Preparation of acrylic ester copolymer emulsion for pressure-sensitive adhesive

A technology of pressure-sensitive adhesives and acrylates, applied in the direction of ester copolymer adhesives, adhesive types, etc., can solve the problem of not being able to simultaneously achieve initial adhesion performance, peeling performance and sticking performance, initial adhesion performance and peeling performance. Poor stickiness, poor stickiness and other problems, to achieve the effect of reducing the amount of residual glue, improving initial tack, and improving stickiness

Active Publication Date: 2010-11-10

HEBEI UNIV OF TECH

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Common emulsion acrylate pressure-sensitive adhesives on the market are mostly polymer-polymer type, and this type of adhesive has the following disadvantages: when the initial adhesion and peeling performance of the pressure-sensitive adhesive are good, the holding performance will be poor; When it is good, the initial adhesion performance and peeling performance will become poor, and the balance [M.D.Gower, R.A.Shanks.The effect of varied monomer composition on adhesive performance and peeling master cures for acrylic pressure-sensitive adhesives.Journal of Applied Polymer Science, 2004, Vol.93, 2909-2917]

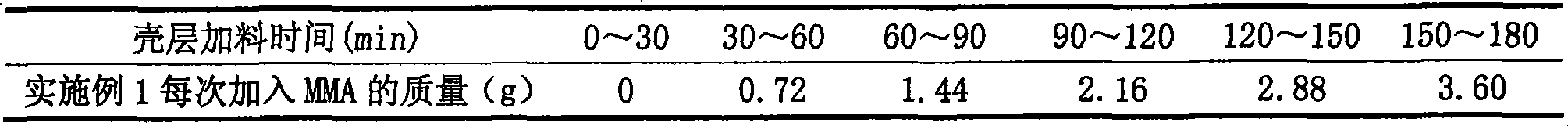

However, due to the uniform addition of methyl methacrylate (MMA) in the process of introducing hard monomers through the shell layer, the emulsion-type acrylate pressure-sensitive adhesive produced by the latex particles is easy to leave residue on the adherend after peeling off. When the glue and initial adhesive force are large, the holding force will decrease, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2~3

