Desert aeolian sand modified concrete technology

A desert aeolian sand and modification technology, applied in the field of building materials, can solve the problems of tensile stress exceeding tensile strength, affecting concrete durability, volume change, etc., achieving good durability, improving freeze-thaw resistance, and volume shrinkage. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

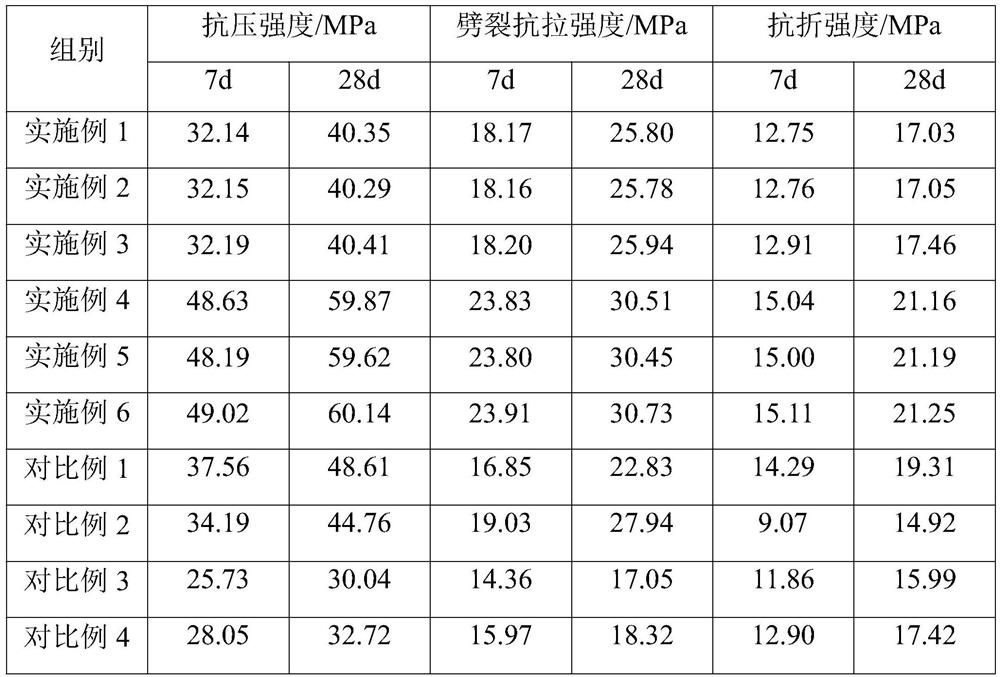

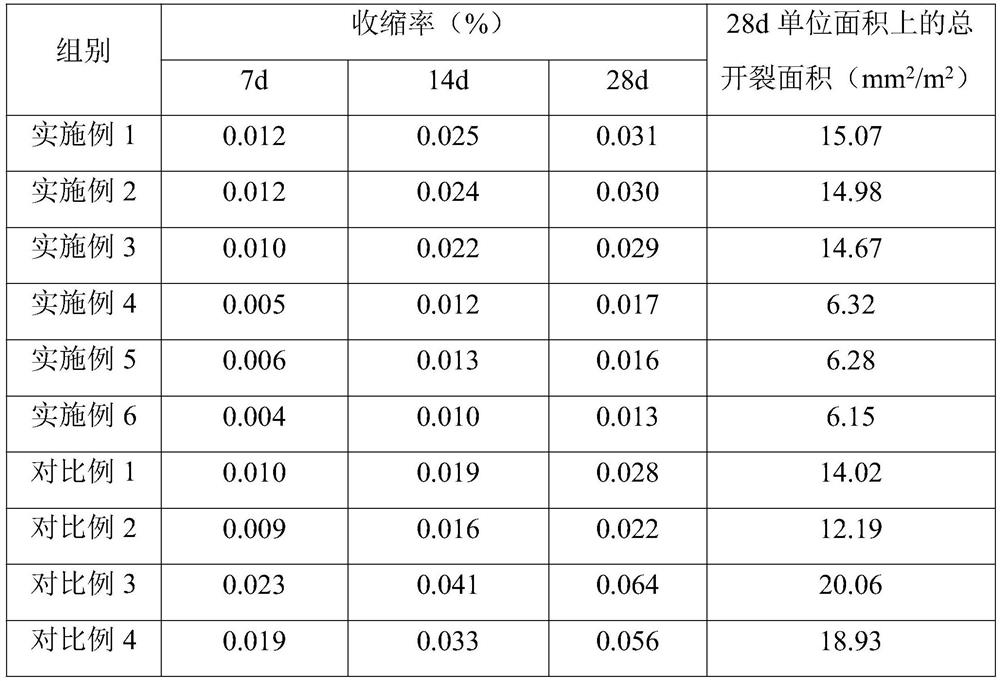

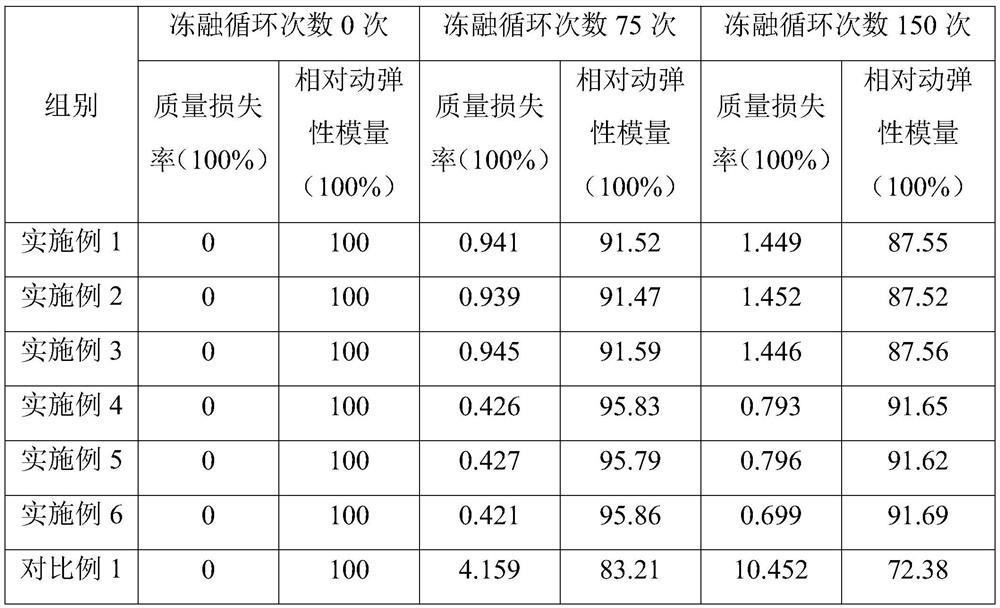

Examples

preparation example Construction

[0021] Wherein, the raw material components of the activator include by weight: 3-5 parts by weight of sodium silicate, 1-2 parts by weight of dipotassium hydrogen phosphate, and 15-20 parts by weight of hydrochloric acid solution with a mass fraction of 10%-15%. , 10-15 parts by weight of silica powder, 9-11 parts by weight of metakaolin, 5-9 parts by weight of graphene oxide, 3-5 parts by weight of borax, 1-2 parts by weight of aluminum oxide and 3-4 parts by weight of calcium chloride part; the preparation method comprises the steps of: weighing silicon micropowder, metakaolin, graphene oxide, borax and aluminum oxide in proportion and mixing them evenly, then pulverizing so that more than 90% of the particles have a particle size of no more than 1 μm; Calcining at a temperature of ℃ for 2-3 hours, then adding other remaining raw material components, mixing evenly, raising the temperature to 200-210℃ at a rate of 1-2℃ / min, continuing calcination for 5-6 hours, and cooling do...

Embodiment 1

[0028] This embodiment provides a desert aeolian sand modified concrete technology, including the following steps.

[0029] Step 1: Mix the first raw material components thoroughly to obtain a mixed material; the first raw material component includes an activator, cement and fiber in a mass ratio of 1:10:2.

