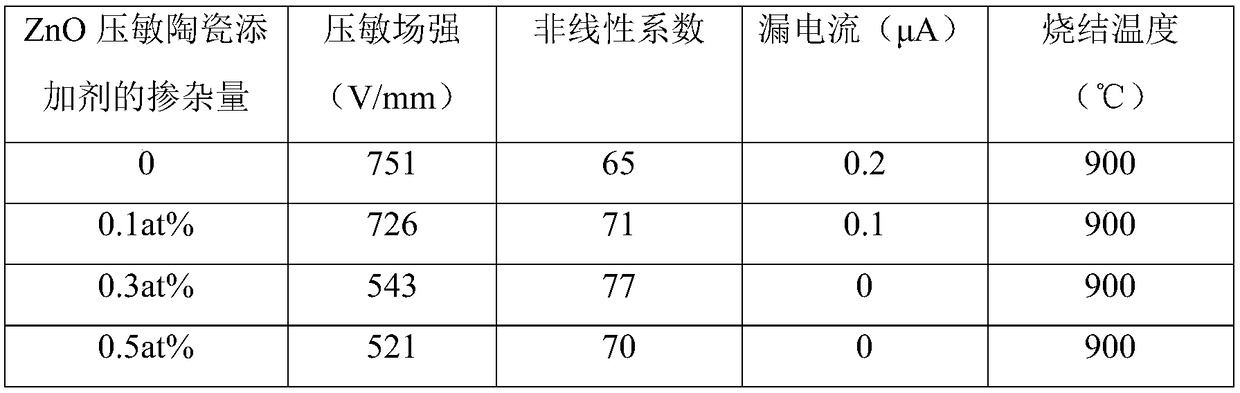

[0033] To (97at%-x)ZnO-(1at%)Bi 2 o 3 -(0.5at%)Sb 2 o 3 -(0.5at%)MnO 2 -(0.5at%) Co 2 o 3 -(0.5at%)Cr 2 o 3 X (x=0at%, 0.1at%, 0.3at%, 0.5at%) amount of ZnO varistor ceramic additives are respectively added to the initial powder of the system varistor ceramics. Weigh raw materials according to the stoichiometric ratio in the above general formula of ingredients: ZnO, Bi 2 o 3 , Sb ...

Embodiment 2

[0038] Example 2 ZnO and Sb 2 o 3 The molar ratio is 14:1

[0039] 1) Combine ZnO and Sb 2 o 3 Using absolute ethanol as the medium ball mill for 4h to obtain the slurry, in which ZnO and Sb 2 o 3 The molar ratio is 14:1;

[0040] 2) Dry the slurry obtained in step 1) and grind it, then press the powder into a large piece and put it into a crucible for calcination, wherein the drying temperature is 120°C, the drying time is 8h, and the calcination temperature is 850°C. Calcination time is 12h;

[0041] 3) Grinding the calcined powder and sieving through a 60-mesh sieve to obtain the ZnO pressure-sensitive ceramic additive.

[0042] To (97.5at%-x)ZnO-(1at%)Bi 2 o 3 -(0.5at%)Sb 2 o 3 -(0.5at%)MnO 2 -(0.5at%) Co 2 o 3 X (x=0at%, 0.2at%, 0.4at%, 0.6at%) amount of ZnO varistor ceramic additives are respectively added to the initial powder of the system varistor ceramics. Weigh raw materials according to the stoichiometric ratio in the above general formula of ingredi...

