Sealing rubber strip for vacuum bag used at room temperature to 200 DEG C and preparation method for sealing rubber strip

A sealing strip and vacuum bag technology, which is applied in the field of vacuum bag sealing strip and its preparation, can solve the problems of sealing strip foaming, low temperature of sealing strip, low viscosity of sealing strip, etc., and achieve good adhesion Performance, high tensile and shear strength, and excellent sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

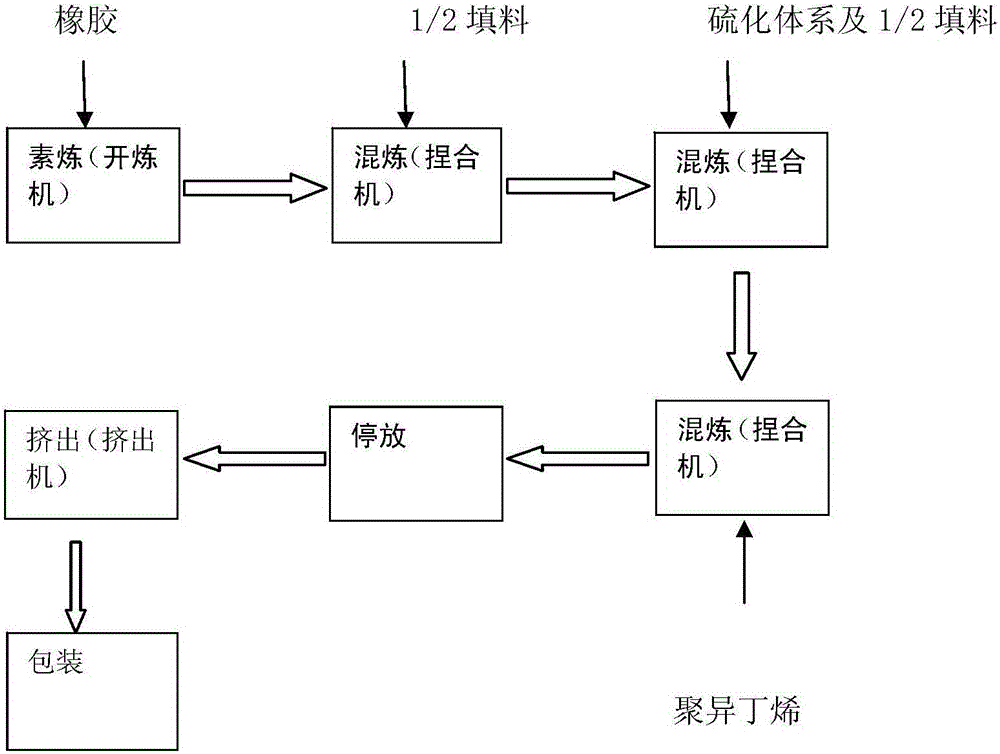

[0075] 100 parts by mass of butyl rubber, 70 parts by mass of precipitated white carbon black (the white carbon black is first processed in an alcohol solution of 1% mass KH560, pulverized, and dried), 90 parts by mass of medium molecular weight aluminum-based polyisobutylene, and tertiary 7 parts by mass of butylphenolic resin, 3 parts by mass of stannous chloride, and 4 parts by mass of calcium oxide.

[0076] Put butyl rubber in a two-roller rubber mixing machine, adjust the roller distance to 1 mm, masticate for 10 minutes, add half of the filler, and mix evenly; Mix the vulcanization system and the other half of the filler, knead evenly; add polyisobutylene, knead evenly, and discharge; stop for 48 hours; heat the extruder to 60-80°C, extrude, and pack.

[0077]The vacuum bag prepared by the sealing strip can provide a pressure close to 1 atm, and the sealing strip will not leak for a long time from room temperature to 200°C; it is bonded with aluminum alloy (the thicknes...

Embodiment 3

[0079] 100 parts by mass of butyl rubber, 20 parts by mass of methylated silica, 50 parts by mass of kaolin, 100 parts by mass of medium molecular weight aluminum-based polyisobutylene, 1 part by mass of n-butyl titanate, 8 parts by mass of p-isooctyl phenolic resin 10 parts by mass of bromobutyl rubber, 3 parts by mass of zinc oxide, and 5 parts by mass of calcium oxide.

[0080] Put butyl rubber in a two-roller rubber mixing machine, adjust the roller distance to 1 mm, masticate for 10 minutes, add half of the filler, and mix evenly; Mix the vulcanization system and the other half of the filler, knead evenly; add polyisobutylene, knead evenly, and discharge; stop for 36 hours; heat the extruder to 60-80°C, extrude, and pack.

[0081] The vacuum bag prepared by the sealing strip can provide a pressure close to 1 atm, and the sealing strip will not leak for a long time from room temperature to 200°C; it is bonded with aluminum alloy (the thickness of the sealing strip is 2mm),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com