Construction method for cast-in-place integral light-weight partition wall

A construction method and wall technology, applied in the direction of walls, buildings, building components, etc., can solve problems such as the inability to completely eliminate common quality problems, and achieve the effect of reducing wall cracking, reducing internal stress, and improving the quality of the board surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

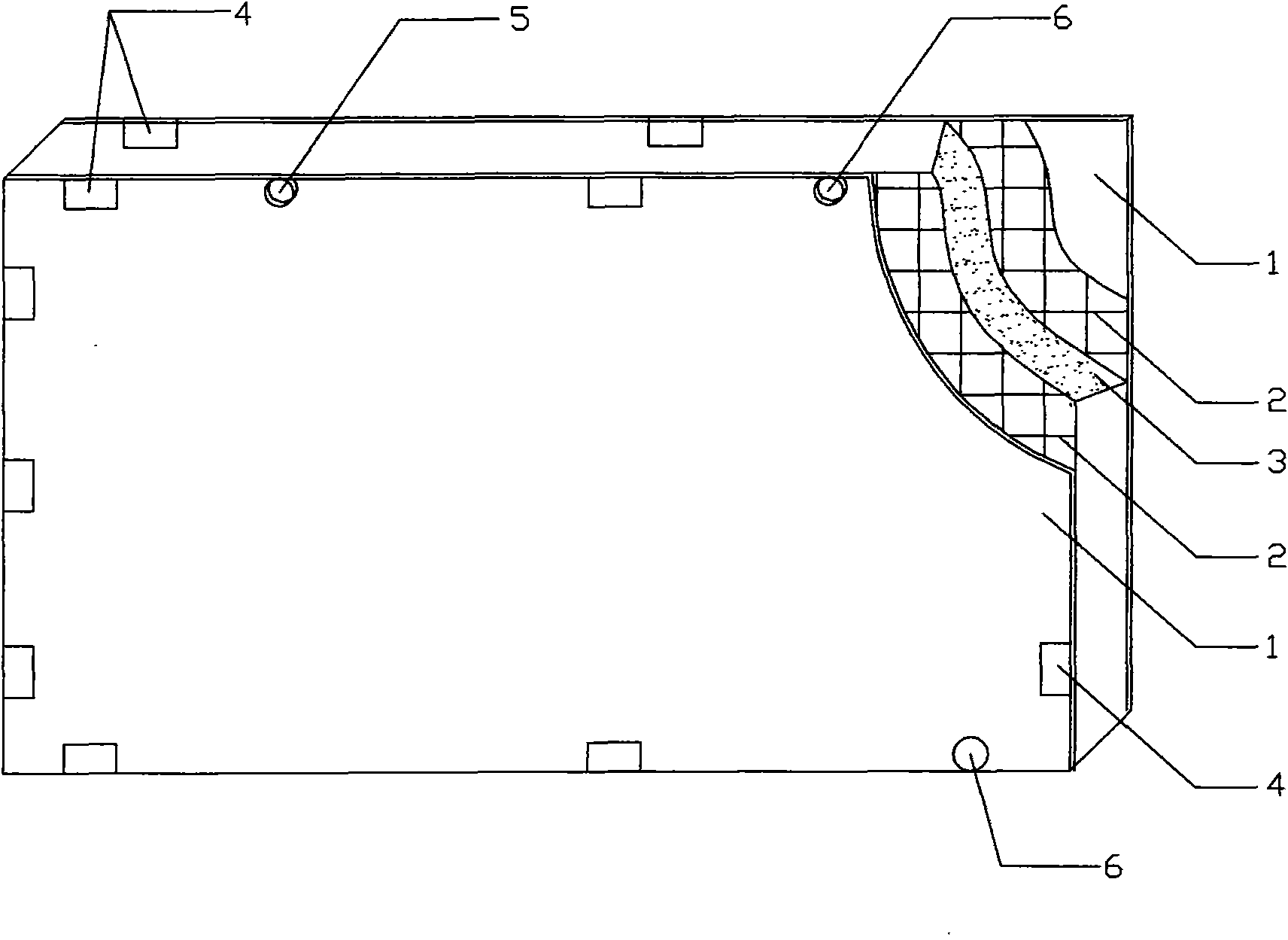

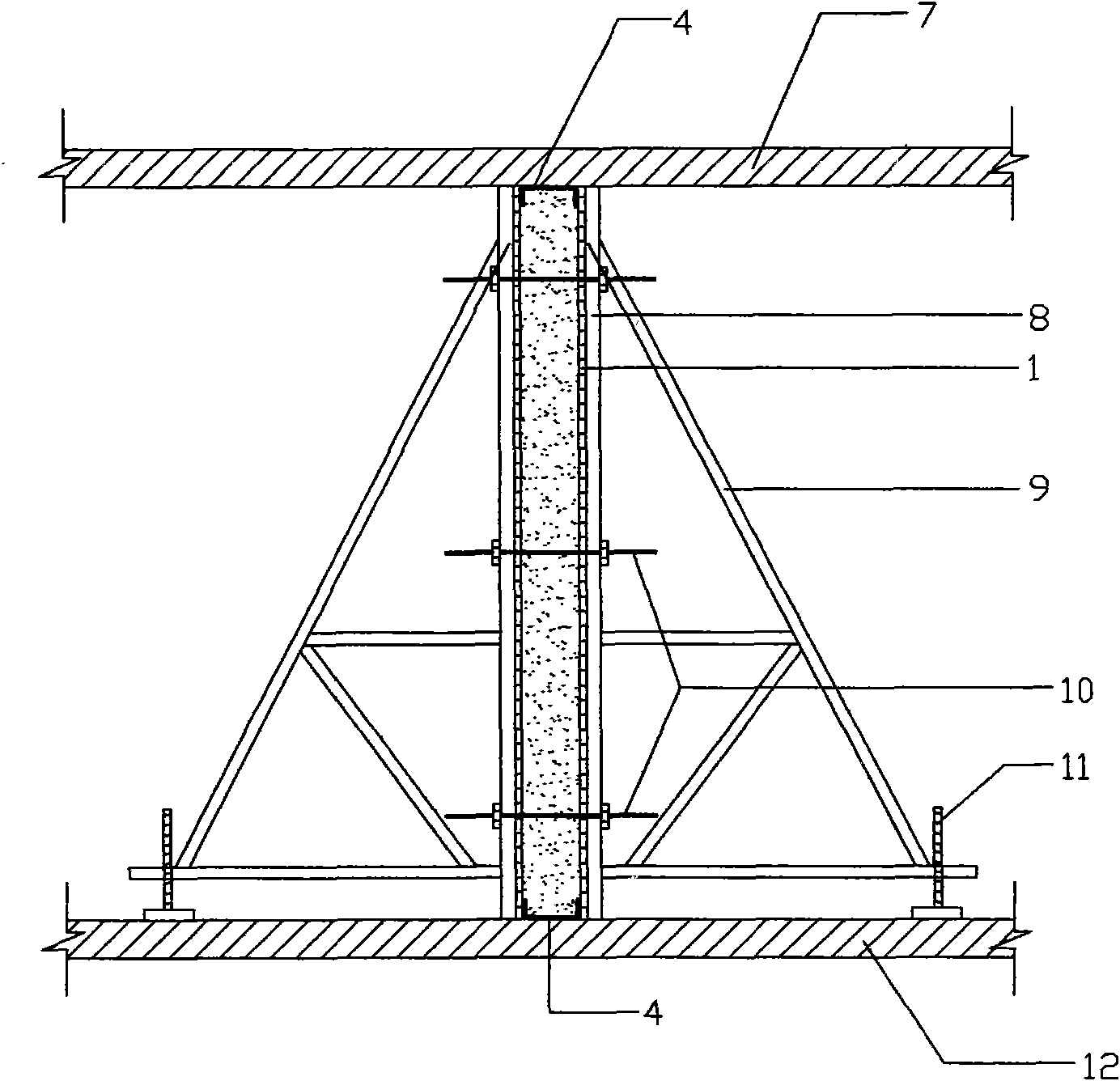

