High-performance concrete suitable for high-temperature areas

A high-performance concrete, regional technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of ordinary concrete mechanics and durability degradation, difficulty in maintaining the strength of concrete structure, affecting compressive strength, etc. , to achieve the effect of improving freeze-thaw resistance, improving fluidity and compactness, and reducing cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

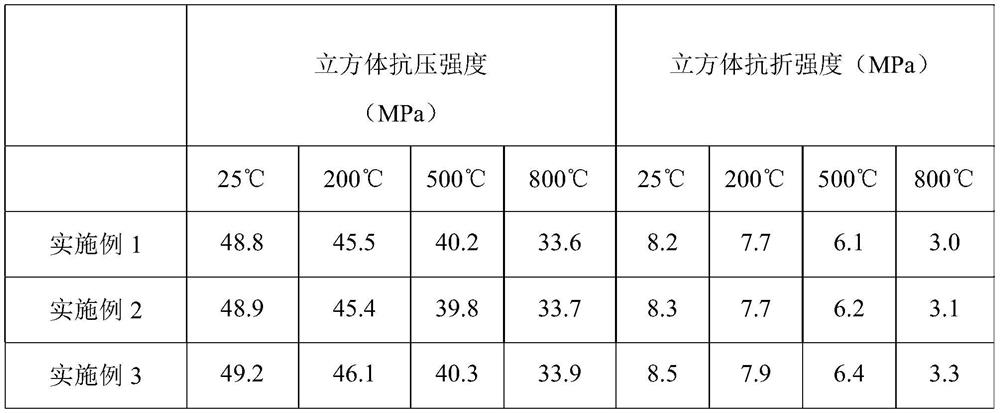

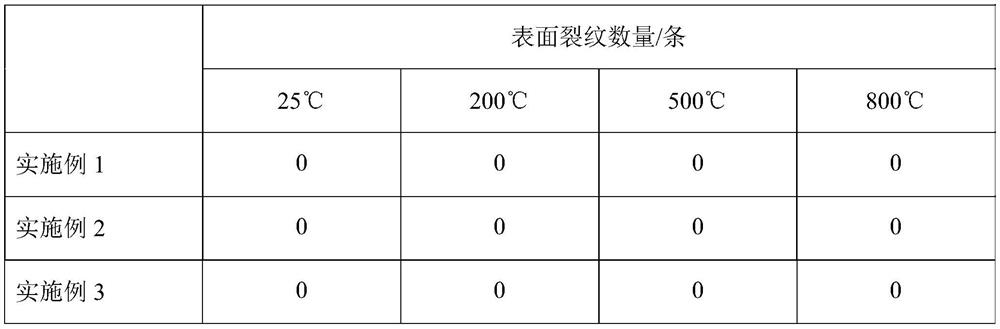

Embodiment 1

[0030] This embodiment provides a kind of high-performance concrete suitable for high-temperature areas, comprising: 100 parts of cement; 150 parts of modified metakaolin; 150 parts of clay clinker; 80 parts of coal ash powder; 130 parts of sand; 70 parts of glass; 20 parts of sodium silicate; 30 parts of asphalt; 15 parts of functional additives; water: 220 parts;

[0031] Portland cement with cement strength grade 52.5 and above;

[0032] Fly ash is a mixture of Class II fly ash and Class I fly ash at a mass ratio of 1:1, and the compressive strength of fly ash is 1.5MPaMPa;

[0033] The sand is uniformly mixed with silica sand, river sand and desalinated sea sand at a weight ratio of 1:1:0.6, and its particle size is 500 μm, 700 μm, and 900 μm respectively, and the content of silicon dioxide in the silica sand is ≥98%;

[0034] Functional additives include 10 parts of polycarboxylate superplasticizer, 5 parts of phosphoric acid-based retarder, 7 parts of admixture, 20 part...

Embodiment 2

[0038] This embodiment provides a high-performance concrete suitable for high-temperature areas, including: 200 parts of cement; 190 parts of modified metakaolin; 220 parts of clay clinker; 80-190 parts of coal ash powder; 100 parts of sand 60 parts of water glass; 40 parts of sodium silicate; 40 parts of asphalt; 20 parts of functional additives; water: 300 parts;

[0039] Portland cement with cement strength grade 52.5 and above;

[0040] Fly ash is a mixture of Class II fly ash and Class I fly ash at a mass ratio of 1:1, and the compressive strength of fly ash is 1.5MPaMPa;

[0041] The sand is uniformly mixed with silica sand, river sand and desalinated sea sand at a weight ratio of 1:1:0.6, and its particle size is 300 μm, 500 μm, and 700 μm respectively, and the content of silicon dioxide in the silica sand is ≥98%;

[0042] Functional additives include 15 parts of polycarboxylate superplasticizer, 8 parts of phosphoric acid-based retarder, 10 parts of admixture, 25 par...

Embodiment 3

[0046] This embodiment provides a kind of high-performance concrete suitable for high temperature areas, including: 100-280 parts of cement; 150-230 parts of modified metakaolin; 150-260 parts of clay clinker; 80-260 parts of coal ash powder 190 parts; sand 100-150 parts; water glass 50-100 parts; sodium silicate 15-50 parts; asphalt 30-80 parts; functional additives 15-25 parts; water: 200-400 parts.

[0047] Portland cement with cement strength grade 52.5 and above;

[0048] Fly ash is a mixture of Class II fly ash and Class I fly ash at a mass ratio of 1:1, and the compressive strength of fly ash is 1.5MPaMPa;

[0049]The sand is uniformly mixed with silica sand, river sand and desalinated sea sand at a weight ratio of 1:1:0.6, and its particle size is 400 μm, 600 μm, and 800 μm respectively, and the content of silicon dioxide in the silica sand is ≥98%;

[0050] Functional additives include 22 parts of polycarboxylate superplasticizer, 10 parts of phosphoric acid-based re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com