Patents

Literature

85results about How to "Good alkali corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

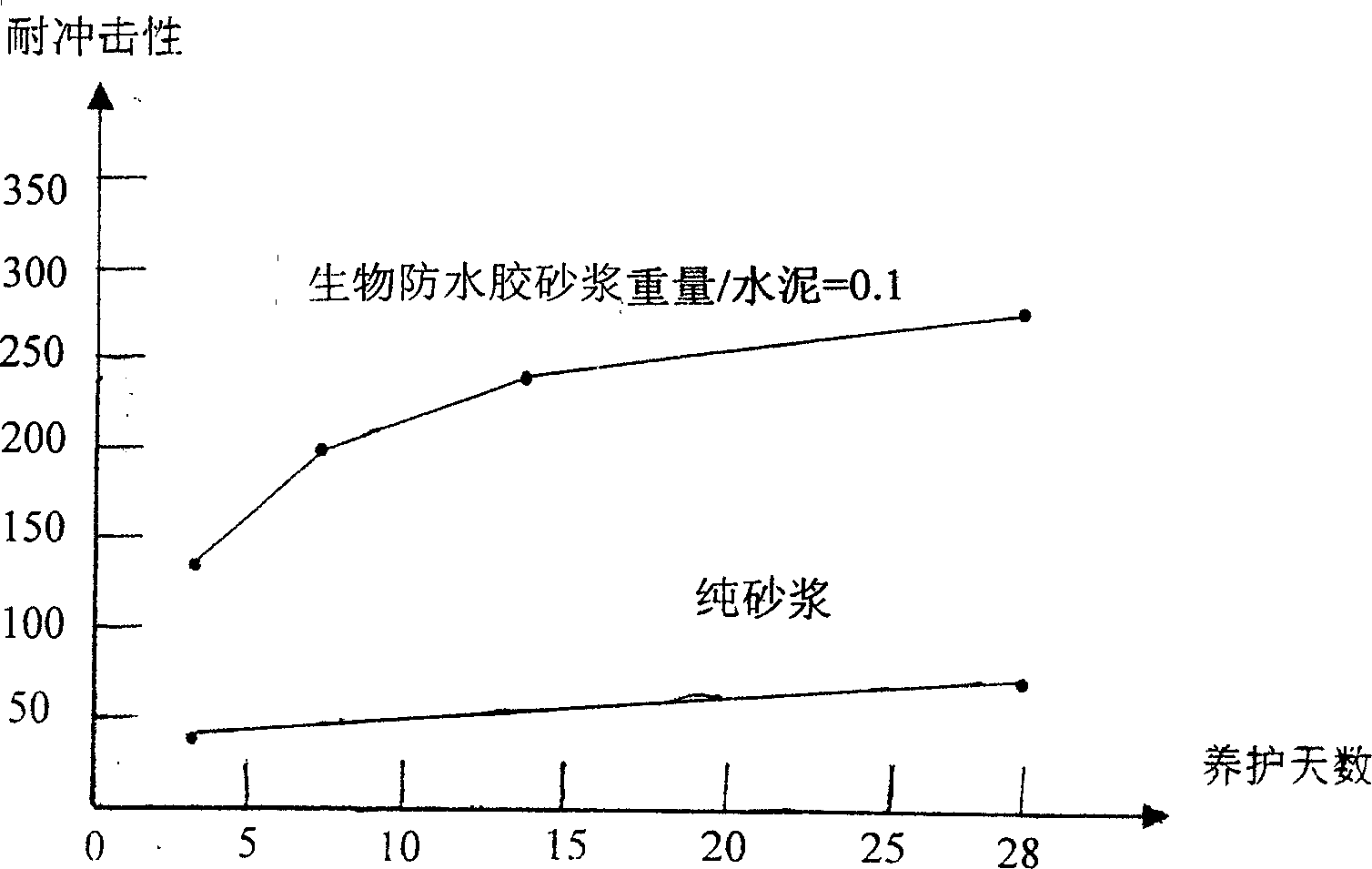

Biologic waterproof glue and usage

InactiveCN1727424AImprove adhesionImprove impermeabilityNatural rubber adhesivesStarch adhesivesEmulsionAdhesive

A biologic water-proof adhesive for building, wood, metal, ceramic, glass, etc is prepared from glutinous rice, water, ethene-vinyl acetate emulsion, dioctyl phthalate, PVC, tung oil, acrylic emulsion and natural rubber. Its advantages are high weatherability, adhesion, tension strength, elongation percentage for breaking and resistance to water, acid and alkali.

Owner:赵春发 +1

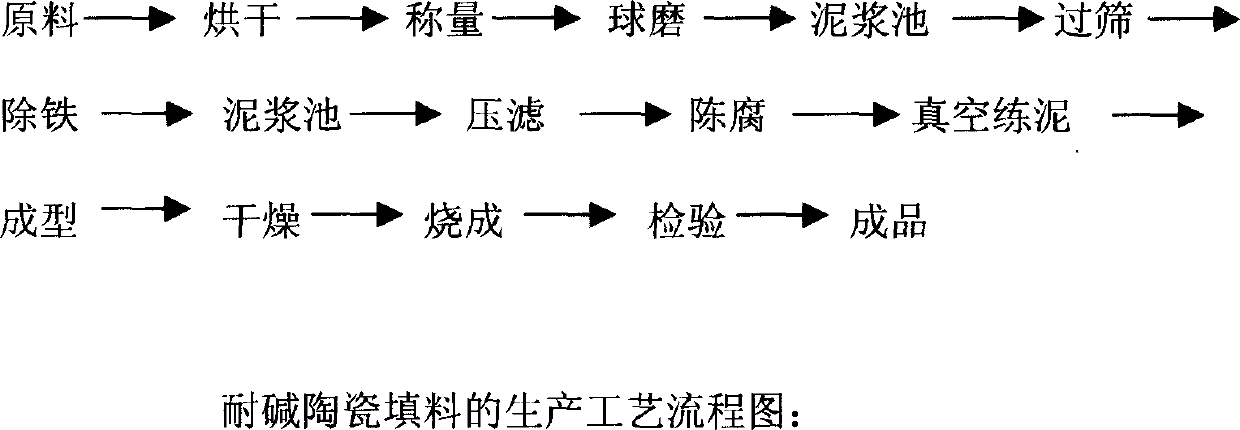

Alkliproof corrosion resistant ceramic packing and producing technique

InactiveCN1519050AExcellent alkali corrosion resistanceExtensive sources of raw materialsChemical/physical/physico-chemical processesCorrosion resistantTalc

An alkali corrosion resistant ceramic filler is prepared from wollastonite, diopside, black talc, magnesite, and clay as adhesive. Its advantages are low hydroscopicity, high volume density, hardness and alkali resistance.

Owner:FUJIAN JUNGIE NEW MATERIAL TECH CO LTD

Sound absorption noise reduction thermal insulation wallboard and manufacturing method therefor

The invention discloses a sound absorption noise reduction thermal insulation wallboard. On the one hand, soybean straw fibers are subjected to high temperature steam pretreatment, then part of pectin is removed, acetic acid is added, acetylation treatment is carried out, free hydroxide radicals in cellulose are enclosed, the hydrophobic performance and the thermal stability of the material are raised, then a waterproof agent immersion method is employed for processing, the material water absorption is lowered, the alkali corrosion resistance of the material in a cement-based material is raised and the capability of resisting microorganisms from depolymerization is raised. On the other hand, river sludge, phosphogypsum powder and the like are modified, utilized, and blended with nano tin antimony oxide and polypropylene , granulation is carried out, the intensity and the toughness of the product are raised, the product is not easy to fracture, the thermal insulation wallboard prepared according to the method is low in cost, the added modified soybean straw fibers can absorb released energy when a cement-based material cracks, therefore extension of the crack in the cement-based material is stopped, namely, the toughness of the material is raised, the compression toughness index is raised, and the provided thermal insulation wallboard has advantages of high hardness, sound absorption, noise reduction, thermal insulation, good adsorbability and the like.