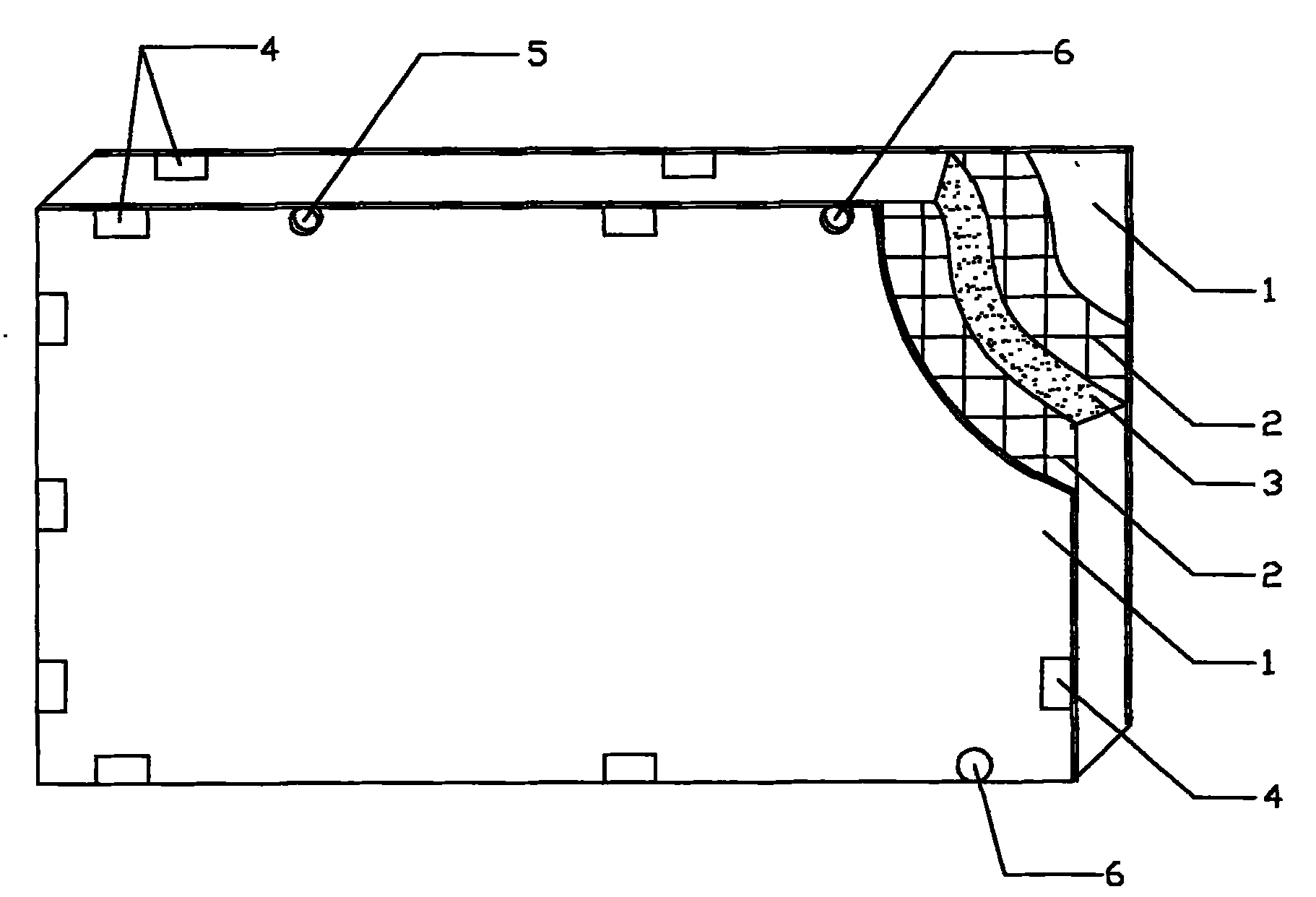

[0035] figure 1 and figure 2 Medium: 1 is a permanent template, which can be made of gypsum board, cement board, polystyrene board, and plastic board. 2 is a steel mesh or steel mesh for wall reinforcement, which is used when the wall is too long or too high to strengthen the strength and integrity of the wall. 3 is the wall filler (light aggregate concrete or aerated concrete), which is transported by a pressure pump, and the filler is injected into the wall through the grouting hole 6. 4 is the template positioning embedded part, which is convenient for template installation and accurate template positioning. 5 Exhaust holes, the function is to discharge the air when pouring the filling material in the wall. 6 Grouting holes, which can be reserved at the bottom, middle or top of the wall. 8. The keel used for formwork reinforcement plays the role of reinforcing formwork, and can be made of steel, aluminum profiles, wood and other materials. 9. The support for formwork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com