Patents

Literature

71results about How to "Excellent pressure sensitive performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

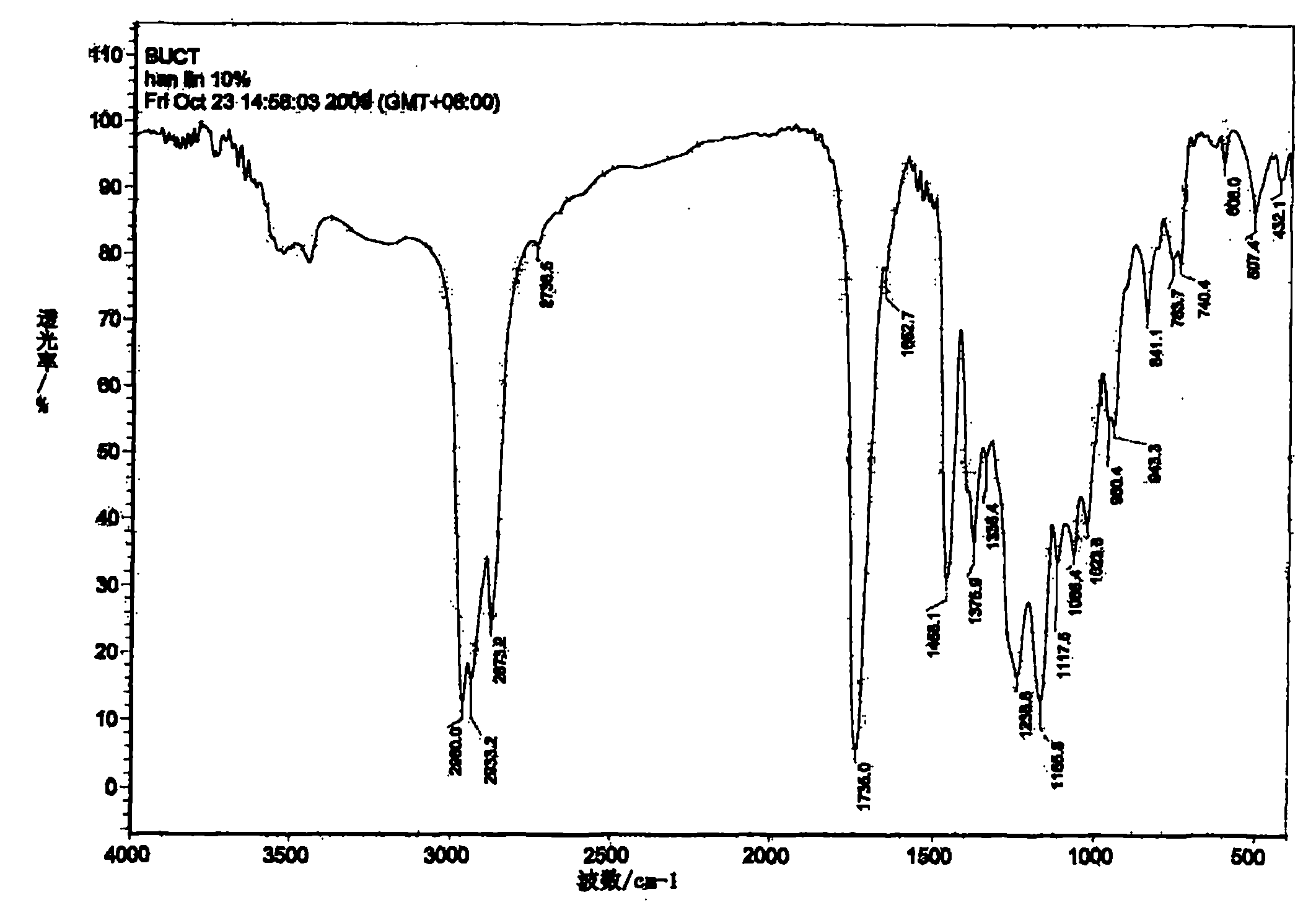

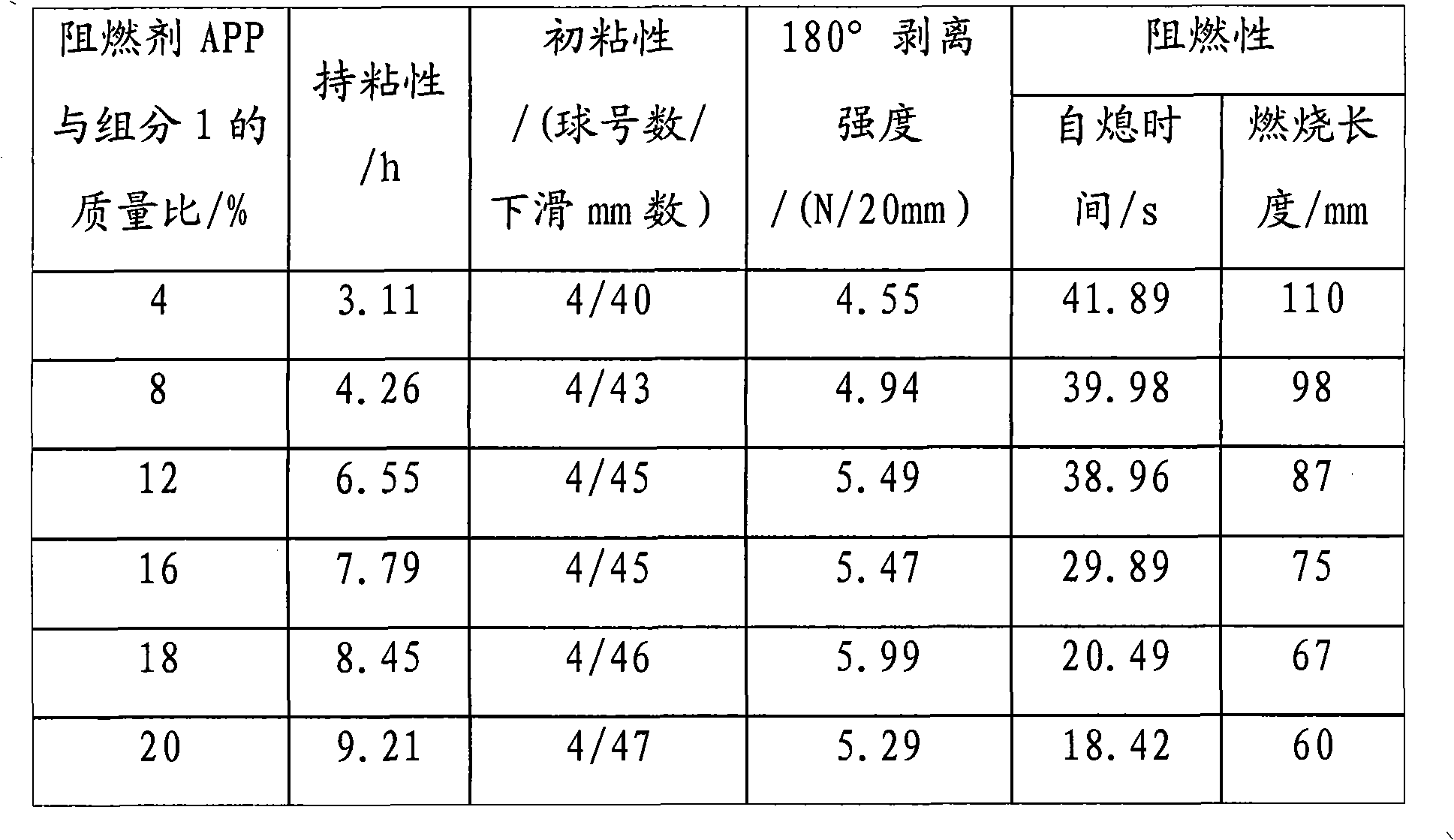

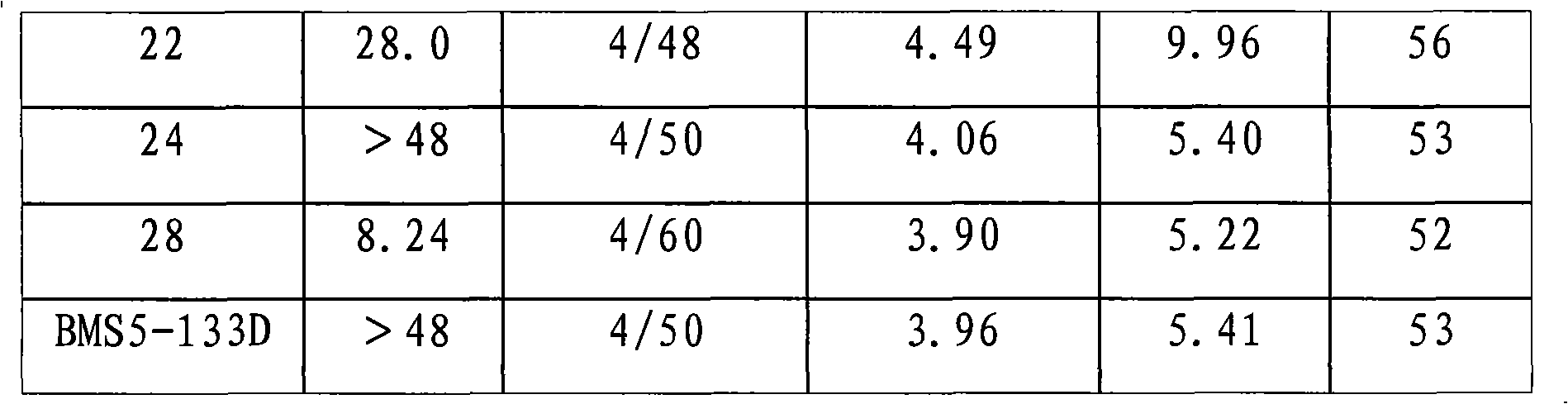

Preparation method of combined phosphorus type flame-retardant acrylate pressure-sensitive adhesive

InactiveCN101805567AImprove flame retardant performanceImprove stabilityFilm/foil adhesivesEster polymer adhesivesCarbon Dioxide / HeliumShielding gas

The invention discloses a preparation method of a combined phosphorus type flame-retardant acrylate pressure-sensitive adhesive. The preparation method comprises the following steps: adopting a free radical solution polymerization process and a multistep polymerization process to polymerize flame-retardant phosphorous acrylate monomers and common acrylate monomers to prepare a combined phosphorus type flame-retardant acrylate pressure-sensitive cement by using N2 as shielding gas under the conditions of normal pressure and the temperature of 70-85 DEG C; coating the pressure-sensitive cement, and drying to prepare the combined phosphorus type flame-retardant acrylate pressure-sensitive adhesive; and in order to better enhance the flame retardant property of the pressure-sensitive adhesive, optionally adding flame-retardant sizing to the pressure-sensitive cement, then coating, and drying. The method has a simple process, and the prepared pressure-sensitive adhesive has excellent properties and avoids the environmental pollution caused by a halogenated flame retardant.

Owner:BEIJING UNIV OF CHEM TECH

Poly acrylate composite emulsion for pressure' sensitive adhesive and its preparing and using method

