Laser holographic composite film and manufacture method thereof

A technology of laser holography and composite film, applied in the field of holographic anti-counterfeiting printing and packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

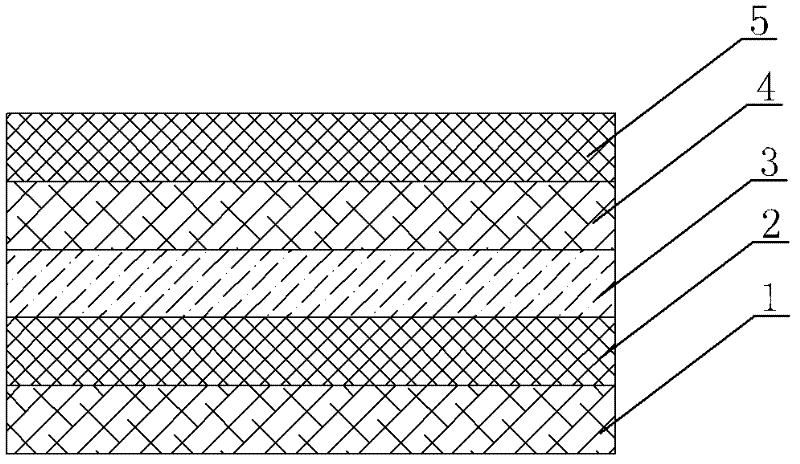

[0016] The structure of the laser holographic composite film of the present invention is as figure 1 As shown, one side of the polyester film 5 is respectively a printed graphic layer 4, a UV varnish layer 3, a holographic image layer 2, and an aluminum-coated layer 1 from top to bottom. the

[0017] The present invention prepares the technological process of laser holographic composite film as figure 2 Shown: polyester film→printing graphic layer→coating UV varnish layer→pre-drying; prefabricated laser holographic BOPP film→coating UV varnish layer→pre-drying; second embossing) → first UV curing → second UV curing → second compounding (ie second imprinting) → peeling → vacuum aluminum plating.

[0018] When preparing the laser holographic composite film of the present invention, first make the printed graphic layer 4 on one side of the polyester film 5;

[0019] Then, using the image 3 The production line shown makes the holographic image layer 2: on the printed graphic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com