Embodiment 3

[0047] Example 3 ZnO and Sb 2 o 3 The molar ratio is 6:1

[0048] 1) Combine ZnO and Sb 2 o 3 Using absolute ethanol as the medium ball mill for 4h to obtain the slurry, in which ZnO and Sb 2 o 3 The molar ratio is 6:1;

[0049] 2) After drying the slurry obtained in step 1), grind it into a crucible for calcination, wherein the drying temperature is 80°C, the drying time is 8h, the calcination temperature is 700°C, and the calcination time is 10h;

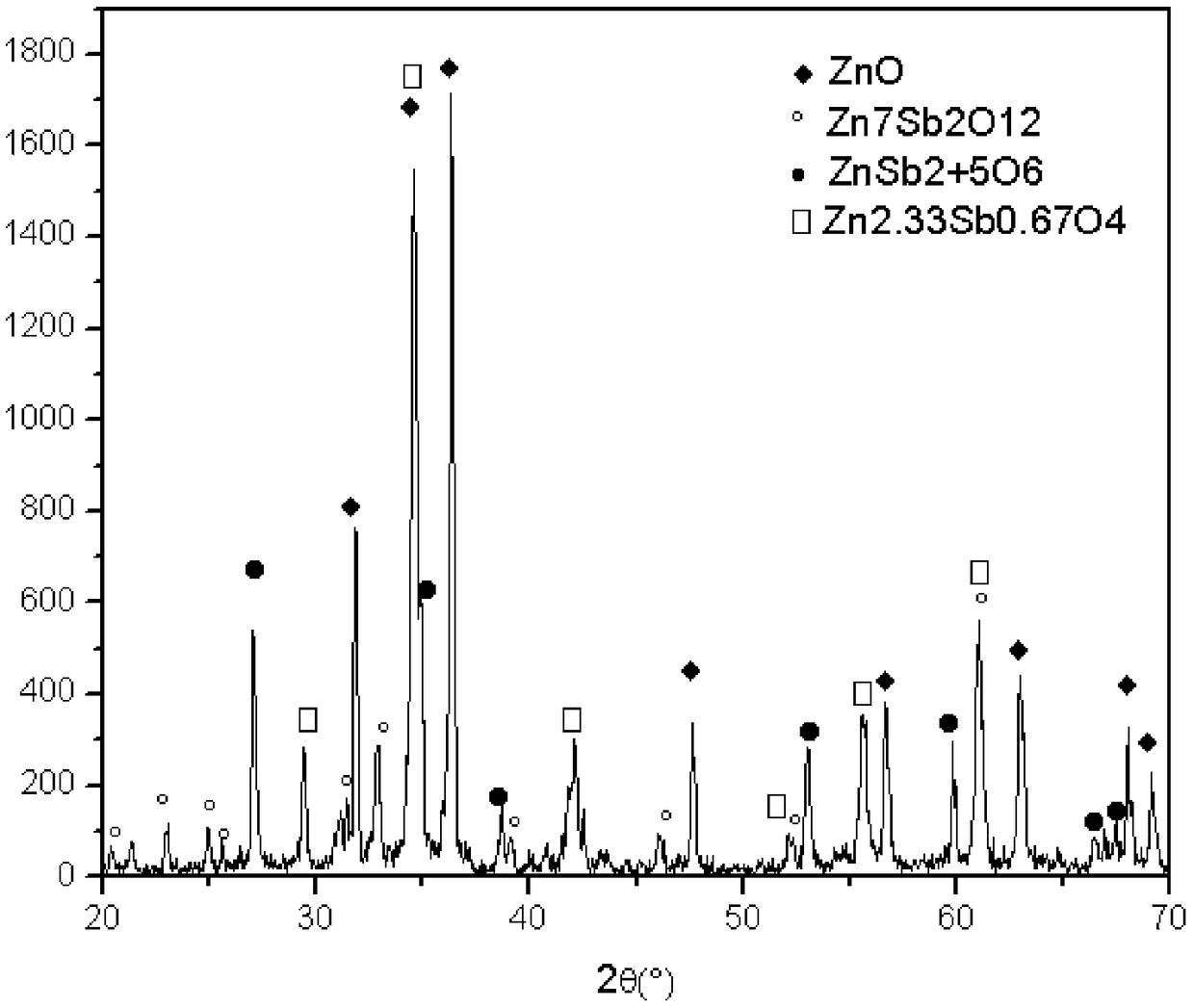

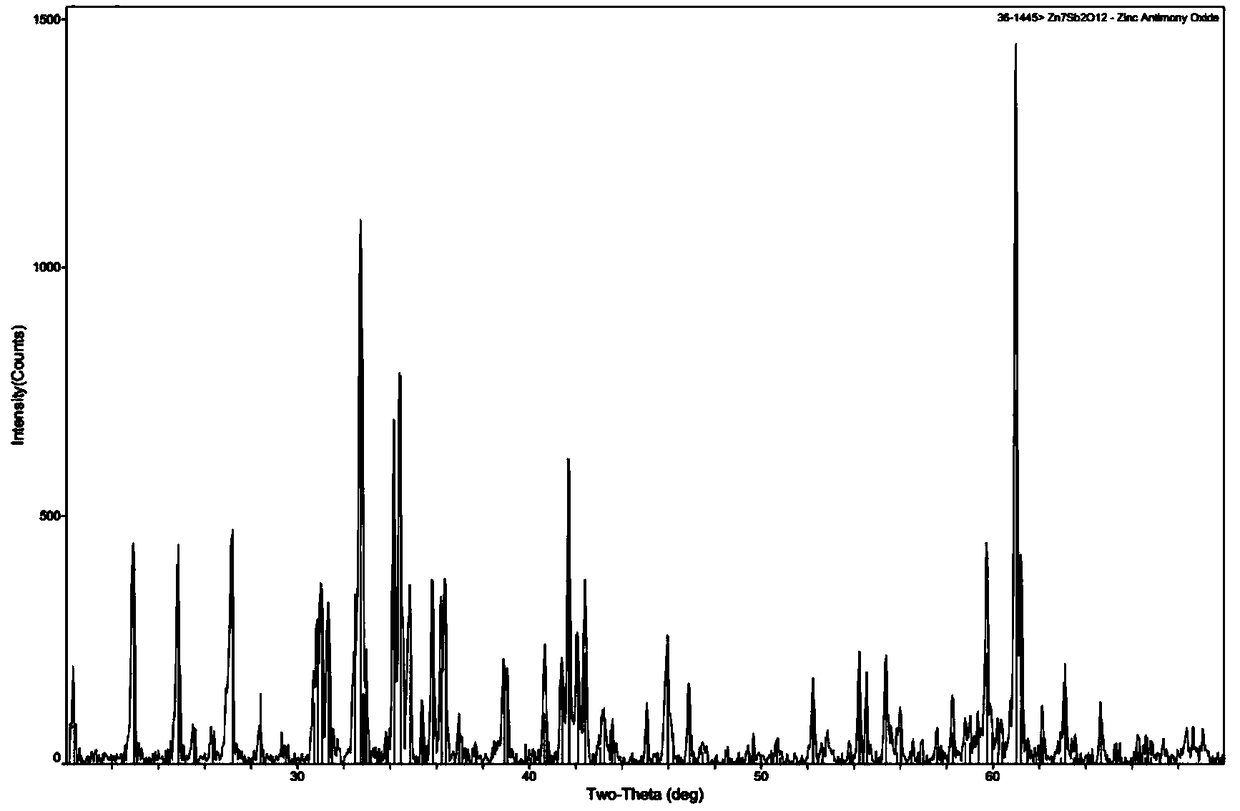

[0050] 3) Grind the calcined powder and sieve through a 60-mesh sieve to obtain the ZnO pressure-sensitive ceramic additive, which is mainly composed of ZnO, Sb 2 o 3 , Sb 2 o 4 , ZnSb 2+5 o 6 , Zn 2.33 Sb 0.67 o 4 Phase composition, in which ZnO is the main crystal phase.

[0051] To (97.5at%-x)ZnO-(1at%)Bi 2 o 3 -(0.5at%)Sb 2 o 3 -(0.5at%)MnO 2 -(0.5at%) Co 2 o 3 X (x=0at%, 0.2at%, 0.4at%, 0.6at%) amount of ZnO varistor ceramic additives are respectively added to the initial powder of the system varistor ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com