Preparation method of castor oil-based fully-crosslinked UV (Ultraviolet) photoinduced peelable glue for silicon wafer cutting process

A castor oil-based, cutting process technology, applied in the direction of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problems of difficult to improve light peel strength and difficult light curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

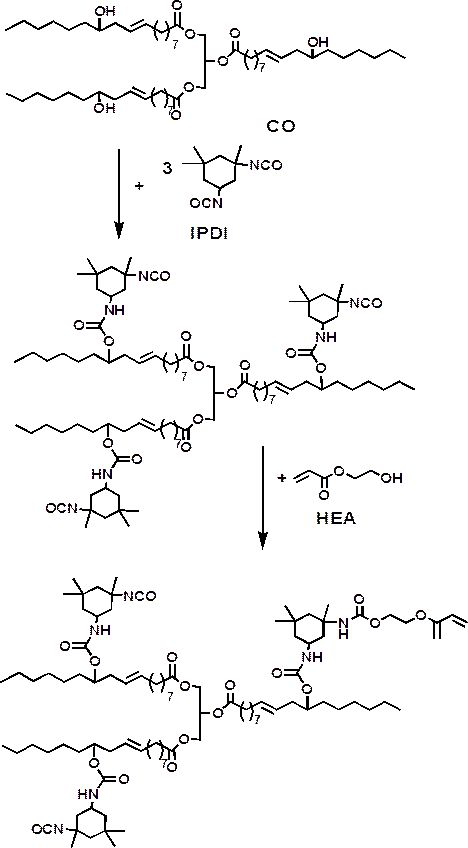

[0021] (1) Synthesis of castor oil-based urethane acrylate prepolymer containing acrylate group and -NCO group: under nitrogen atmosphere, add IPDI 28g, CO 6.7g, dibutylene dilaurate 0.00767g, para 0.0382g of tert-butylcatechol, stirred, slowly heated up to 60°C, and reacted for 6h to obtain a castor oil-modified isocyanate prepolymer terminated by a trifunctional isocyanate group. Add 9g of HEA, and continue to react for 4h to obtain a A castor oil-based polyurethane acrylate prepolymer CO-PUB containing both acrylate groups and -NCO groups.

[0022] (2) Preparation of photopolymerizable network acrylate copolymer pressure-sensitive adhesive: Weigh 0.680g acrylic acid, 1.748g methyl methacrylate, 1.045g hydroxyethyl acrylate, 4.001g butyl acrylate, 16.001g isooctyl acrylate Esters were uniformly mixed in a beaker to obtain a monomer solution; benzoyl peroxide was weighed to dissolve 1% of the total mass of the monomer solution in ethanol to obtain an initiator solution; 15% o...

Embodiment 2

[0025] (1) Synthesis of castor oil-based urethane acrylate prepolymer containing acrylate group and -NCO group: under nitrogen atmosphere, add IPDI 28g, CO 6.7g, dibutylene dilaurate 0.00767g, para 0.0382g of tert-butylcatechol, stirred, slowly heated up to 60°C, and reacted for 6h to obtain a castor oil-modified isocyanate prepolymer terminated by a trifunctional isocyanate group. Add 9g of HEA, and continue to react for 4h to obtain a A castor oil-based polyurethane acrylate prepolymer CO-PUB containing both acrylate groups and -NCO groups.

[0026] (2) Preparation of photopolymerizable network acrylate copolymer pressure-sensitive adhesive: Weigh 0.680g acrylic acid, 1.748g methyl methacrylate, 1.045g hydroxyethyl acrylate, 4.001g butyl acrylate, 16.001g isooctyl acrylate Esters were uniformly mixed in a beaker to obtain a monomer solution; benzoyl peroxide was weighed to dissolve 1% of the total mass of the monomer solution in ethanol to obtain an initiator solution; 15% of ...

Embodiment 3

[0029] (1) Synthesis of castor oil-based urethane acrylate prepolymer containing acrylate group and -NCO group: under nitrogen atmosphere, add IPDI 28g, CO 6.7g, dibutylene dilaurate 0.00767g, para 0.0382g of tert-butylcatechol, stirred, slowly heated up to 60°C, and reacted for 6h to obtain a castor oil-modified isocyanate prepolymer terminated by a trifunctional isocyanate group. Add 9g of HEA, and continue to react for 4h to obtain a A castor oil-based polyurethane acrylate prepolymer CO-PUB containing both acrylate groups and -NCO groups.

[0030] (2) Preparation of photopolymerizable network acrylate copolymer pressure-sensitive adhesive: Weigh 0.680g acrylic acid, 1.748g methyl methacrylate, 1.045g hydroxyethyl acrylate, 4.001g butyl acrylate, 16.001g isooctyl acrylate Esters were uniformly mixed in a beaker to obtain a monomer solution; benzoyl peroxide was weighed to dissolve 1% of the total mass of the monomer solution in ethanol to obtain an initiator solution; 15% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com