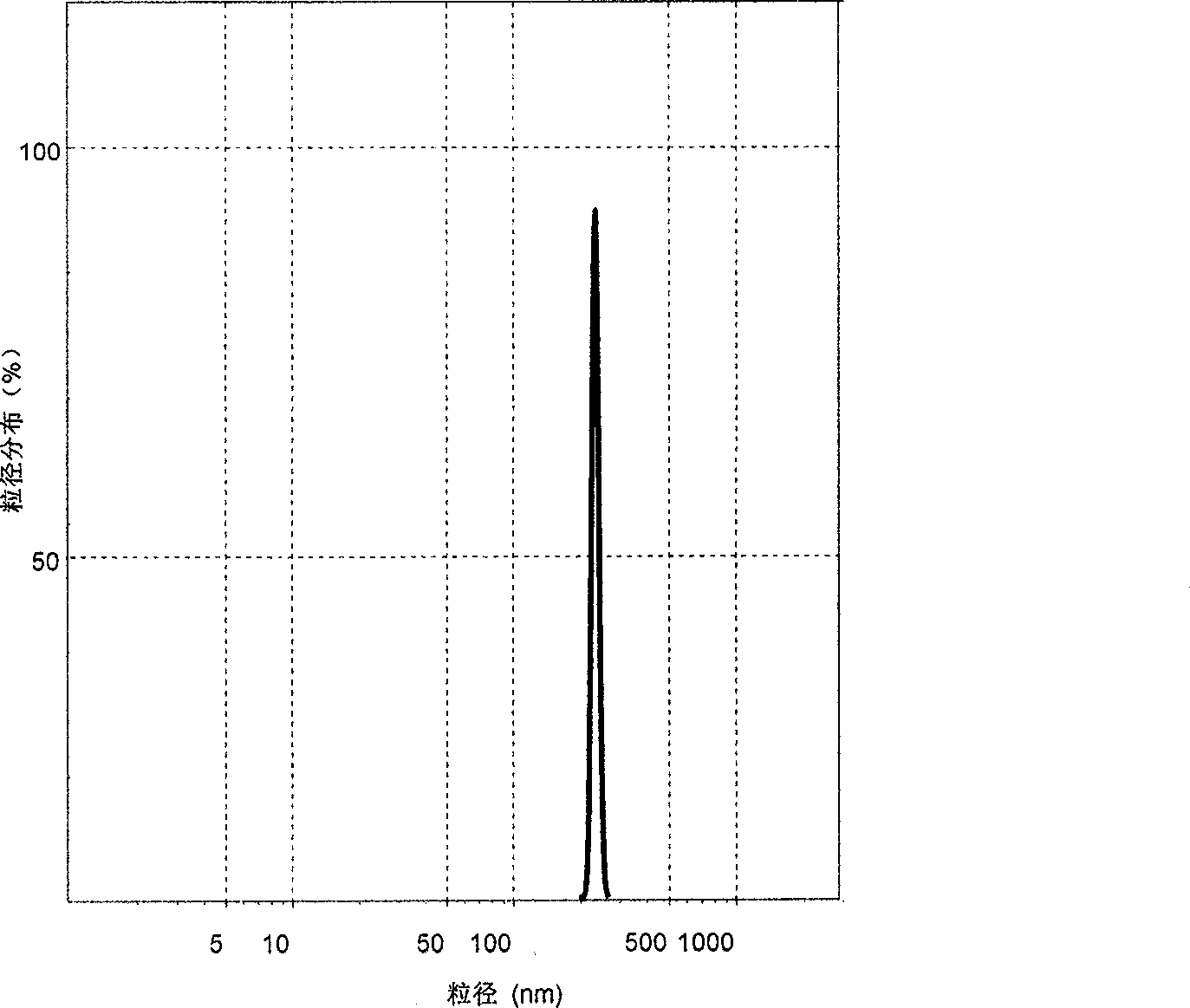

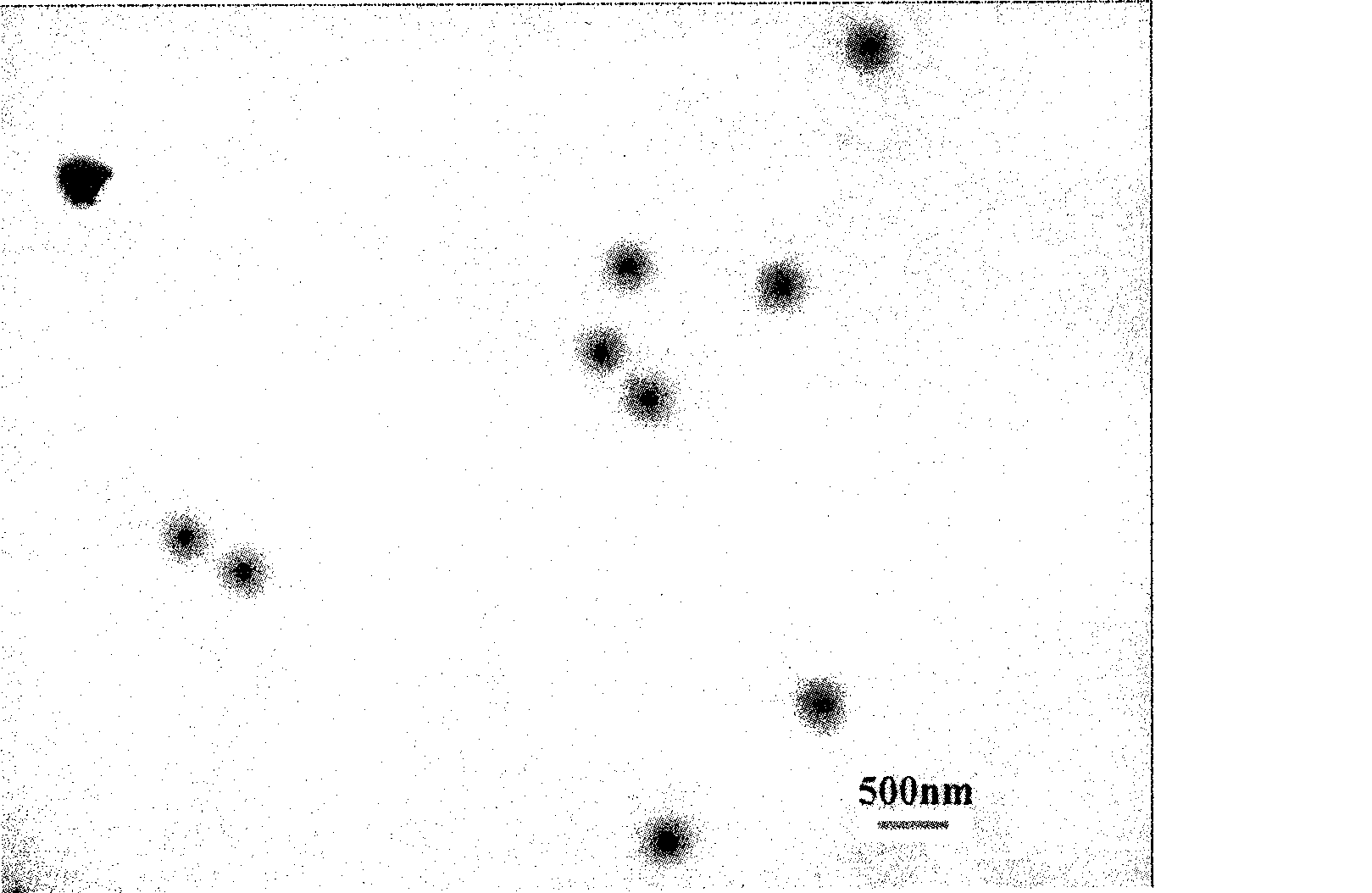

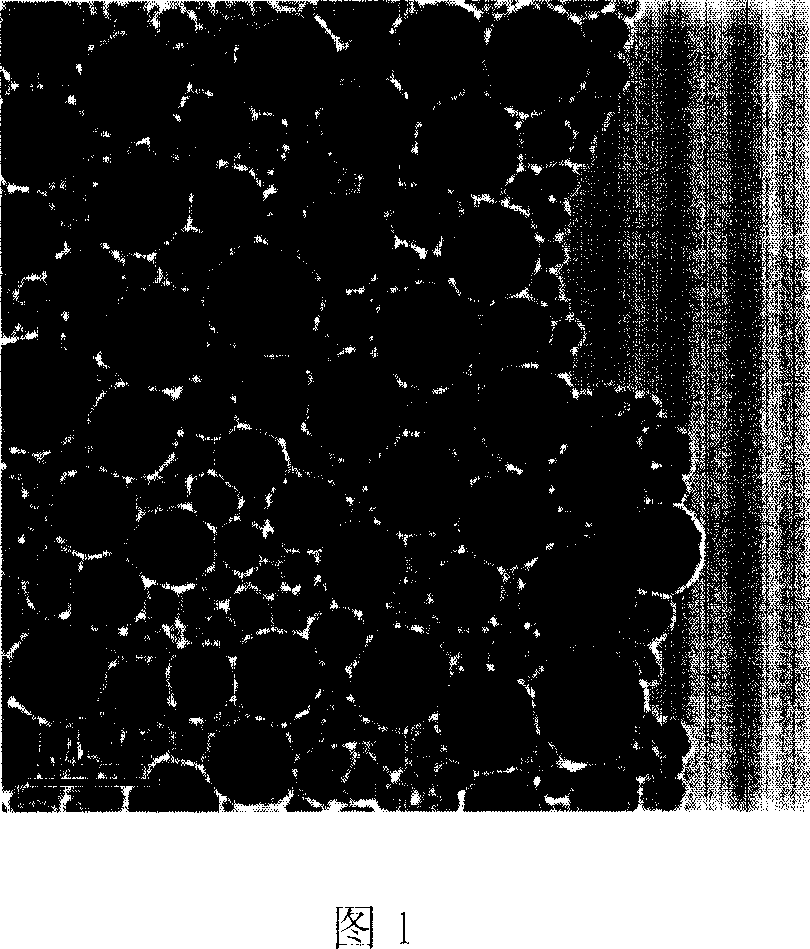

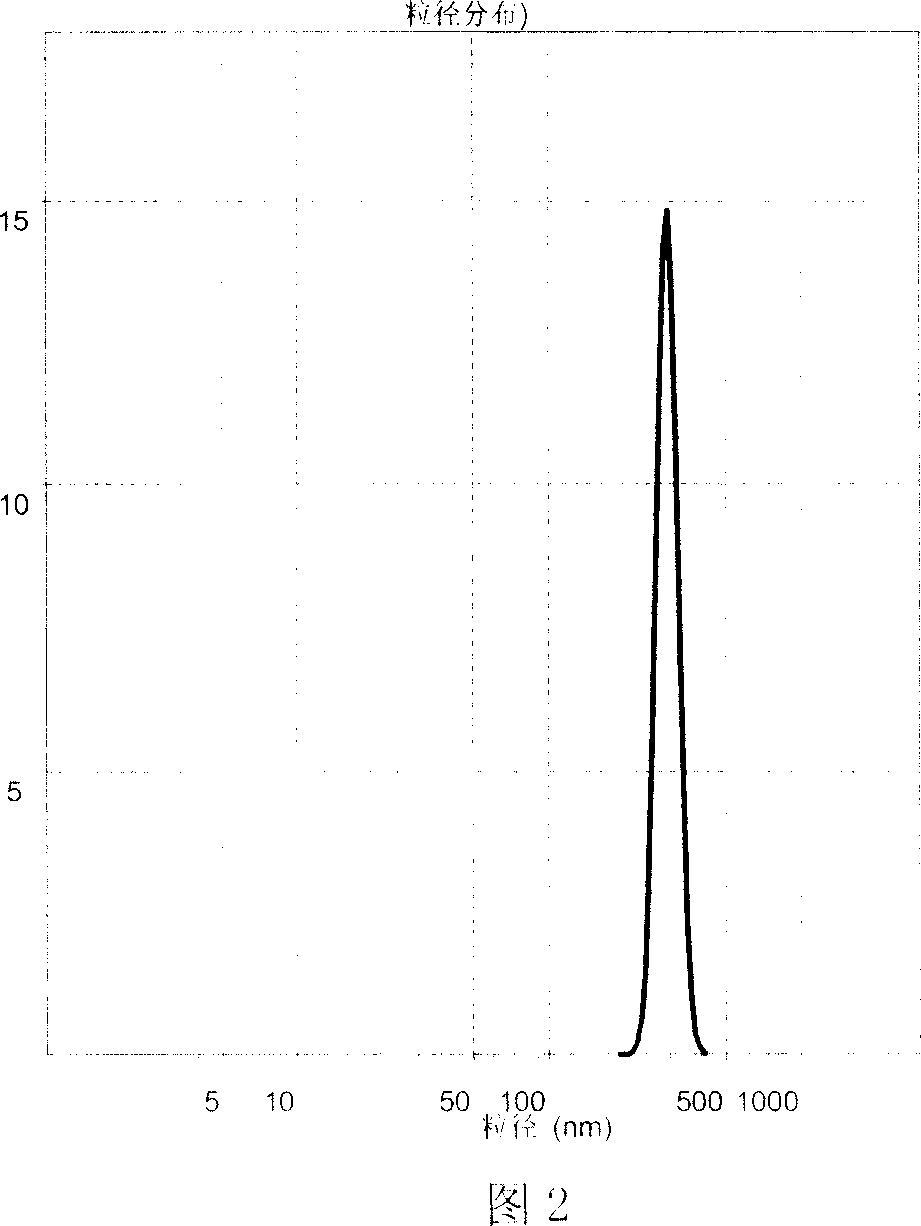

InactiveCN1944479AImprove interface compatibilityUniform particle sizeFilm/foil adhesivesEster polymer adhesivesEmulsionAcrylic acid

