Preparation process of synthetic quartzite imitating three-dimensional textures of natural stone

A technology of imitating natural stone and preparation process, which is applied in the field of synthetic quartz stone preparation technology imitating the three-dimensional texture of natural stone, can solve the problems of poor texture, poor strength and corrosion resistance of synthetic quartz stone, and achieve rich colors and reduce volatilization. Quantity, showing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

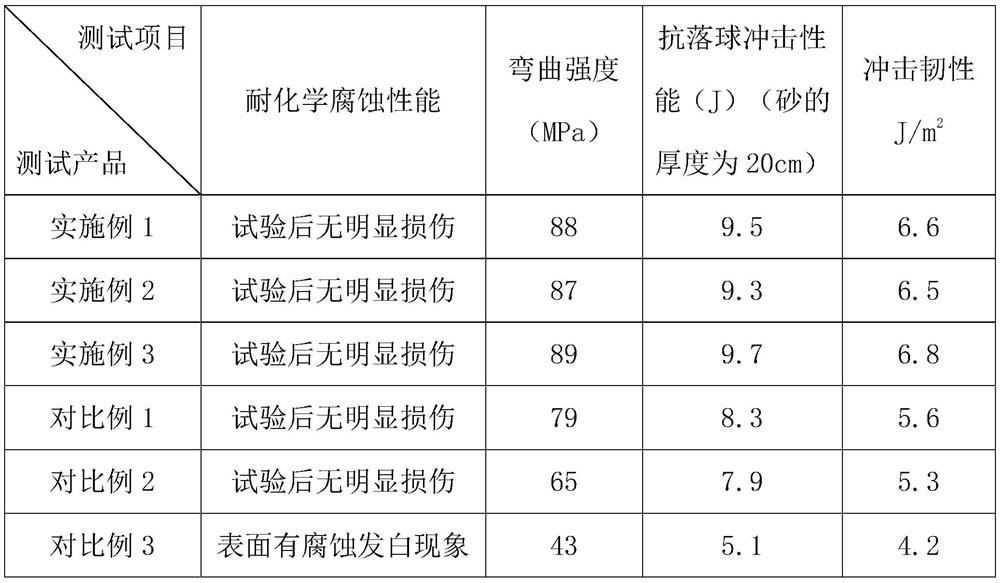

[0054] (1) In the existing preparation process of synthetic quartz stone, the adhesive used is unsaturated polyester resin, and styrene is added as diluent and crosslinking agent in the existing unsaturated polyester resin. On the one hand, styrene will volatilize into the production workshop during the production process, which is not conducive to the health of employees; on the other hand, styrene and the iron filings mixed in the quartz ore during the crushing process will have a miscible reaction, and the gray-black color will affect the whiteness of the board surface. In order to improve the whiteness of the board surface, titanium dioxide needs to be added. The shading effect of titanium dioxide affects the transparency of the surface layer, making it difficult for the surface layer to present an ideal three-dimensional texture effect. The fabric of the present invention adopts epoxy resin without styrene, which reduces the volatilization of styrene in the production work...

Embodiment 1

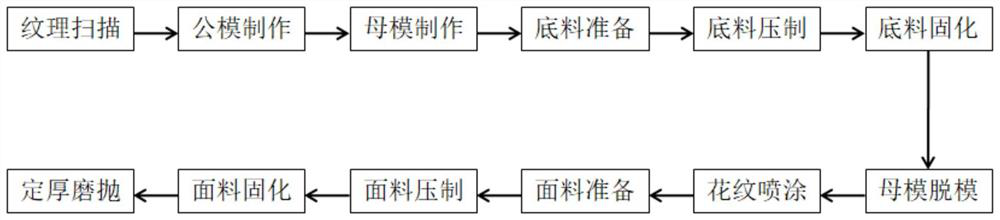

[0115] A preparation process of synthetic quartz stone imitating the three-dimensional texture of natural stone, comprising the following steps:

[0116] a1. Pattern texture scanning: Send the natural stone slab to a high-resolution scanner, scan the texture on the surface of the natural stone slab and form a graphic file;

[0117] a2. male mold making: the graphics file is input into the engraving machine (the depth of the natural stone pattern texture color in the graphics file corresponds to the depth of the engraved knife), and engraving is carried out on the male mold material (being specifically an aluminum alloy plate) to obtain a material with For a three-dimensional concave-convex textured male mold, the surface of the male mold is coated with a release agent (specifically polyvinyl alcohol solution);

[0118] a3. Master mold making: On a flat and clean platform, use a level to check and adjust the platform feet until it is completely level. The male mold is placed o...

Embodiment 2

[0131] A preparation process of synthetic quartz stone imitating the three-dimensional texture of natural stone, comprising the following steps:

[0132] a1. Pattern texture scanning: Send the natural stone slab to a high-resolution scanner, scan the texture on the surface of the natural stone slab and form a graphic file;

[0133] a2. male model making: described graphics file is input engraving machine (the depth of natural stone pattern texture color in the graphic file corresponds to the depth of engraving lower knife), engraves on male model material (being specifically magnesium alloy plate), obtains with For the male model with three-dimensional concave-convex texture, apply a release agent (specifically liquid wax) on the surface of the male model;

[0134] a3. Master mold making: On a flat and clean platform, use a level to check and adjust the platform feet until it is completely level. Male model is placed on this platform, surrounds (the height of fence is specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com