Patents

Literature

48results about How to "Accelerated volume shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive silver glue, preparation method and application thereof

ActiveCN106753133AImprove conductivityFast curingNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyShrinkage rate

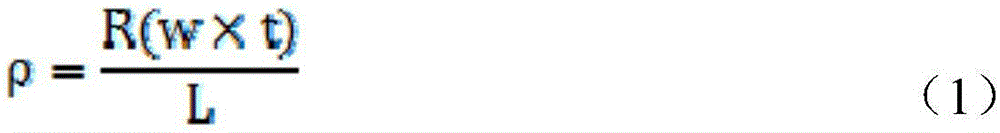

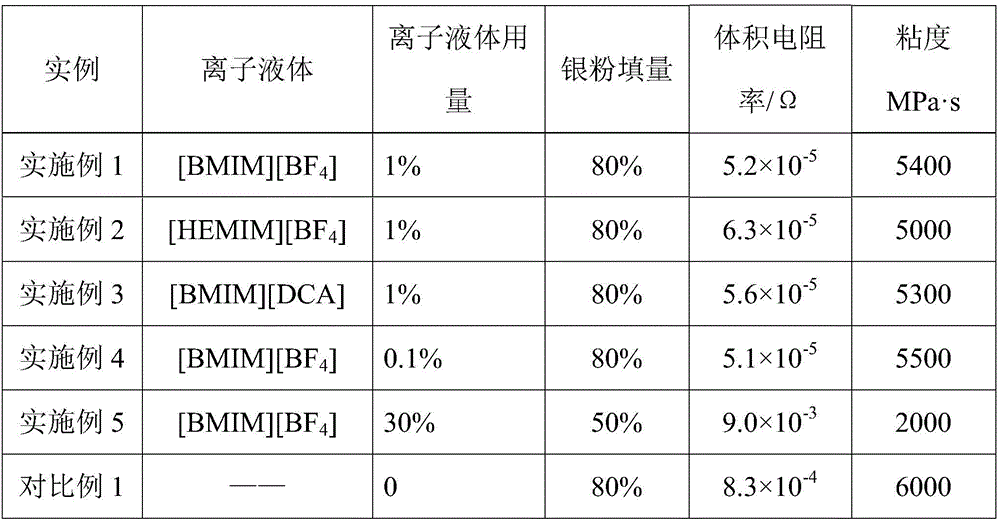

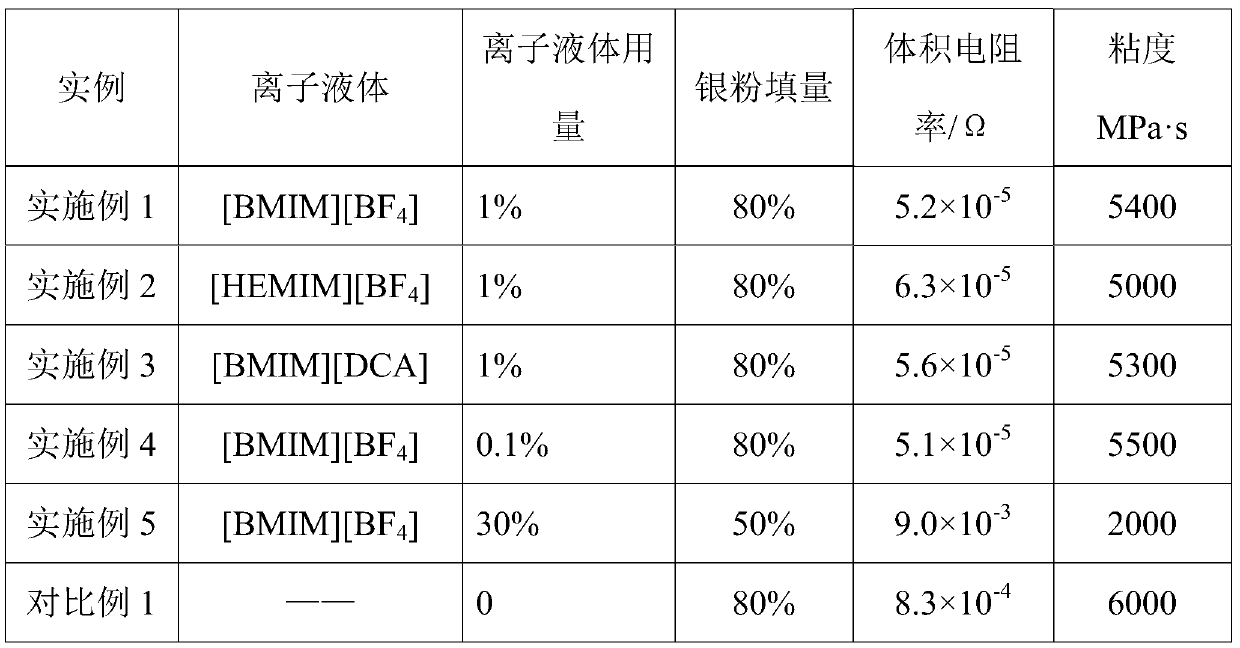

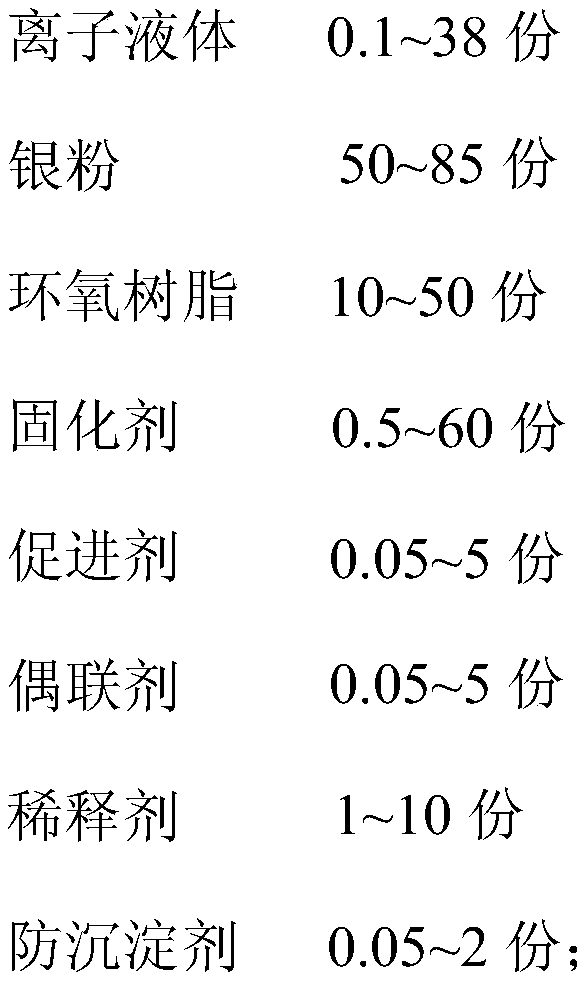

The invention relates to conductive silver glue, the conductive silver glue comprises the following components by weight: 0.1-60 parts of an ionic liquid, 50-85 parts of silver powder, 10-50 parts of epoxy resin, 0.5-60 parts of a curing agent, 0.05-5 parts of an accelerator, 0.05-5 parts of a coupling agent, 1-10 parts of a diluent and 0.05-2 parts of an anti settling agent. The ionic liquid with catalytic activity is introduced into a conductive adhesive formula to promote the further curing of the epoxy resin, improve the volume shrinkage rate and greatly improve the conductivity of the conductive silver glue. By addition of the same amount of silver powder, the conductivity of the conductive silver glue is greatly increased (to 10<-5> orders of magnitudes and to reach a higher level in the market); the dispersion of a conductive filler is promoted, the viscosity of the conductive silver glue is reduced, and the operating performance of the product is improved. The method has the advantages of simple operation and low material cost, the cost of the conductive silver glue is reduced, and the conductive silver glue can be widely used in solar cells, integrated circuits and LED packaging and other fields.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method for preparing graphene reinforced copper base composite material

The invention discloses a method for preparing a graphene reinforced copper base composite material. Uniformly mixed graphene and copper powder are covered by a thin pure copper chip; the pouring speed is not higher than 1 mm / s; the influence on the graphene dispersing process by flowing of molten copper in the pouring process is controlled; and the temperature of the poured molten copper is not lower than 1080 DEG C and not higher than 1200 DEG C. The method can prominently improve distribution of graphene in a copper matrix in the process of using a casting method to prepare the graphene reinforced copper base composite material, and enhances the material strength and hardness; the average hardness of the graphene reinforced copper base composite material in the method can reach above 80 HV; the electric conductivity under normal temperature is not lower than 80% IACS; and the heat conducting coefficient under normal temperature is not lower than 339 w / (mK).

Owner:JIANGXI UNIV OF SCI & TECH +1

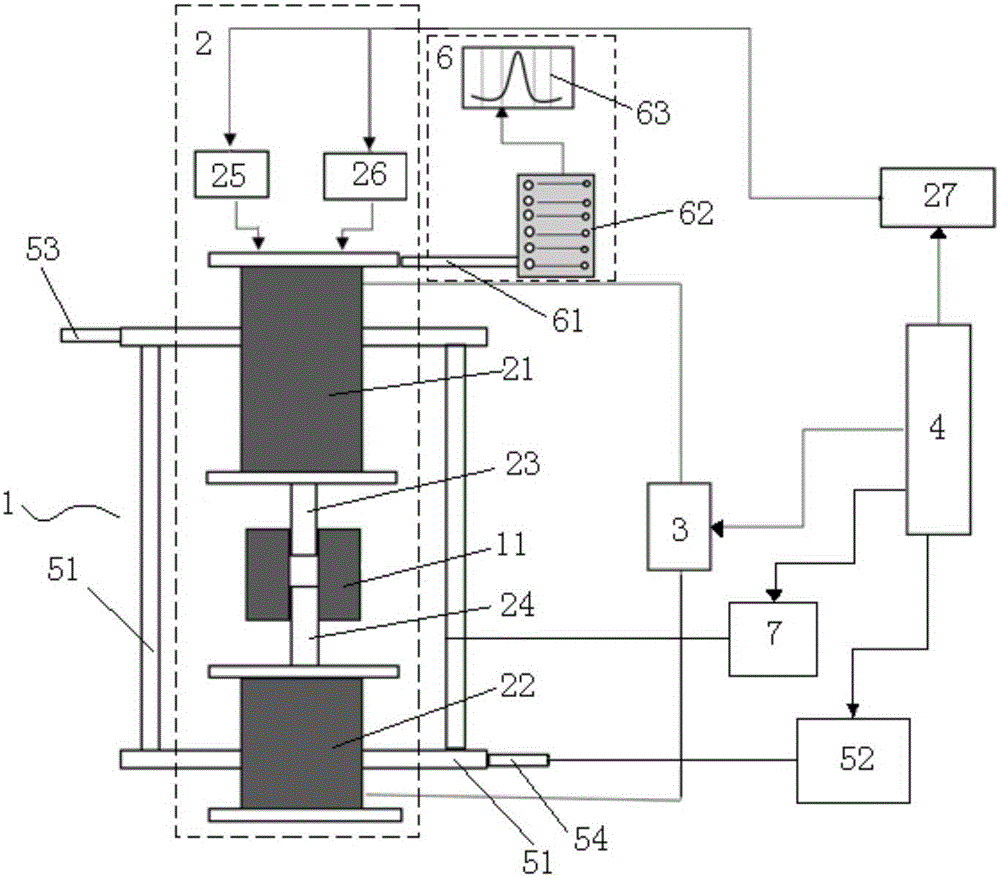

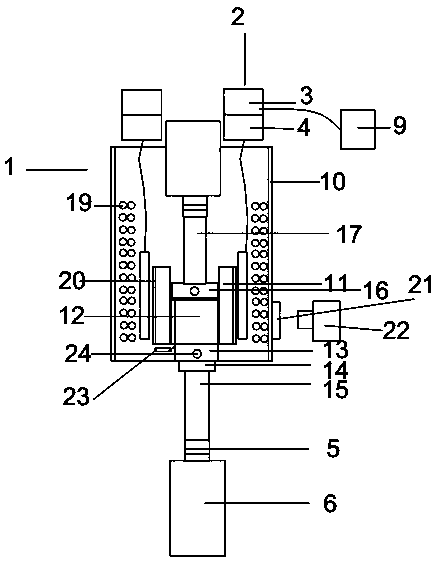

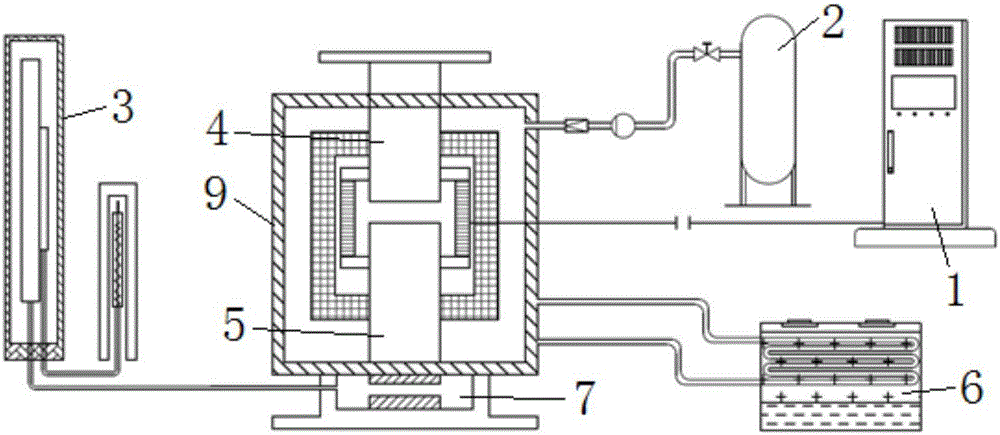

Dynamic pressure electric pulse double-field control sintering furnace and sintering method

ActiveCN105135873ALower sintering temperatureShorten the sintering timeMuffle furnacesMaintainance of heating chambersElectrical impulseDynamic pressure

The invention relates to a dynamic pressure electric pulse double-field control sintering furnace and a sintering method. The sintering furnace comprises a furnace body, a dynamic pressure system, a pulse current generator and a sintering controller. The furnace body is connected with the dynamic pressure system and the pulse current generator. The dynamic pressure system and the pulse current generator are both connected to the sintering controller. A die is arranged in the furnace body. The dynamic pressure system comprises an upper press head electrode, a lower press head electrode, an upper press head, a lower press head, a constant pressure control module, a dynamic pressure control module and a pressure master control module. The dynamic pressure system is connected with the sintering controller. The pulse current generator is connected with the upper press head electrode and the lower press head electrode and connected with the sintering controller as well. The sintering controller controls the dynamic pressure system and the pulse current generator to generate the adjustable dynamic pressure for a material to be sintered and conduct plasma pulse current sintering on the material to be sintered. The dynamic pressure electric pulse double-field control sintering furnace and the sintering method can be widely applied to sintering of the high-performance material.