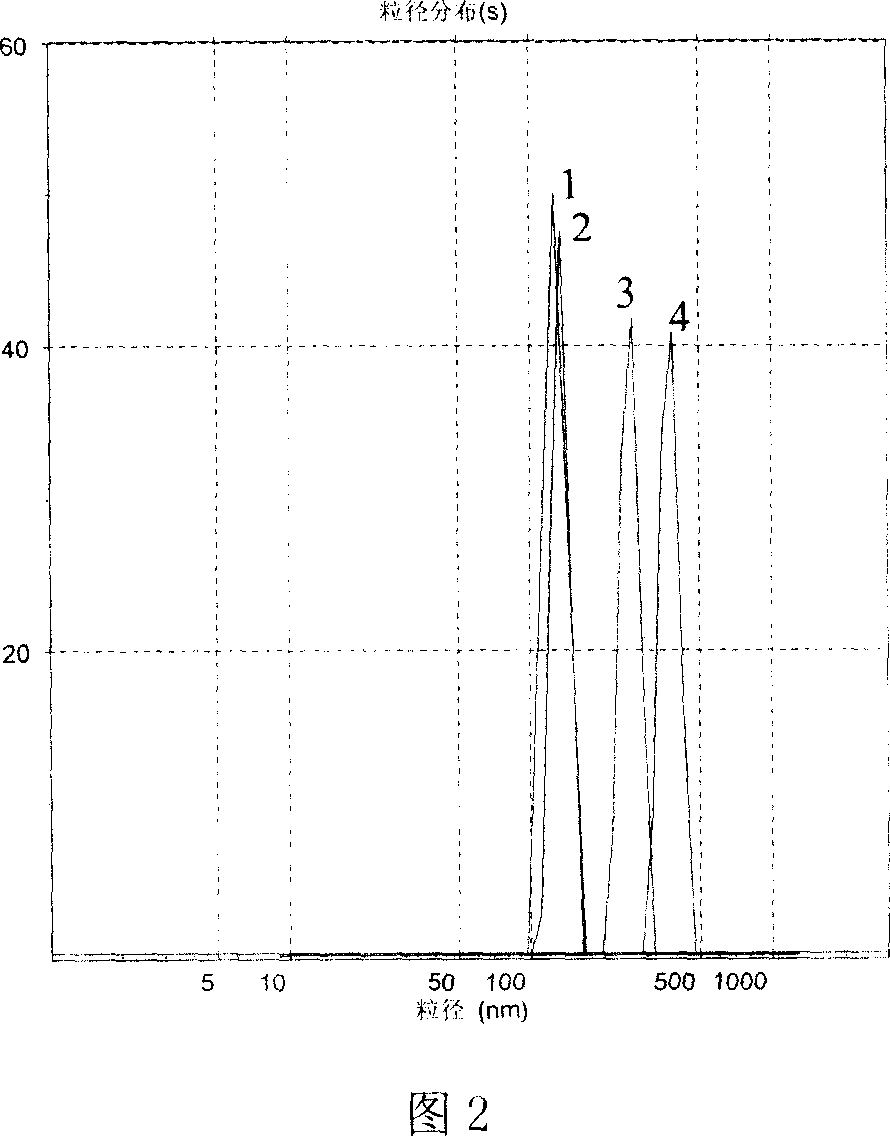

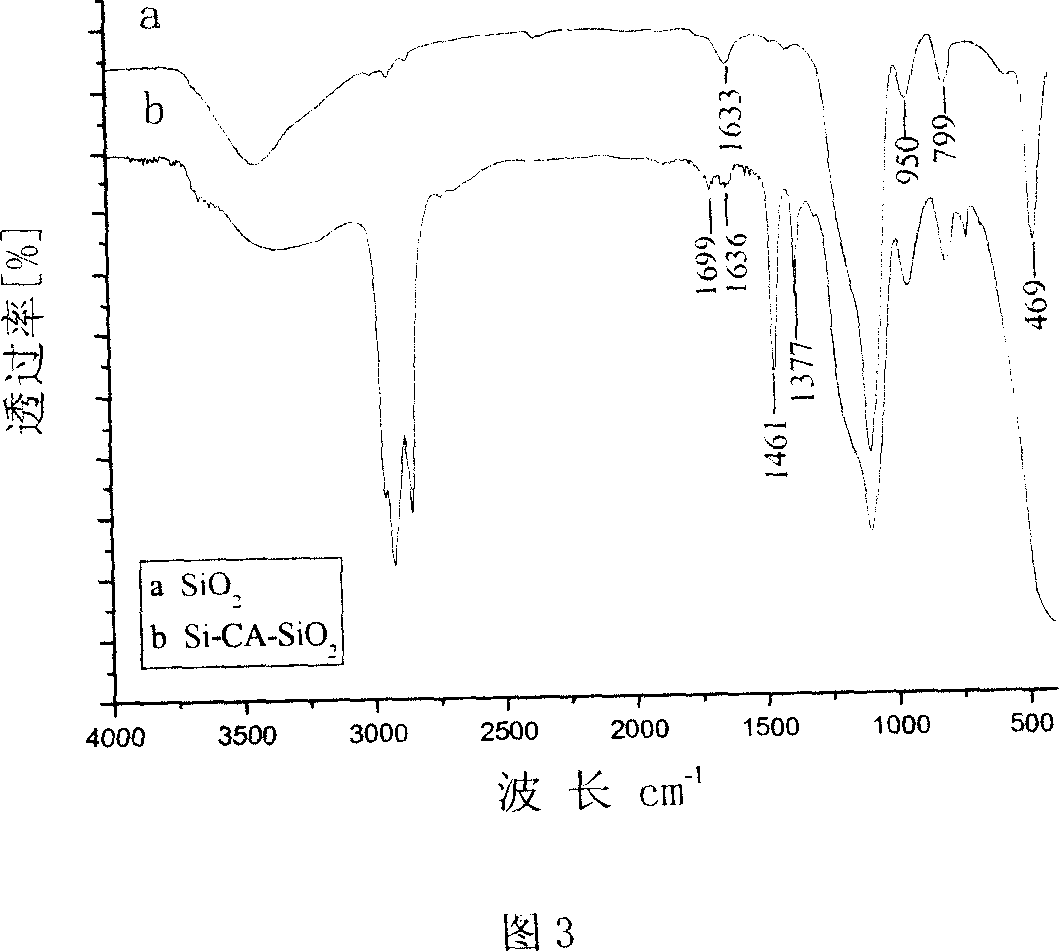

The present invention is composite polyacrylate emulsion for pressure sensitive adhesive and its preparation process and application, and relates to polyacrylate based adhesive. The composite emulsion is one core-shell structure with silane cross-linking agent surface modified nanometer silica as the core and the copolymer of acrylate and acrylic acid as the shell, and has solid content of 30-40 %, viscosity of 1-6 mPa.s, composite emulsion particle size of 250-700 nm and particle size dispersing index of 0.005-0.15. The composite polyacrylate emulsion is prepared through preparing nanometer silica alcohol sol, surface modification of nanometer silica and preparing nanometer silica-polyacrylate composite emulsion. The composite polyacrylate emulsion coating is dried to obtain the pressure sensitive adhesive with high initial adhering performance and cohesive property.

Owner:HEBEI UNIV OF TECH

Method for preparing modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive

InactiveCN103435760AGood pressure sensitivityImprove water resistanceGraft polymer adhesivesEpoxyPolyurethane dispersion

The invention discloses a method for preparing a modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The method comprises the following steps: adding polyisocyanate and low polymer polyhydric alcohol into reaction equipment, further adding a hydrophilic chain extender to react to obtain a polyurethane prepolymer, subsequently adding acrylic ester containing hydroxyl and a modified epoxy resin so as to obtain the modified polyurethane prepolymer; further adding a neutralizer to neutralize, adding water, subsequently dispersing by using a high-speed dispersing machine so as to obtain a modified waterborne polyurethane dispersoid; uniformly dripping acrylate monomer, a modified rosin resin and an initiating agent so as to obtain a modified waterborne polyurethane dispersoid; further adding a defoaming agent, and finally adding a curing agent additionally so as to obtain the modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The pressure-sensitive adhesive prepared through the method is high in primary adhesion property, release force, adhesion lasting property and high-temperature adhesion lasting property; a high-temperature-resistant pressure-sensitive adhesive tape prepared from the adhesive can meet the requirements of automobile and electronic industries. According to the invention, the preparation process is simple, the production period is short and the operation cost is low.

Owner:SOUTH CHINA UNIV OF TECH

Vacuum bag sealing adhesive tape applicable under room temperature to 220 DEG C, and preparation method thereof

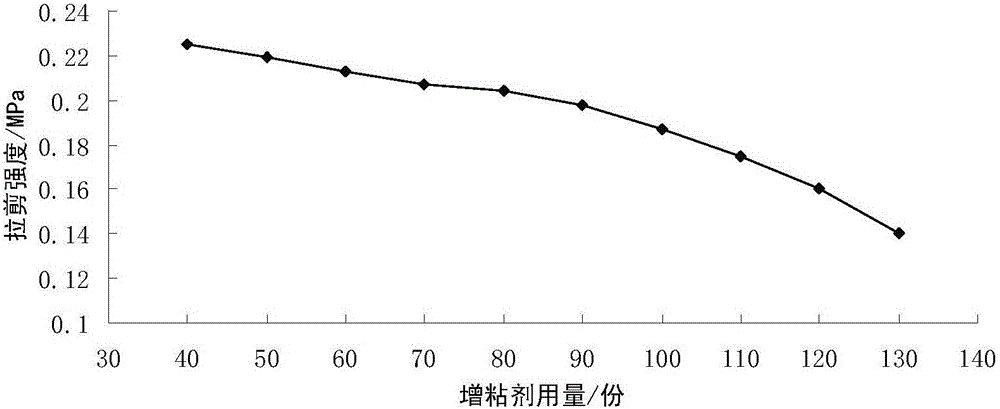

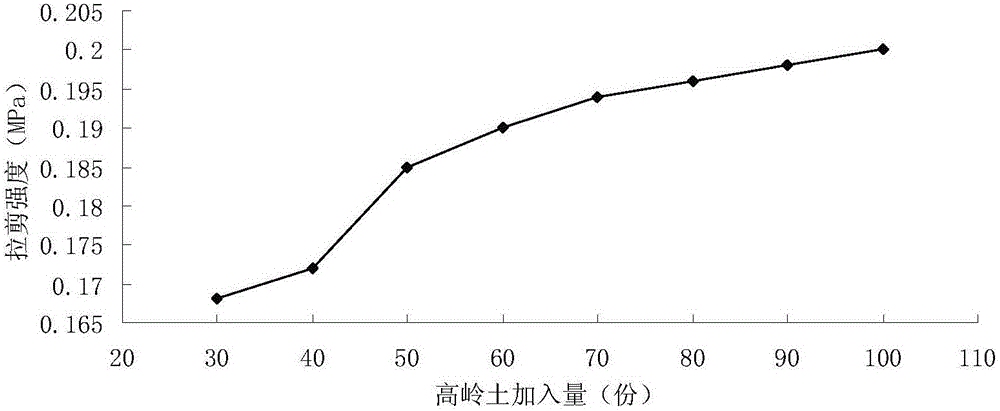

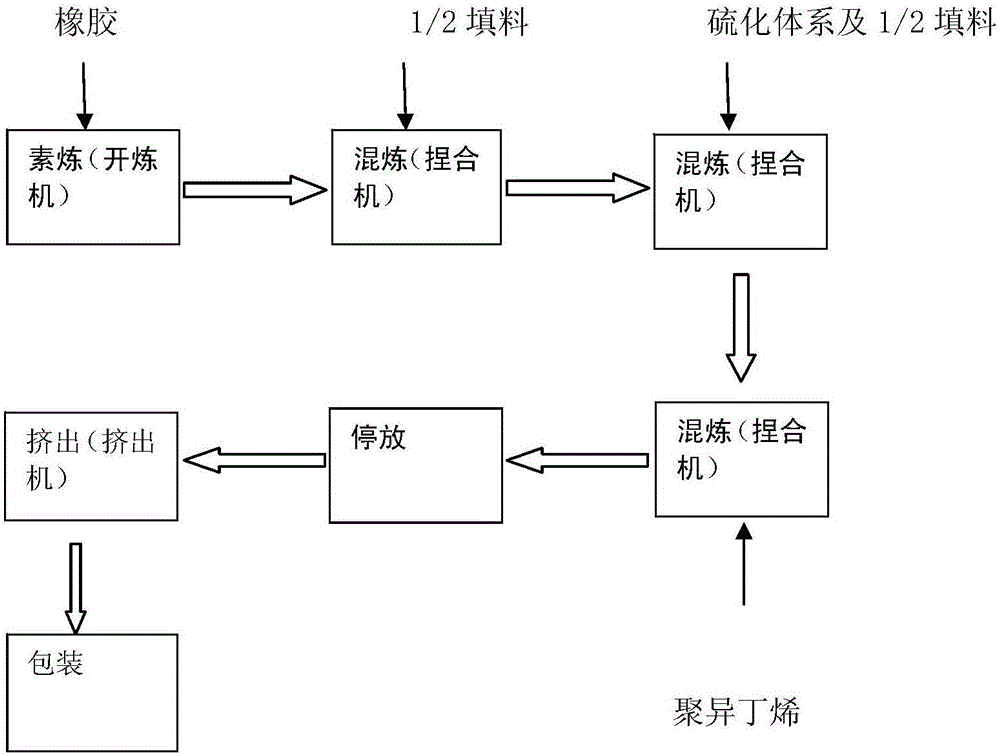

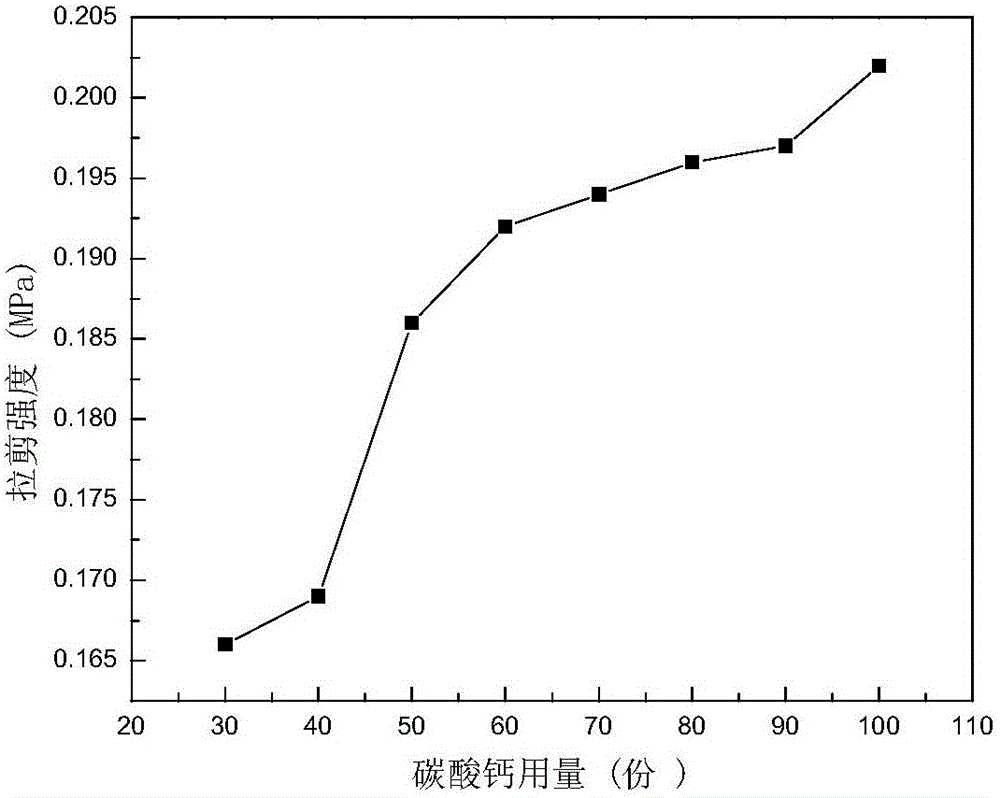

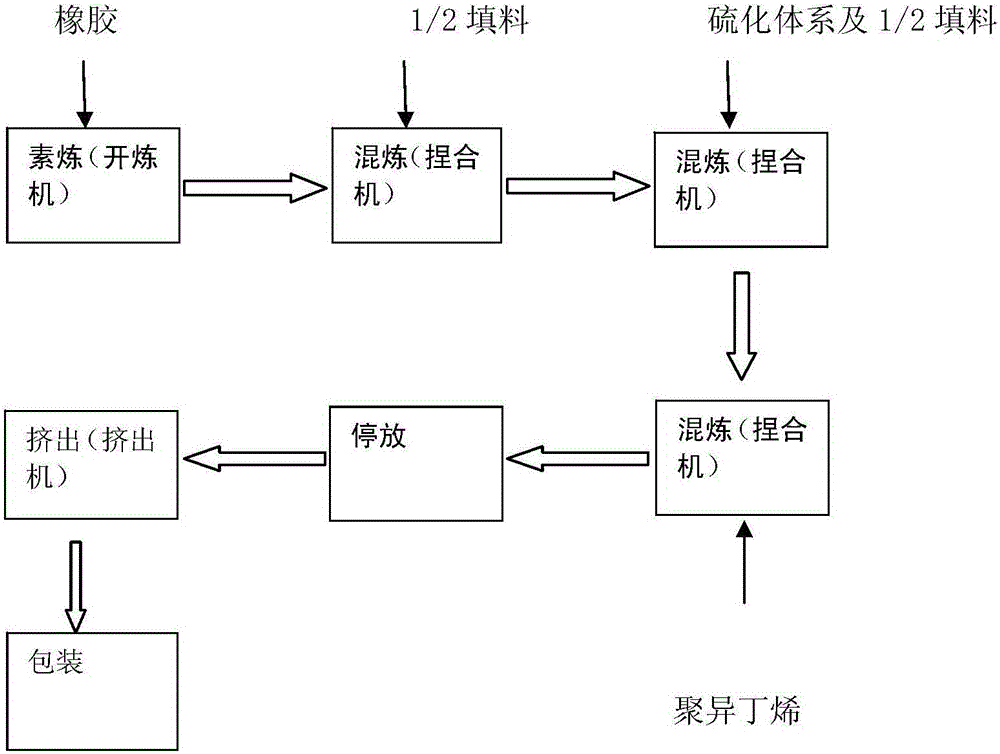

The invention relates to a pressure sensitive vacuum bag sealing adhesive tape applicable under room temperature to 220 DEG C. Chlorinated butyl rubber is adopted as the base adhesive material of the sealing adhesive tape. Tackifying resin, a filler, a vulcanizing agent, an activator, a scorch retarder, a water-absorbing agent, and a coupling agent are added to the base adhesive material. The adhesive tape has the following advantage: the air permeation of chlorinated butyl rubber is the lowest among all general rubbers, such that chlorinated butyl rubber has good air tightness; the sealing adhesive tape has good heat resistance, wherein phenolic resin vulcanized chlorinated butyl rubber has as an application temperature range from room temperature to 220 DEG C; the sealing adhesive tape is pressure sensitive, such that sealing can be realized with finger pressure, wherein the pressure sensitivity is provided by polyisobutylene; the sealing adhesive tape has good adhesiveness on various sealing films and molds. A vacuum bag prepared with the sealing adhesive tape can provide pressure close to 1atm. With the sealing adhesive tape, long-time sealing can be realized under room temperature to 220 DEG C, and leakage is prevented. The sealing adhesive tape is convenient to use.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Preparation of acrylic ester copolymer emulsion for pressure-sensitive adhesive

