A kind of preparation method of castor oil-based fully cross-linked UV photoreleasable adhesive for silicon wafer cutting process

A castor oil-based, cutting process technology, applied in the direction of adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of difficulty in improving light peeling strength, difficult light curing, etc., to reduce peeling strength and Residual glue, improve peel strength, improve the effect of cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

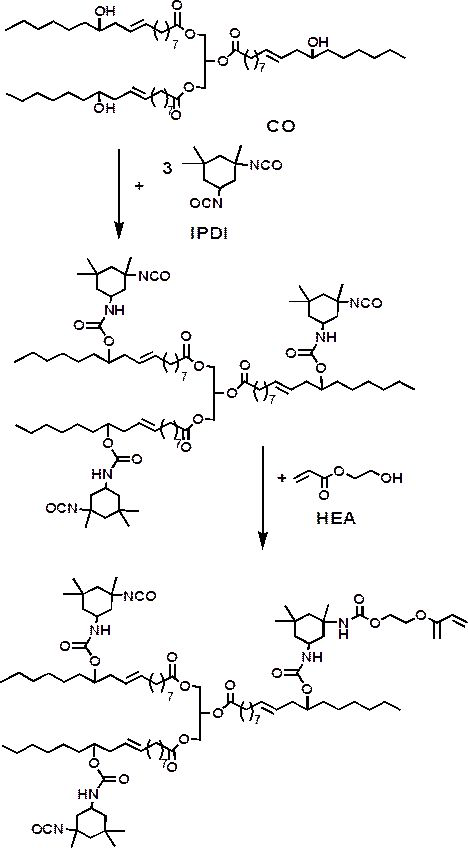

[0021] (1) Synthesis of castor oil-based urethane acrylate prepolymer containing acrylate group and -NCO group: under nitrogen atmosphere, add IPDI 28g, CO 6.7g, dibutylene dilaurate 0.00767g, para 0.0382g of tert-butylcatechol, stirred, slowly heated up to 60°C, and reacted for 6h to obtain a castor oil-modified isocyanate prepolymer terminated by a trifunctional isocyanate group. Add 9g of HEA, and continue to react for 4h to obtain a A castor oil-based polyurethane acrylate prepolymer CO-PUB containing both acrylate groups and -NCO groups.

[0022] (2) Preparation of photopolymerizable network acrylate copolymer pressure-sensitive adhesive: Weigh 0.680g acrylic acid, 1.748g methyl methacrylate, 1.045g hydroxyethyl acrylate, 4.001g butyl acrylate, 16.001g isooctyl acrylate Esters were uniformly mixed in a beaker to obtain a monomer solution; benzoyl peroxide was weighed to dissolve 1% of the total mass of the monomer solution in ethanol to obtain an initiator solution; 15% o...

Embodiment 2

[0025] (1) Synthesis of castor oil-based urethane acrylate prepolymer containing acrylate group and -NCO group: under nitrogen atmosphere, add IPDI 28g, CO 6.7g, dibutylene dilaurate 0.00767g, para 0.0382g of tert-butylcatechol, stirred, slowly heated up to 60°C, and reacted for 6h to obtain a castor oil-modified isocyanate prepolymer terminated by a trifunctional isocyanate group. Add 9g of HEA, and continue to react for 4h to obtain a A castor oil-based polyurethane acrylate prepolymer CO-PUB containing both acrylate groups and -NCO groups.

[0026] (2) Preparation of photopolymerizable network acrylate copolymer pressure-sensitive adhesive: Weigh 0.680g acrylic acid, 1.748g methyl methacrylate, 1.045g hydroxyethyl acrylate, 4.001g butyl acrylate, 16.001g isooctyl acrylate Esters were uniformly mixed in a beaker to obtain a monomer solution; benzoyl peroxide was weighed to dissolve 1% of the total mass of the monomer solution in ethanol to obtain an initiator solution; 15% of ...

Embodiment 3

[0029] (1) Synthesis of castor oil-based urethane acrylate prepolymer containing acrylate group and -NCO group: under nitrogen atmosphere, add IPDI 28g, CO 6.7g, dibutylene dilaurate 0.00767g, para 0.0382g of tert-butylcatechol, stirred, slowly heated up to 60°C, and reacted for 6h to obtain a castor oil-modified isocyanate prepolymer terminated by a trifunctional isocyanate group. Add 9g of HEA, and continue to react for 4h to obtain a A castor oil-based polyurethane acrylate prepolymer CO-PUB containing both acrylate groups and -NCO groups.

[0030] (2) Preparation of photopolymerizable network acrylate copolymer pressure-sensitive adhesive: Weigh 0.680g acrylic acid, 1.748g methyl methacrylate, 1.045g hydroxyethyl acrylate, 4.001g butyl acrylate, 16.001g isooctyl acrylate Esters were uniformly mixed in a beaker to obtain a monomer solution; benzoyl peroxide was weighed to dissolve 1% of the total mass of the monomer solution in ethanol to obtain an initiator solution; 15% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com