[0030] Wherein, the raw material components of the activator include by weight: 3 parts by weight of sodium silicate, 2 parts by weight of dipotassium hydrogen phosphate, 20 parts by weight of hydrochloric acid solution with a mass fraction of 10%, 10 parts by weight of silica micropowder, metakaolin 11 parts by weight, 5 parts by weight of graphene oxide, 5 parts by weight of borax, 1 part by weight of aluminum oxide and 4 parts by weight of calcium chloride; the preparation method comprises the steps of: mixing silica powder, metakaolin, graphene oxide, borax and three Weigh the aluminum oxide in proportion and mix it evenly, then crush it so that more than 90% of the p...

Embodiment 2

[0035] This embodiment provides a desert aeolian sand modified concrete technology, including the following steps.

[0036] Step 1: Mix the first raw material components thoroughly to obtain a mixed material; the first raw material component includes an activator, cement and fiber in a mass ratio of 1:12:3.

[0037] Wherein, the raw material components of the activator include by weight parts: 5 parts by weight of sodium silicate, 1 part by weight of dipotassium hydrogen phosphate, 15 parts by weight of hydrochloric acid solution with a mass fraction of 15%, 15 parts by weight of silicon micropowder, metakaolin 9 parts by weight, 9 parts by weight of graphene oxide, 3 parts by weight of borax, 2 parts by weight of aluminum oxide and 3 parts by weight of calcium chloride; the preparation method comprises the steps of: mixing silica powder, metakaolin, graphene oxide, borax and three Aluminum oxide is weighed in proportion and mixed evenly, then pulverized so that more than 90% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com