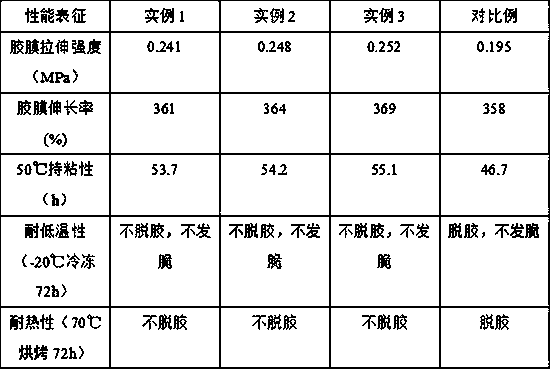

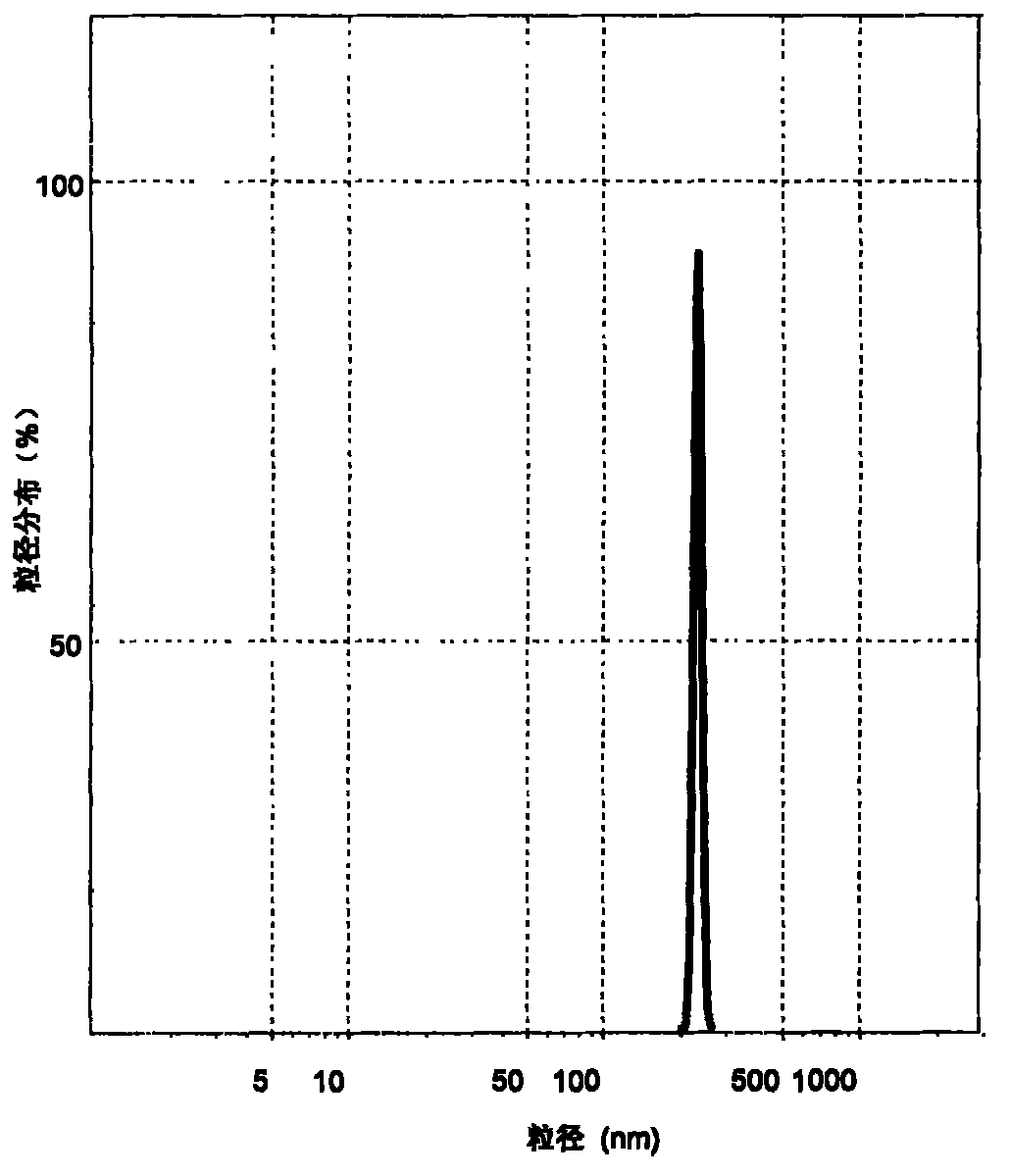

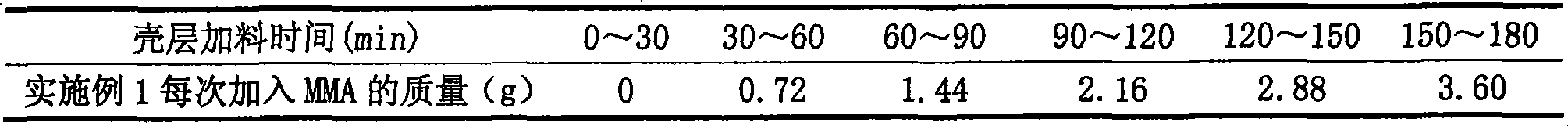

ActiveCN101412783AGood pressure sensitivityImprove performanceEster polymer adhesivesEmulsionOrganic inorganic

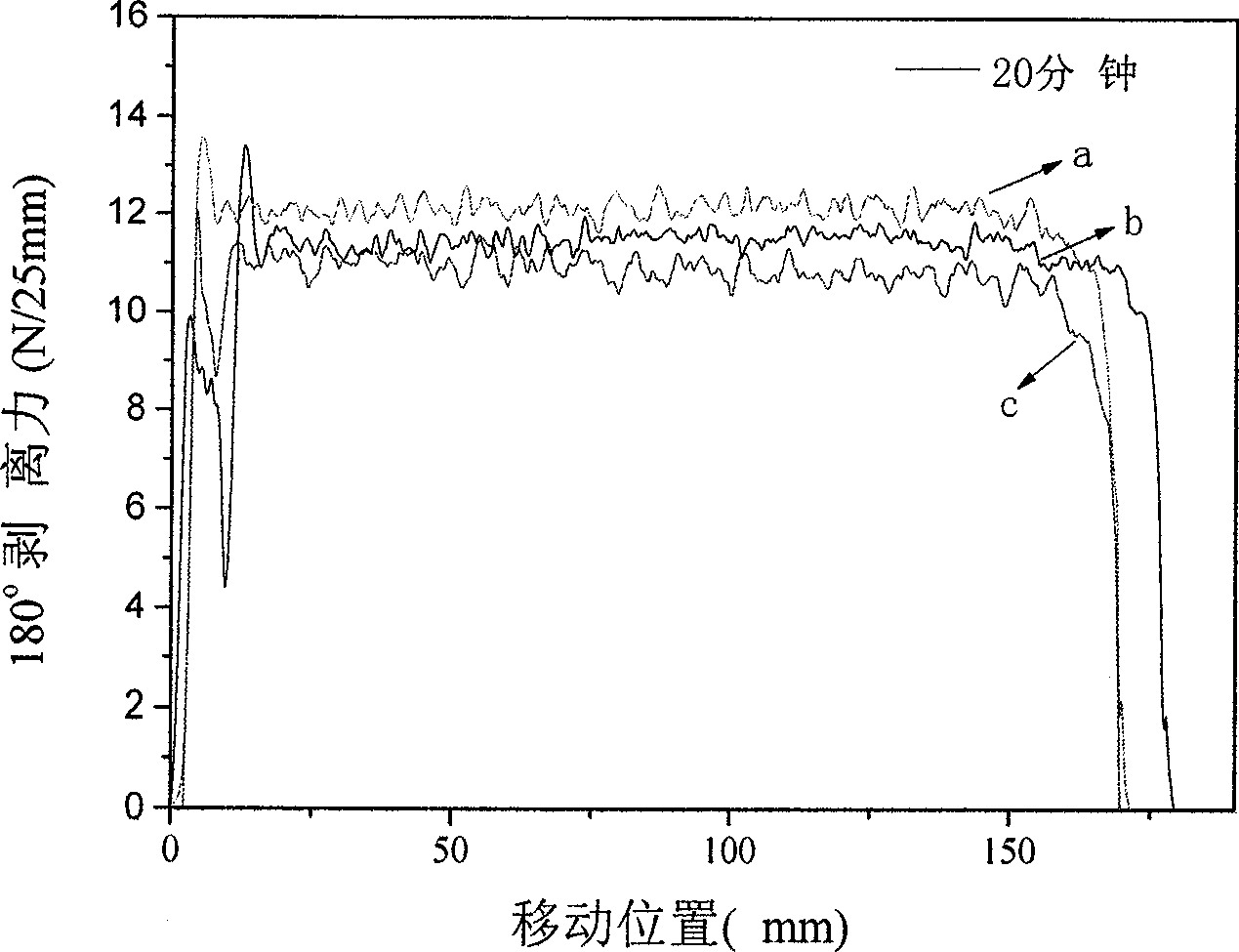

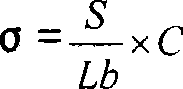

The invention relates to a method for preparing an acrylate polymer emulsion used for a pressure sensitive adhesive, which belongs to an adhesive based on acrylate polymer. The method for preparing the acrylate polymer emulsion used for the pressure sensitive adhesive comprises the following steps: (1) preparation of a seed emulsion; (2) pre-emulsification of shell layer monomers; and (3) gradient feeding of a shell layer. The method adopts the seed emulsion polymerization technology to drip a hard monomer, namely methyl methacrylate (MMA) into the shell layer, so that the concentration is subjected to discontinuous change and the organic-inorganic acrylate polymer emulsion provided with an obvious core-shell structure is prepared, wherein nano silicon dioxide is taken as a core and a copolymer of acrylic ester and acrylic monomers is taken as the shell layer; and the hard monomer of the shell layer is subjected to concentration gradient change. The acrylate polymer emulsion can be used as the pressure sensitive adhesive after drying and film forming; the prepared pressure sensitive adhesive has the advantages of high continuous viscous force and reduction of the residual gum content under the condition of gum peeling; and the initial adhesion and the peeling strength can be improved when the continuous viscous force is larger.

Owner:HEBEI UNIV OF TECH

Process for preparing poly acrylate composite emulsion for pressure sensitive adhesive

The present invention is preparation process of composite polyacrylate emulsion for pressure sensitive adhesive, and relates to polyacrylate based adhesive. The composite emulsion in core-shell structure is prepared through compounding nanometer silica hydrosol and polyacrylate emulsion. Specifically, the preparation process includes the following steps: 1. preparing seed emulsion, of which the nanometer silica hydrosol is prepared through sodium silicate hydrolyzing process and has solid content of 42-45 %, particle size of 50-100nm and particle size dispersing index of 0.05-0.195; 2. pre-emulsifying of shell monomer; and 3. preparing nanometer silica polyacrylate composite emulsion. The composite polyacrylate emulsion coating is dried to obtain the pressure sensitive adhesive with high initial adhering performance and good long time adhering performance.

Owner:HEBEI UNIV OF TECH

Sealing rubber strip for vacuum bag used at room temperature to 200 DEG C and preparation method for sealing rubber strip

The invention relates to a sealing rubber strip for a vacuum bag used at room temperature to 200 DEG C and a preparation method for the sealing rubber strip. By taking butyl rubber as a basic rubber material, tackifying resin, filler, a vulcanization system, a water absorbent and a coupling agent are added into the sealing rubber strip. The sealing rubber strip provided by the invention has the advantages that butyl rubber is the lowest in air permeability among all universal rubber and is good in air impermeability. The sealing rubber strip has a good heat-resisting performance, and the using temperature of the butyl rubber vulcanized by phenolic resin is ranged from room temperature to 200 DEG C; the sealing rubber strip is pressure-sensitive and can be sealed by finger pressing; the sealing rubber strip has a good adhesive performance on various sealing films and dies; the sealing rubber strip has relatively high tensile strength; the water absorbent is used to absorb water released from the high-temperature vulcanized phenolic resin, so that air bubbles generated by high-temperature vulcanization of the sealing rubber strip is avoided; the sealing rubber strip used is easy to removed, and the residual sealing rubber strip is not left on the die. The vacuum bag prepared by the sealing rubber strip can provide a pressure close to 1 atm and the sealing rubber strip can be used for sealing without leakage for a long time from room temperature to 200 DEG C; the sealing rubber strip is convenient to use.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