Owner:冯丹

Plating liquid with high phosphoric acidity for chemical plating Ni-P alloy

InactiveCN1924093AImprove stabilityGood alkali corrosion resistanceMetallic material coating processesChemical platingAlloy

The invention discloses a high-phosphoric chemical coated Ni-P alloy depositing liquid, which is characterized by the following: adopting NiSO4 .6H2O as main salt, NaH2PO2 .H2O as reducer, lactic acid as main complex builder and citrate, glycine, EDTA disodium as auxiliary complex builder; making amber acid as accelerant and KIO3 as stabilizer; adding non-ion surface activator OP-10. The PdCl2 stability is superior by 2400s in the accelerating erosion experience, which possesses 11-13wt% phosphor.

Owner:SHANDONG UNIV

Preparation method of antioxidant carbon block with heat and alkaline etching resistance

ActiveCN103130507AImprove high temperature resistanceImprove alkali corrosion resistanceAluminium oxide/hydroxide preparationAluminium hydroxide preparationCarbide siliconCrucible

A preparation of an antioxidant carbon block with heat and alkaline etching resistance belongs to the heat and alkaline etching resistance material field. The preparation of the antioxidant carbon block with heat and alkaline etching resistance is characterized in that the antioxidant carbon block comprises the following raw materials, by mass, 60% to 80% of graphite micro powders, 5% to 20% of silicon powders, 5% to 30% of alumina sol, and 0% to 15% of silicon carbide micro powders, and the antioxidant carbon block is prepared by mixing materials, spray drying, forming, presintering and sintering. Heat and alkaline etching resistant and antioxidant experimental tests show that: carbon block materials of the antioxidant carbon block have alkaline etching resistant service life of 120 to 240 hours and antioxidant service life of 70 to 120 hours under high temperature of 1750 DEG C. Besides, the preparation of the antioxidant carbon block with heat and alkaline etching resistance is simple in process, capable of achieving production of a crucible large in size or furnace liner materials, convenient to apply to industries, and capable of being repeatedly used and lowering production cost.

Owner:宁夏高创特能源科技有限公司

Lightweight antifreezing straw fiber thermal insulation wallboard and manufacturing method therefor

The invention discloses a lightweight antifreezing straw fiber thermal insulation wallboard and a manufacturing method therefor. On the one hand, straw fibers are subjected to high temperature steam pretreatment, then part of pectin is removed, acetic acid is added, acetylation treatment is carried out, free hydroxide radicals in cellulose are enclosed, the hydrophobic performance and the thermal stability of the material are raised, then a waterproof agent immersion method is employed for processing, the material water absorption is lowered, the alkali corrosion resistance of the material in a cement-based material is raised and the capability of resisting microorganisms from depolymerization is raised. On the other hand, wastes of fly ash, iron ore tailings, ceramic polishing residues and the like are modified, utilized, and blended with sulfonated ethylene propylene rubber, granulation is carried out, the intensity and the toughness of the product are raised, the product is not easy to fracture, the thermal insulation wallboard prepared according to the method is low in cost, the added modified straw fibers can absorb released energy when a cement-based material cracks, therefore extension of the crack in the cement-based material is stopped, namely, the toughness of the material is raised, the compression toughness index is raised, and the provided thermal insulation wallboard has advantages of antifreezing, ventilation and good warmth retention.

Owner:冯丹

High-temperature bluing method of long and large part

ActiveCN101922005AImprove bluingEasy flipMetallic material coating processesHot TemperatureMaterials science

The invention discloses a high-temperature bluing method of a long and large part, which comprises: placing a support on the bottom of a bluing tank, determining a preset bluing temperature and preset bluing time, preparing bluing solution, aging the bluing solution, preheating the washed long and large part, placing the preheated part on the support for bluing, setting the temperature of the bluing solution when the part enters the tank at the highest value of the preset bluing temperature, taking the part out of the tank slowly after the bluing is finished, washing the surface of the part with at least three water heads at the same time, transferring the part to a clear water tank after the part is taken out of the tank completely, washing off the alkaline bluing solution on the surface of the part completely, placing the long and large part washed completely by clear water on a wooden sleeper with a wrapping cloth pad, checking the long and large part, and applying oil onto the long and large part is the long and large part is qualified. The method has the advantages that: the structure is simple; the operation is simple and the washing effect is good; and a high-quality blued film can be formed on the long and large part conveniently, and the blued film is more compact, firmer and more alkaline corrosion resistant.