Owner:TSINGHUA UNIV

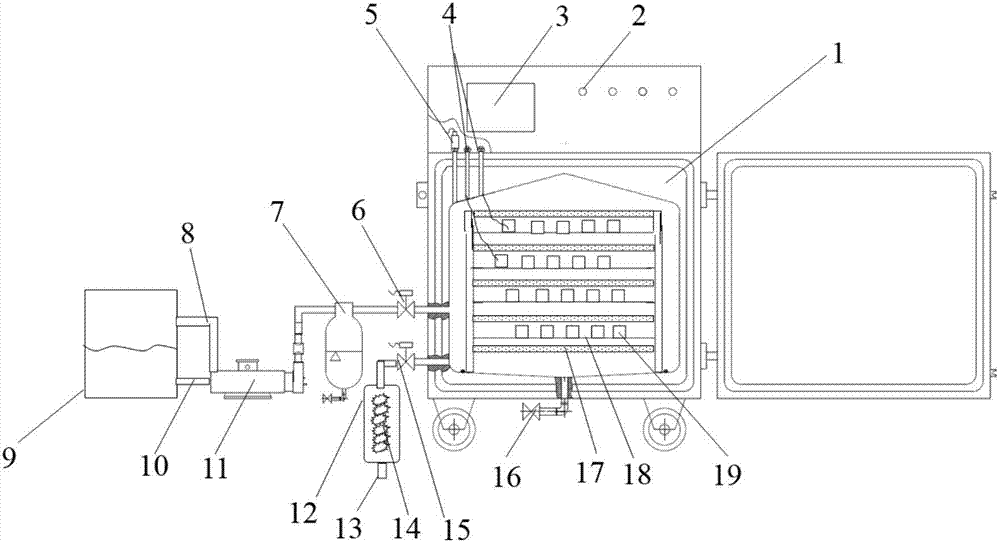

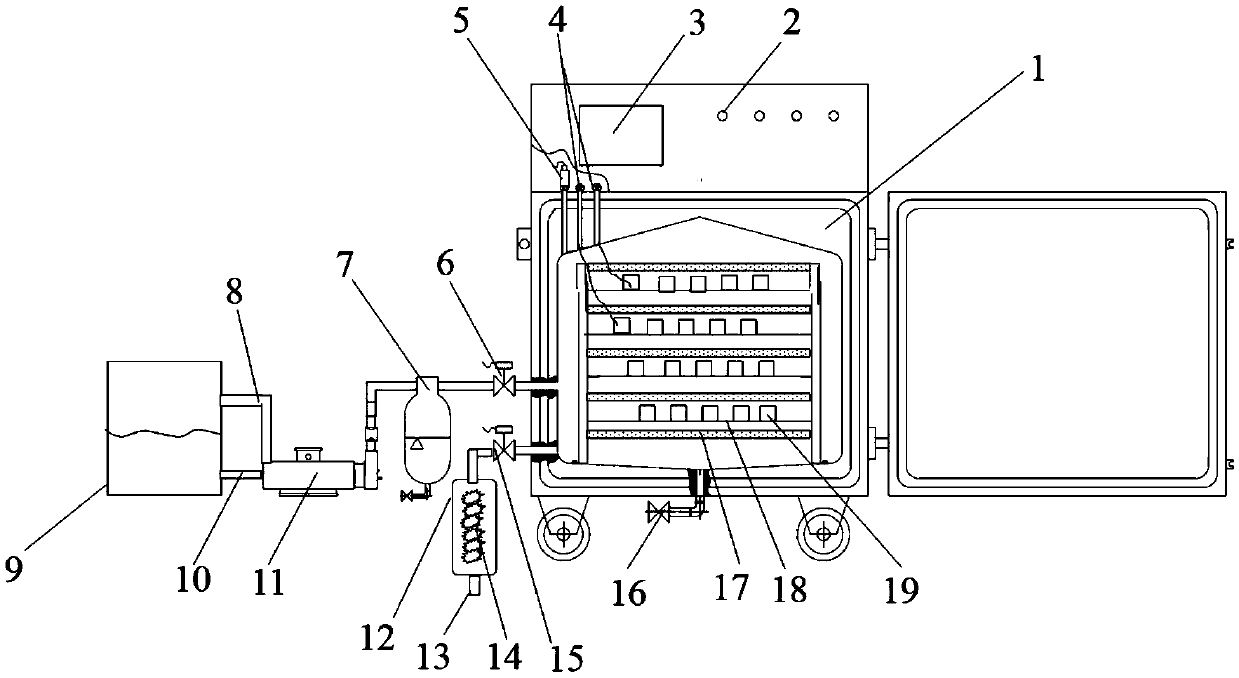

Method and device for drying poria cocos through vacuum pulsation

ActiveCN107166897AAvoid crackingAvoid breakingLighting support devicesDrying solid materials without heatControl systemPulp and paper industry

The invention belongs to the technical field of agricultural product processing and relates to a nutrition-loss-free poria cocos processing method and equipment, in particular to a method and device for drying poria cocos through vacuum pulsation. According to the method, a vacuum drying mode is adopted for drying diced poria cocos, and the situation that due to the fact that internal and external humidity gradients are uneven, volume contraction is uneven, so that materials are cracked or broken is avoided. By means of the method and device for drying the poria cocos through vacuum pulsation, under the pulsation condition that the pressure inside a drying chamber (1) is continuous, microcosmic pore channels of the diced poria cocos (19) can be expanded and contracted ceaselessly and furthermore made to communicate with one another; and volume contraction, generated in the drying process, of the diced poria cocos can be effectively promoted, and high material strength is maintained. The device comprises a vacuum system, an auxiliary hot air drying system, a heating system and a control system. By means of the device, intelligent adjustment of the temperature and the vacuum degree can be effectively achieved; the diced poria cocos can be dried quickly and evenly; and the dried diced poria cocos (19) is high in compactness and not prone to breakage.

Owner:CHINA AGRI UNIV

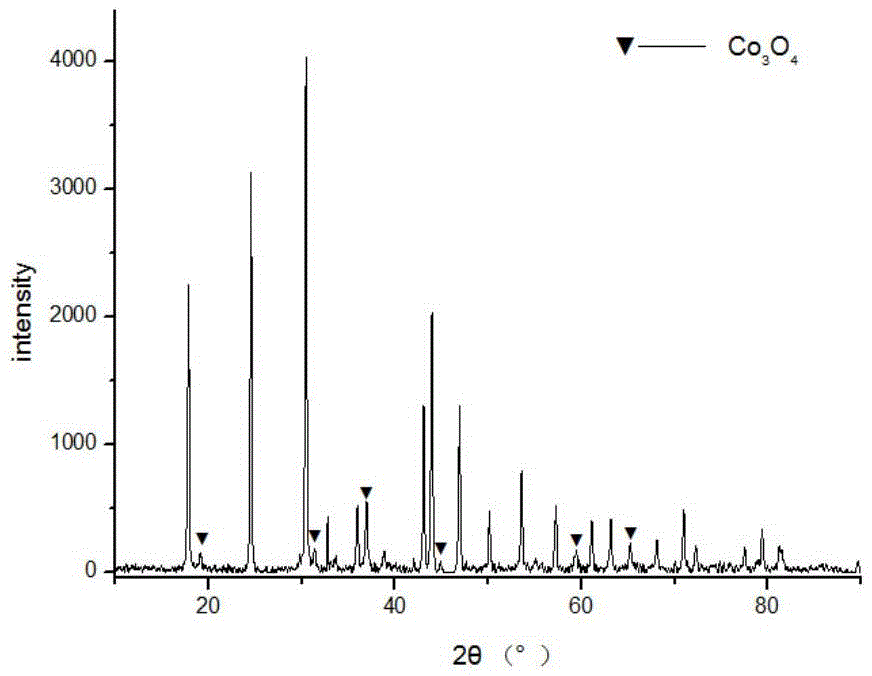

Graphene oxide rare earth compound catalytic material and preparation method thereof

ActiveCN104307530AUnique Surface Interface StructureHigh catalytic activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCombustionHydrazine compound

The invention discloses a graphene oxide rare earth compound catalytic material and a preparation method thereof. The catalytic material comprises the following raw materials in percentage by mass: 0.47-1.48% of graphene oxide, 11.71-28.25% of perovskite type rare earth oxide and 70.62-87.82% of an additive. The catalytic material is prepared from graphene oxide, perovskite type rare earth oxide and the additive by using a hydrothermal method; the perovskite type rare earth oxide is ABO3 oxide; the additives are ethanediamine, hydrazine hydrate or urea. The catalyst disclosed by the invention is excellent in methane combustion catalytic activity, the initial combustion temperature is 300 DEG C, complete conversion can be achieved at 405 DEG C, the activity effect is relatively good, the initial combustion temperature is identical, and the complete conversion temperature is reduced by 85 DEG C.

Owner:HEBEI UNIV OF TECH

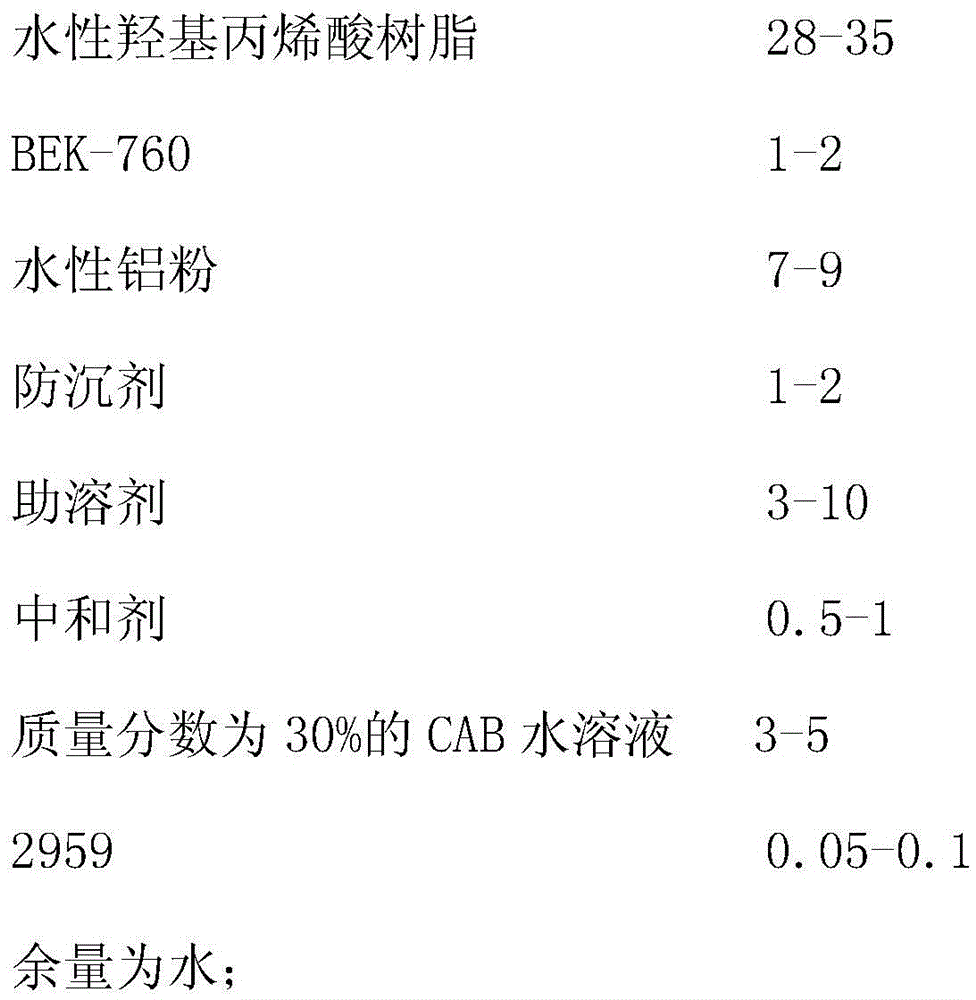

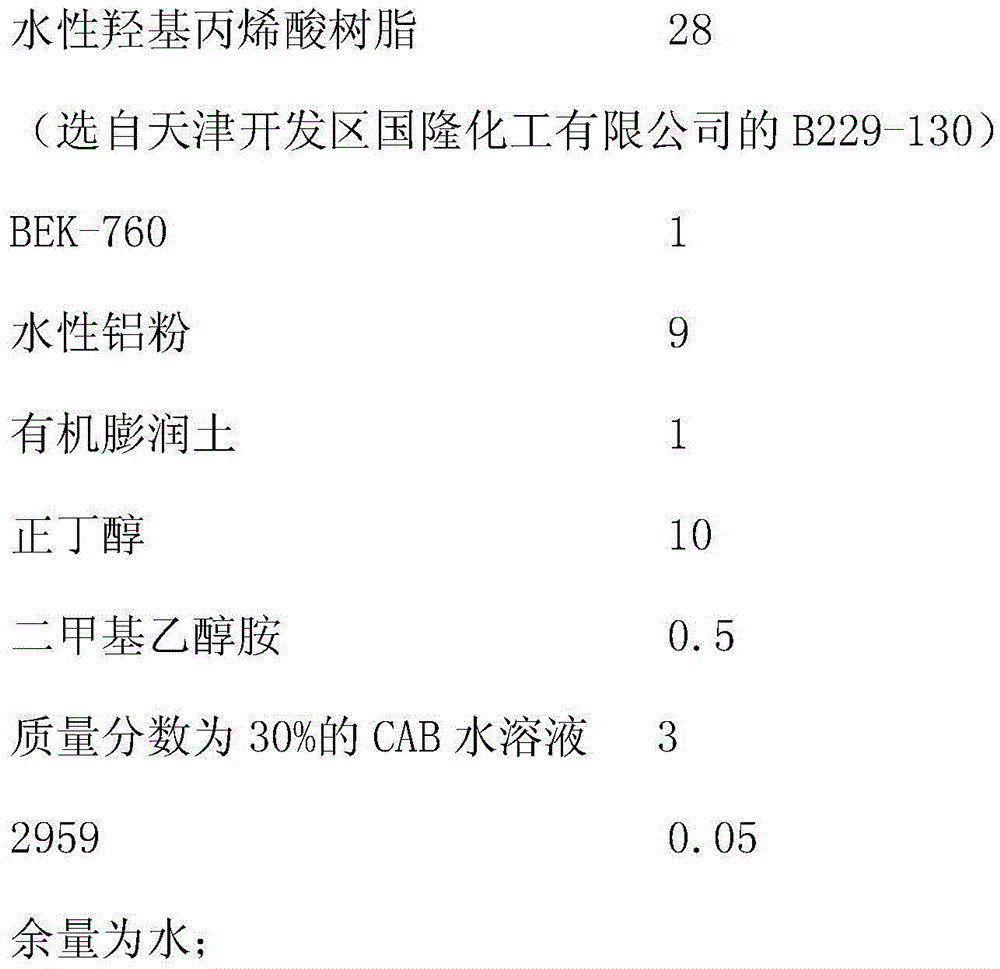

Water-based acrylic acid shining paint and preparation method thereof

The invention relates to the technical field of water-based paint, in particular to water-based acrylic acid shining paint. The water-based acrylic acid shining paint is composed of, by weight, 90-95 parts of a component A and 5-10 parts of a component B; the component A comprises water-based hydroxy acrylic resin, BEK-760, water-based aluminium powder, an anti-settling agent, cosolvent, neutralizer, a CAB aqueous solution with the mass fraction being 30%, 2959 and the balance water; the component B comprises water dispersion type polyisocyanates. According to the water-based acrylic acid shining paint, a paint film is high in drying speed, metallic pigment is uniformly arranged, the paint film is uniform in color, and excellent adhesion is achieved. The photoinitiator 2959 is added to the paint, in the construction process, the paint is sprayed at the same time of being cured through illumination of an ultraviolet lamp, the paint film is high in drying speed, meanwhile, 2529 can further promote system volume shrinkage, arrangement of the aluminium powder is facilitated, thereby a good arrangement effect is achieved, and the paint film can be uniform in color.