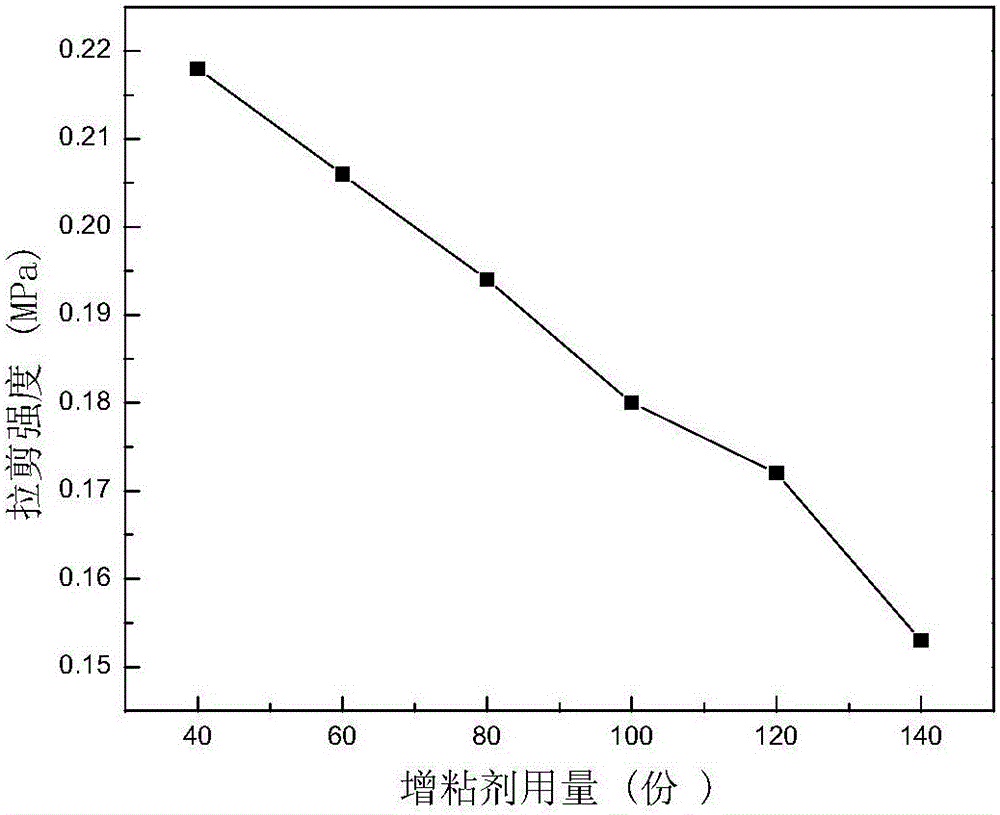

Pressure-sensitive adhesive applied to ultra-thin double faced adhesive tape and preparation method of pressure-sensitive adhesive

ActiveCN104087215AExcellent pressure sensitive performanceGood weather resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAluminium acetylacetonateAcetylacetone

Owner:东莞宏石功能材料科技有限公司

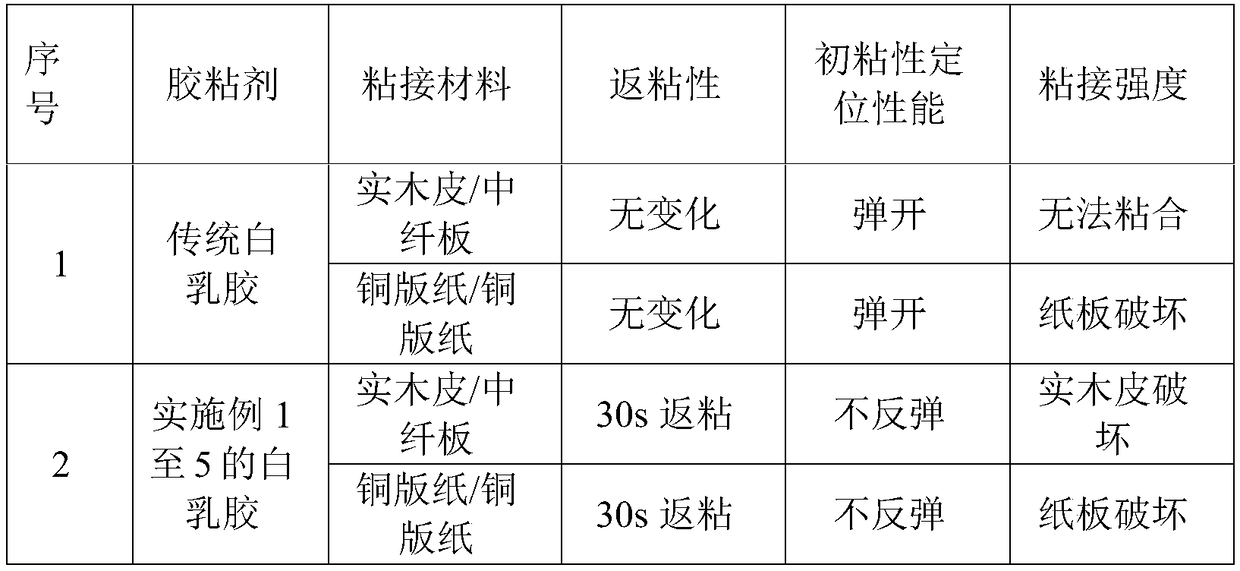

Rewetting repairable modified waterborne white latex and preparation method thereof

ActiveCN109306250ASolve irreparable technical problemsSensitive rehumidity responseMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPersulfateAdhesive

The invention relates to the technical field of waterborne adhesives and in particular relates to rewetting repairable modified waterborne white latex and a preparation method thereof. A formula comprises the following components: 35.0 to 50.0 parts of de-ionized water, 10.0 to 20.0 parts of protective colloid polyvinyl alcohol, 0.5 to 2.5 parts of a non-ionic emulsifier, 0.5 to 2.5 parts of a buffering agent, 0.5 to 1.5 parts of a persulfate initiator, 0.01 to 0.05 part of a chain transfer agent dodecyl mercaptan, 25.0 to 54.0 parts of vinyl acetate, 5.0 to 15.0 parts of butyl acrylate, 5.0 to 15.0 parts of a carboxyl-containing polymerizable monomer, a crosslinking agent and the like. Compared with the prior art, the white latex provided by the invention can be used for realizing secondary adhesion through the effect of water and the technical difficult in the prior art that the white latex cannot be repaired after the white latex is cured into a film is overcome; the wet-state adhesion performance of the white latex is greatly improved; the rewetting repairable modified waterborne white latex has the advantages of rapid rewetting viscosity response, good initial adhesion positioning and high bonding strength.

Owner:DONGGUAN STAR COSM POLYMER

Natural adhesive

InactiveCN103666368AIncrease stickinessStrong thickeningNon-macromolecular adhesive additivesStarch adhesivesRosinGum arabic

The invention relates to the technical field of adhesives, and in particular relates to a natural adhesive which is nonhazardous and high in adhesion degree. The natural adhesive is characterized by being prepared from the following components by mass: 80-90% of vegetable gelatin, 80-90% of animal glue, 0.5-5% of boric acid, 0.2-4% of potassium sorbate, 0.5-5% of methylcellulose, 0.3-4% of ethanol and the balance of water, wherein the vegetable gelatin is characterized by being prepared from one or more of Arabic gum, rosin and dextrin; the animal glue is characterized by being prepared from one or more of shellac and bone glue. The natural adhesive selects vegetable gelatin and animal glue which are non-pollution, nonhazardous, pure and natural as main machining raw materials, the viscosity is improved on the basis of the conventional adhesive, and meanwhile, no harm can be resulted for human bodies.

Owner:栾晓健

Plastic label adhesive and preparation method thereof

InactiveCN105647441AImprove pass rateHigh viscosityNon-macromolecular adhesive additivesStarch derivtive adhesivesAmmonium sulfateSolvent

The invention discloses a plastic label adhesive which comprises water, hydroxypropyl distarch phosphate, polyvinyl alcohol, vinyl acetate, butyl acrylate, vinyl versatate, dibutyl maleate, ethylene glycol, tributyl citrate, polyisobutylene, alkyl phenol polyoxypropylene, sodium dodecyl benzene sulfonate and ammonium persulfate. The invention also discloses a preparation method of the plastic label adhesive. The preparation method mainly comprises a solvent technique and polymerization reaction. The preparation method is simple and easy to implement, is nontoxic and environment-friendly in the preparation process, and has the advantage of low preparation cost. The label adhesive has higher adhesive force for plastics under the condition that no solvent is allowed, has certain pressure sensitiveness, and is suitable for both manual and mechanical bonding.

Owner:苏州市丛岭胶粘剂有限公司

Ultraviolet curing solvent-free medical pressure sensitive adhesive and preparation process thereof

InactiveCN109575848AExcellent pressure sensitive performanceGood weather resistanceFilm/foil adhesivesEster polymer adhesivesBenzoyl peroxideUltraviolet

The invention relates to the technical field of medical pressure sensitive adhesives, and especially relates to an ultraviolet curing solvent-free medical pressure sensitive adhesive and a preparationprocess thereof. The pressure sensitive adhesive includes, by weight, the following components: 0-50 parts of butyl acrylate, 10-50 parts of 2-ethylhexyl acrylate, 0-2 parts of acrylic acid, 0-5 parts of 2-hydroxyethyl acrylate, 10-80 parts of ethyl acetate, 0.2-2 parts of benzoyl peroxide, 1.5-3 parts of dilauroyl peroxide, 5-30 parts of terpene hydrocarbon and phenolic resin, and 0.1-2 parts ofa photoinitiator. A medical pressure sensitive adhesive product prepared by utilizing the ultraviolet curing solvent-free medical pressure sensitive adhesive of the invention has high adhesion, simultaneously has good retention force, and greatly satisfies requirements for the adhesion more than 1kg / in and the retention force more than 24 hours of the medical pressure sensitive adhesive product.

