Geopolymer dry powder material and preparation method thereof

A technology of geopolymer and dry powder, applied in cement production and other directions, can solve the problems of inconvenience, restricting the popularization and application of geopolymer, high preparation cost, transportation and storage, etc. The effect of high temperature curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

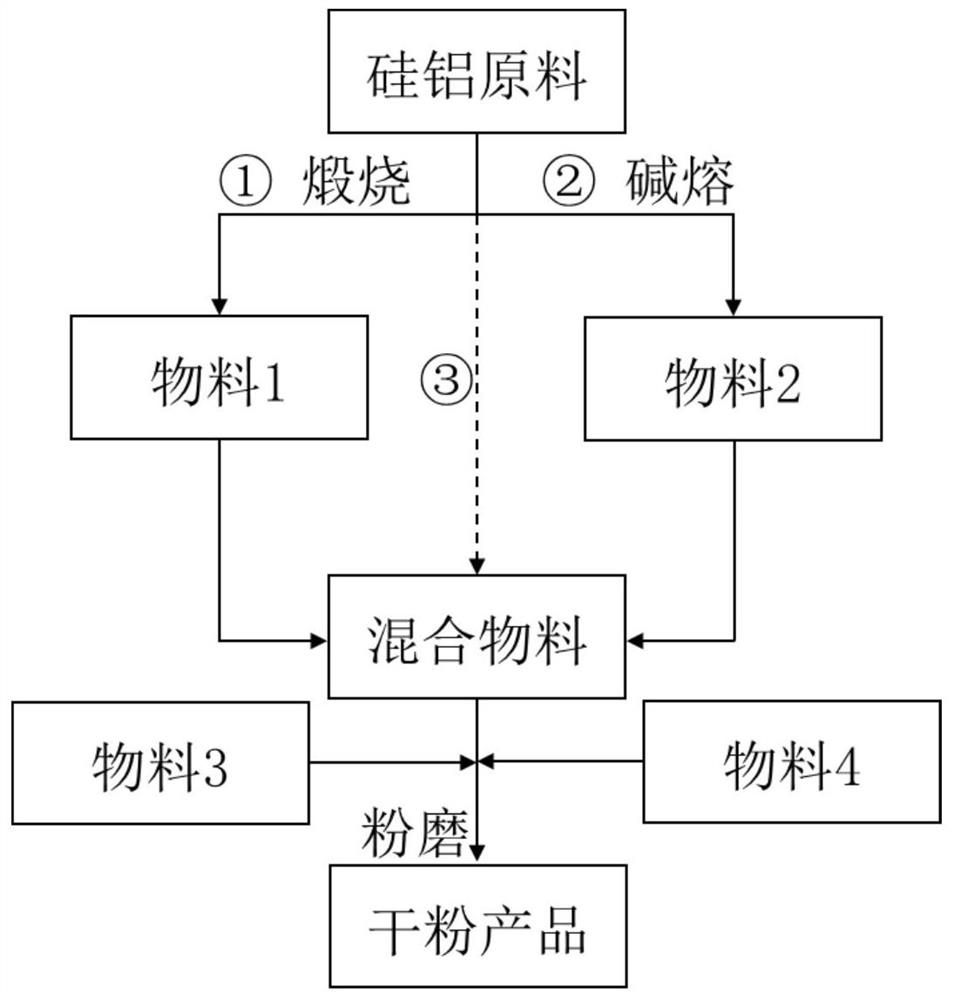

[0024] A method for preparing geopolymer dry powder of the present invention adopts the method of alkali fusion treatment of part of the silicon-aluminum raw material, and replaces the activated silicon-aluminum raw material with the alkali-fused material, and then mixes it with other adjustment materials, and after grinding , to obtain geopolymer dry powder materials, such as figure 1 As shown, the specific steps are as follows:

[0025] a. Part of the silicon-aluminum raw material is subjected to the operation of path ① (calcination) to obtain material 1. If the raw material used is an industrial by-product after high-temperature calcination, it can directly enter path ③;

[0026] b. Mix part of the silicon-aluminum raw material with alkali flux, and carry out the treatment of path 2 (alkali fusion) to obtain material 2;

[0027] c. Mix the obtained material 1 (or the obtained material of path 3) with the material 2, wherein the content of the material 2 is controlled at 25...

Embodiment 1

[0031] Kaolin with a particle size of less than 1mm is used as the raw material of silicon-alumina, and it is calcined at 700°C for 12 hours to become metakaolin. In addition, a small part of kaolin is mixed with sodium hydroxide at a mass ratio of 1:1.2, and after proper grinding, it is heated at 500°C Calcined for 3 hours, then mixed the metakaolin and the alkali-fused material at a mass ratio of 1:0.35, then adjusted the silicon-aluminum ratio of the material to 2 by adding a certain amount of silica fume, and added a certain amount of calcium oxide, calcium oxide The added amount is 10% of the total material amount, and the finally obtained material is thoroughly mixed through grinding to obtain a geopolymer dry powder material, and the particle size is below 40 microns.

[0032] Prepare the geopolymer slurry according to the water-cement ratio of 0.4. After fully stirring, the slurry is put into a cylindrical mold with a diameter of 50 mm and a height of 100 mm. The curin...

Embodiment 2

[0034] Fly ash with a particle size of less than 1mm is used as the raw material of silica-alumina (fly ash itself is a high-temperature calcined product and has pozzolanic activity), and a part of fly ash is mixed with sodium hydroxide at a mass ratio of 1:1.5. Calcined at ℃ for 1.5h, then mixed the fly ash and the alkali-fused material at a mass ratio of 1:0.3, then adjusted the silicon-aluminum ratio of the material to 2.5 by adding a certain amount of silica fume, and added a certain amount of oxidation Calcium and calcium oxide are added in an amount of 5% of the total amount of materials, and the finally obtained materials are ground and mixed thoroughly to obtain geopolymer dry powder materials with a particle size of less than 40 microns.

[0035] Prepare geopolymer slurry according to the water-cement ratio of 0.35. After fully stirring, the slurry is put into a cylindrical mold with a diameter of 50mm and a height of 100mm. The curing box with a humidity of 93% was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com