Owner:广东绿色大地化工有限公司

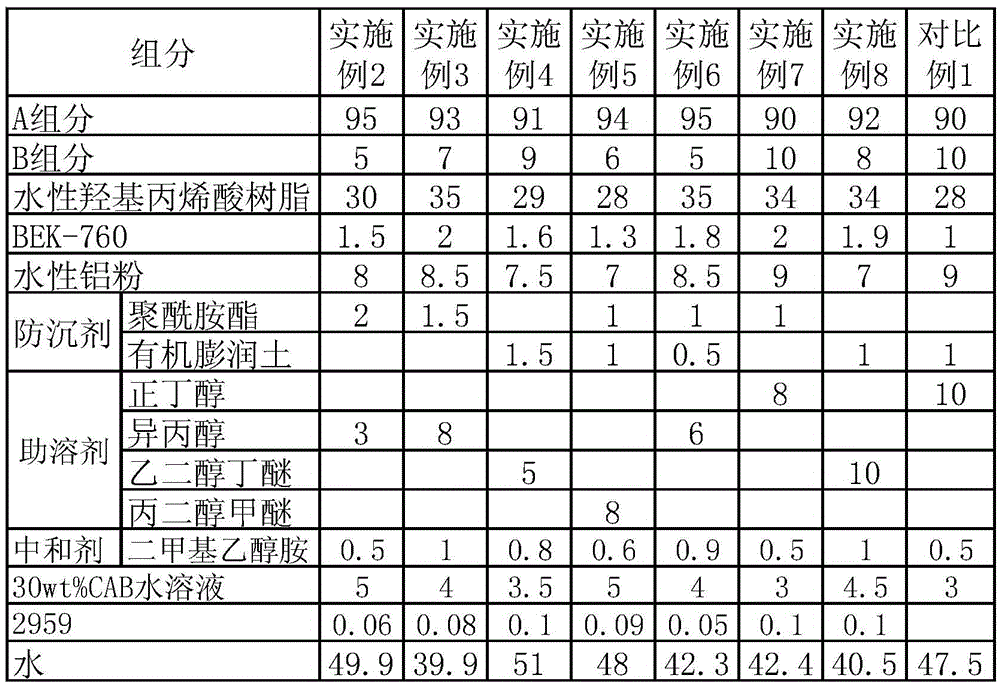

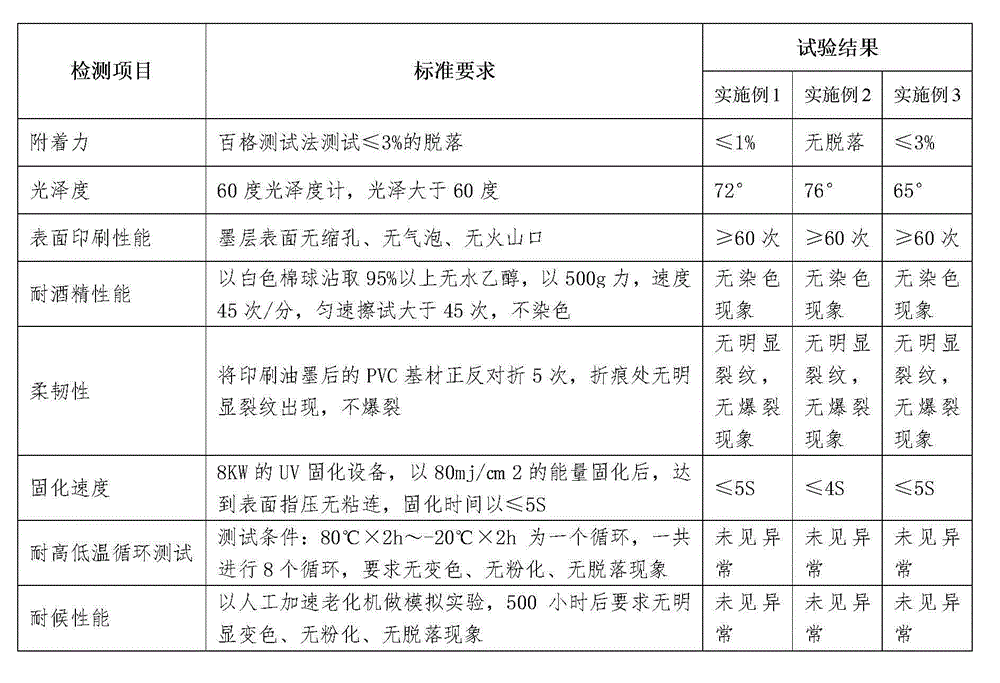

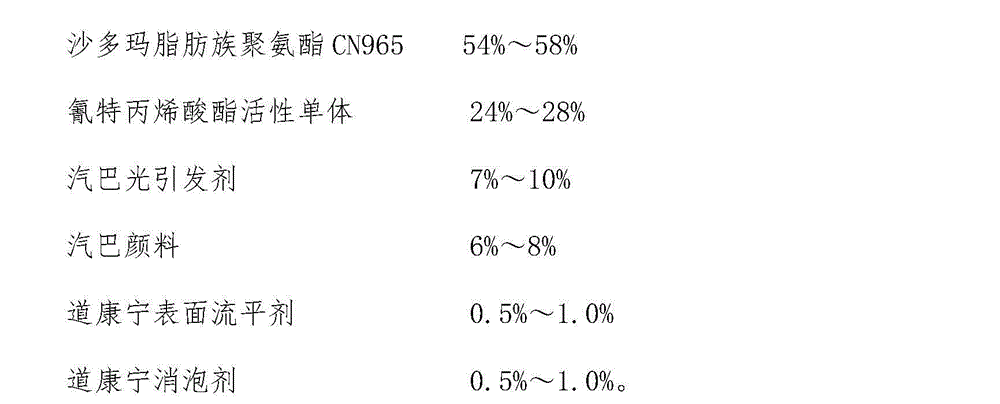

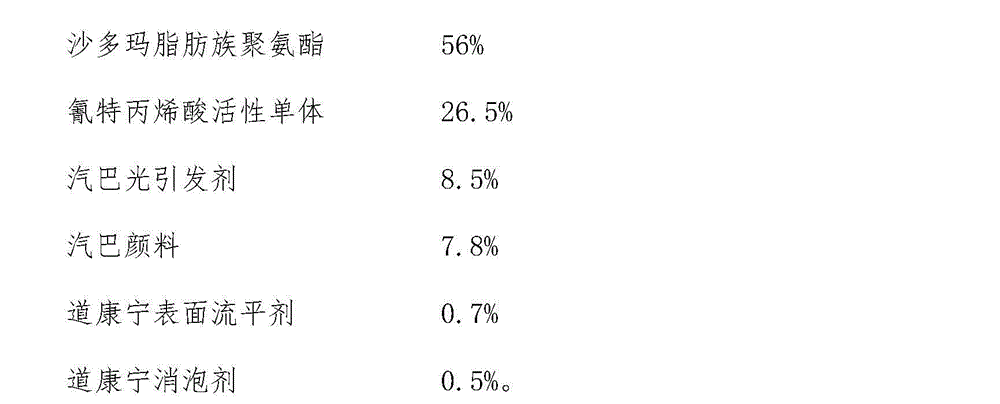

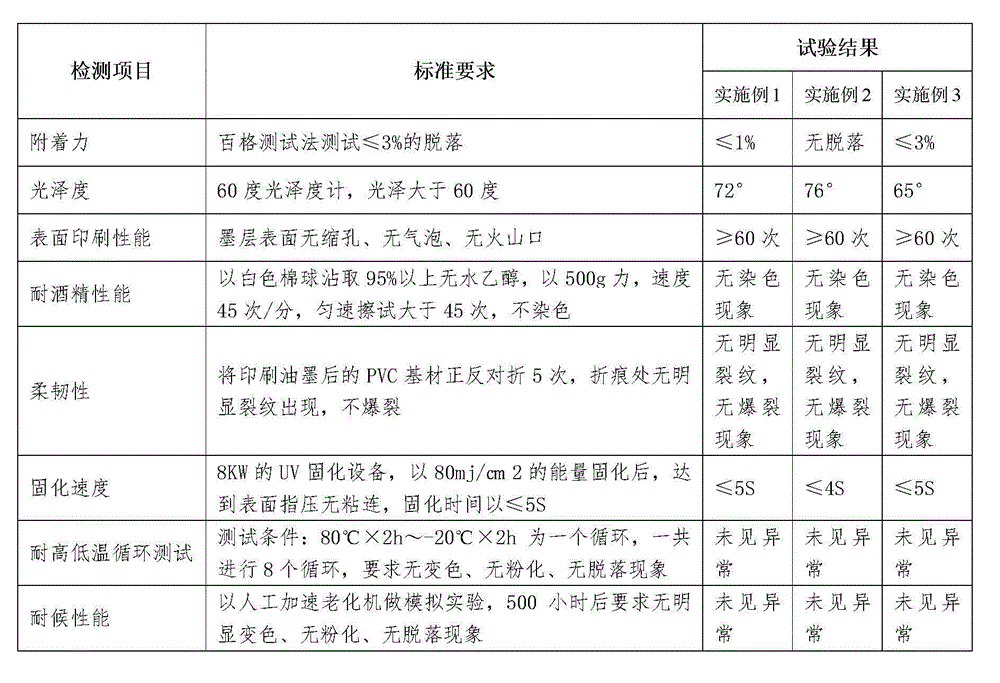

Ultra violet (UV) silk screen printing ink

The invention relates to an ultra violet (UV) silk screen printing ink. The UV silk screen printing ink comprises components of, by weight, 54%-58% of Sartomer aliphatic polyurethane CN965, 24%-28% of Cytec acrylic ester activated monomers, 7%-10% of Ciba photoinitiators, 6%-8% of Ciba pigments, 0.5%-1.0% of Dow Corning surface flatting agents and 0.5%-1.0% of Dow Corning antifoaming agents, wherein the Cytec acrylic ester activated monomers are formed by mixing propoxylate oneopentylglycol diacrylate and ethoxylated trimethylolpropane triacrylate according to the ratio of 1: 1, adding the components into a stirrer to be dispersed until the temperature reaches 50 DEG C, and putting the components into a three-roller machine to be ground until the fineness of the components is smaller than or equal to 5 mu m. The UV silk screen printing ink is good in adhesive force and bending resistance performance.

Owner:中山市中益油墨涂料有限公司

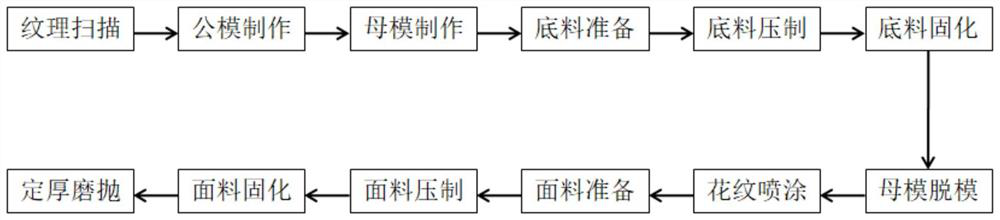

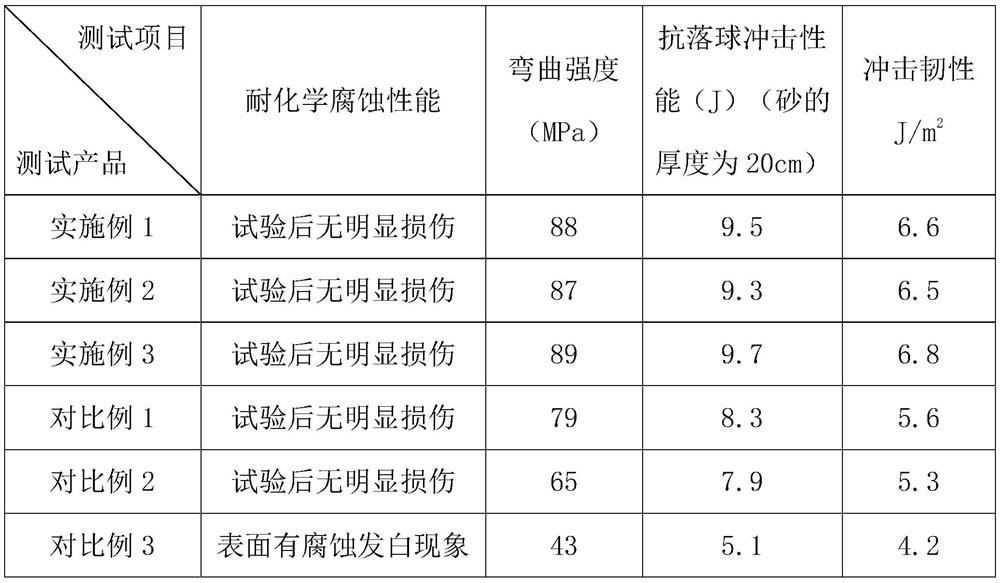

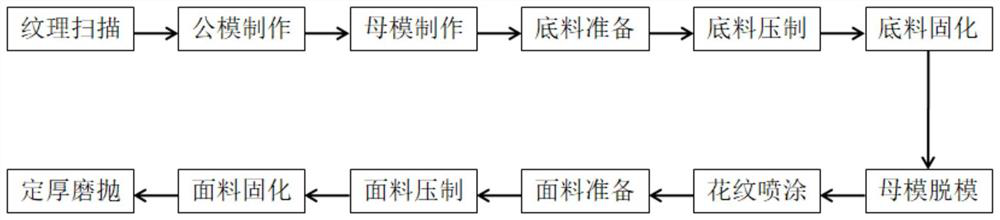

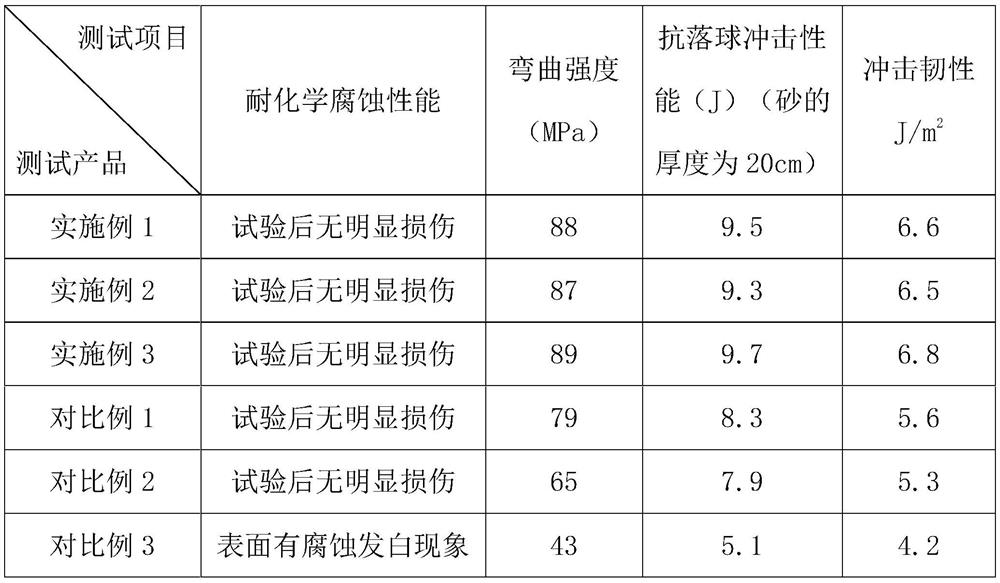

Preparation process of synthetic quartzite imitating three-dimensional textures of natural stone

ActiveCN112373073AReduce volatilityGood light transmissionFlat articlesPolymer sciencePolyester resin

The invention discloses a preparation process of synthetic quartzite imitating three-dimensional textures of natural stone. The preparation process comprises the following steps: a, manufacturing a mold, specifically, scanning textures on the surface of a natural stone plate and forming a graphic file; manufacturing a male die and a female die with three-dimensional concave-convex textures according to the graphic file; b, preparing a backing material, specifically, uniformly stirring raw materials of the backing material, wherein the raw materials of the backing material comprise resin, and the resin is unsaturated polyester resin; and c, pressing the backing material, specifically, uniformly spreading the backing material on the female die, strickling, vacuumizing, and carrying out vibration pressing. According to the preparation process of the synthetic quartzite imitating the three-dimensional textures of the natural stone, the prepared synthetic quartzite is strong in pattern texture three-dimensional sense, rich in color and comparable with the textures of the natural stone, and has the advantages of corrosion resistance, high strength, smoothness, difficulty in deformation and no delamination, and the problems that existing synthetic quartzite is poor in texture, strength and corrosion resistance are solved..