Owner:KUNSHAN SUMEI FINE CHEM CO LTD

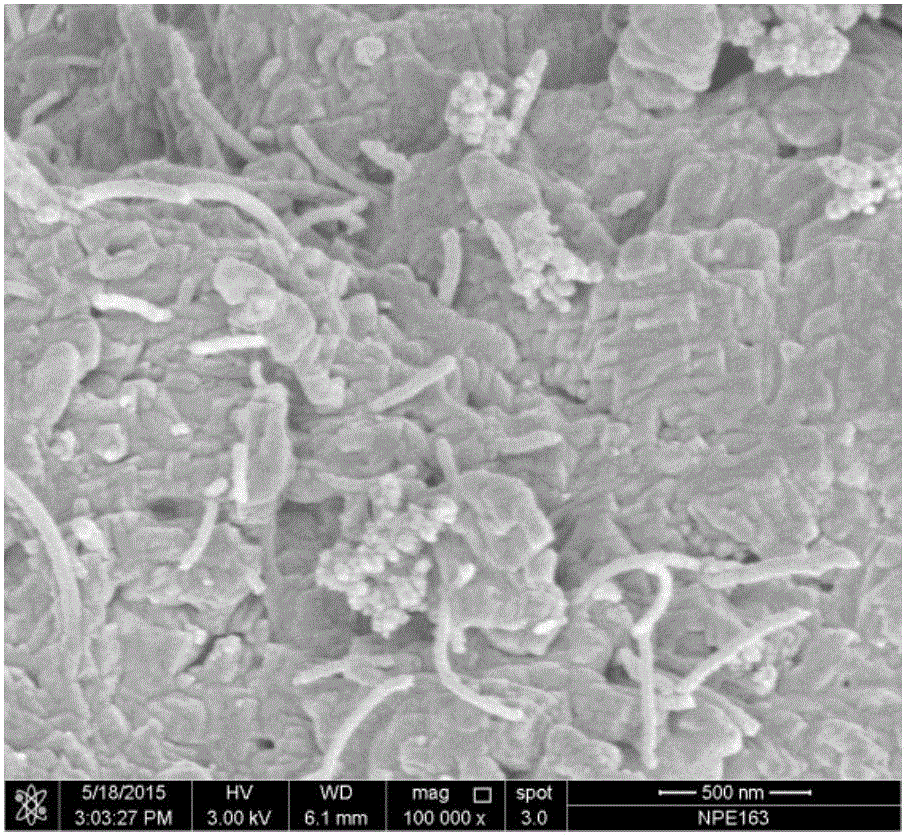

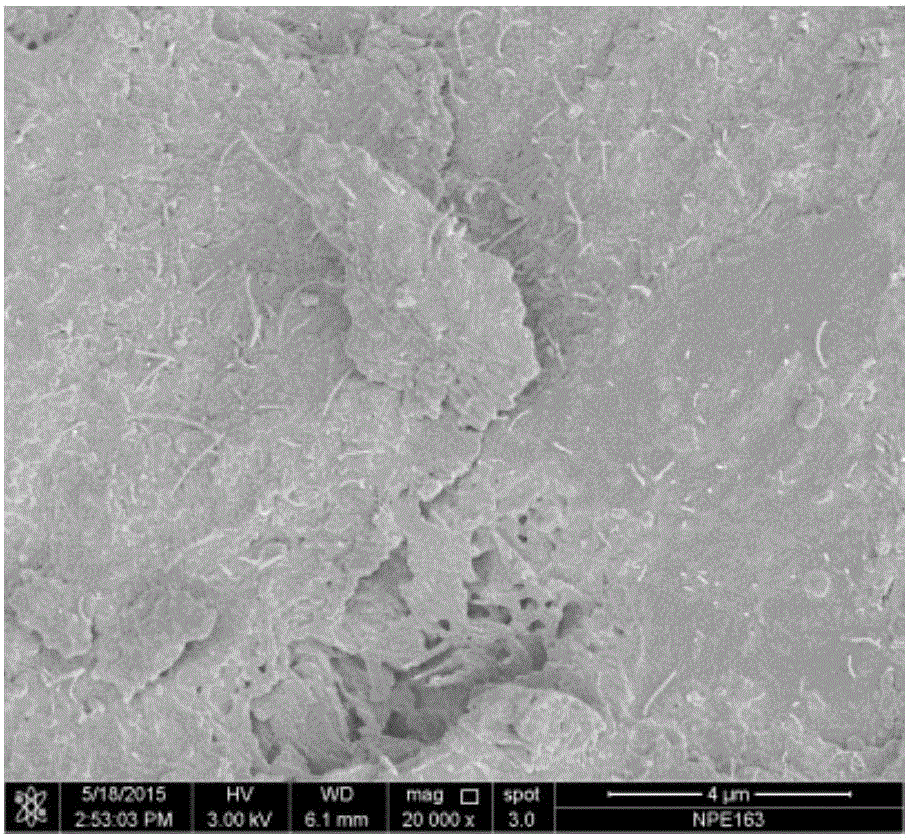

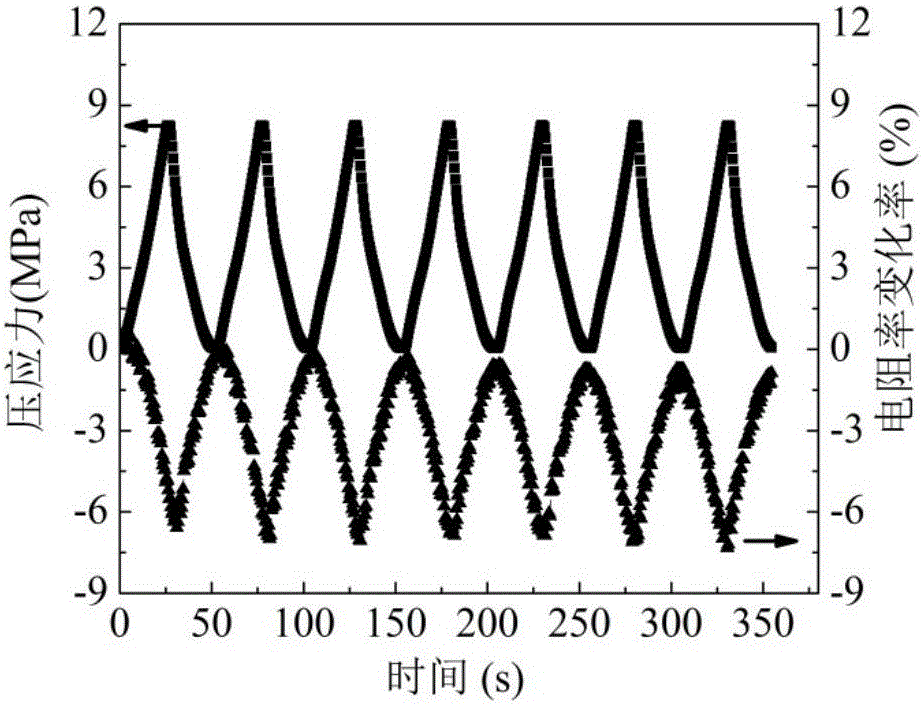

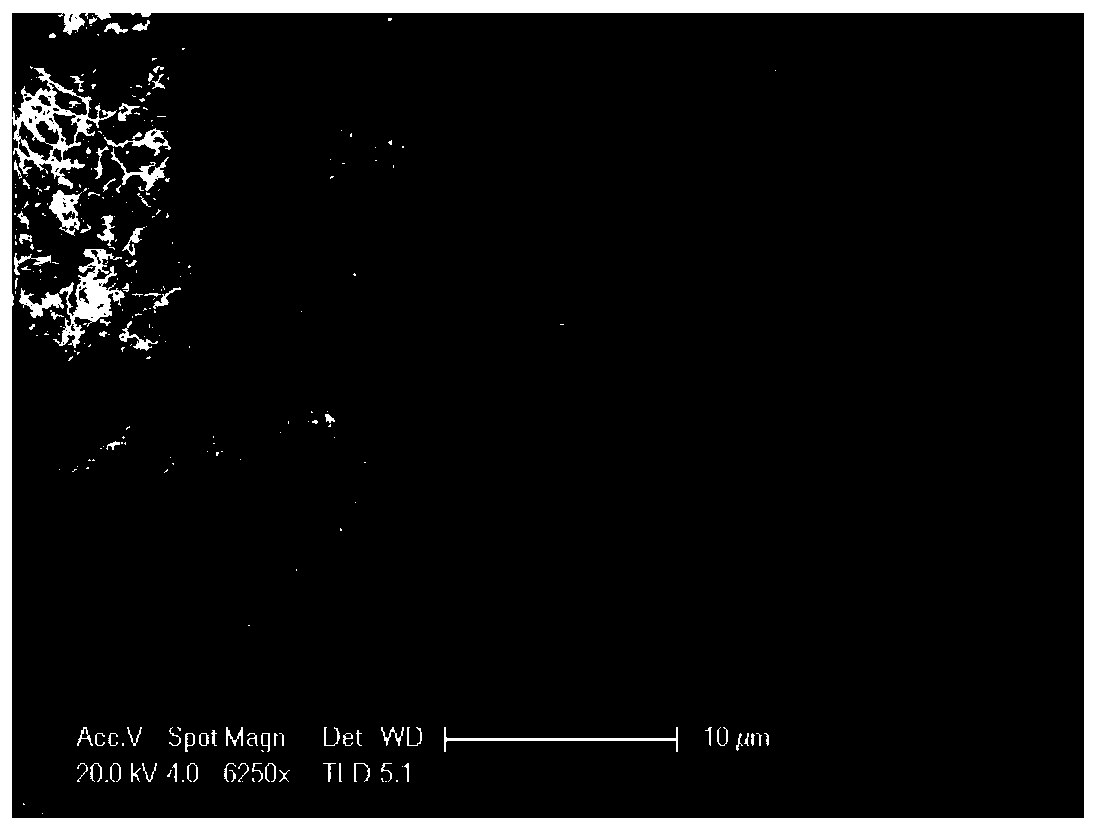

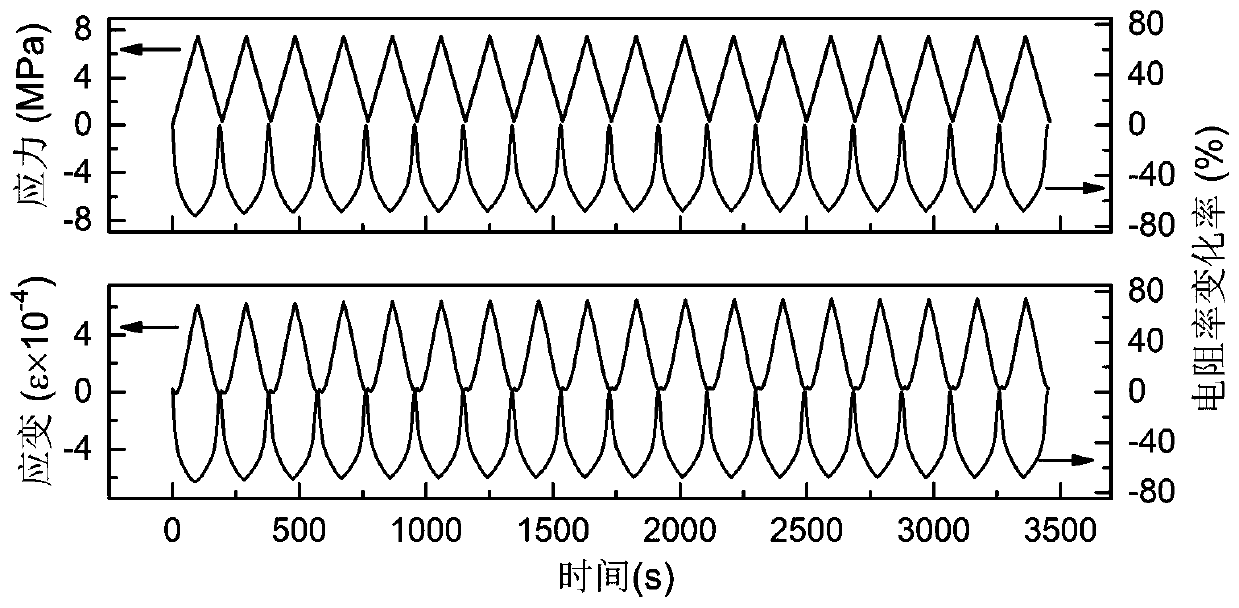

Electrostatic self-assembly carbon nano tube/nano-carbon black composite mortar as well as preparation method and application thereof

The invention discloses electrostatic self-assembly carbon nano tube / nano-carbon black composite mortar. Raw materials of the mortar comprise cement, silica fume, electrostatic self-assembly carbon nano tubes / nano-carbon black, a water reducing agent, sand and water. The minimum static resistivity of the mortar reaches 0.45 omega*m, the range of an absolute value of the resistivity change rate is 3.3%-22.1%, the change range of stress sensitivity is 0.40%-2.69% / MPa, and the change range of the strain sensitivity is 105-704. Compared with the prior art, the electrostatic self-assembly carbon nano tube / nano-carbon black composite mortar and the preparation method thereof solve the problem about dispersion of nanofiller in the mortar very well, and the carbon nano tubes and the nano-carbon black have the collaborative conductive effect, so that the mortar can acquire very low static resistivity and has excellent pressure-sensitivity by the aid of a small mixing amount of electrostatic self-assembly carbon nano tubes / nano-carbon black.

Owner:DALIAN UNIV OF TECH

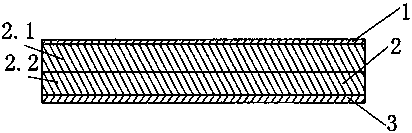

Medical scar treatment plaster and preparation method thereof

InactiveCN109847055AReduce needReduce depositionPeptide/protein ingredientsSynthetic polymeric active ingredientsPeppermintsSodium hyaluronate

The invention provides a medical scar treatment plaster. The medical scar treatment plaster comprises a back lining layer, a gel coagulation layer and an antisticking layer, wherein the gel coagulation layer sequentially comprises a medical silicone gel layer and a hyaluronic acid gel coagulation layer; the medical silicone gel layer is a mixture consisting of active substances, peppermint oil, aradix salviae miltiorrhizae extract, a cortex phellodendri extract, rhododendron root powder, and purified water; and the hyaluronic acid gel coagulation layer is a mixture consisting of sodium hyaluronate and crust growth factors. The invention further provides a preparation method of the medical scar treatment plaster. The medical scar treatment plaster has the beneficial effects of being soft in texture, high in auto-adhesion and convenient to use, has favorable moisture permeability and air permeability, can promote scars to be softened and flat, can lighten pigment, and is high in safetyand suitable for children. The medical scar treatment plaster can restrain hair cell hyperplasia, reduce collagen deposition, control scar hyperplasia, and promote skin tissue repair and healing. Thepreparation method of the medical scar treatment plaster is simple to operate, the raw materials are wide in source, the preparation cost is low, and the medical scar treatment plaster is safe and reliable to use.

Owner:济南秦鲁药业科技有限公司

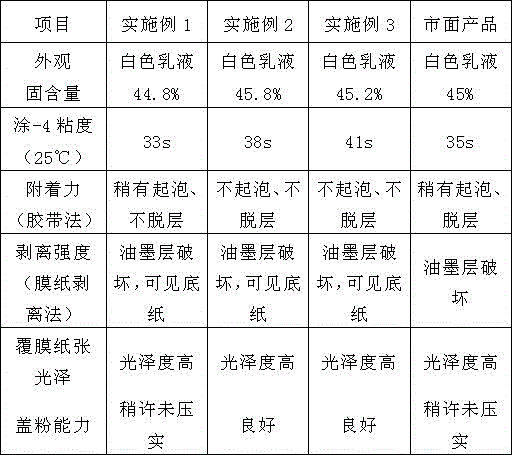

Aqueous dry lamination adhesive and preparation method thereof

ActiveCN105482745AFully bondedImprove adhesionEster polymer adhesivesRosin adhesivesSodium bicarbonateIsooctyl acrylate

The invention discloses an aqueous dry lamination adhesive and a preparation method thereof. Raw materials of the aqueous dry lamination adhesive comprise styrene, butyl acrylate, isooctyl acrylate, acrylonitrile, N-methylolacrylamide, hydroxyethyl acrylate, acrylic acid, rosin, potassium persulfate, sodium dodecylbenzene sulfonate, isooctyl phenol polyoxyethylene ether, sodium bicarbonate, deionized water, ammonia water, a wetting agent and antifoaming agent. Aqueous latex with a core-shell structure is prepared through a segmented polymerization technology, so functional groups make a substrate and a plastic film be fully bonded, and polymer molecular chains are self-crosslinked, thereby the adhesion and the peeling strength of the substrate are improved, the adhesive has excellent initial adhesion, pressure sensitivity and covering ability, the excellent leveling property and the dynamic wetability of the adhesive make a laminated product have brilliant gloss, and the adhesive can be widely used in paper plastic lamination.

Owner:常德市雄鹰科技有限责任公司

Nitrile rubber and preparation method thereof

The invention discloses nitrile rubber in the technical field of rubber production. The nitrile rubber is prepared from the following ingredients in parts: 100phr of nitrile rubber, 60 to 80phr of carbon black, 30 to 40phr of dioctyl sebacate, 50 to 60phr of modified talcum powder, 5 to 8phr of zinc oxide, 1 to 3phr of stearic acid, 5 to 8phr of coumarone, 2 to 3phr of anti-aging agents RD, 1.5 to 4phr of anti-aging agents 4010NA, 2 to 4phr of dispersing agents, 15 to 20phr of moisture absorbents, 3 to 5phr of sulphur S, 1 to 2phr of accelerators D, 2 to 4phr of accelerators M and 2 to 4phr of accelerators DPTT. According to the vulcanization process, extrusion products are subjected to microwave vulcanization molding through first-section microwave and second-section hot air vulcanization equipment. The nitrile rubber has the advantages that the low-temperature resistant performance is good; the intensity is high; the pressure change is low; the anti-aging performance is realized; the service life is long; the forming is realized through a microwave vulcanization method; the cost is low; the efficiency is high and the finished product rate is high.

Owner:扬州华通橡塑有限公司

Water-based environment-friendly adhesive suitable for adhesion between ground decoration layer and cushion layer

ActiveCN105754521AImprove initial tackImprove sticking powerNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterWater based

The invention provides a water-based environment-friendly adhesive suitable for adhesion between a ground decoration layer and a cushion layer. The adhesive is prepared from following components by weight through evenly mixing: 35%-60% of an acrylic resin emulsion, 10%-50% of a tackifying resin emulsion and 2%-10% of a plasticizer, wherein the acrylic resin emulsion is one or more of a styrene-modified acrylic resin emulsion, a fluorine-modified acrylic resin emulsion, a polyurethane acrylic resin emulsion and a silicone-modified acrylic resin emulsion which have the glass transition temperature ranging from subzero 30 DEG C to 0 DEG C, the solid content percentage ranging from 57wt% to 75wt% and the molecular weight ranging from 100,000 to 500,000; the tackifying resin emulsion is one or more of a petroleum resin emulsion, a terpene resin emulsion and a rosin resin emulsion which have the softening temperature ranging from 20 DEG C to 80 DEG C, the solid content percentage ranging from 35% to 55% and the molecular weight ranging from 2,000 to 3,000; the plasticizer is one or more of a benzoate plasticizer, a phthalic acid ester plasticizer, a polyester plasticizer and a polyol ester plasticizer. The adhesive has good initial adhesion and wonderful flexibility, can be uncovered and adhered repeatedly and can be produced with the simple production technology.

