Protection film for protecting work-piece in processing state, and applications thereof

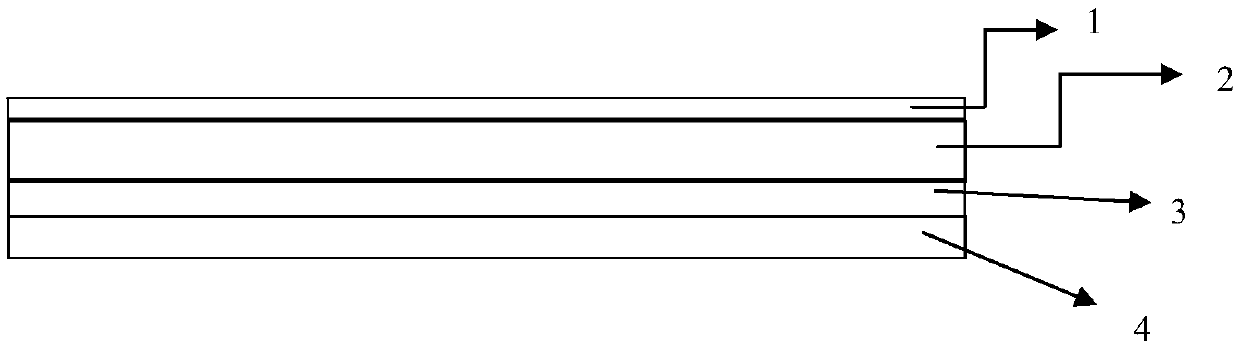

A processing state, protective film technology, applied in the direction of film/sheet adhesive, pressure sensitive film/sheet, graft polymer adhesive, etc., can solve the problem of poor surface accuracy, poor appearance quality, contaminated surface, etc. problems, to achieve the effect of enhancing chemical resistance and solvent resistance, high cleanliness, and increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Raw materials are calculated in parts by weight.

[0047] Add 50 parts of acrylic resin, 2 parts of acrylic acid, and 90 parts of ethyl acetate into the stirring tank, stir well, then add 40 parts of vinyl siloxane, 3 parts of tackifying resin, stir well, then add 0.5 parts of curing agent, 0.01 parts of curing accelerator, 10 parts of ethyl acetate, fully stirred until uniform.

[0048] Use a scraper coater to coat the stirred glue on the release surface of the release film, and enter the hot drying tunnel until the solvent is completely evaporated. At the same time, the polyacrylate surface of the polyvinyl chloride / polyacrylate composite film is corona-coated, compounded with a release film coated with an adhesive layer, and wound up.

[0049] Then, the rolled film is passed through electron beam irradiation equipment, and the irradiation dose is 50 kGy. Rewind, place in a drying room at 60°C, take it out after 24 hours, cut to the required width, and divide into rol...

Embodiment 2

[0051] Raw materials are calculated in parts by weight.

[0052] Add 30 parts of acrylic resin, 1 part of acrylic acid, and 90 parts of ethyl acetate into the stirring tank, stir well, then add 30 parts of vinyl siloxane, 3 parts of tackifying resin, stir well, then add 0.3 parts of curing agent, 0.01 parts of curing accelerator, 10 parts of ethyl acetate, fully stirred until uniform.

[0053] Use a scraper coater to coat the stirred glue on the release surface of the release film, and enter the hot drying tunnel until the solvent is completely evaporated. At the same time, the polyacrylate surface of the polyvinyl chloride / polyacrylate composite film has a good corona, and it is composited with the release film coated with an adhesive layer and rolled up.

[0054] Then, the rolled film is passed through electron beam irradiation equipment, and the irradiation dose is 40 kGy. Rewind, place in a drying room at 60°C, take it out after 24 hours, cut to the required width, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com