Embodiment 4~6

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

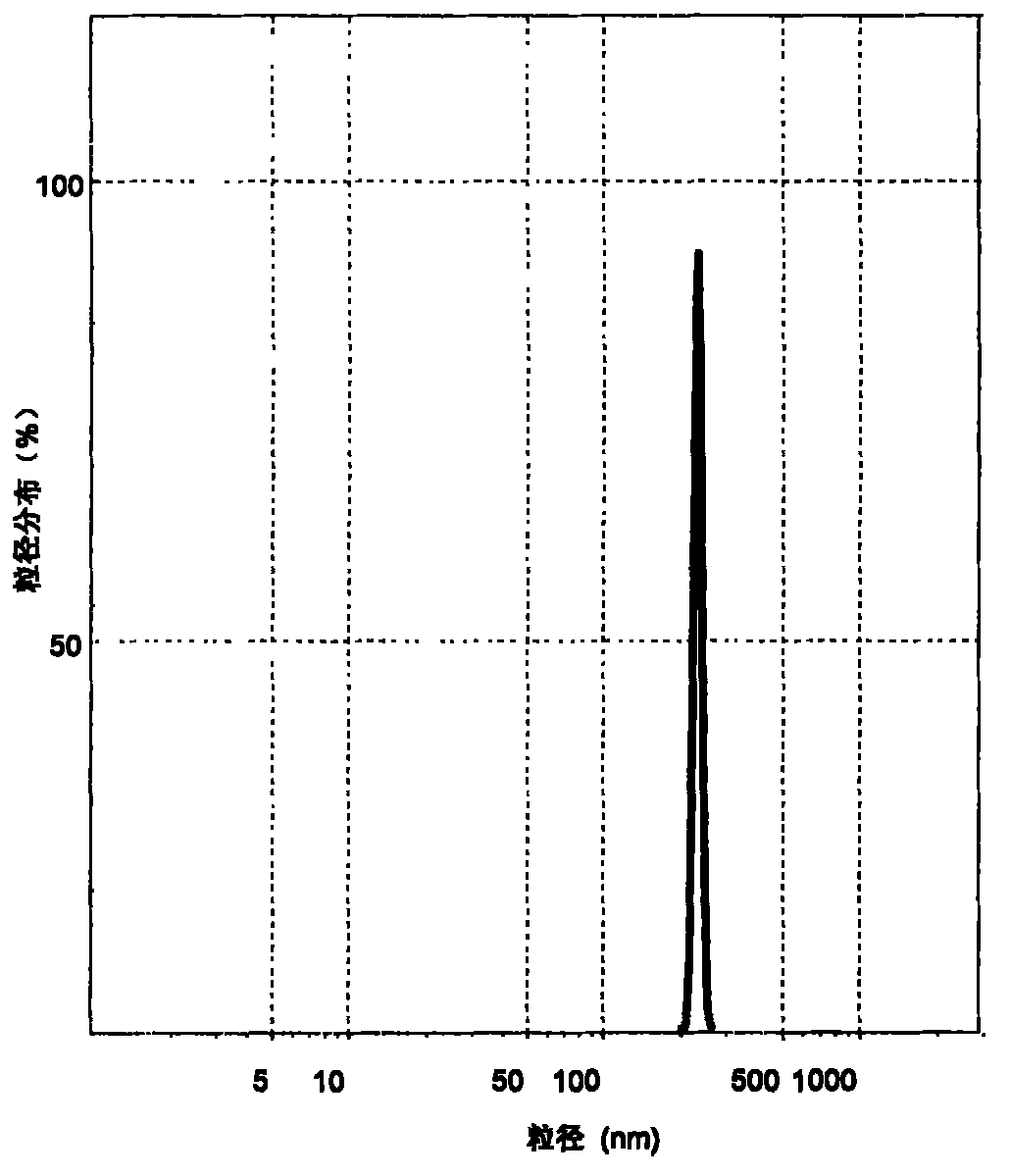

The invention relates to a method for preparing an acrylate polymer emulsion used for a pressure sensitive adhesive, which belongs to an adhesive based on acrylate polymer. The method for preparing the acrylate polymer emulsion used for the pressure sensitive adhesive comprises the following steps: (1) preparation of a seed emulsion; (2) pre-emulsification of shell layer monomers; and (3) gradient feeding of a shell layer. The method adopts the seed emulsion polymerization technology to drip a hard monomer, namely methyl methacrylate (MMA) into the shell layer, so that the concentration is subjected to discontinuous change and the organic-inorganic acrylate polymer emulsion provided with an obvious core-shell structure is prepared, wherein nano silicon dioxide is taken as a core and a copolymer of acrylic ester and acrylic monomers is taken as the shell layer; and the hard monomer of the shell layer is subjected to concentration gradient change. The acrylate polymer emulsion can be used as the pressure sensitive adhesive after drying and film forming; the prepared pressure sensitive adhesive has the advantages of high continuous viscous force and reduction of the residual gum content under the condition of gum peeling; and the initial adhesion and the peeling strength can be improved when the continuous viscous force is larger.

Description

A kind of preparation method of acrylate copolymer emulsion for pressure-sensitive adhesive technical field The technical solution of the present invention relates to an adhesive based on an acrylate copolymer, in particular to a method for preparing an acrylate copolymer emulsion for a pressure-sensitive adhesive. Background technique Pressure-sensitive adhesives can be prepared by processes such as emulsion polymerization, solution polymerization, heating and melting, and UV curing. However, in recent years, with people's emphasis on environmental protection, safety, energy saving, etc. and the continuous expansion of the application of pressure-sensitive adhesives, pressure-sensitive adhesives have been promoted to develop in the direction of low pollution, energy saving, high performance and multi-functionality, especially in developed countries. After putting forward pollution-free, pollution-free, resource-saving and energy-saving as the prerequisites for developing ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F220/18C08F2/24C08F2/44C08K3/36C09J133/08C08F220/14

Inventor 瞿雄伟王农跃杨建光张愚姚艳梅张广林

Owner HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com