Owner:广东龙湖科技股份有限公司

Preparation method of carbon nanotube modified flame-retardant waterborne polyurethane coating and adhesive

ActiveCN111117466AImprove mechanical propertiesImprove flame retardant performanceFireproof paintsNon-macromolecular adhesive additivesAdhesive cementPolymer science

The invention relates to a preparation method of a carbon nanotube modified flame-retardant waterborne polyurethane coating and adhesive. The preparation method comprises the following steps: firstly,preparing a modified heat-conducting filler by utilizing a coupling agent, deionized water, tannic acid and a boron nitride nanosheet layer; then preparing a component A by utilizing polymer polyol and the modified heat-conducting filler; finally, adding a modifier, a polyol chain extender, a cross-linking agent and a filler polymerization chain to the component A, isocyanate and dibutyltin dilaurate to prepare polyurethane A, and adding a tackifier to the polyurethane A to prepare the carbon nanotube modified flame-retardant polyurethane coating and adhesive. The obtained polyurethane coating and adhesive have the outstanding advantages that the combustion smoke performance is better reduced, and the pressure-sensitive performance is improved.

Owner:YANTAI UNIV

Hexahydroxy copolymer water-based pressure-sensitive adhesive without adhesive residue and preparation method of hexahydroxy copolymer water-based pressure-sensitive adhesive

The invention relates to a hexahydroxy copolymer water-based pressure-sensitive adhesive without adhesive residue and a preparation method of the hexahydroxy copolymer water-based pressure-sensitive adhesive. The preparation method of the hexahydroxy copolymer water-based pressure-sensitive adhesive comprises the following steps: (1) taking water as solvent, uniformly mixing polyvinyl alcohol, anionic surfactant, emulsifier and pH regulator, increasing temperature to 50 DEG C, and adding acrylic monomer, cross-linking monomer and polymerization degree regulator to react for 1h at the temperature of 60-65 DEG C, thus obtaining a pre-emulsified solution; (2) uniformly mixing 25% of pre-emulsified solution with 40% of initiator, increasing the temperature to 80-85 DEG C, adding the rest of pre-emulsified solution when the liquid turns blue, adding 20% of initiator every 1h so as to drip off all the initiator within 3h, at last replenishing surplus initiator, and keeping temperature for reflux for 1-1.5h at the temperature of 90 DEG C; and (3) lowering the temperature of the reaction liquid to 40 DEG C, adding a bridging agent, and after uniformly mixing the mixture, cooling the mixture to room temperature. The hexahydroxy copolymer water-based pressure-sensitive adhesive has the advantages of low price, high production rate, strippability and the like and can avoid the pollution of solvent type pressure-sensitive adhesive to environment, thus being an environment-friendly water-based strippable pressure-sensitive adhesive.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

Chromium-free, lead-free and low-voltage piezoresistor

The invention discloses a chromium-free, lead-free and low-voltage piezoresistor which is prepared from the following raw materials in molar percent through conventional solid phase method: ZnO:Bi2O3:Co2O3:MnCO3:SiO2:Ni2O3:Bi4Ti3O12:SnO2=(98.17-X):0.4:(0.6-Y):(0.5+Y):0.05:0.1:(0.1+X):0.08, wherein X is more than or equal to 0 and less than or equal to 2 and Y is more than or equal to 0 and less than or equal to 0.1; the additive amount of B2O3 accounts for 0.02% of total weight of all raw materials. According to the chromium-free, lead-free and low-voltage piezoresistor, Bi3Ti3O112 is used to replace TiO2 to dope, the inhibiting effect on generation of Zn2TiO4 by reaction of TiO2 and ZnO at high temperature relative to grain growth can be effectively reduced, so that the low voltage piezoresistor with lower electric potential gradient is obtained. Meanwhile, better pressure-sensitive and higher flow capacity and energy absorption capability are maintained. The high performance chromium and lead free low voltage piezoresistor developed is free of any chromium and lead elements and is environment-friendly.

Owner:GUANGXI NEW FUTURE INFORMATION IND

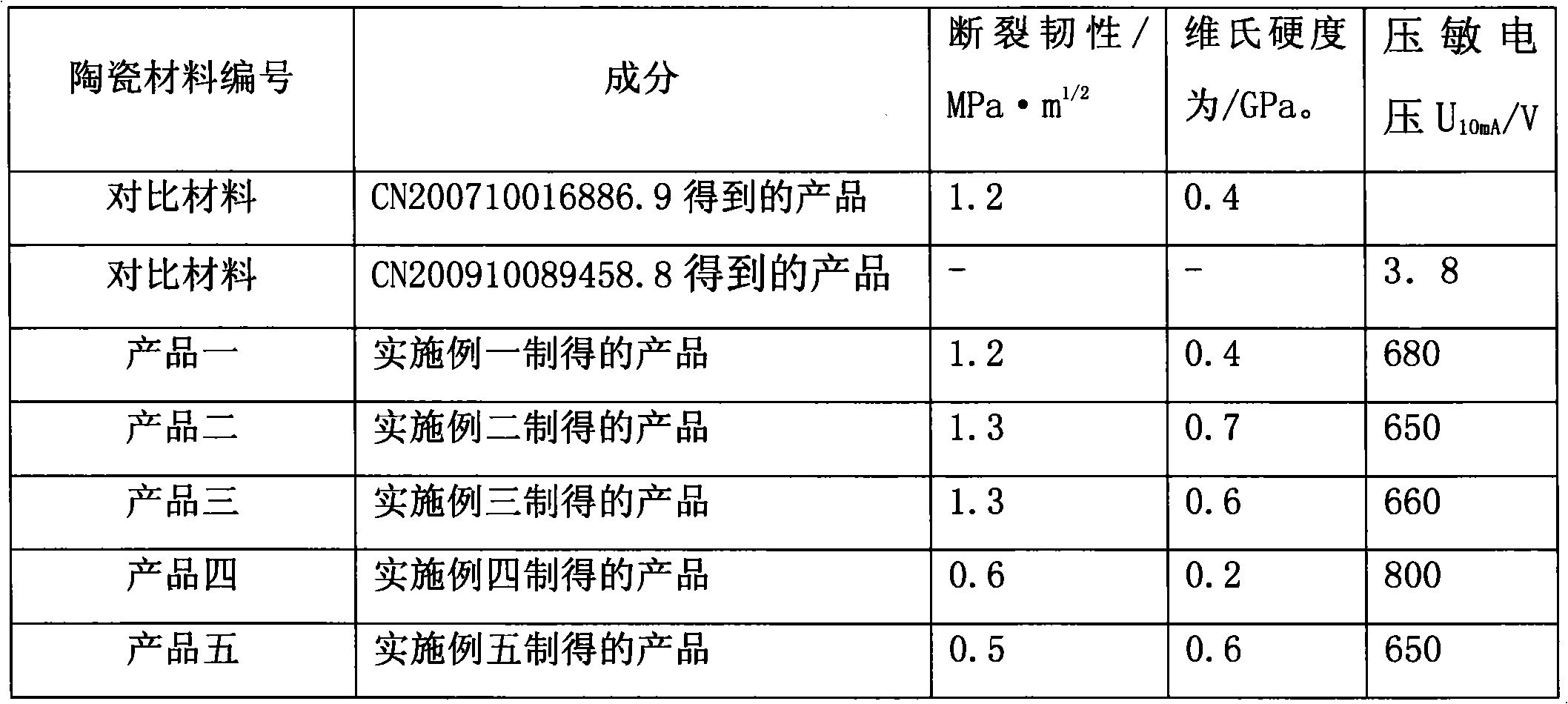

Voltage-sensitive ceramic material and preparation method thereof

InactiveCN103496970AExcellent pressure sensitive performanceNo pollution in the processVaristor ceramicsBall mill

The invention relates to a voltage-sensitive ceramic material and a preparation method thereof, belonging to the field of ceramic process technologies. The voltage-sensitive ceramic material comprises the following components: 93-95 parts of ZnO, 0.6-0.8 part of Bi2O3, 0.9-1.3 parts of Sb2O3, 1.0-1.3 parts of CoO, 0.5-0.8 part of MnCO3, 0.5-0.8 part of Cr2O3, 0.5-0.8 part of NiO, and 1.0-1.5 parts of Pr6O11. The preparation method comprises the following steps of pouring the components into a stirring ball mill according to proportion, adding pure water of 85-93% of the total weight of additives, ball milling for 2-4 hours till the grain size is less than 1.3mu m, then heating the obtained mixed solution up to 85-100 DEG C, keeping warm and stirring continuously till the solvent is evaporated and becomes paste, drying the paste, keeping warm for 6-8 hours at 500-580 DEG C, finally ball milling, and obtaining the zinc oxide voltage-sensitive ceramic compound powder. The ceramic material has excellent voltage-sensitive property, has a simple preparation method, has no toxicity and no environment contamination, and is beneficial to industrial large scale production.

Owner:陈锐群

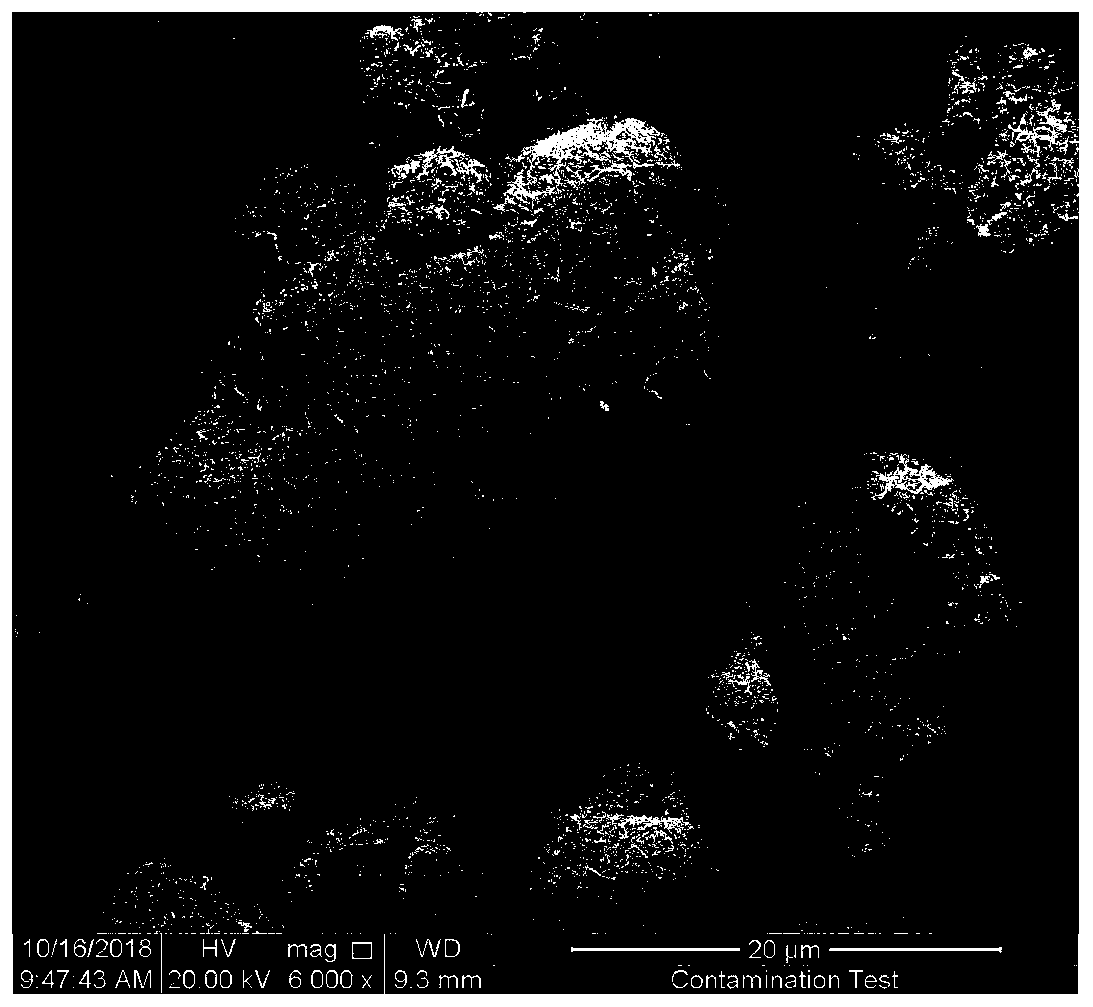

Ultrahigh-sensitivity pressure-sensitive cement-based composite material as well as preparation method and application thereof

InactiveCN110627431AImprove dispersion uniformityEvenly dispersedElectrical/magnetic solid deformation measurementStructural health monitoringCarbon nanotube

The invention discloses an ultrahigh-sensitivity pressure-sensitive cement-based composite material as well as a preparation method and application thereof. The pressure-sensitive cement-based composite material comprises the following raw materials in parts by weight: 75-95 parts of cement, 5-25 parts of a mineral admixture for in-situ growth of carbon nanotubes, 0.1-3 parts of a water reducing agent, 100-300 parts of sand and 30-60 parts of water. The preparation method comprises the steps: firstly, uniformly dispersing the mineral admixture for in-situ growth of the carbon nanotubes in water; then blending cement and sand firstly, then adding the dispersed mineral admixture for in-situ growth of the carbon nanotubes and the water reducing agent, and blending; and finally, molding the blend material, and curing to obtain the product. The mineral admixture is used as a carrier, the carbon nanotubes grow on the surface of the mineral admixture in situ, and the carbon nanotubes is uniformly dispersed in the cement matrix by virtue of the characteristic that the mineral admixture is easy to disperse in the cement matrix, so that the pressure-sensitive property and mechanical propertyof the cement-based composite material are improved. Therefore, the ultrahigh-sensitivity pressure-sensitive cement-based composite material can be used for structural health monitoring.

Owner:SOUTHEAST UNIV

Preparation method of nano carbon black modified conductive cement

The invention discloses a preparation method of nano carbon black modified conductive cement, wherein the nano carbon black modified conductive cementis prepared from the following components in partsby weight: 80-95 parts of silicate cement, 9-12 parts of coal ash, 5-8 parts of stainless microfilaments, 0.02-1.00 part of a water reducer, 2-8 parts of nano carbon black and 2-5 parts of an aqueousdispersant, wherein the grain sizes of the nano carbon black are 36-40nm, the specific surface area is 1612-1856 m<2> / g and the resistivity is 0.2-5.6 ohm.cm. The cement obtained by the method disclosed by the invention has excellent conductivity, pressure sensitivity and durability, and has good compatibility with a concrete structure.