Owner:WUHAN MARINE MACHINERY PLANT

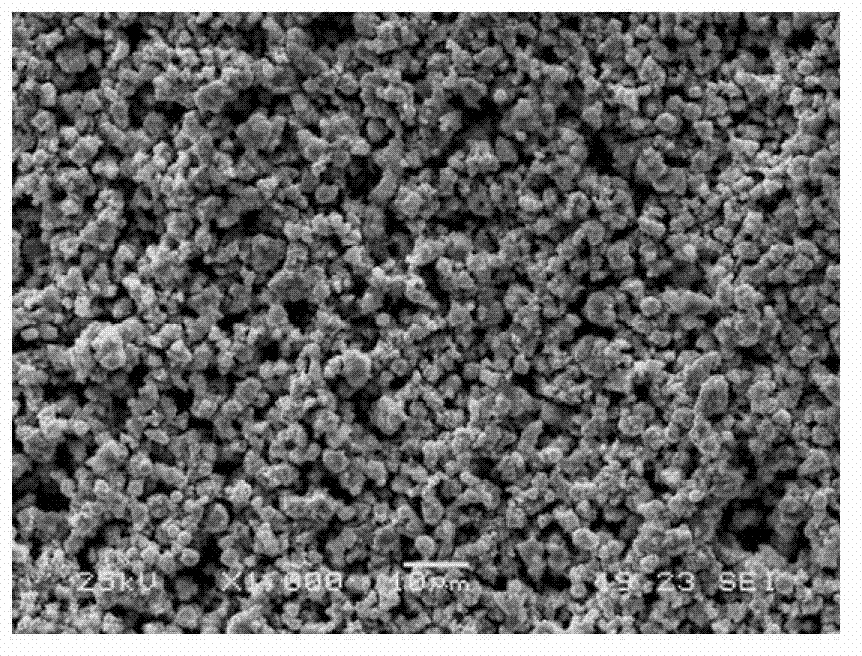

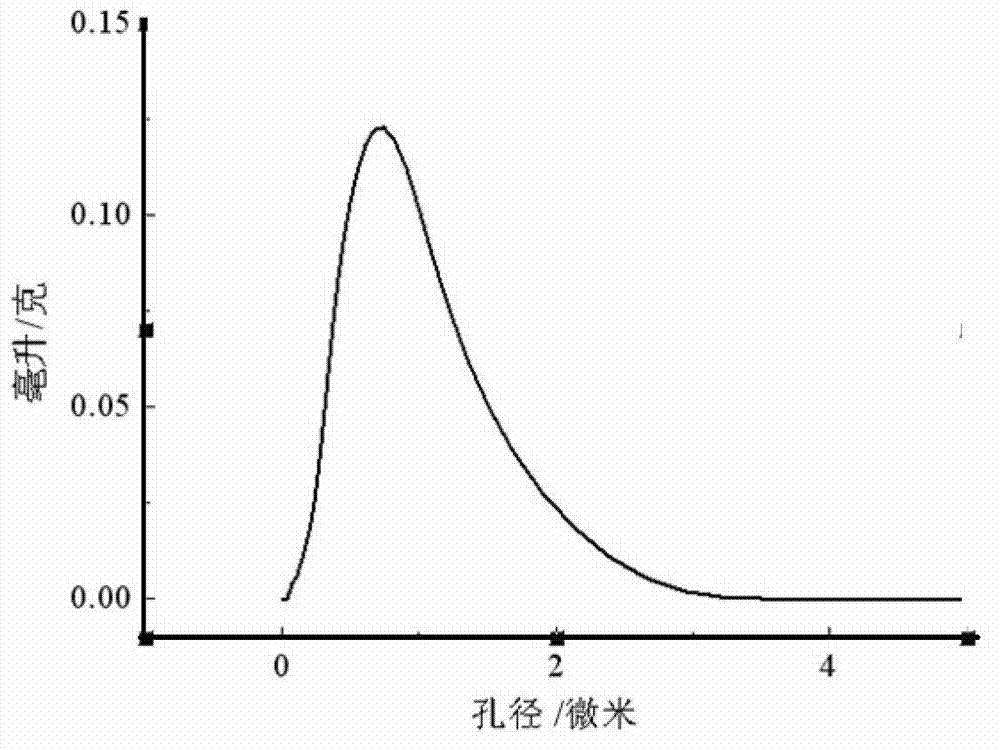

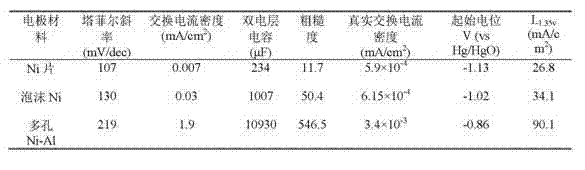

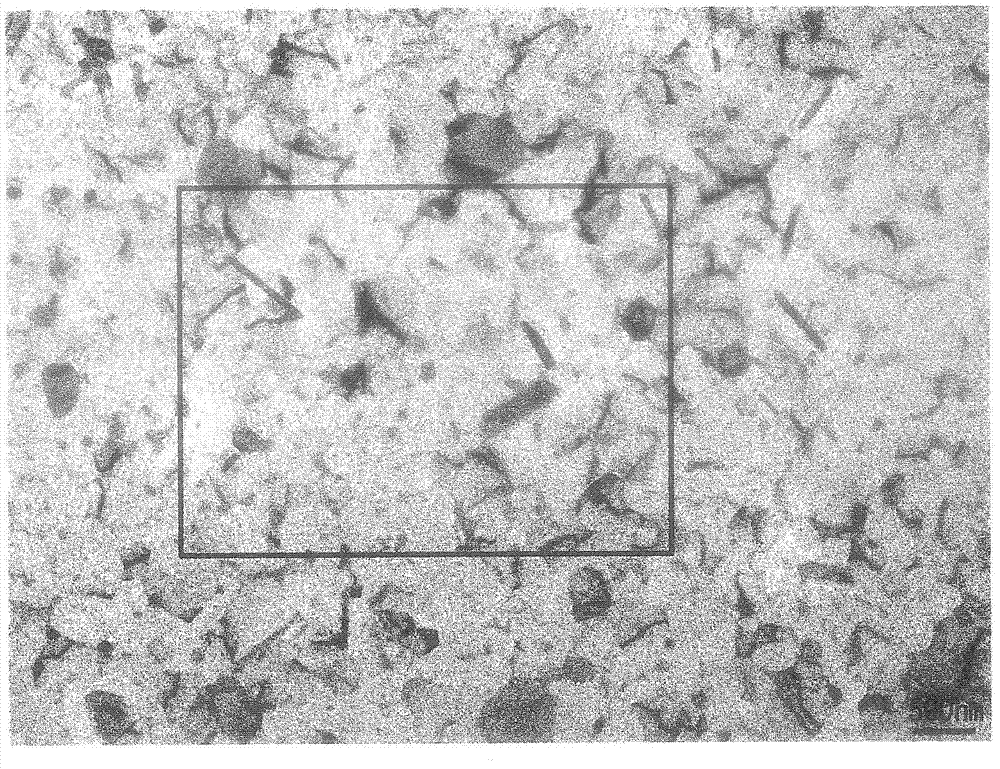

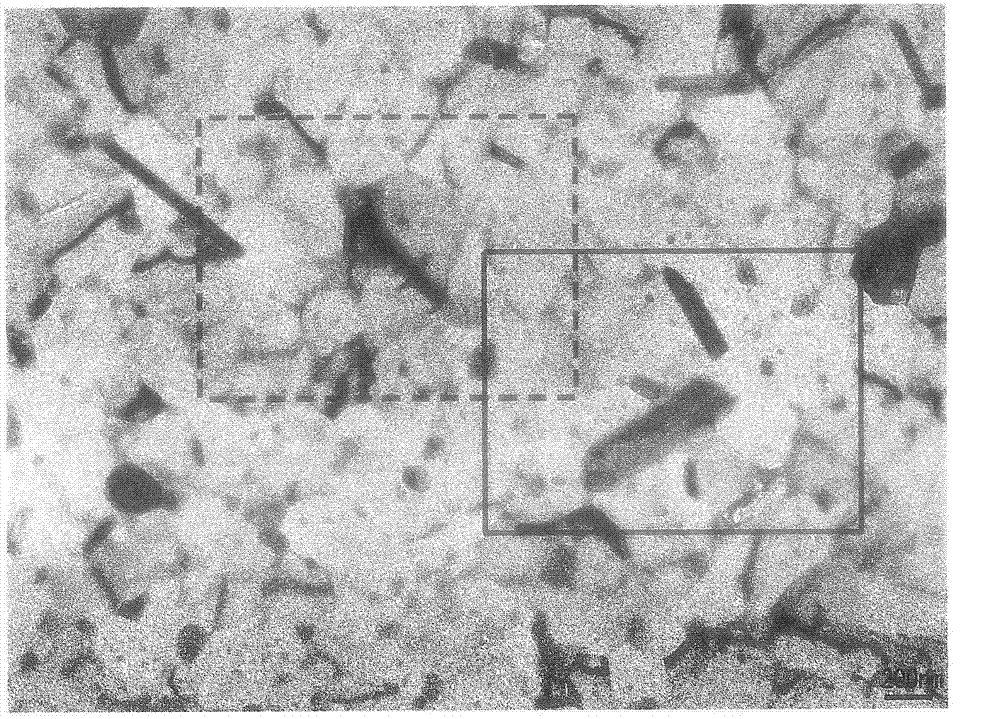

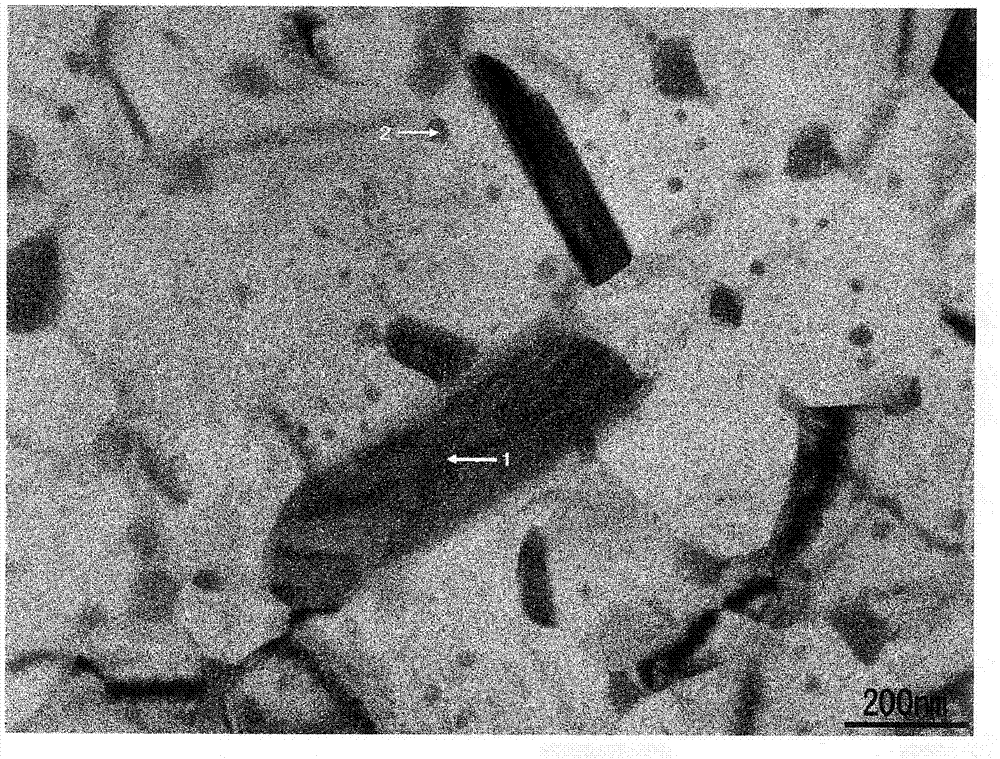

Preparation method for water electrolysis hydrogen production electrode material

ActiveCN103042217ASimple preparation processLower sintering temperatureElectrode shape/formsHydrogen productionPore diameter

The invention discloses a preparation method for a water electrolysis hydrogen production electrode material. The method comprises the steps of (1) performing cold press molding: mixing Ni powder and Al powder to make a mixture, enabling the mixture to undergo cold press molding to make pressure blank; by weight, enabling the Ni powder to be 80-95% and enabling the Al powder to be 5-20% on the basis of the Ni powder and the Al powder; (2) performing sintering and cooling: heating the pressure blank to 350-500 DEG C under vacuum, preserving heat for 60-90min, then warming to 700-950 DEG C, preserving heat for 30-120min, cooling to room temperature, and obtaining the water electrolysis hydrogen production electrode material. The water electrolysis hydrogen production electrode material has uniformity in pore diameter distribution, has high specific surface and high activity, and is long in service life, high in catalytic efficiency, simple in production method and low in cost. A novel cathode material choice is provided for water electrolysis hydrogen production, and the water electrolysis hydrogen production electrode material has wide applied prospect.

Owner:海南爱华环保科技有限公司

Al alloy film for display device

InactiveCN102741449ALower resistanceImprove heat resistanceTransistorSemiconductor/solid-state device detailsElectrical resistance and conductanceRare-earth element

Disclosed is an Al alloy film for use in a display device, which does not undergo the formation of hillocks even when exposed to high temperatures of about 450 to 600 DEG C, and has excellent high-temperature heat resistance, low electrical resistance (wiring resistance) and excellent corrosion resistance under alkaline environments. Specifically