Owner:中旗(湖北)新材料有限公司

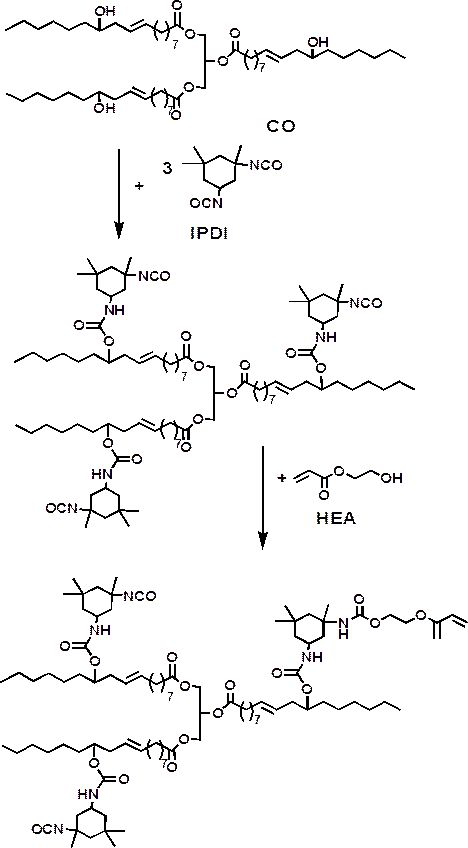

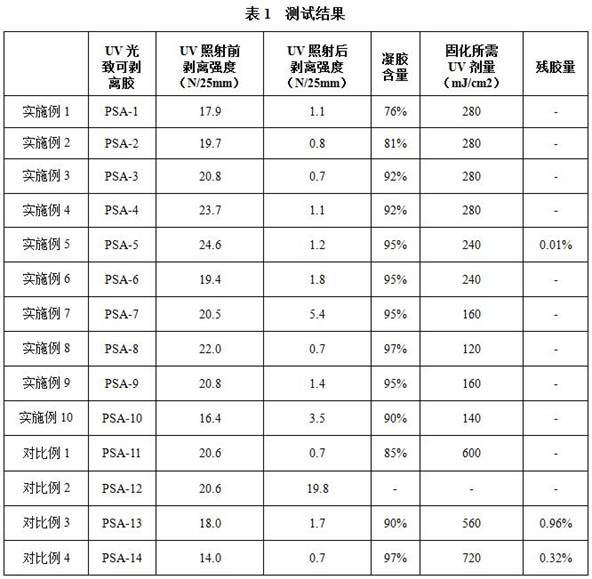

Preparation method of castor oil-based fully-crosslinked UV (Ultraviolet) photoinduced peelable glue for silicon wafer cutting process

ActiveCN112646537AHigh peel strengthReduce UV doseNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceWafer dicing

The invention provides a preparation method of castor oil-based fully-crosslinked UV (Ultraviolet) photoinduced peelable glue suitable for a silicon wafer cutting process. The preparation method comprises the following steps: reacting hydroxyl in castor oil with isocyanate groups in diisocyanate to obtain castor oil-based polyurethane containing -NCO groups; and then adding hydroxylated acrylate to prepare the urethane acrylate prepolymer containing the -NCO group and the acrylate group. The -NCO group in the prepolymer can be subjected to a cross-linking reaction with an acrylate copolymer-based adhesive containing hydroxyl and carboxyl before illumination so as to obtain a photopolymerizable reticular pressure-sensitive adhesive, and the acrylate group is subjected to cross-linking copolymerization with a functional diluent during illumination so as to form a fully cross-linked structural adhesive film. Before illumination, the pressure-sensitive adhesive can effectively improve the peel strength before illumination. The effective combination of the pressure-sensitive adhesive, a diluent and a photoinitiator can reduce the UV dosage required by photocuring; and the fully-crosslinked three-dimensional network structure adhesive film formed after photocuring is beneficial to improving the crosslinking degree, increasing the volume shrinkage and reducing the residual adhesive amount.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

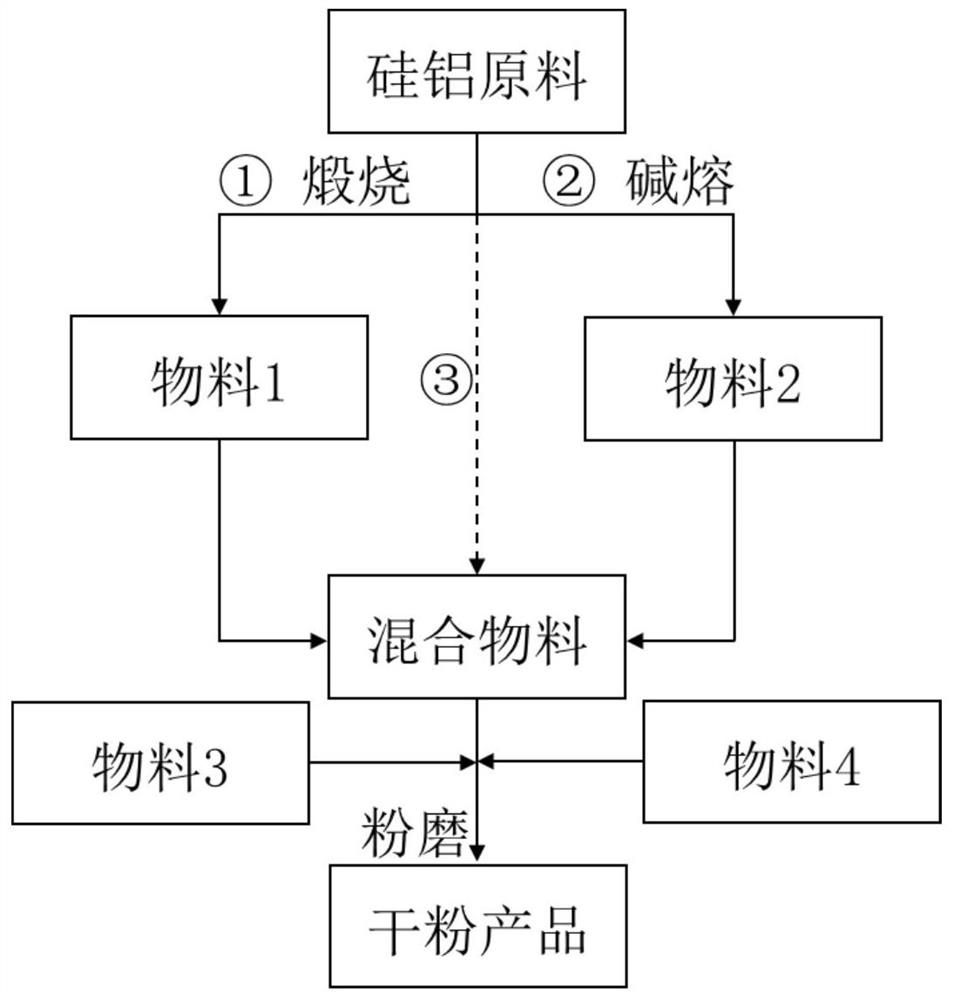

Geopolymer dry powder material and preparation method thereof

The invention discloses a geopolymer dry powder material and a preparation method thereof. The preparation method comprises the following steps: by taking waste residues containing silicon and aluminum components as silicon and aluminum raw materials, carrying out high-temperature calcination activation on part of the silicon and aluminum raw materials; mixing a part of the silicon-aluminum raw material with an alkali flux, and carrying out high-temperature alkali fusion treatment; mixing the material subjected to high-temperature activation with the material subjected to alkali fusion, wherein the content of the material subjected to alkali fusion is controlled to be 25-40%; adding silica fume into the mixed material to adjust the silica-alumina ratio to be 1.5-5, meanwhile, adding calcium and magnesium oxides or hydroxides , and wherein the adding amount of the calcium and magnesium oxides or hydroxides is controlled to be within 15% of the total material amount; and grinding the obtained material to obtain the geopolymer dry powder material. The method overcomes the defects of high cost and inconvenience caused by the use of a sodium silicate solution in the traditional geopolymer synthesis; the synthesis raw material is the waste residue containing silicon and aluminum components, and is wide in source, low in price; and operation is simple.

Owner:CHINA UNIV OF MINING & TECH

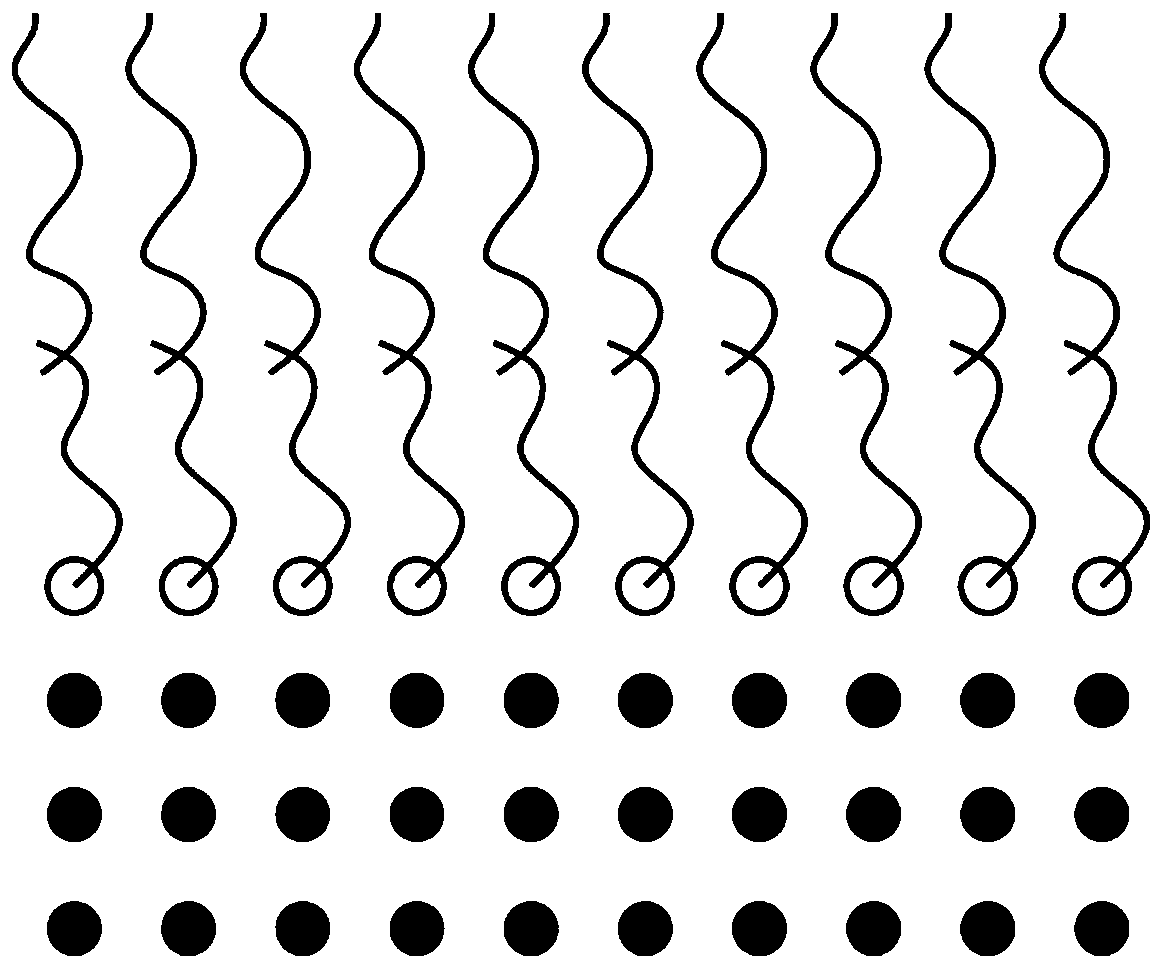

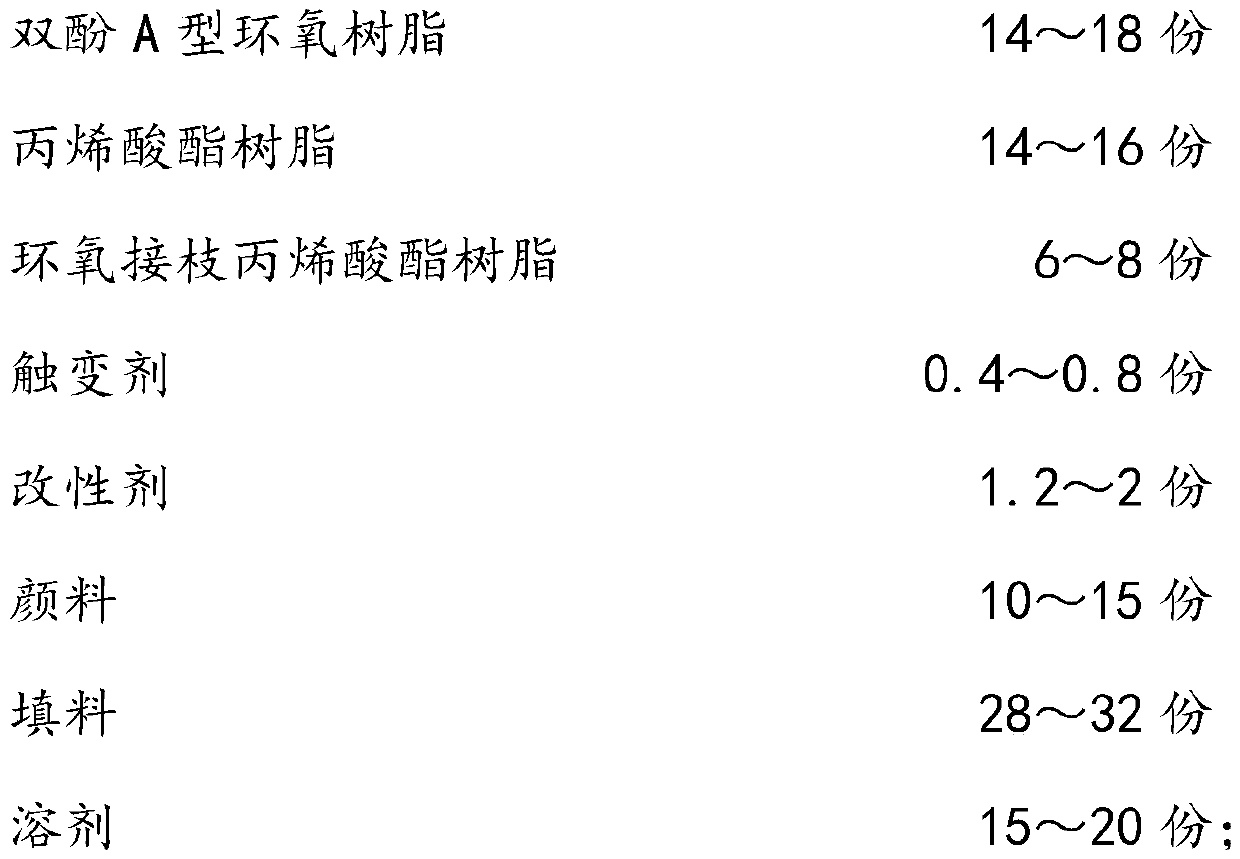

Epoxy grafted acrylate self-layering connecting paint and preparation method thereof

ActiveCN110724436ABig difference in structureSolubility parameter difference is largeEpoxy resin coatingsAnti-fouling paintFirming agent