Owner:DALIAN UNIV OF TECH

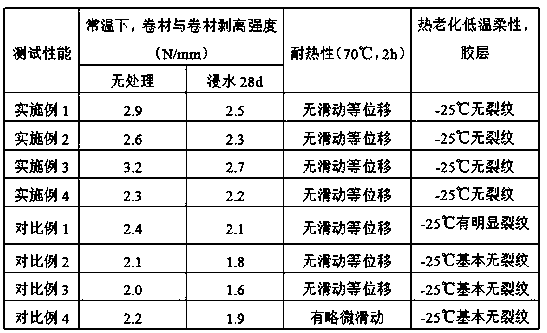

Special hot-melt pressure-sensitive adhesive for low-temperature waterproof coiled material butt-joint adhesive tape and preparation method thereof

InactiveCN111548758APromote plasticizationReduce high temperature viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention relates to a special hot-melt pressure-sensitive adhesive for a low-temperature waterproof coiled material butt-joint adhesive tape and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises the following components in parts by weight: 50 to 60 parts of an SIS thermoplastic elastomer, 20 to 40 parts of a polyisobutylene compound, 5 to 10 parts of hydrogenated monomer resin, 10 to 15 parts of a tackifying resin compound, 1 to 2 parts of an antioxidant and 0.5 to 1.5 parts of an ultraviolet absorbent. Compared with the prior art, the hot-melt pressure-sensitive adhesive has the characteristics of high peel strength, good water resistance, and good low-temperature resistance, and can be widely applied to engineering construction of waterproof coiled materials.

Owner:SHANGHAI JIAHAO ADHESIVE PROD CO LTD

Multifunctional ceramic composite material and preparation method thereof

The invention provides a multifunctional ceramic composite material and a preparation method thereof. The ceramic composite material has the advantages of excellent performance and high strength. The preparation method has the advantages of simple process, low production cost, low energy consumption and suitability for industrial production. The multifunctional ceramic composite material comprises the following components in weight percentage: 25%-35% of SiC, 25%-35% of TiCN, 5%-10% of Si3N4, 0.5%-1.5% of V2O5, 1%-2% of BaO, 4%-6% of SiO2, 2%-5% of TiO2, 1%-3% of ZrO2, 0.10%-0.15% of La2O3 and the balance of Al2O3.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Preparation method of high-temperature-resistant pressure-sensitive adhesive tape

InactiveCN111234728AAccelerateLow reaction temperatureNon-macromolecular adhesive additivesEster polymer adhesivesReflow solderingPolymer chemistry

The invention discloses a preparation method of a high-temperature-resistant pressure-sensitive adhesive tape. The preparation method comprises the following three steps: preparation of a high-temperature-resistant acrylate pressure-sensitive glue, modification of a solvent type pressure-sensitive glue and preparation of the high-temperature-resistant pressure-sensitive adhesive tape. The high-temperature-resistant pressure-sensitive adhesive tape prepared by the invention has excellent high-temperature resistance; after baking at 240 DEG C for 30 minutes, excellent pressure ensitivity is maintained, no apperance bubbling or server yellowing is caused;the prepared high-temperature-resistant pressure-sensitive adhesive tape can be used for SMT (Surface Mount Technology) in the production process of FPCs (Flexible Printed Circuit Boards) and PCBs (Printed Circuit Boards), can resisthigh temperature of wave soldering and reflow soldering, and has the effects of high-temperature shieldingand part fixing.

Owner:东莞爵士先进电子应用材料有限公司

Super-weather-resistant environment-friendly ultraviolet light curing pressure-sensitive adhesive for high-end waterproof materials, and preparation method thereof

InactiveCN110857384AExcellent pressure sensitive performanceGood weather resistanceMineral oil hydrocarbon copolymer adhesivesEster polymer adhesivesIsooctyl acrylateAdhesive cement

A purpose of the invention is to overcome the defects of the existing waterproof material technology. The invention specifically relates to a super-weather-resistant environment-friendly ultraviolet light curing pressure-sensitive adhesive for high-end waterproof materials, and a preparation method thereof, wherein the adhesive comprises, by weight, 20-45 parts of butyl acrylate, 10-50 parts of 2-ethylhexyl acrylate, 0.5-2 parts of acrylic acid, 0-2 parts of hydroxyethyl acrylate, 60-90 parts of ethyl acetate, 0.2-2 parts of benzoyl peroxide, 0.5-3 parts of dilauroyl peroxide, 10-30 parts of apetroleum resin, 0-5 parts of an antioxidant and 0.1-10 parts of a photoinitiator. The waterproof coiled material prepared by utilizing the ultraviolet light curing adhesive disclosed by the invention has advantages of excellent weather resistance, excellent heat resistance, high adhesive force and good water resistance, and substantially meets the requirement of waterproof materials on durability.

Owner:KUNSHAN SUMEI FINE CHEM CO LTD

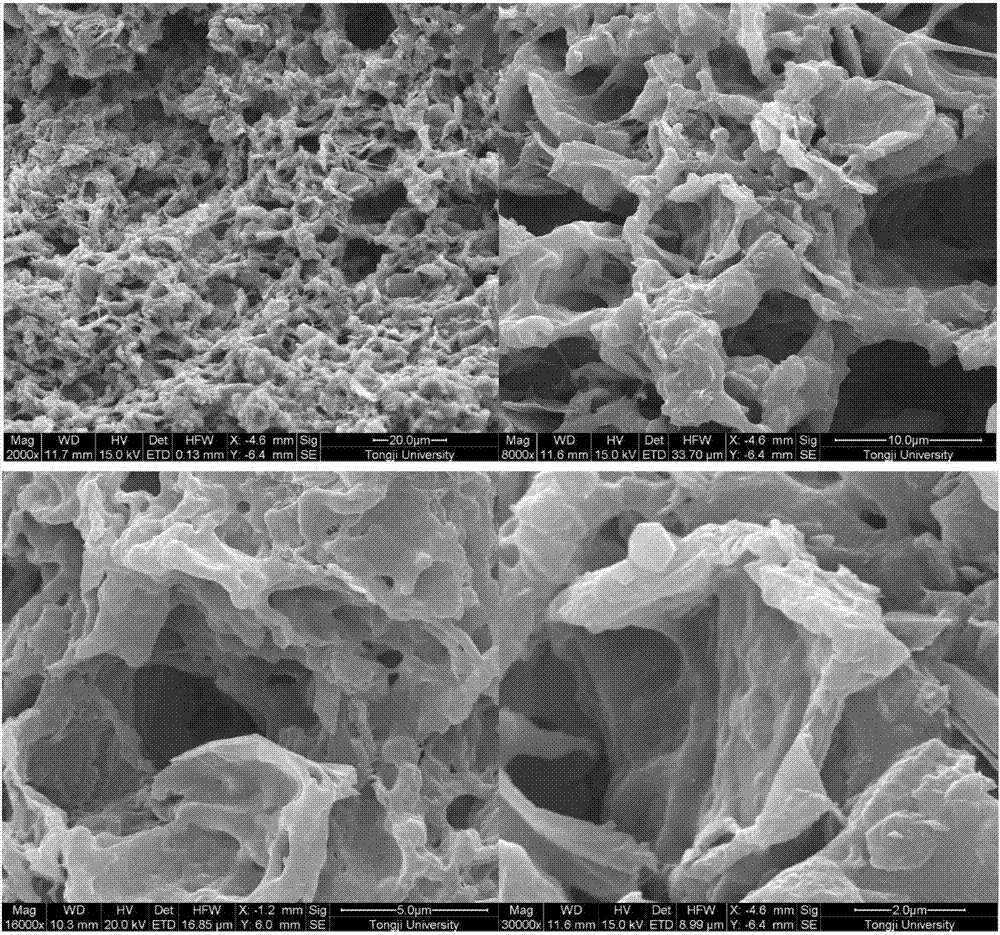

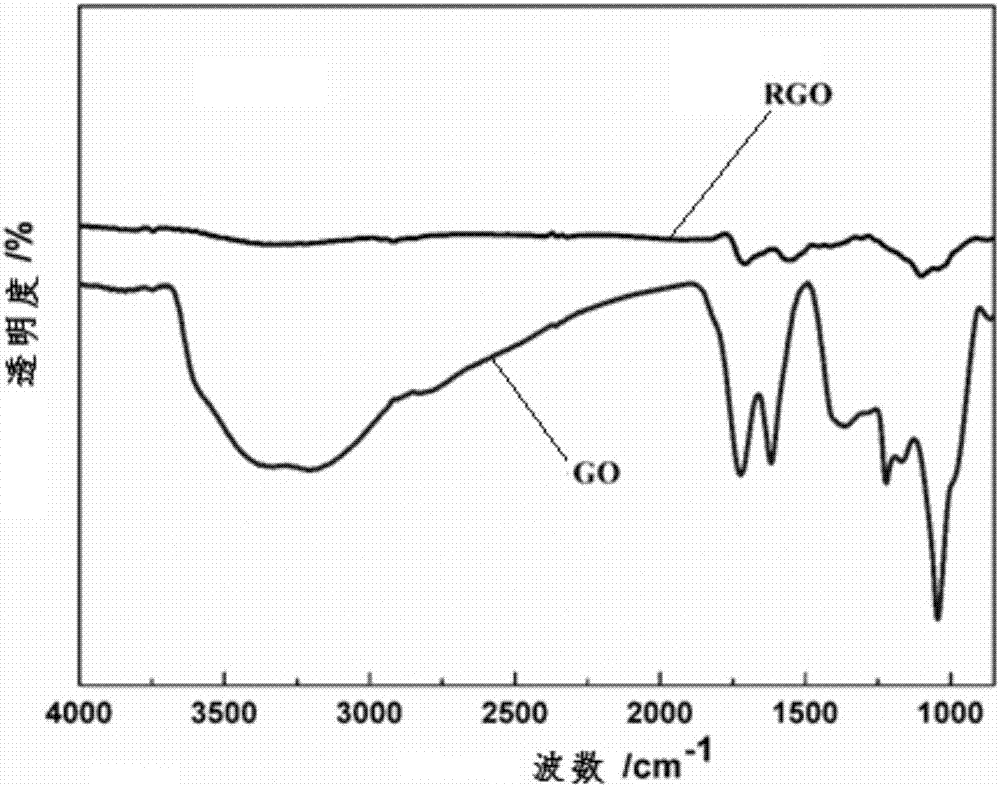

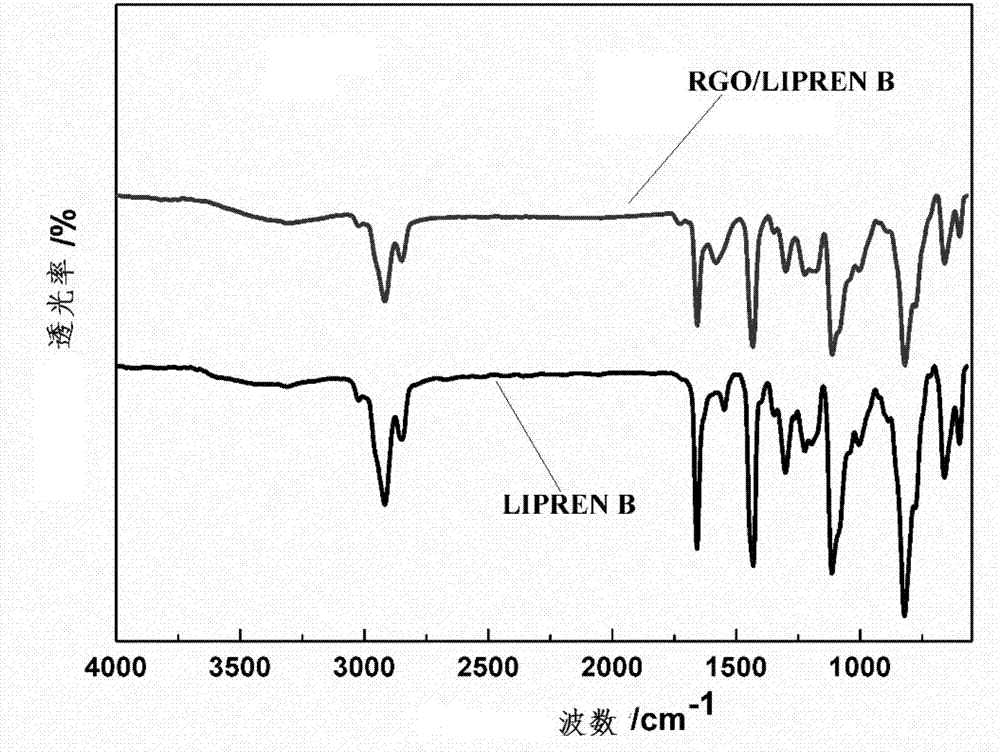

Graphene polymer pressure sensitive composite material and preparation method thereof

The invention relates to a graphene polymer pressure sensitive composite material and a preparation method thereof. The preparation method comprises the following steps: reducing graphene oxide through a thermal recovery reaction to form three-dimensional network graphene, compounding the three-dimensional network graphene in polymer emulsion, and carrying out vacuum freeze drying to obtain the graphene polymer pressure sensitive composite material. Compared with the prior art, the preparation method provided by the invention has the advantages that the three-dimensional graphene is used as the skeleton, the polymer is coated on the surface of the skeleton for solving the dispersion problem and the durability problem of the composite material, the graphene network is used as a conductive template, the conductivity of the obtained composite material is obviously improved, and the composite material has excellent pressure sensitivity; and in addition, the whole method only comprises two steps, one is to prepare a graphene cross-linked network, and the other is to perform dipping compounding of the material, the types of the adopted reagents are few, the process method is simple, the cost is low, and industrial production expansion is easy to implement.

Owner:TONGJI UNIV

Water-based environment-friendly sealing adhesive and preparation method thereof

InactiveCN107936874AImprove performanceEasy to combineMonocarboxylic acid ester polymer adhesivesNatural rubber adhesivesEnvironmental resistanceWater based

Belonging to the technical field of encapsulation, the invention relates to a water-based environment-friendly sealing adhesive and a preparation method thereof. According to a polymer alloyage designconcept, a polyacrylate emulsion, a rosin terpene resin emulsion, a self-crosslinking emulsion, natural latex and a water-based SBS emulsion are blended, because of the action of mechanical shearingforce, chain breaking occur to parts of high polymers, then grafting or blocking, also or group and chain segment exchange can be carried out so as to form the water-based environment-friendly sealingadhesive between polymers, the characteristics of different macromolecules can be optimally combined, thus significantly improving the material performance, or endowing the material with originally absent performance, and different macromolecular polymers that are thermodynamically incompatible can be compounded compatibly, thus obtaining the novel sealing adhesive with the advantages of all thepolymers.

Owner:常州莱尚纺织品有限公司

Preparation of acrylic ester copolymer emulsion for pressure-sensitive adhesive

ActiveCN101412783BReduce the amount of residual glueExcellent pressure sensitive performanceEster polymer adhesivesPolymer scienceConcentration gradient

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com