disclosed is an Al alloy film for use in a display device, which comprises at least one element selected from a group X consisting of Ta, Nb, Re, Zr, W, Mo, V, Hf and Ti and at least one rare earth element, and which meets the following requirement (1) when heated at 450 to 600 DEG C. (1) Precipitates each having an equivalent circle diameter of 20 nm or more are present at a density of 500,000 particles / mm2 or more in a first precipitation product containing at least one element selected from Al and the elements included in the group X and at least one rare earth element.

Owner:KOBE STEEL LTD

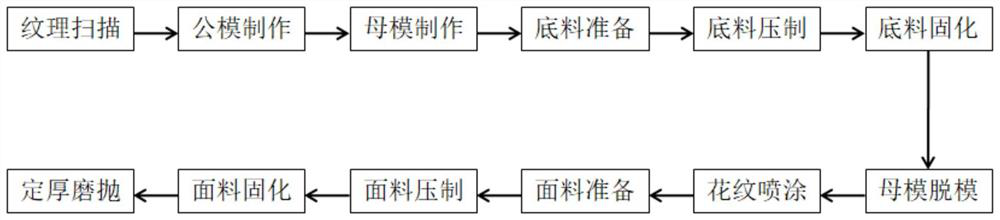

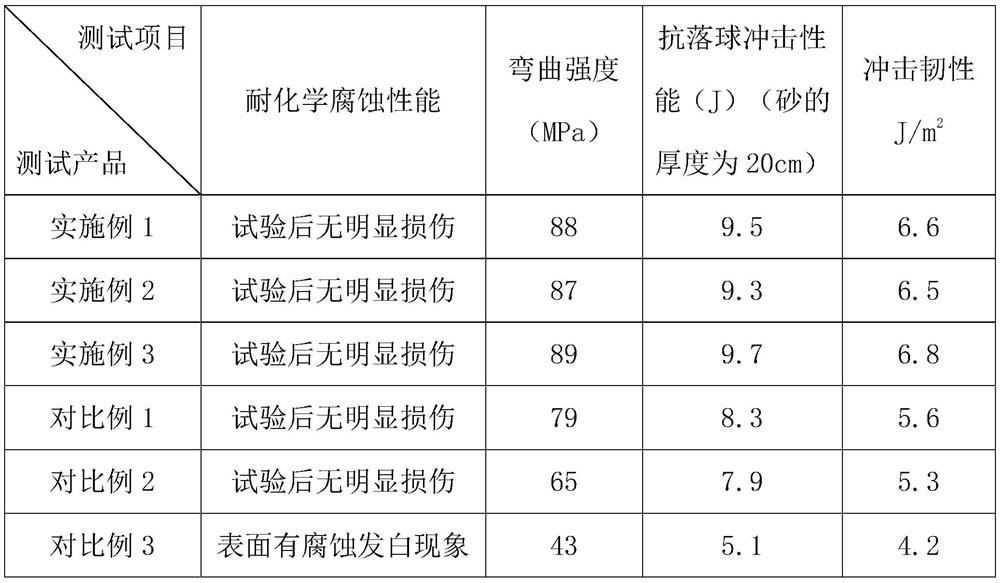

Preparation process of synthetic quartzite imitating three-dimensional textures of natural stone

ActiveCN112373073AReduce volatilityGood light transmissionFlat articlesPolymer sciencePolyester resin

The invention discloses a preparation process of synthetic quartzite imitating three-dimensional textures of natural stone. The preparation process comprises the following steps: a, manufacturing a mold, specifically, scanning textures on the surface of a natural stone plate and forming a graphic file; manufacturing a male die and a female die with three-dimensional concave-convex textures according to the graphic file; b, preparing a backing material, specifically, uniformly stirring raw materials of the backing material, wherein the raw materials of the backing material comprise resin, and the resin is unsaturated polyester resin; and c, pressing the backing material, specifically, uniformly spreading the backing material on the female die, strickling, vacuumizing, and carrying out vibration pressing. According to the preparation process of the synthetic quartzite imitating the three-dimensional textures of the natural stone, the prepared synthetic quartzite is strong in pattern texture three-dimensional sense, rich in color and comparable with the textures of the natural stone, and has the advantages of corrosion resistance, high strength, smoothness, difficulty in deformation and no delamination, and the problems that existing synthetic quartzite is poor in texture, strength and corrosion resistance are solved..