Owner:XIAMEN SUNRUI SHIP COATING

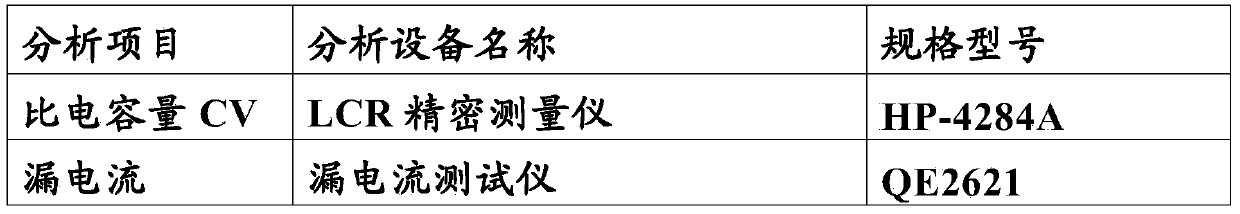

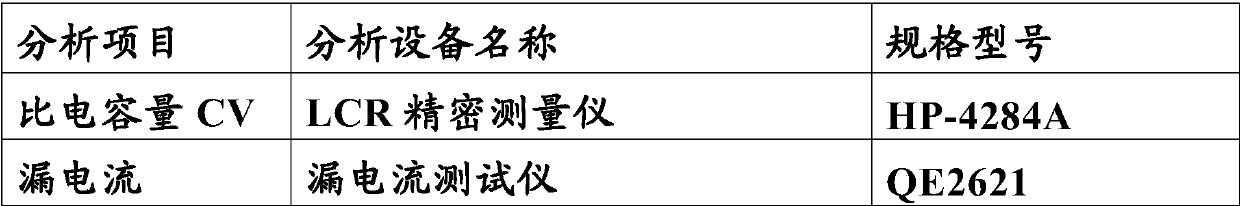

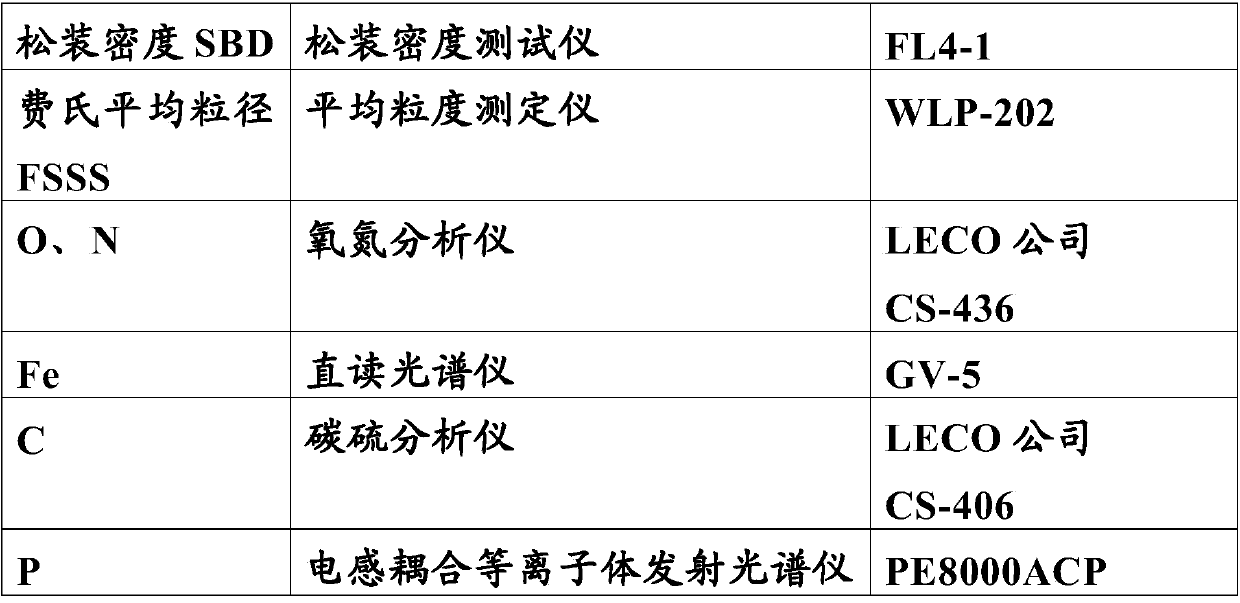

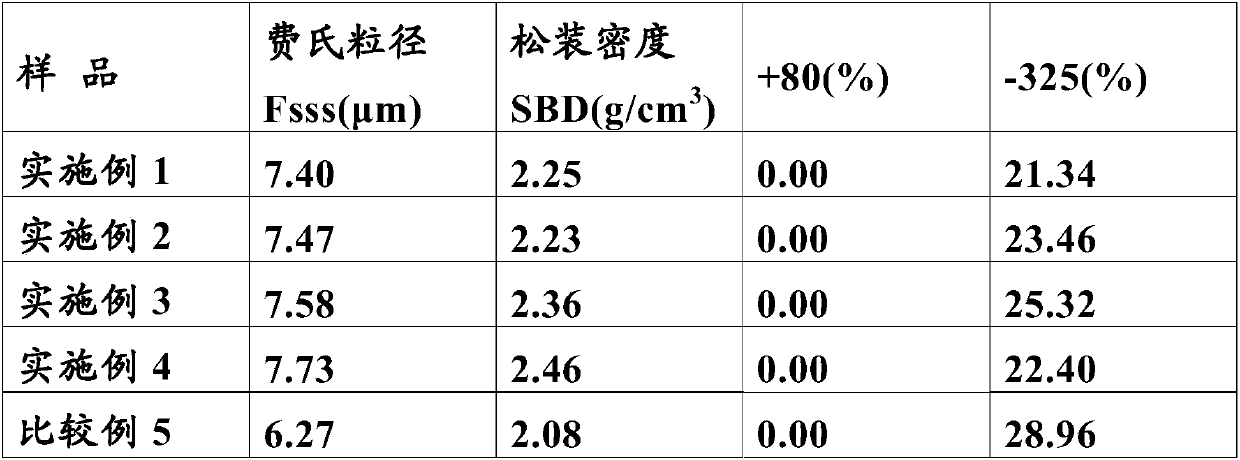

Medium-voltage tantalum powder and preparation method thereof

The invention belongs to the field of capacitor-grade tantalum powder and particularly relates to medium-voltage tantalum powder and preparation method thereof. The specific capacitance of the tantalum powder provided by the invention is 5000-8000uFV / G, the breakdown voltage is not smaller than 210V, and the tantalum powder has higher breakdown voltage and improved leak current.

Owner:NINGXIA ORIENT TANTALUM IND +1

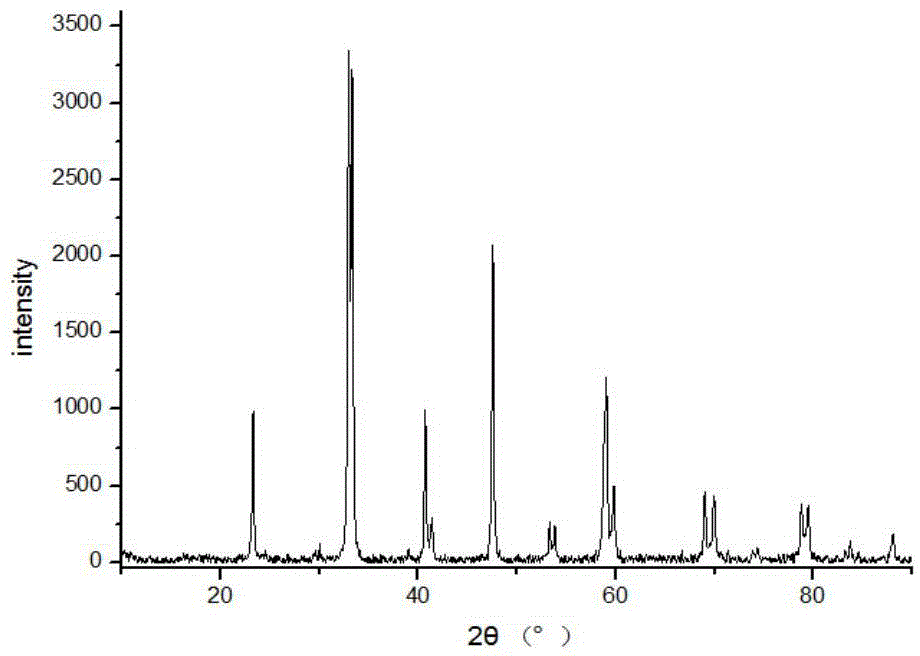

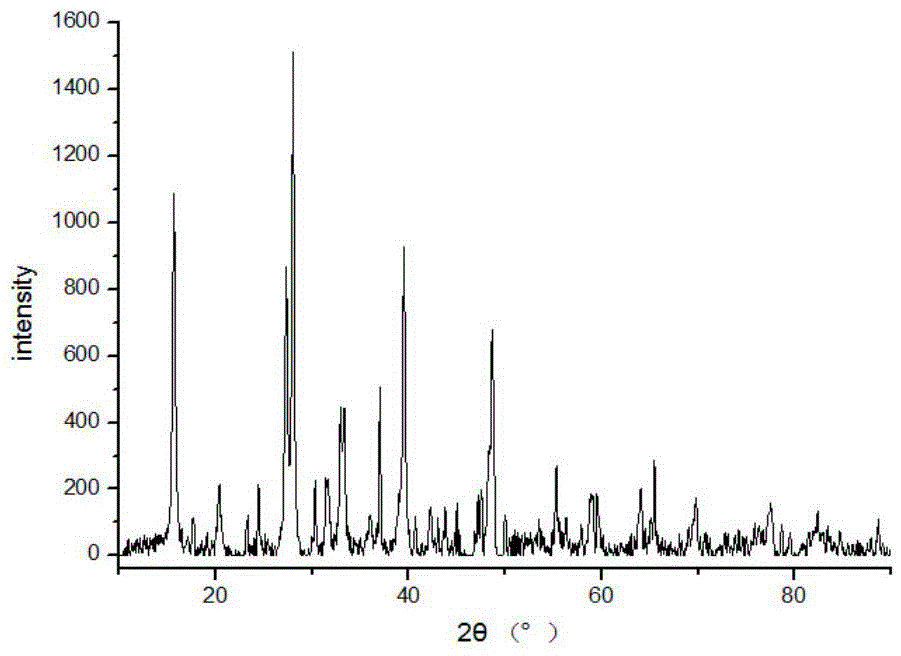

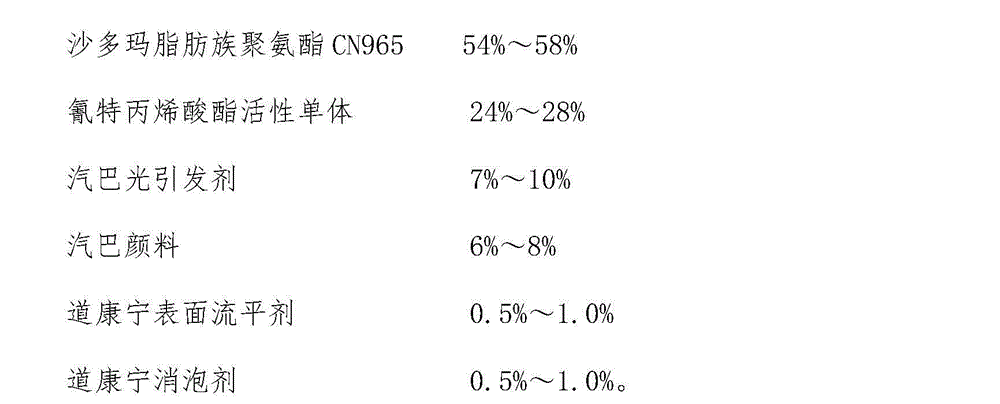

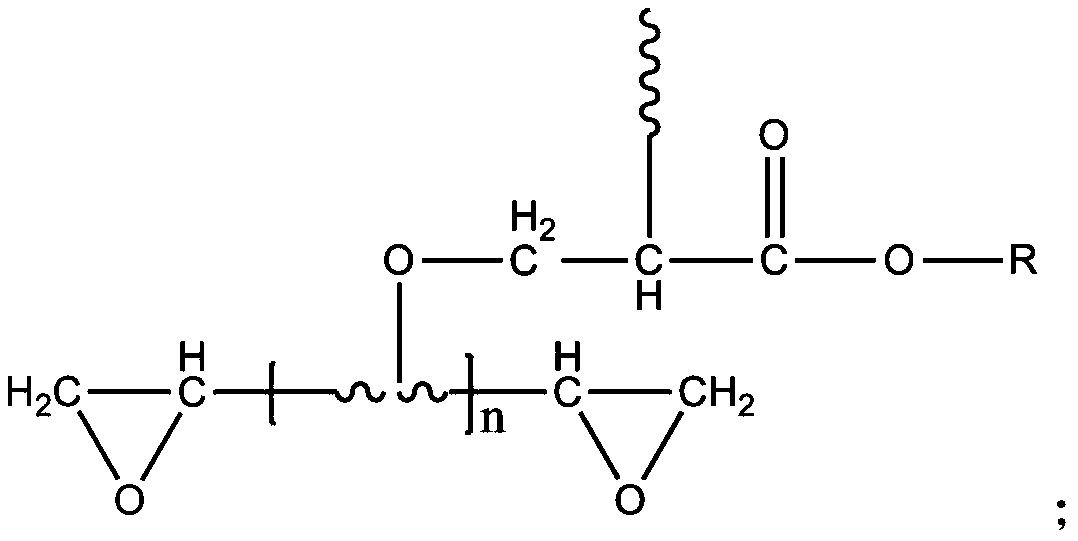

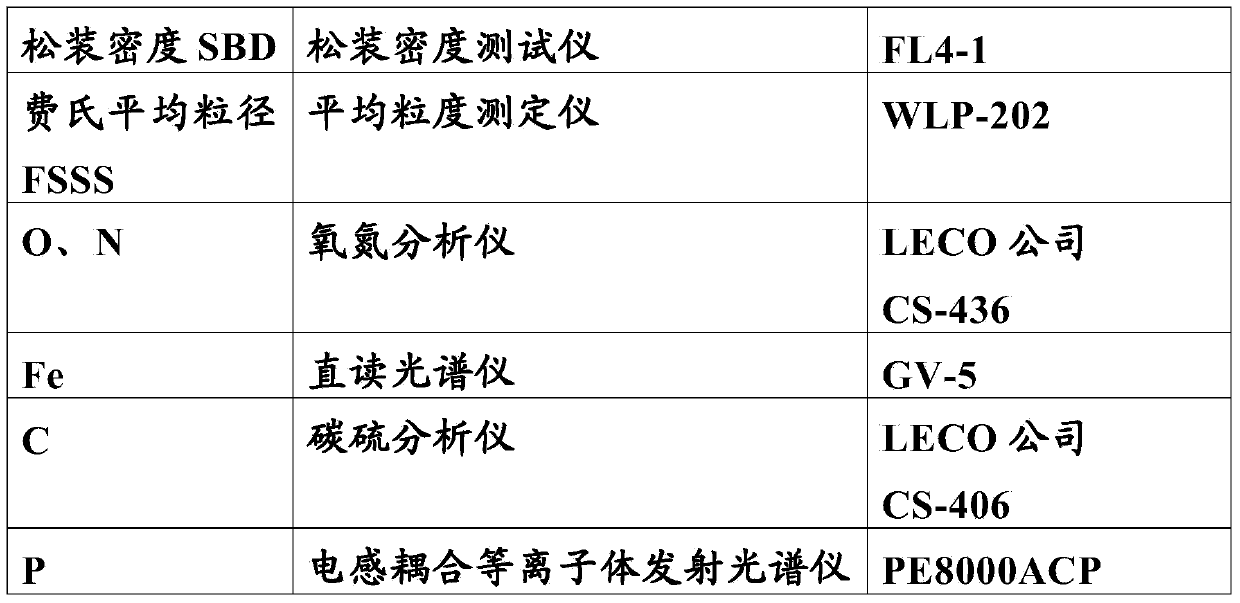

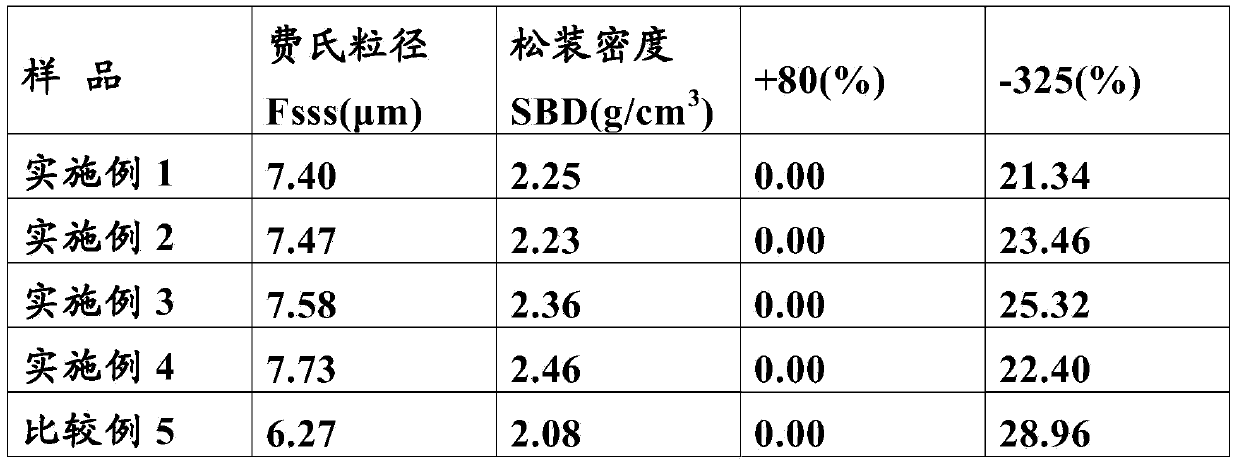

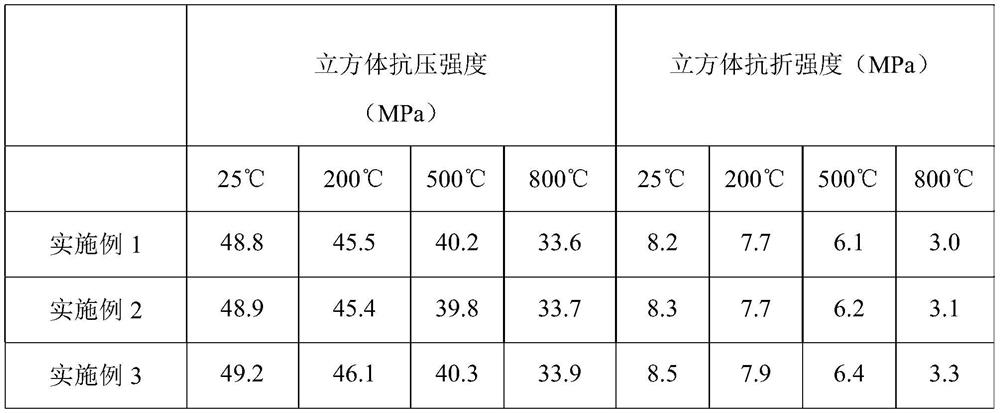

Synthesis method of spiro-compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane

InactiveCN103360405AHigh expansion rateIncrease distanceOrganic chemistrySynthesis methodsMagnesium bromide

The invention relates to a synthesis method of a spiro-compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane. The synthetic route is 1,3-dibromo-2,2-di(bromomethyl)propane, 1,3-magnesium dibromide-2,2-di(magnesium bromide methyl)propane, 1,3-dicarboxyl-2,2-di(acetoxy)propane, and 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane. The 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane can be used as a novel expansion curing agent for an epoxy resin to reduce the volume shrinkage of the system to 0-1%, thereby overcoming the defect of poor mechanical properties of the epoxy resin cured by aliphatic acid anhydride, and improving the problem of volume shrinkage of the material. The invention is mainly used in the fields of epoxy resin casting and composite materials thereof.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Resin cementing material for repairing normal temperature cold mixing steel bridge floor swag

The invention discloses a resin cementing material for repairing a normal temperature cold mixing steel bridge floor swag. The resin cementing material consists of a mixture A and a mixture B, wherein the mixture A consists of the following components in parts by weight: 15-100 parts of bisphenol A epoxy resin, 80-100 parts of terminal epoxy block polyether, 2-25 parts of terminal epoxy liquid acrylonitrile butadiene rubber and 2-12 parts of butyl glycidyl ether; the mixture B consists of the following components in parts by weight: 10-75 parts of 651 low molecular polyamide, 2-5 parts of gamma-aminopropyltriethoxysilane and 2-10 parts of 2,4,6-tri(dimethylaminomethyl) phenol; the weight ratio of the mixture A to the mixture B is 3:1. The resin cementing material disclosed by the invention can fully meet requirements for pavement maintenance engineering of an epoxy asphalt bridge floor, and can effectively prevent secondary cracking of construction joints.

Owner:JSTI GRP CO LTD

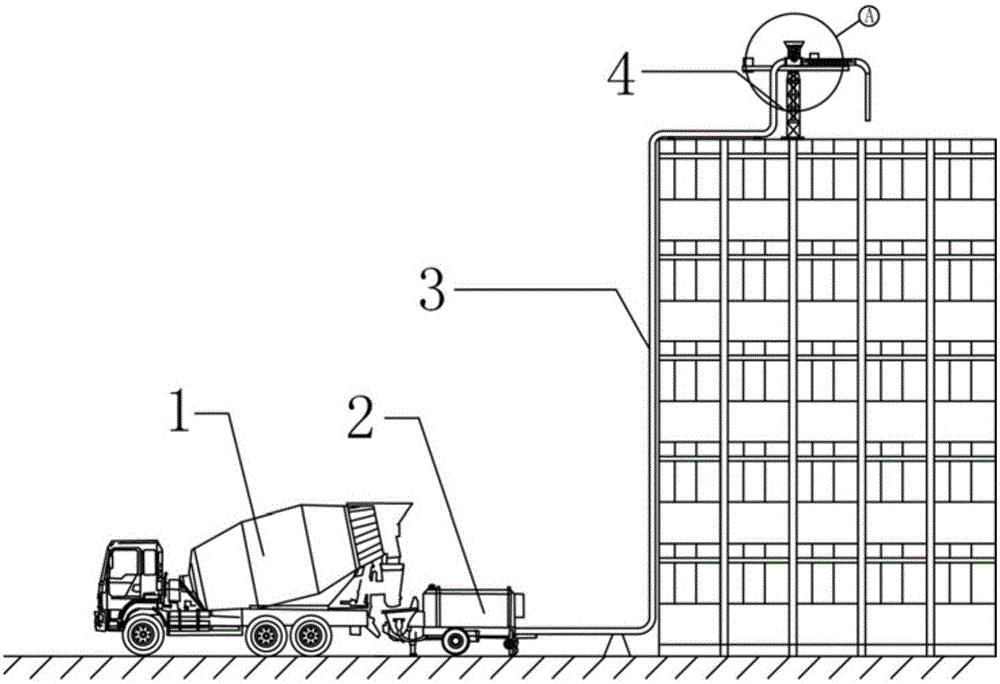

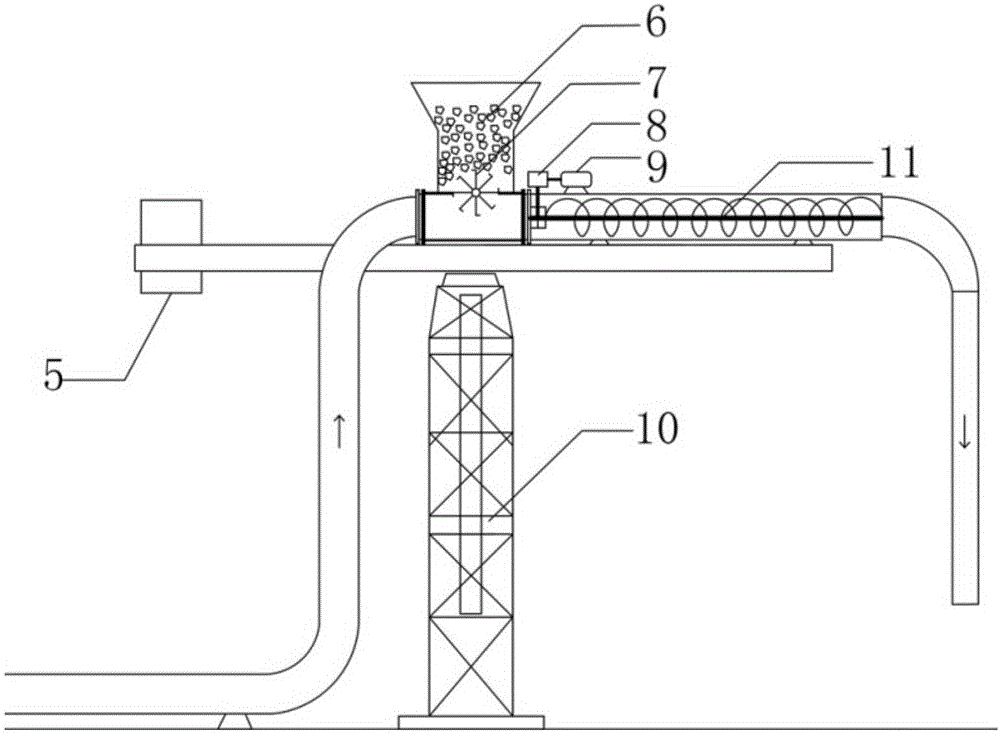

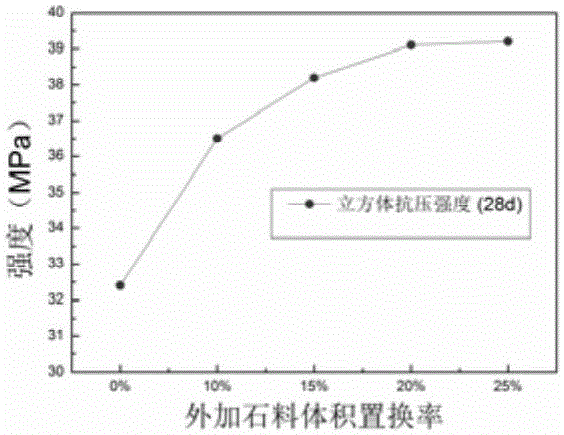

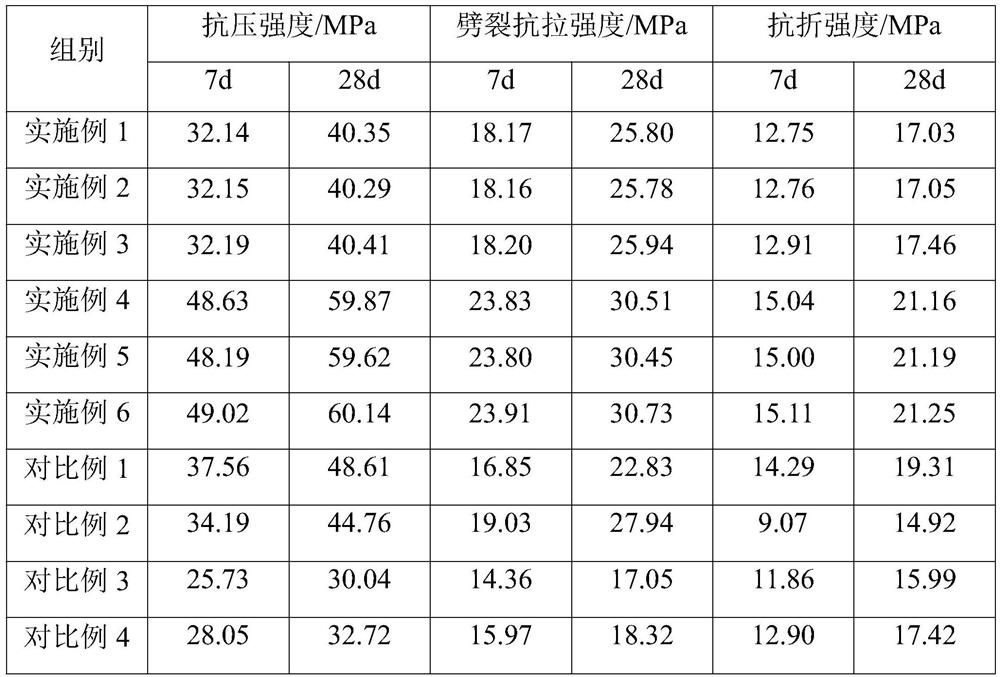

Construction technology of green concrete

ActiveCN105108905AReduce shrinkage cracksImprove structural durabilityBuilding material handlingCement mixing apparatusImpellerMechanical property

The invention discloses a construction technology of green concrete. The construction technology is characterized in that commercial concrete is delivered to a working surface by a concrete delivery pump and a concrete delivery pipeline; a stone storage silo is mounted above an opening between the tail end of the delivery pipeline of the commercial concrete and an inlet of a helical mixing delivery device; a rotational impeller is arranged at the lower end of a feeding opening of the stone storage silo; extra stones are added from the feeding opening, and are automatically distributed to the flowing commercial concrete by employing the rotation of the impeller driven by the flowing inertia of the flowing commercial concrete; and the extra stones and the flowing commercial concrete are mixed uniformly by the helical mixing delivery device to form the green concrete to be delivered to a spreader pipeline for spreading and pouring. Compared with a construction technology of the conventional commercial concrete, the construction technology of the green concrete has a series of advantages as follows: (1) phenomena of drying shrinkage and cracking are reduced greatly; (2) the green concrete has excellent mechanical property; (3) the volume stability is good; (4) the cement usage is saved to a great extent; and (5) the pumpability of the commercial concrete is not affected.

Owner:贾金青

Desert aeolian sand modified concrete technology

The invention relates to a desert aeolian sand modified concrete technology which comprises the following steps: uniformly mixing and stirring a first raw material component to obtain a mixed material; adding the second raw material component into the mixed material, then stirring for a preset time, then loading into a mold, and carrying out molding maintenance to obtain desert aeolian sand modified concrete; wherein the first raw material component comprises an excitant, cement and fibers, the second raw material component comprises desert aeolian sand and water, the mass ratio of the excitant to the cement to the fibers is 1 : (10-12) : (2-3), the mass ratio of the desert aeolian sand to the water is (1.2-2) : 1, and the mass ratio of the first raw material component to the second raw material component is 1 : (1.6-1.8). According to the invention, the desert aeolian sand, the excitant, the cement and the fibers are adopted as raw materials, the 7-day compressive strength of the prepared desert aeolian sand modified concrete can reach 30 MPa or above, the breaking strength can reach 10 MPa or above, the volume shrinkage rate is low, and durability is good.

Owner:黄勇

High-performance concrete suitable for high-temperature areas

The invention relates to high-performance concrete suitable for a high-temperature area. The high-performance concrete comprises the following components in parts by mass: 100-280 parts of cement; 150 to 230 parts of modified metakaolin; 150 to 260 parts of clay clinker; 80-190 parts of coal ash powder; 100 to 150 parts of sand; 50 to 100 parts of water glass; 15 to 50 parts of sodium silicate; 30 to 80 parts of asphalt; 15 to 25 parts of a functional additive; 200 to 400 parts of water; according to the invention, various mechanical properties and high temperature resistance of the concrete are improved, and the freeze-thaw resistance of the concrete is effectively improved.

Owner:JIANGSU DONGZHAO CONSTR IND INNOVATION & DEV RES INST CO LTD

Atraumatic vitreous ion cement liquid formulation and preparing process thereof

InactiveCN1187032CSimple processEasy to controlImpression capsDentistry preparationsIsooctyl acrylateGlass ionomers

A non-traumatic glass ion-cement liquid for repairing decayed tooth is prepared from distilled water, acrylic acid, unsaturated carboxylic acid, 4-methylpropenoyloxyethyl trimellitate anhydride, isooctyl acrylate, isopropanol, and initiator through dissolving, introducing N2, removing air from reactor, heating, reaction, evaporating isopropanol, and vacuum concentrating.

Owner:武汉大学口腔医学院口腔药物材料厂

A kind of conductive silver glue and its preparation method and use

ActiveCN106753133BImprove conductivityFast curingNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFirming agent

The invention relates to conductive silver glue, the conductive silver glue comprises the following components by weight: 0.1-60 parts of an ionic liquid, 50-85 parts of silver powder, 10-50 parts of epoxy resin, 0.5-60 parts of a curing agent, 0.05-5 parts of an accelerator, 0.05-5 parts of a coupling agent, 1-10 parts of a diluent and 0.05-2 parts of an anti settling agent. The ionic liquid with catalytic activity is introduced into a conductive adhesive formula to promote the further curing of the epoxy resin, improve the volume shrinkage rate and greatly improve the conductivity of the conductive silver glue. By addition of the same amount of silver powder, the conductivity of the conductive silver glue is greatly increased (to 10<-5> orders of magnitudes and to reach a higher level in the market); the dispersion of a conductive filler is promoted, the viscosity of the conductive silver glue is reduced, and the operating performance of the product is improved. The method has the advantages of simple operation and low material cost, the cost of the conductive silver glue is reduced, and the conductive silver glue can be widely used in solar cells, integrated circuits and LED packaging and other fields.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Impulse-pressurzing sintering furnace

PendingCN108692564AAccelerated volume shrinkageRapid densificationMuffle furnacesMaintainance of heating chambersEngineeringLoop control

The invention discloses an impulse-pressurizing sintering furnace. The impulse-pressurizing sintering furnace comprises a sintering furnace and an impulse-pressurizing device. The impulse-pressurizingdevice comprises an impulsator, an impulse converter, a servo valve, a servo oil cylinder, a force sensor, and a sensing signal transmitter. The impulsator is connected with the impulse converter. The servo valve is connected to an opening of the servo oil cylinder. The force sensor is connected with the sensing signal transmitter. The impulse converter, the servo valve and the sensing signal transmitter are all connected with a sintering controller. The sintering furnace comprises a furnace body. The furnace body is of a cylinder type. A mold is arranged in the middle position of the furnacebody. A sintering area is arranged inside the mold. The impulse-pressurizing sintering furnace has the beneficial effects that because plasma pulse current sintering is conducted on a material to besintered by adopting an impulse current generator, and the servo oil cylinder is controlled by the servo valve, the upper pressing rod and the lower pressing rod are impacted in opposite directions and pressurized; pressure is in closed-loop control; pressure on the upper pressing rod and the lower pressing rod are adjusted automatically; and the sintering temperature and sintering time needed bythe material to be sintered can be lowered.

