Protective sealing door for underground refuge chamber

A technology of refuge chamber and airtight door, which is applied to fire doors, door leaves, windows/doors, etc., can solve problems such as damage to insulation cotton, poor sealing of door leaves, and environmental deterioration of refuge chambers, and achieves low water absorption and linearity. Effects of thermal expansion coefficient, excellent self-lubrication and wear resistance, excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

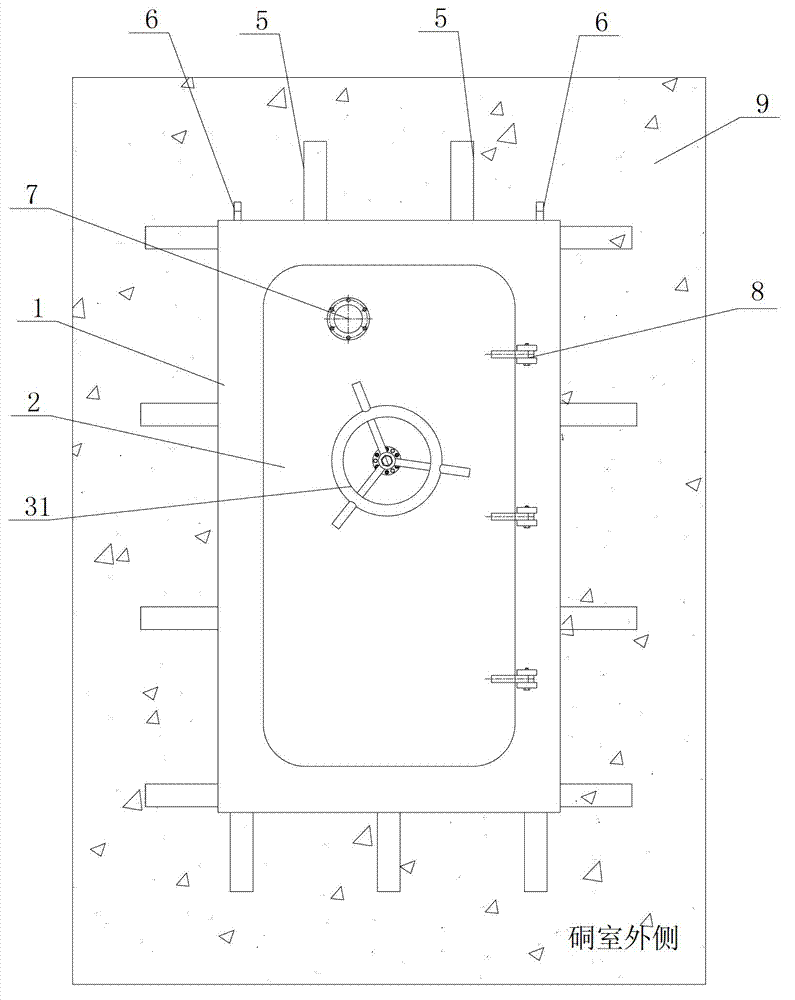

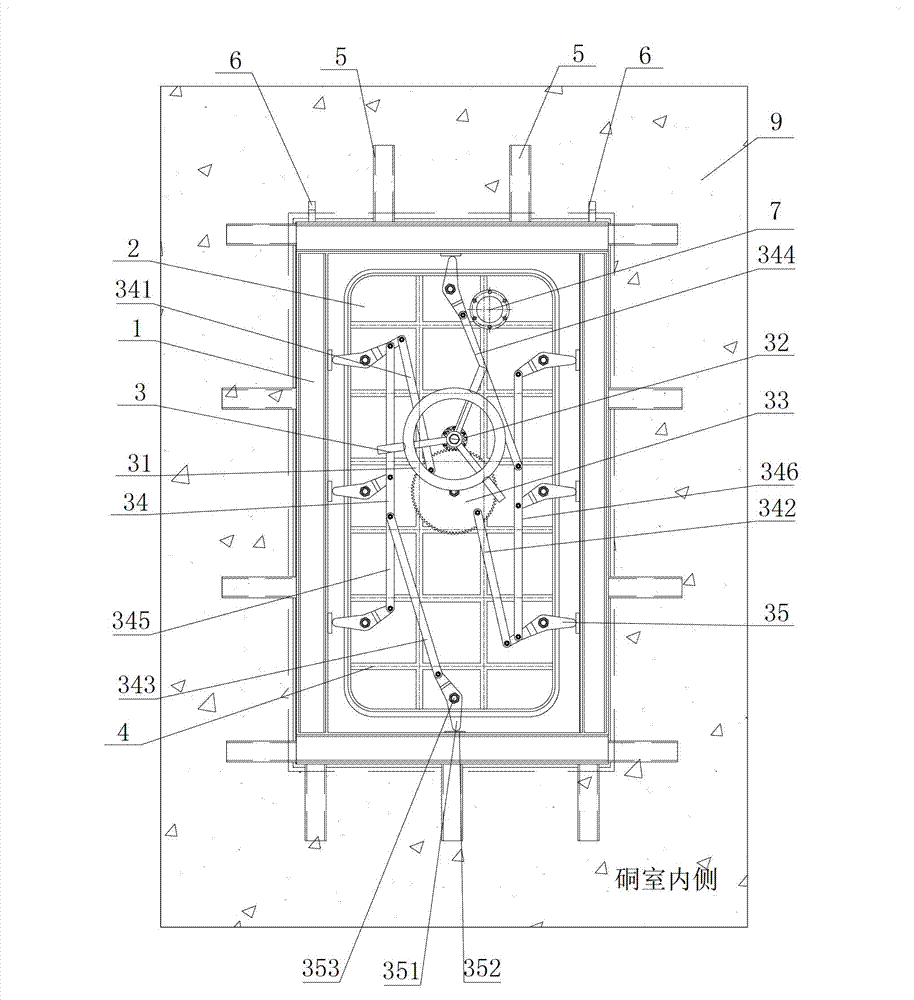

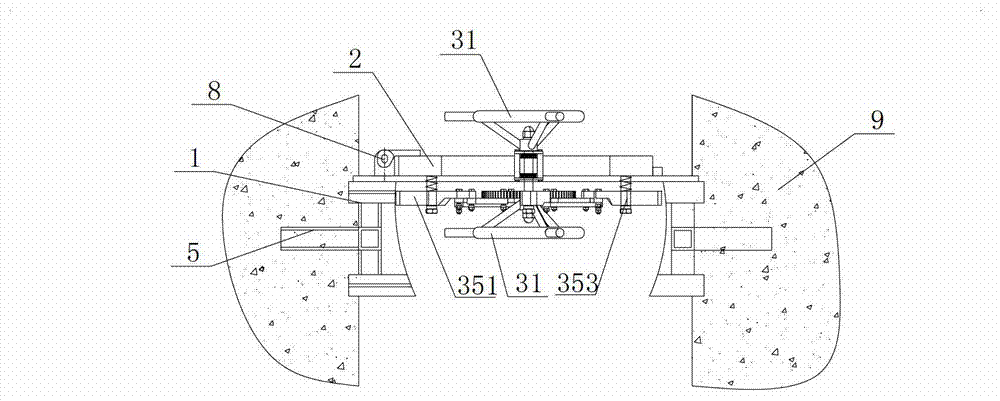

[0078] Such as Figure 1~6As shown, the protective airtight door of the underground refuge chamber described in this invention includes a door frame 1 and a door panel 2, the door panel 2 is rotated on the door frame 1 through a rotating shaft 8, and the door panel 2 is also provided for locking it on the door frame 1 on the locking mechanism 3.

[0079] The door frame 1 is fixedly arranged in the explosion-proof wall 9 of the refuge chamber, and fourteen second reinforcing ribs 5 are arranged on the outer peripheral edge of the door frame 1, and are fixed to the explosion-proof wall 9 through these fourteen second reinforcing ribs 5, and the second reinforcing ribs The distribution of ribs 5 is as follows: two second ribs 5 are fixed on the upper side of door frame 1, three second ribs 5 are fixed on the lower side of door frame 1, four second ribs 5 are fixed on the left side of door frame 1, and two second ribs 5 are fixed on the left side of door frame 1. The side is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com