Owner:中旗(湖北)新材料有限公司

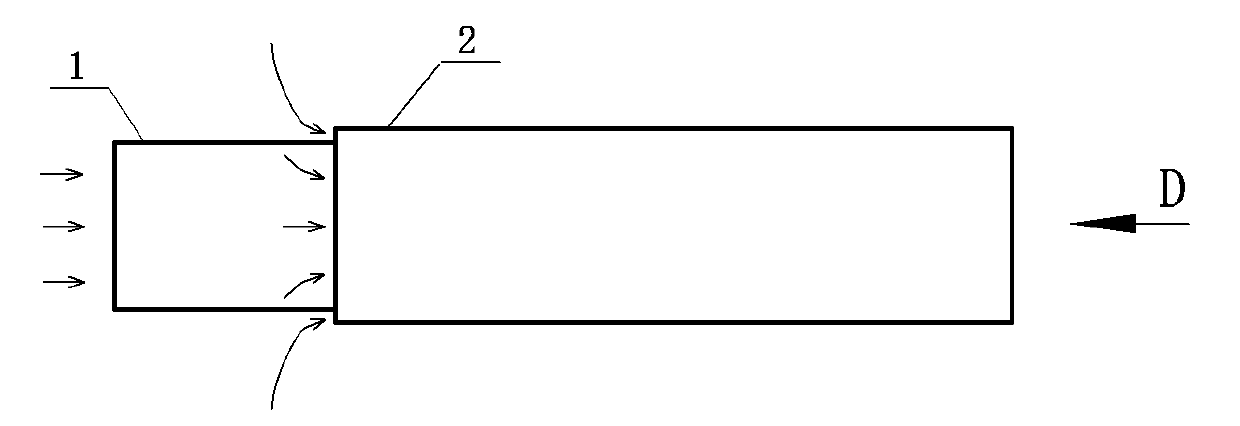

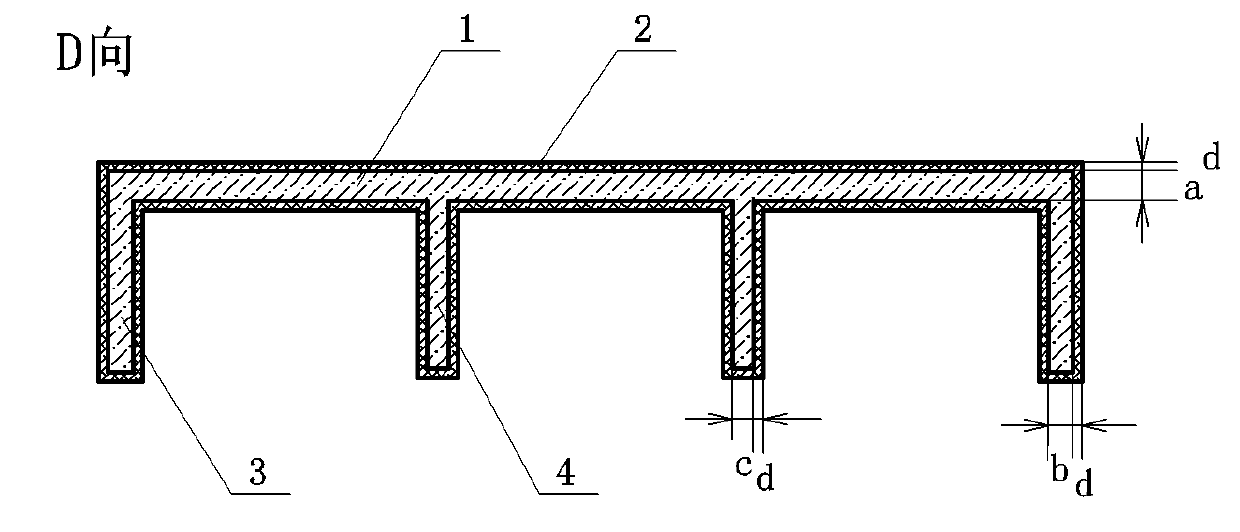

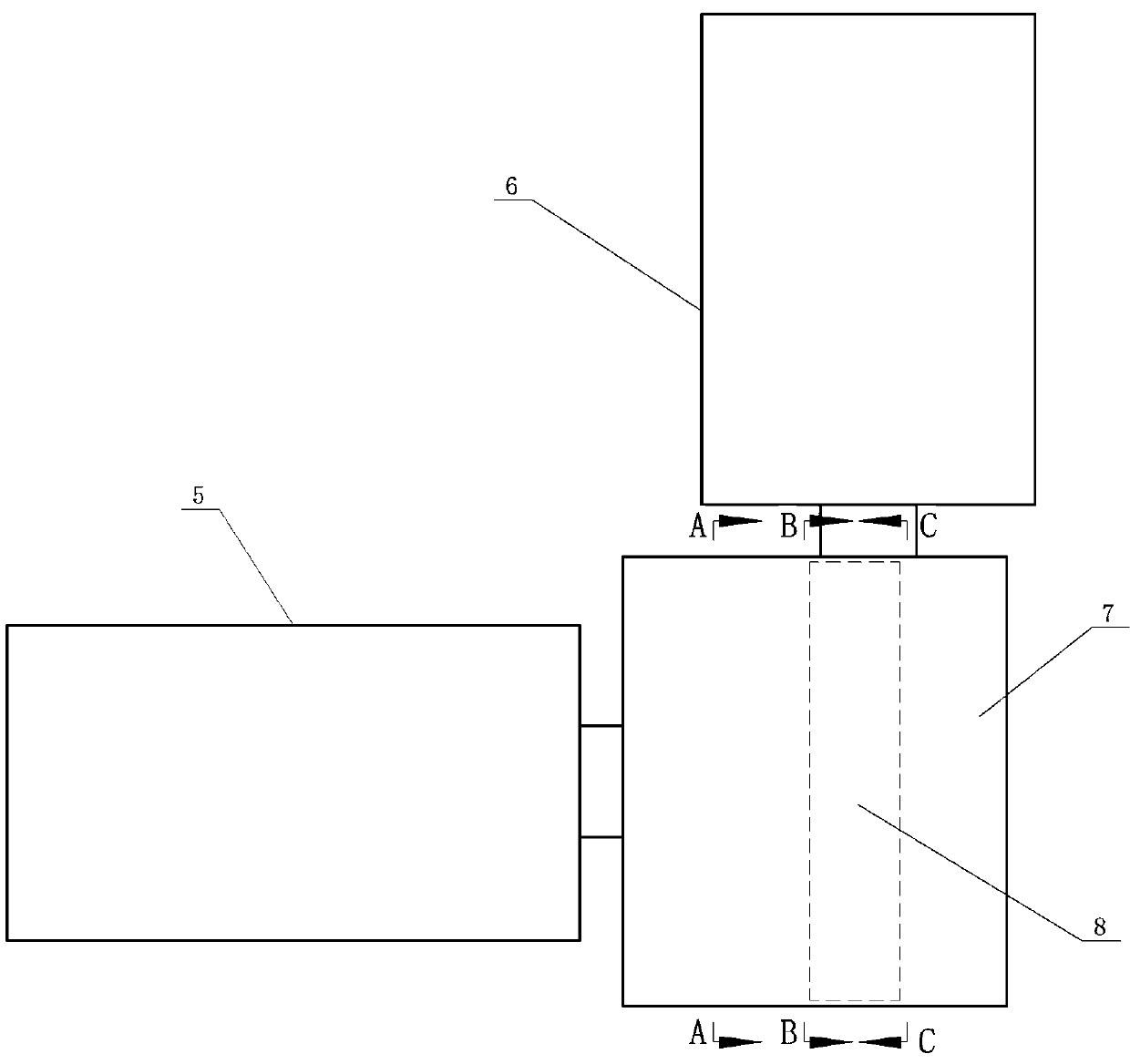

Process for producing building plastic formwork by co-extrusion method and compound mould