Owner:浙江晨华科技有限公司

Method for eliminating sulfur dioxide in sulfited semi-finished fruits

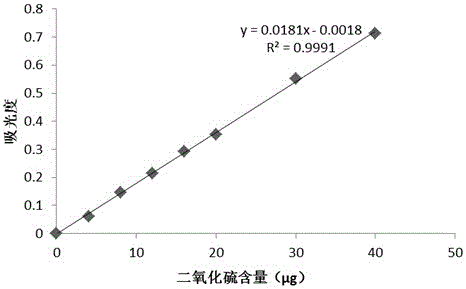

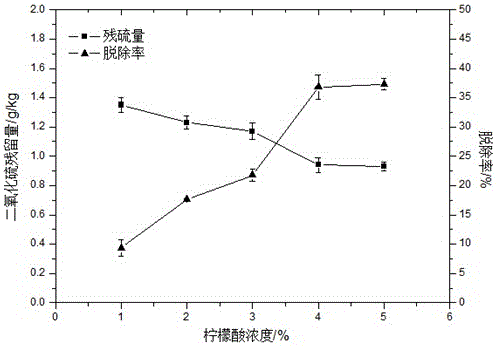

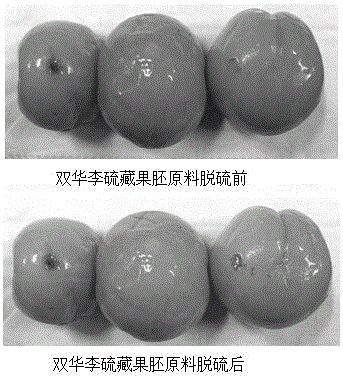

InactiveCN106036374AHigh removal rateImprove desulfurization effectFood scienceAdditive ingredientNational standard

The invention discloses a method for eliminating sulfur dioxide in sulfited semi-finished fruits. The method comprises the following steps: S1, the sulfited semi-finished fruits are washed; S2, the sulfited semi-finished fruits are soaked in a citric acid solution under a heating condition; S3, the sulfited semi-finished fruits are bleached; S4, the sulfited semi-finished fruits are drained. The desulfurization process for sulfited semi-finished fruit raw materials of Cantonese preserved fruits has a good desulfurization effect, and the removal rate of residual sulfur in the semi-finished fruits is up to 88.59% and meets the national standard. Besides, the adopted citric acid solution is an ingredient of a color protection solution used in the early processing period of Cantonese preserved fruit and candied fruit products, has no influence on the semi-finished fruit raw materials, has a color protection effect on the semi-finished fruit raw materials and products and can reduce the sizes of the raw materials, improve the transparency and improve the appearance of the raw materials, the appearance of the desulfurized semi-finished fruits is good, and the boiling fastness of the semi-finished fruits is improved. Besides, the desulfurization process is simple and convenient, the desulfurization speed is high, desulfurization can be finished within 15-20 min, the cost is low, and the method has great significance in production and popularization of Cantonese preserved fruits.

Owner:SOUTH CHINA AGRI UNIV

Medium-frequency unidirectional-vibration atmosphere sintering furnace

InactiveCN106524748AReduce manufacturing costImprove compactnessMuffle furnacesCharge treatment typeVibration amplitudePressure system

The invention discloses a medium-frequency unidirectional-vibration atmosphere sintering furnace. The medium-frequency unidirectional-vibration atmosphere sintering furnace comprises a furnace body with a pressure system. An upper pressing head is arranged on the upper portion of the furnace body, and a lower pressing head is arranged on the lower portion of the furnace body. An electro-hydraulic servo pressure application device with frequency, vibration amplitude and pressure adjustable is arranged at the bottom of the lower pressing head. The electro-hydraulic servo pressure application device is connected to an electro-hydraulic servo system. By means of the medium-frequency unidirectional-vibration atmosphere sintering furnace, particles can be pushed to be rearranged in the vibrating sintering process; volume shrinkage is accelerated; the purpose of rapid compacting is achieved; compactness and mechanical performance of sintered products are effectively improved; high-performance ceramic and powder metallurgical materials which are more excellent are obtained; in addition, sintering of high-performance ceramic and powder metallurgical products can be conducted under different types of atmosphere, and thus appropriate atmosphere media are selected according to the various different materials.

Owner:SOUTHWEST JIAOTONG UNIV

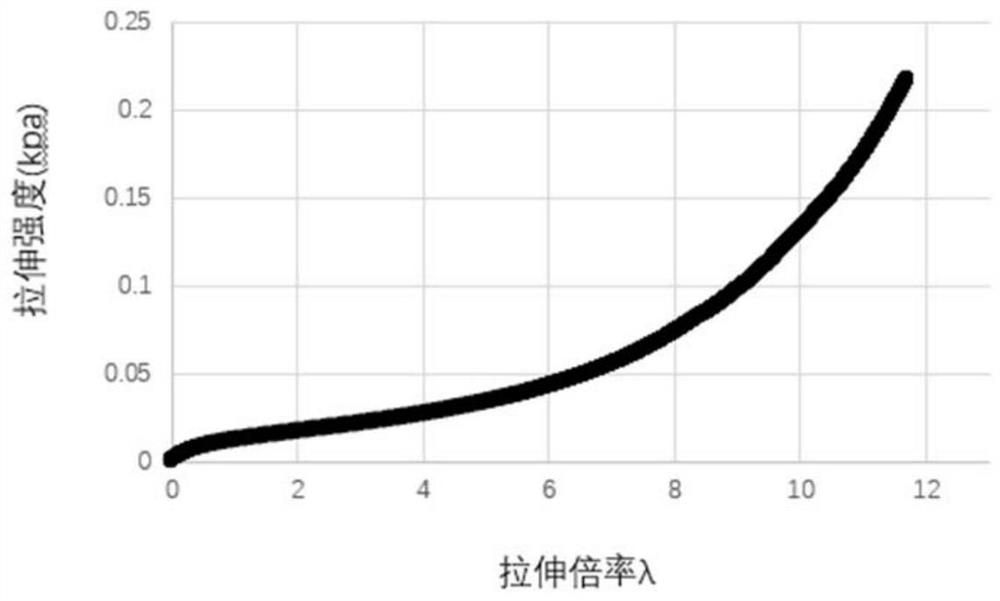

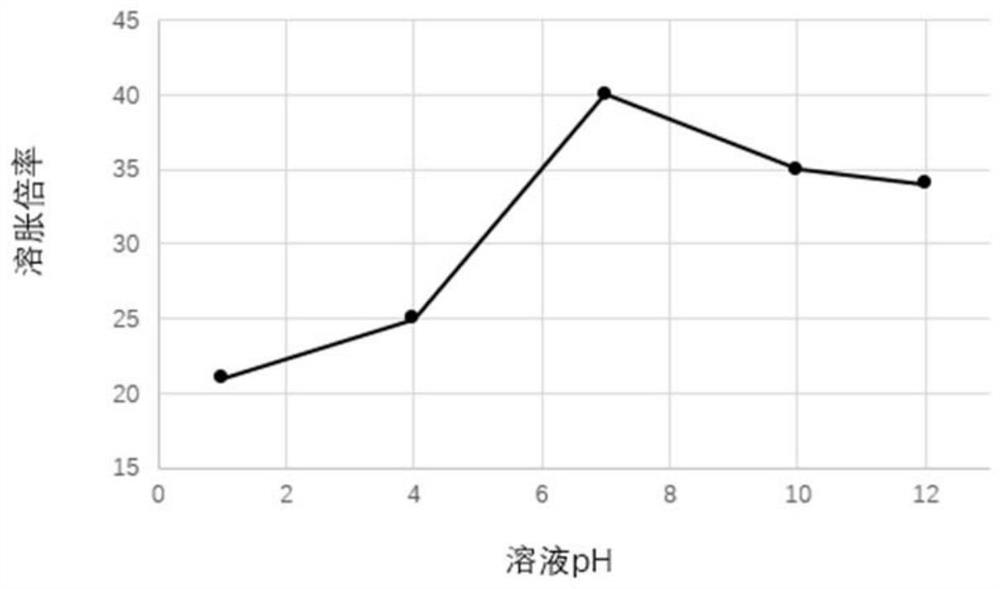

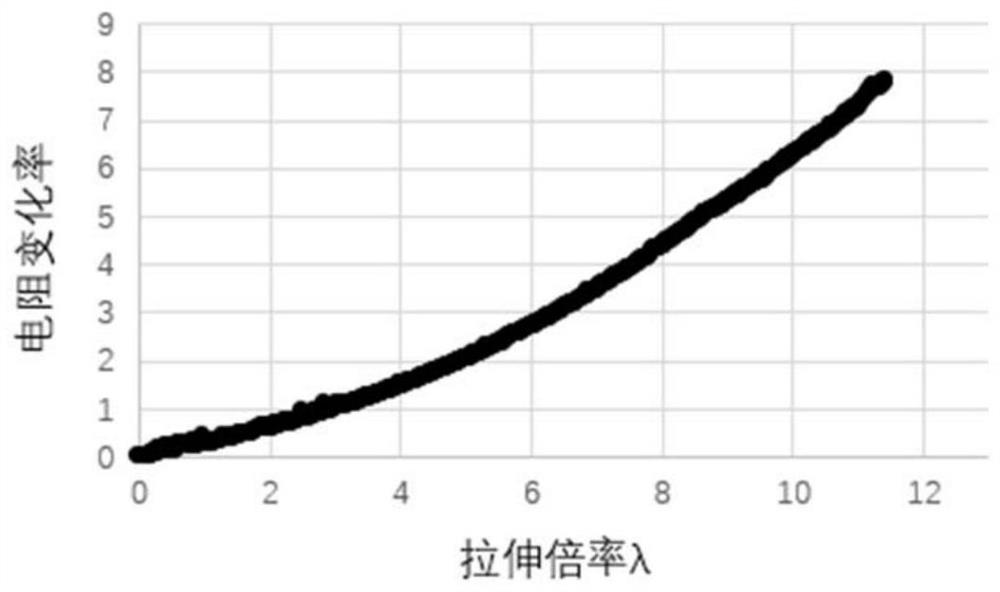

High-strength self-recoverable multifunctional conductive hydrogel with temperature/pH dual response as well as preparation method and application of high-strength self-recoverable multifunctional conductive hydrogel

ActiveCN114316144AExcellent temperature sensitive performanceNIPA improvedControlled releasePharmaceutical drug

The invention relates to high-strength self-restorable conductive hydrogel with temperature / pH dual response as well as a preparation method and application thereof. The hydrogel is prepared by dissolving a comonomer A, a comonomer B, a biomacromolecule C, a chemical cross-linking agent D and a physical cross-linking agent E in water and then polymerizing. The hydrogel prepared by the invention not only has temperature sensitive characteristics and pH sensitive characteristics, but also has relatively high strength and tensile rate, can be circularly stretched, and can be self-recovered and even self-enhanced. Besides, the hydrogel disclosed by the invention also has electrical conductivity, and the electrical conductivity of the hydrogel can be changed along with the change of the temperature, the stretching ratio and the environmental pH value, so that the electrical conductivity of the hydrogel has multiple sensitivities, and in addition, the hydrogel also has universal adhesion. Based on the attributes, the hydrogel is expected to be applied to a plurality of biomedical fields such as biosensors, wearable electronic skin, soft tissue engineering, drug controlled release and the like.

Owner:ZHEJIANG UNIV

A kind of medium-pressure tantalum powder and its preparation method

ActiveCN104209512BReduce lossSmall volume shrinkageElectrolytic capacitorsElectric capacityCapacitor

Owner:NINGXIA ORIENT TANTALUM IND +1

Process method for reducing shrinkage rate of coal gangue-based insulating bricks in roasting process

InactiveCN111548127AHigh compressive strengthAccelerated volume shrinkageCeramic materials productionClaywaresFiberCompression molding

The invention discloses a technological method for reducing the shrinkage rate of coal gangue-based insulating bricks in a roasting process, and relates to the technical field of building materials. The technological method specifically comprises the following steps of: 1) preparing a nano chitin dispersion liquid from shrimp shells; 2) adding multiwalled carbon nanotubes into a nanocellulose suspension, and adding alumina fibers and mullite fibers to obtain a fiber dispersion liquid; 3) uniformly mixing aluminum oxide sol and silicon dioxide sol to obtain composite sol; and 4) uniformly mixing the products obtained in the steps 1) and 2), drying an obtained mixture to obtain composite fibers, drying and screening coal gangue, fly ash and engineering spoil, adding water, adding the composite fibers and the composite sol, performing aging, adding expanded perlite, and carrying out compression molding, drying, and roasting. According to the production process provided by the invention, the volume shrinkage rate of the insulating bricks can be effectively reduced, and the deformation of the insulating bricks is reduced, so that the insulating bricks are not easy to crack in a high-temperature roasting process, and the performance of the insulating bricks is improved.

Owner:蚌埠创特新材料科技有限公司

Method and device for vacuum pulsation drying poria cocos

ActiveCN107166897BAvoid crackingAvoid breakingLighting support devicesDrying solid materials without heatControl systemPulp and paper industry

Owner:CHINA AGRI UNIV

A preparation process of synthetic quartz stone imitating three-dimensional texture of natural stone

ActiveCN112373073BReduce volatilityGood light transmissionFlat articlesPolyester resinUltimate tensile strength

The invention discloses a synthetic quartz stone preparation process imitating the three-dimensional texture of natural stone, comprising the following steps: a. Mold making: scanning the surface texture of the natural stone plate and forming a graphic file; Concave-convex texture male mold and female mold; b. base material preparation: stir the base material raw materials evenly, the raw material components of the base material include resin, and the resin is unsaturated polyester resin; c. base material pressing: put The base material is evenly spread on the master mold, and scraped, and vibrated and pressed after vacuuming. According to the synthetic quartz stone preparation process imitating the three-dimensional texture of natural stone, the pattern texture of the prepared synthetic quartz stone has a strong sense of three-dimensionality, rich colors, and a texture comparable to natural stone texture, and has corrosion resistance, high strength, smoothness, no deformation, and no peeling off. The advantage of the layer is to solve the problems of poor texture, poor strength and corrosion resistance of the existing synthetic quartz stone.

