A kind of ramie biochemical degumming method

A technology of biochemistry and degumming method, which is applied in the direction of producing bast fiber by chemical method, chemical post-treatment of fiber, plant raw materials, etc. It can solve the problems of great influence on fiber strength, complex process parameters, high processing cost, etc., and achieve the amount of residual glue Small size, simple process, and the effect of reducing residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

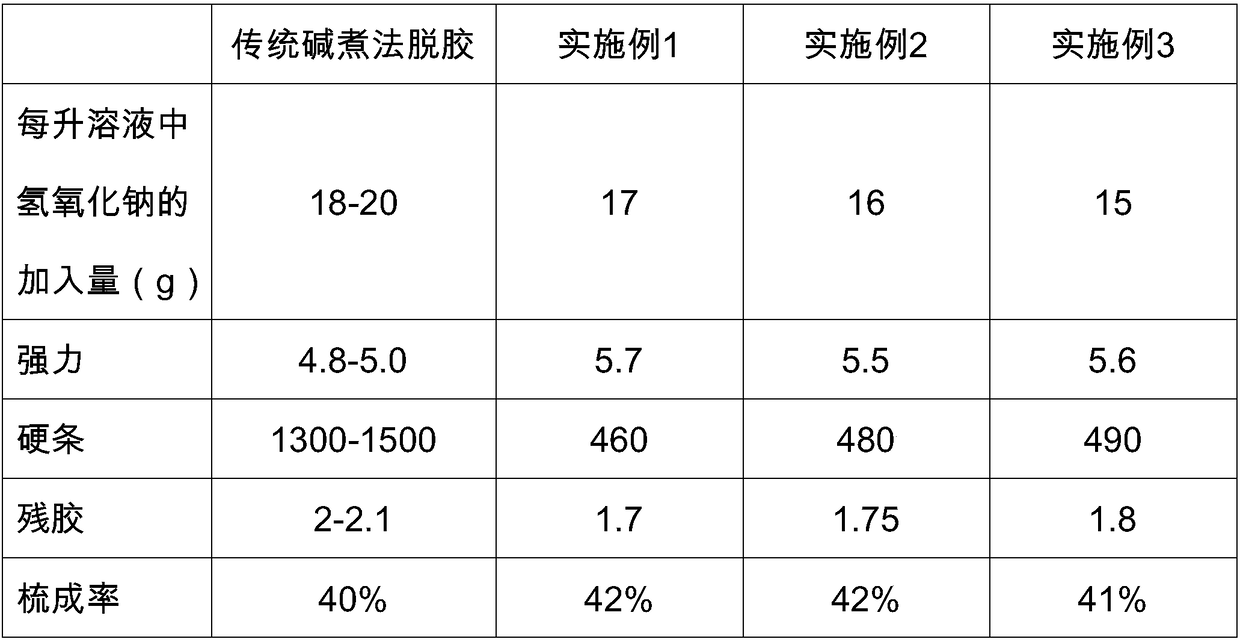

Embodiment 1

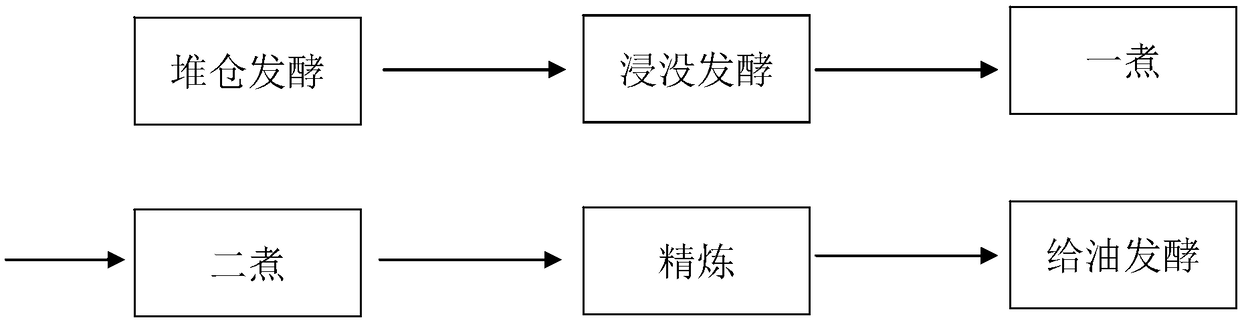

[0025] figure 1 It is the embodiment of the present invention 1 ramie degumming process flow, specifically:

[0026] Chop and cut the bast of the root of raw hemp, treat it with a softening machine, then get 550kg of raw hemp and spray the biological enzyme preparation HP-301 with a concentration of 6.5g / L until the raw hemp is moist, the water content is 40%, and the temperature is Under the condition of 50°C, ferment for 5 days;

[0027] Put the original hemp bars fermented in the warehouse into cages, put them into the fermenter for immersion fermentation, the liquor ratio is 1:8, and ferment for 24 hours;

[0028] After thoroughly washing with clear water, cook according to the bath ratio of 1:10, wherein 6 grams of sodium hydroxide recovery solution is added per liter of solution, so that the mass percentage of sodium hydroxide in the cooking solution is 0.6%, and the steam pressure is 2kg / cm 2 , at a temperature of 120°C, cook for 3 hours; after washing thoroughly agai...

Embodiment 2

[0032] Chop and cut the bast of the root of raw hemp, use a softening machine to soften it, and then take 550kg of raw hemp and spray the biological enzyme preparation HP-309 with a concentration of 5.5g / L until the water content of the raw hemp is 45%, and the temperature is 53°C Under the condition of , ferment for 6 days;

[0033] Put the original hemp bars fermented in the warehouse into cages, put them into the fermenter for immersion fermentation, the liquor ratio is 1:8, and ferment for 24 hours;

[0034] After thoroughly washing with clear water, cook according to the bath ratio of 1:10, wherein 5 grams of sodium hydroxide recovery solution is added to each liter of solution, so that the mass percentage of sodium hydroxide in the cooking solution is 0.5%, and the steam pressure is 2kg / cm 2 , at a temperature of 130°C, cook for 3 hours; after washing thoroughly again, cook again at a bath ratio of 1:10, wherein 15 grams of sodium hydroxide is added per liter of solution...

Embodiment 3

[0038] Chop and cut the bast at the root of the raw hemp, use a softening machine to soften it, and then take 550kg of raw hemp and spray the biological enzyme preparation HP-301 with a concentration of 5.5g / L until the water content of the raw hemp is 50%, and the temperature is 55°C Under the condition of , ferment for 7 days;

[0039] Put the original hemp bars fermented in the warehouse into cages, put them into the fermenter for immersion fermentation, the liquor ratio is 1:8, and ferment for 24 hours;

[0040] After thoroughly washing with clear water, cook according to the bath ratio of 1:10, wherein 7 grams of sodium hydroxide recovery solution is added per liter of solution, so that the mass percentage of sodium hydroxide in the cooking solution is 0.7%, and the steam pressure is 2kg / cm 2 , at a temperature of 125°C, cook for 3 hours; after washing thoroughly again, cook again at a bath ratio of 1:10, wherein 16 grams of sodium hydroxide is added per liter of solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com