The invention discloses a process for producing a building plastic formwork by a co-extrusion method and a compound mould. At least two plastic extruder production lines are adopted; after an inner-layer foaming plastic extruder extrudes a prototype of an inner-layer plastic formwork, a surface-layer structure is extruded on the outer surface of the prototype of the plastic formwork by a surface-layer foaming plastic extruder; and then, a multilayered compound plastic building formwork product is formed through a vacuum sizing machine, a traction machine and a cutting machine in sequence. According to the process for producing the building plastic formwork by the co-extrusion method and the compound mould, waste plastic is used as a main raw material to form an inner layer and 20% of new materials are added to form an outer layer; and a brand-new plastic formwork is produced through a co-extrusion machining process; and the surface strength of products can be improved, the surface smooth finish is high, the strength is high and the compound mould is not easy to damage, the alkaline corrosion resistance is strong and the service life is greatly prolonged. According to the compound mould, surface-layer plastic can be uniformly collected to the center from a chute and pressure is generated; the pressure strength corresponds to an inner layer traveling speed; the utilization effect is good and the working efficiency is high; and the compound mould is very good for popularization and implementation.

Owner:张琪彬

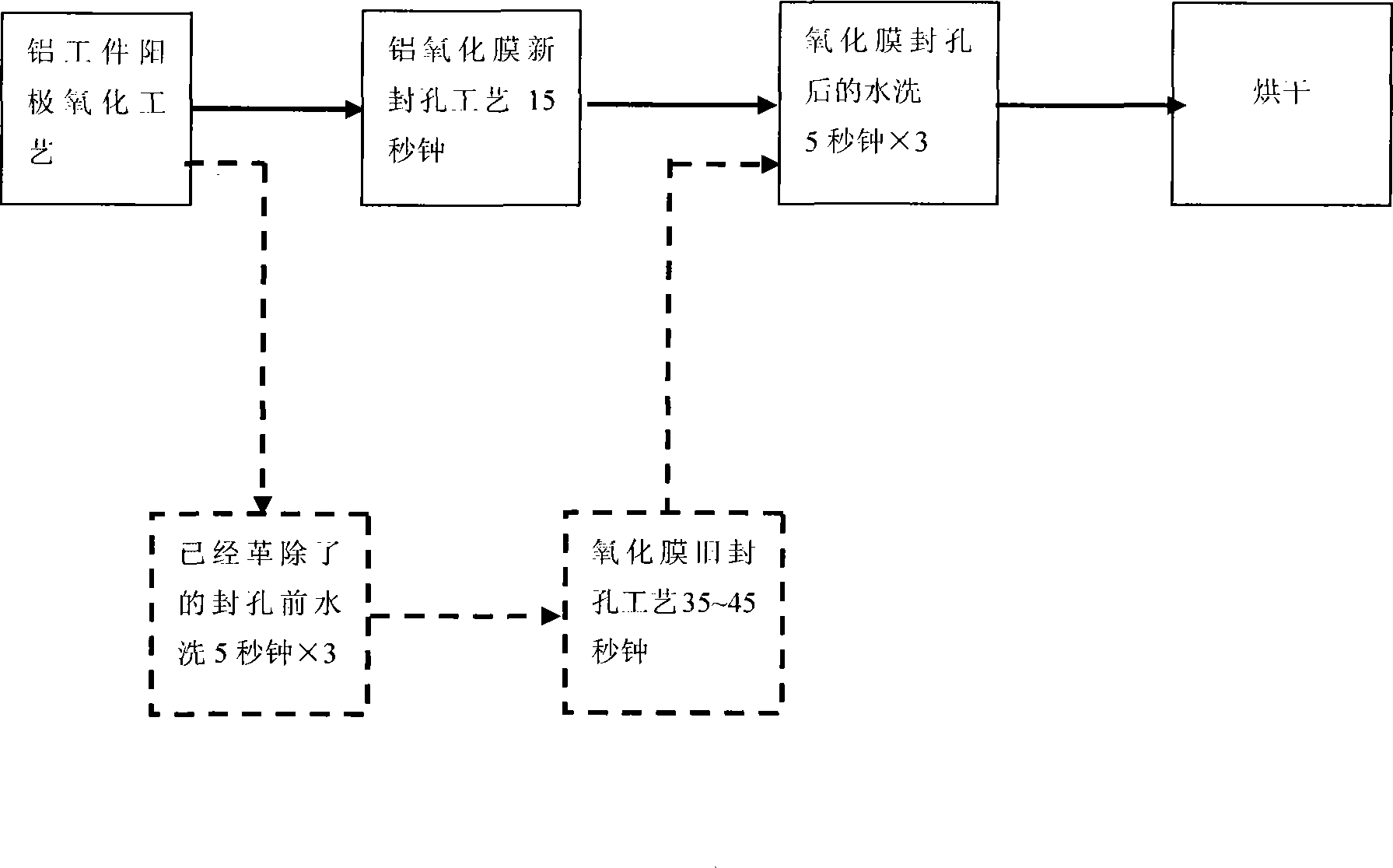

Anodic oxidation and sealing hole washing-free hole sealing technology

InactiveCN101230478AImprove wear resistanceSealing rate increasedSurface reaction electrolytic coatingProduction lineWear resistance

The invention relates to a washing-free hole-sealing process technique between anode oxidation and hole sealing. The invention brings the potential of the hole-sealing solution in the new technique mode into full play and utilizes the sulphuric acid received from the previous technique process to get involved in the hole-sealing reaction, thereby causing the research, development and application of the new hole-sealing prescription more logical and abolishing the middle washing procedure between the period that after the anodic oxidation of the aluminum workpiece and before the hole-sealing technique. The total duration for the whole hole-sealing process is shortened from 65 to 75 seconds for the prior technique to 30 seconds or so for the new technique, the sealing rate of the oxide film after the hole-sealing treatment is enhanced by 30 percent, and the wearing resistance of the oxide film is boosted by 70 percent and the alkali-proof performance of the oxide film is increased by 50 percent. In addition, the process length of the electrochemical section in the production line is shortened by 40 percent and the process cost is accordingly decreased by 35 to 40 percent. All the improvements facilitate the invention to be a good partner for the hole-sealing technique in the production line of PS printing plates and CTP plates.

