Multifunctional ceramic composite material and preparation method thereof

A ceramic composite material and multi-functional technology, applied in the field of inorganic non-metallic materials, can solve the problems of not being able to make structural ceramics, and achieve the effects of low cost, good environmental coordination, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

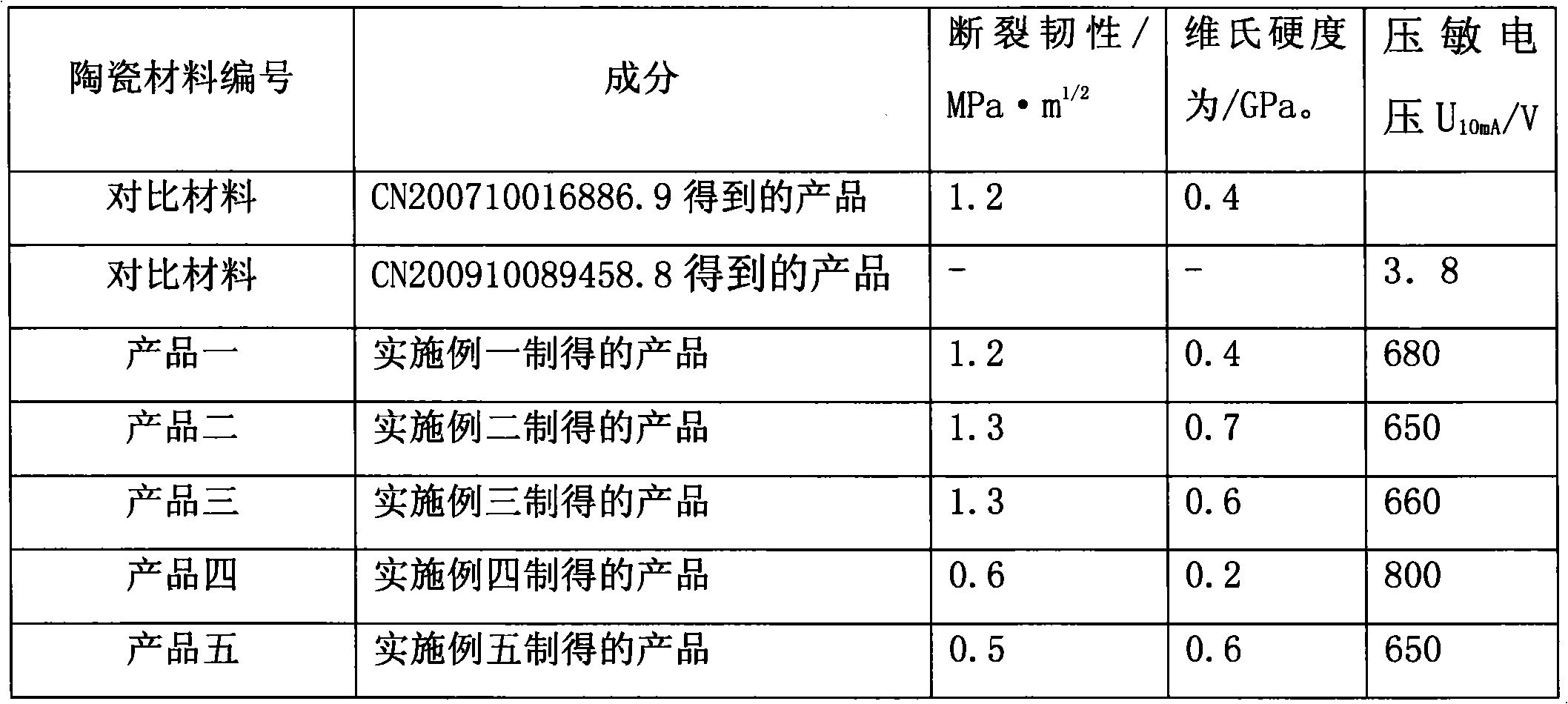

Examples

Embodiment 1

[0025] The preparation process of the multifunctional ceramic composite material of the present invention:

[0026] Raw materials by weight percentage: SiC powder 25%, TiCN powder 25%, Si 3 N 4 Powder 5%, V 2 o 5 Powder 0.5%, BaO powder 1%, SiO 2 Powder 4%, TiO 2 Powder 2%, ZrO 2 Powder 1%, La 2 o 3 Powder 0.10%, the rest is Al 2 o 3 The particle size of each powder is 500-800 mesh; put the above powder into a ball mill, and then inject water, the water injection weight and the total weight ratio of each powder are 1:1; take out the ball mill after wet mixing for 12 hours, and dry it. The drying temperature is 160-210°C, and then the dried material is crushed in a ball mill to 270-500 mesh, put into a mold and apply a pressure of 50MPa, and keep the pressure for 5 minutes; then put it into an electric furnace for sintering, and first heat it to 550-600 ℃ for 0.5-1h, then increase the temperature to 1450-1550°C, keep for 2-4h, and then cool down with the furnace to ob...

Embodiment 2

[0028] Raw materials by weight percentage: SiC 35%, TiCN 35%, Si 3 N 4 10%, V 2 o 5 1.5%, BaO 2%, SiO 2 6%, TiO 2 5%, ZrO 2 3%, La 2 o 3 0.15%, the rest is Al 2 o 3 For batching, the ratio of water weight to the total weight of each powder is 1: 1.3, and the preparation process is the same as in Example 1.

Embodiment 3

[0030] Raw materials by weight percentage: SiC 30%, TiCN 30%, Si 3 N 48 %,V 2 o 5 0.9%, BaO 1.5%, SiO 2 5%, TiO 2 3%, ZrO 2 2%, La 2 o 3 0.12%, the rest is Al 2 o 3 Carry out batching, preparation process is with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com