Owner:中旗(湖北)新材料有限公司

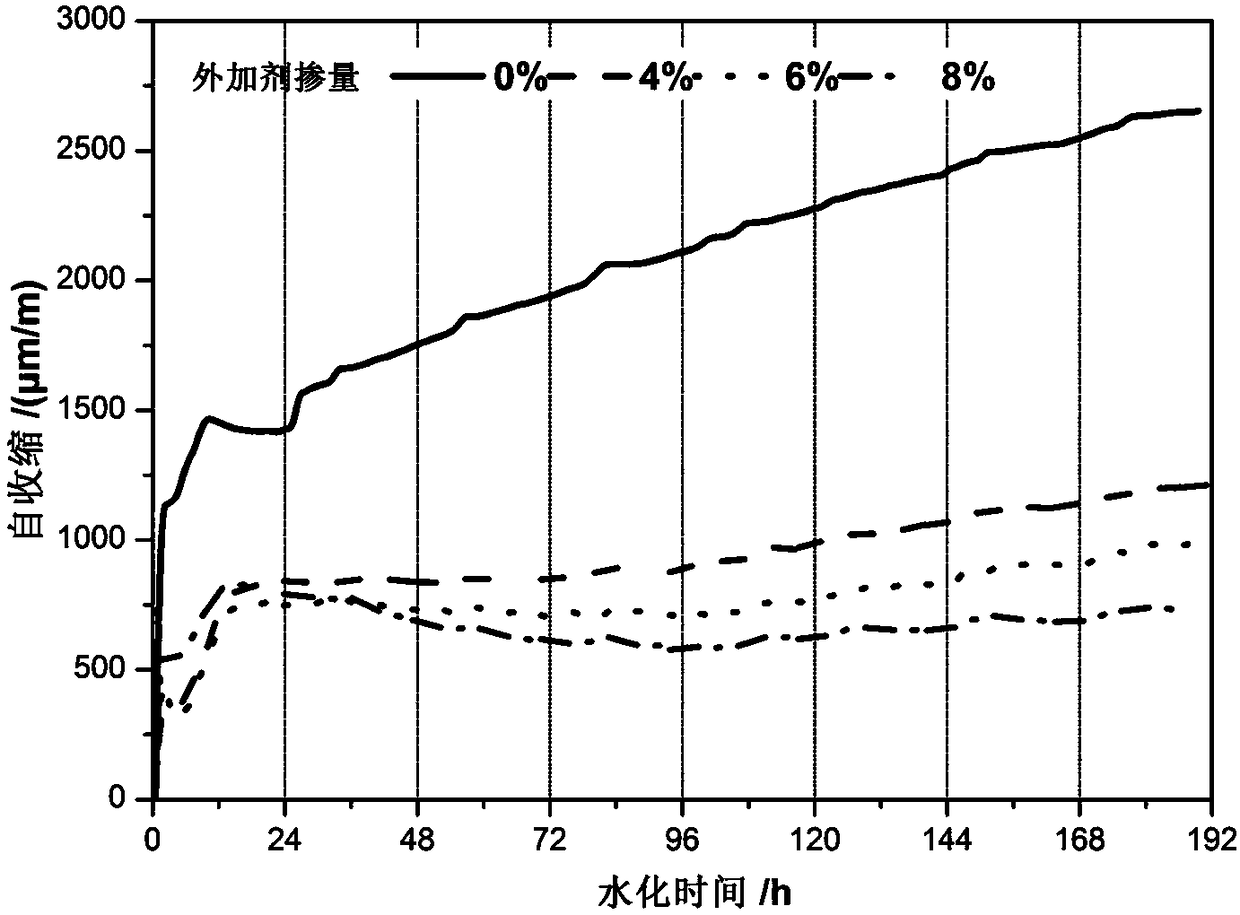

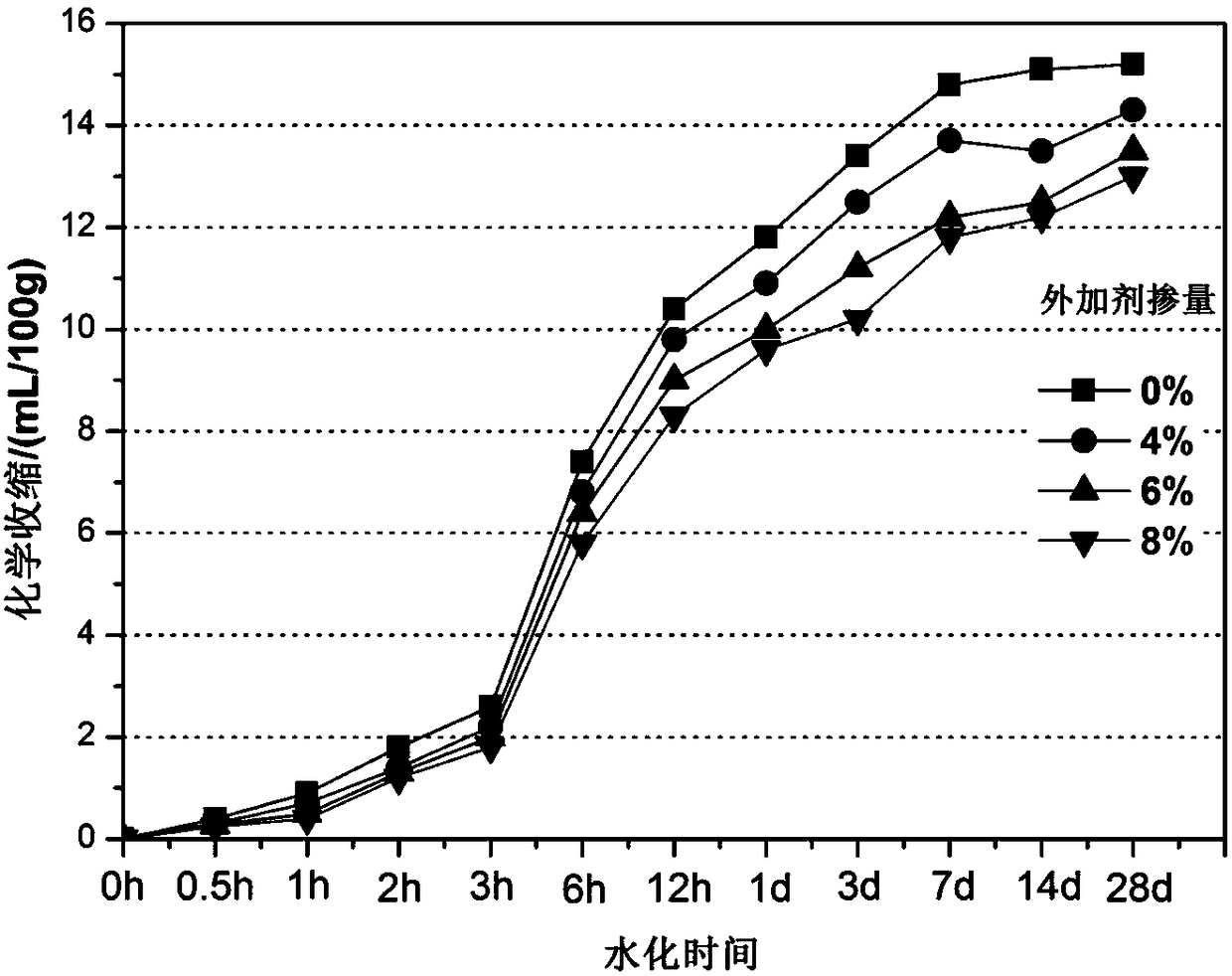

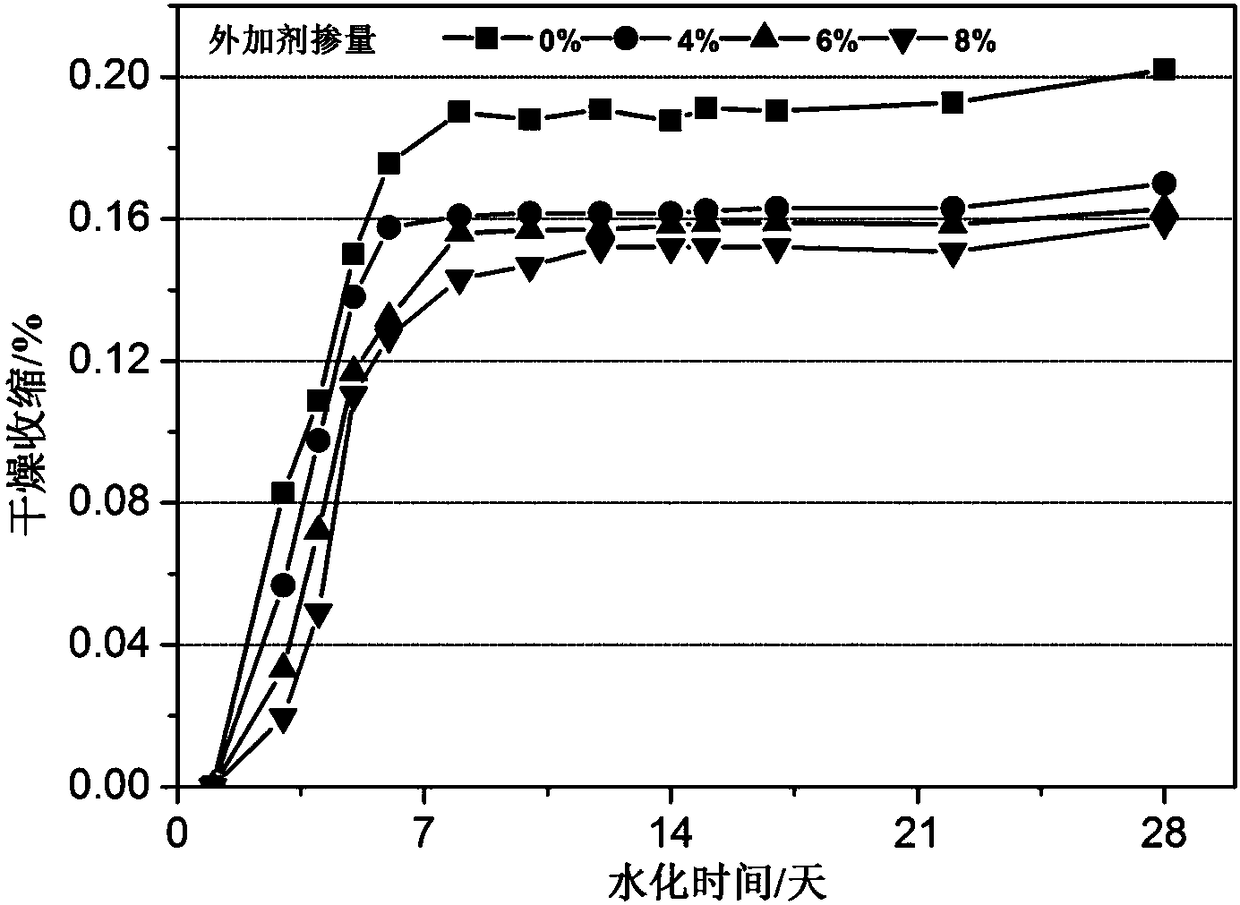

A method for reducing the volume shrinkage of inorganic polymer gelling materials

ActiveCN106587680BGuaranteed StrengthAccelerated volume shrinkageCement productionPolymer scienceSlag

The invention discloses a method for reducing volume shrinkage of an inorganic polymer binding material. The method includes the steps that a shrinkage-compensating additive is added into the inorganic polymer binding material, the materials are mixed to be uniform, and water is added; the shrinkage-compensating additive is formed by mixing high-activity magnesium oxide and nanosilicon dioxide. By means of the method, volume shrinkage of inorganic polymer hardened paste is remarkably relieved while the strength of an inorganic polymer is guaranteed, and great scientific value is achieved for improving the volume stability and durability of a cement-based material. Very great significance is achieved for efficiently utilizing slag, coal ash and other industrial waste residues for producing the inorganic polymer binding material with high strength and good volume stability, protecting the environment and achieving sustainable development of the society.

Owner:GUANGDONG RES INST OF WATER RESOURCES & HYDROPOWER

Ultra violet (UV) silk screen printing ink

The invention relates to an ultra violet (UV) silk screen printing ink. The UV silk screen printing ink comprises components of, by weight, 54%-58% of Sartomer aliphatic polyurethane CN965, 24%-28% of Cytec acrylic ester activated monomers, 7%-10% of Ciba photoinitiators, 6%-8% of Ciba pigments, 0.5%-1.0% of Dow Corning surface flatting agents and 0.5%-1.0% of Dow Corning antifoaming agents, wherein the Cytec acrylic ester activated monomers are formed by mixing propoxylate oneopentylglycol diacrylate and ethoxylated trimethylolpropane triacrylate according to the ratio of 1: 1, adding the components into a stirrer to be dispersed until the temperature reaches 50 DEG C, and putting the components into a three-roller machine to be ground until the fineness of the components is smaller than or equal to 5 mu m. The UV silk screen printing ink is good in adhesive force and bending resistance performance.

Owner:中山市中益油墨涂料有限公司

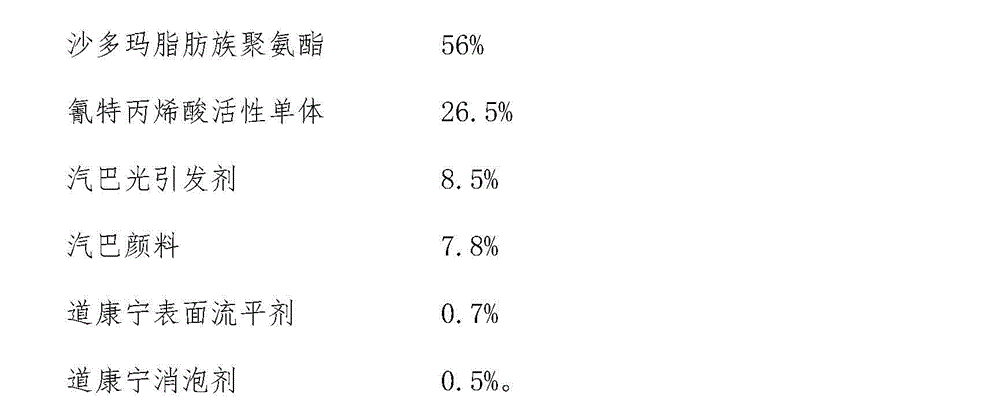

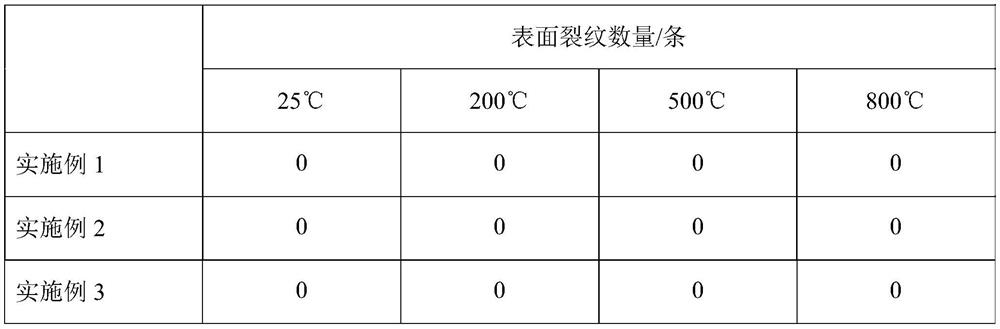

A kind of synthetic method of spiro compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane

InactiveCN103360405BHigh expansion rateIncrease distanceOrganic chemistrySynthesis methodsMagnesium bromide

The invention relates to a synthesis method of a spiro-compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane. The synthetic route is 1,3-dibromo-2,2-di(bromomethyl)propane, 1,3-magnesium dibromide-2,2-di(magnesium bromide methyl)propane, 1,3-dicarboxyl-2,2-di(acetoxy)propane, and 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane. The 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane can be used as a novel expansion curing agent for an epoxy resin to reduce the volume shrinkage of the system to 0-1%, thereby overcoming the defect of poor mechanical properties of the epoxy resin cured by aliphatic acid anhydride, and improving the problem of volume shrinkage of the material. The invention is mainly used in the fields of epoxy resin casting and composite materials thereof.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of spiro-compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane Synthesis method of spiro-compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane](https://images-eureka.patsnap.com/patent_img/3add127c-ec84-4028-a4a1-7e4ddb717a6a/HDA00003243678200011.PNG)

![Synthesis method of spiro-compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane Synthesis method of spiro-compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane](https://images-eureka.patsnap.com/patent_img/3add127c-ec84-4028-a4a1-7e4ddb717a6a/HDA00003243678200012.PNG)

![Synthesis method of spiro-compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane Synthesis method of spiro-compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane](https://images-eureka.patsnap.com/patent_img/3add127c-ec84-4028-a4a1-7e4ddb717a6a/BDA00003243678100031.PNG)

![A kind of synthetic method of spiro compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane A kind of synthetic method of spiro compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane](https://images-eureka.patsnap.com/patent_img/3eac0097-5aa0-47cf-9821-d07a6b09c250/HDA00003243678200011.PNG)

![A kind of synthetic method of spiro compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane A kind of synthetic method of spiro compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane](https://images-eureka.patsnap.com/patent_img/3eac0097-5aa0-47cf-9821-d07a6b09c250/HDA00003243678200012.PNG)

![A kind of synthetic method of spiro compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane A kind of synthetic method of spiro compound 2,4,8,10-tetracarbonyl-3,9-dioxaspiro[5,5]undecane](https://images-eureka.patsnap.com/patent_img/3eac0097-5aa0-47cf-9821-d07a6b09c250/GDA0000364165510000031.PNG)