Owner:李文志

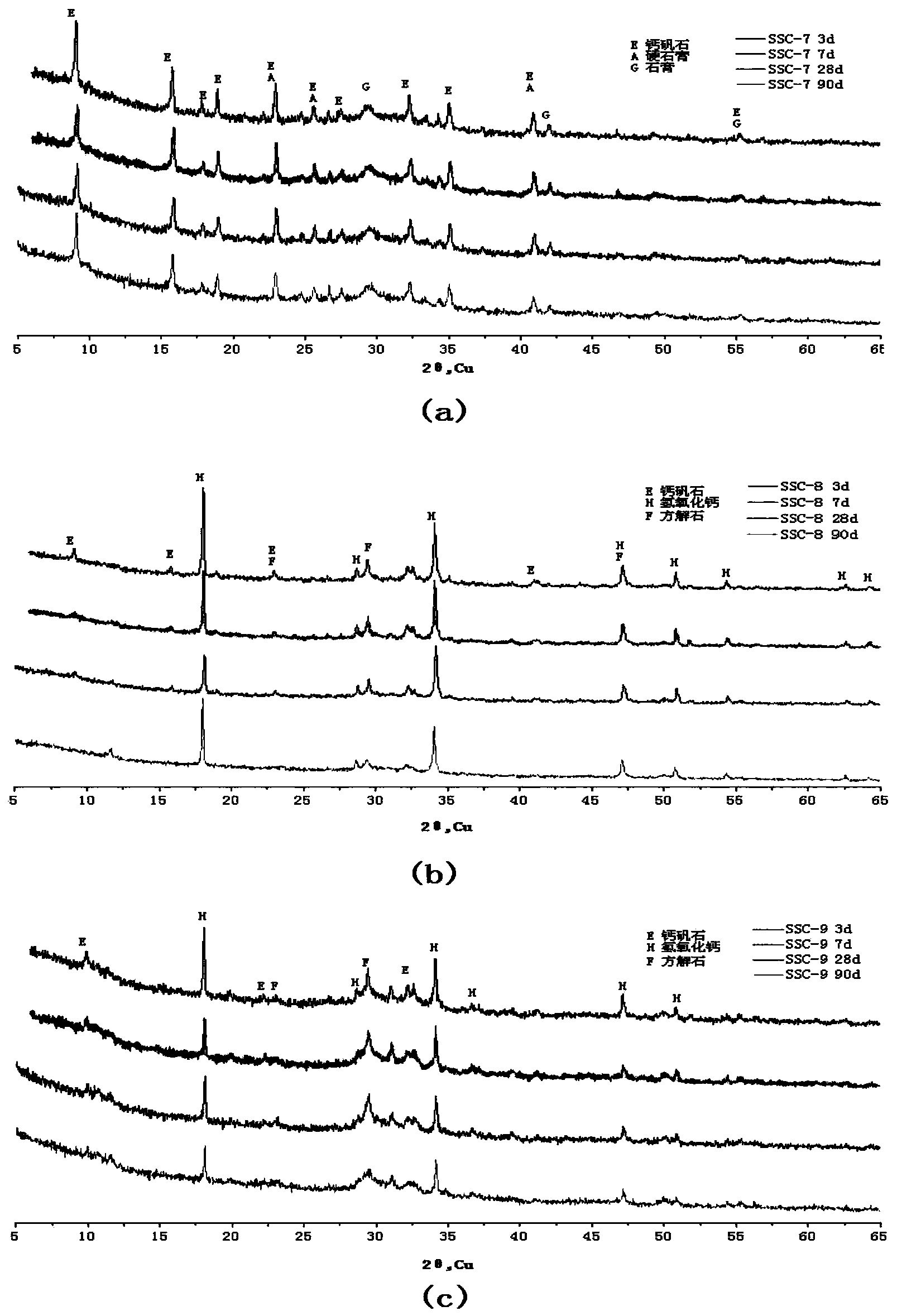

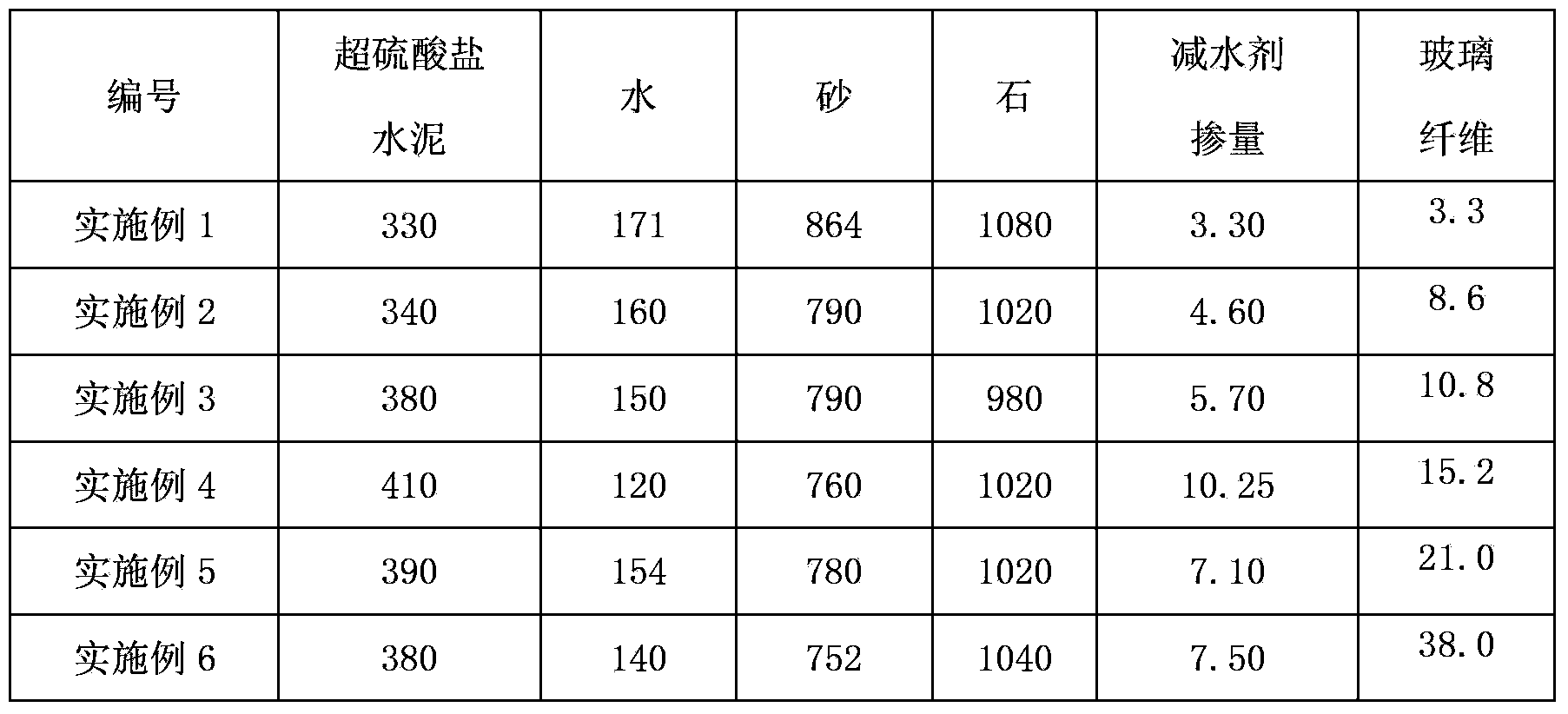

Supersulphated cement-based glass fiber concrete

The invention discloses supersulphated cement-based glass fiber concrete. The supersulphated cement-based glass fiber concrete comprises, by weight, 1 part of supersulphated cement, 0.01-0.10 parts of glass fibers, 1.8-2.6 parts of sand, 2.5-3.3 parts of stone, 0.29-0.52 parts of water and 0.01-0.025 parts of a water reducer. The supersulphated cement comprises, by weight, 70-90 parts of granulated blast-furnace slag and 10-30 parts of a composite exciting agent. The composite exciting agent comprises an alkaline exciting agent, a sulfate exciting agent and an aluminate exciting agent. The glass fibers have medium alkali-resistance or no alkali-resistance and have a mercerization weight loss ratio more than 5%. The supersulphated cement-based glass fiber concrete can obviously improve alkali erosion resistance and a service life of glass fiber concrete.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Anticorrosion aluminum alloy

The invention discloses an anticorrosion aluminum alloy. The anticorrosion aluminum alloy comprises, by weight, 4-5% of silicon, 3-4.3% of magnesium, 1.2-2.7% of lithium, 0.3-0.35% of titanium, 0.4-0.6% of cobalt, 0.6-0.76% of cerium, 0.1-0.2% of ytterbium, and the balance of aluminum. Corrosion resistance, especially alkali corrosion, of the anticorrosion aluminum alloy can be improved evidently, and corrosion rate can be reduced from the original 0.034-0.038 / (m2*h) to about 0.01g / (m2*h).

Owner:WUXI HONGCHANG HARDWARE MFG

Cobalt-chromium-based alloy for porcelain teeth and preparation method thereof

InactiveCN102978446AGood alkali corrosion resistanceNo "black edge" phenomenonImpression capsDentistry preparationsCrucibleNiobium

The present invention provides a cobalt-chromium-based alloy for porcelain teeth and a preparation method thereof. The alloy includes by weight: 23-25% of Cr, 5-7% of molybdenum, 4-6% of tungsten, 0.7-1% of iron, 0.5-1% of niobium, 1-1.5% of titanium, 0.1-0.5% of lanthanum, 0.1-0.5% of manganese, and the balance being cobalt. The ingredients are put into a high-temperature ceramic crucible and heated and melted in a vacuum intermediate frequency or high frequency furnace. The high-temperature molten solution is stirred for 5-10 seconds. The uniformly stirred molten solution is cast into a square mold or a cylindrical mold. An ingot is formed after natural cooling. The surface attachments of the ingot are removed by sandblasting. Lastly the ingot is polished to the cobalt-chromium-based alloy for the porcelain teeth. The cobalt-chromium-based alloy prepared by using the above technical solution has good acid and alkali corrosion resistance, is not easy to generate an allergic reaction with human bodies as the porcelain teeth alloy, and does not make the porcelain teeth produce the dark side phenomenon by long-term use, thereby having a high application value.

Owner:LUOYANG BEIYUAN SPECIAL CERAMICS

Antibacterial anti-compression thermal insulation wallboard and manufacturing method therefor

InactiveCN105399399AImprove hydrophobicityImprove thermal stabilitySolid waste managementCelluloseFiber

The invention discloses an antibacterial anti-compression thermal insulation wallboard. On the one hand, corn straw fibers are subjected to high temperature steam pretreatment, then part of pectin is removed, acetic acid is added, acetylation treatment is carried out, free hydroxide radicals in cellulose are enclosed, the hydrophobic performance and the thermal stability of the material are raised, then a waterproof agent immersion method is employed for processing, the material water absorption is lowered, the alkali corrosion resistance of the material in a cement-based material is raised and the capability of resisting microorganisms from depolymerization is raised. On the other hand, vermiculite powder, building brick garbage and the like are modified, utilized, and blended with chitosan and polyacrylamide, granulation is carried out, the intensity and the toughness of the product are raised, the product is not easy to fracture, the thermal insulation wallboard prepared according to the method is low in cost, the added modified corn straw fibers can absorb released energy when a cement-based material cracks, therefore extension of the crack in the cement-based material is stopped, namely, the toughness of the material is raised, the compression toughness index is raised, and the provided thermal insulation wallboard has characteristics of anti-bacteria, anti-compression, good endurance, water resistance, good thermal insulation performance and the like.

Owner:冯丹

Sound insulation corrosion-resistant thermal insulation wallboard and manufacturing method therefor

InactiveCN105399377AImprove hydrophobicityImprove thermal stabilitySolid waste managementCelluloseFiber

The invention discloses a sound insulation corrosion-resistant thermal insulation wallboard and a manufacturing method therefor. On the one hand, wheat straw fibers are subjected to high temperature steam pretreatment, then part of pectin is removed, acetic acid is added, acetylation treatment is carried out, free hydroxide radicals in cellulose are enclosed, the hydrophobic performance and the thermal stability of the material are raised, then a waterproof agent immersion method is employed for processing, the material water absorption is lowered, the alkali corrosion resistance of the material in a cement-based material is raised and the capability of resisting microorganisms from depolymerization is raised. On the other hand, bauxite clay, Chinese medical stone and the like are modified, utilized, and blended with polyphenylene sulfide particles, granulation is carried out, the intensity and the toughness of the product are raised, the product is not easy to fracture, the thermal insulation wallboard prepared according to the method is low in cost, the added modified wheat straw fibers can absorb released energy when a cement-based material cracks, therefore extension of the crack in the cement-based material is stopped, namely, the toughness of the material is raised, the compression toughness index is raised, and the provided thermal insulation wallboard has characteristics of light weight, thermal insulation, sound insulation, corrosion resistance, convenient installation and the like.

Owner:冯丹

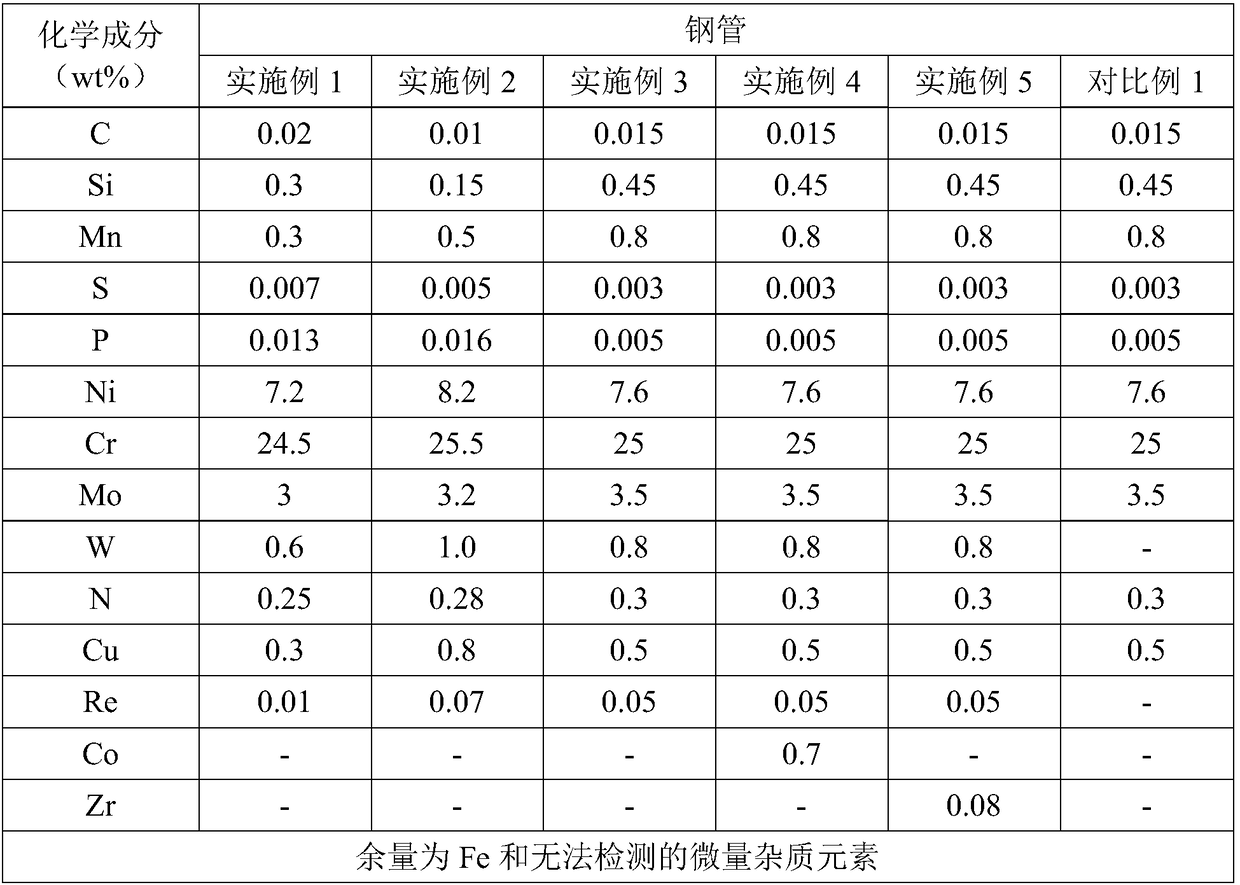

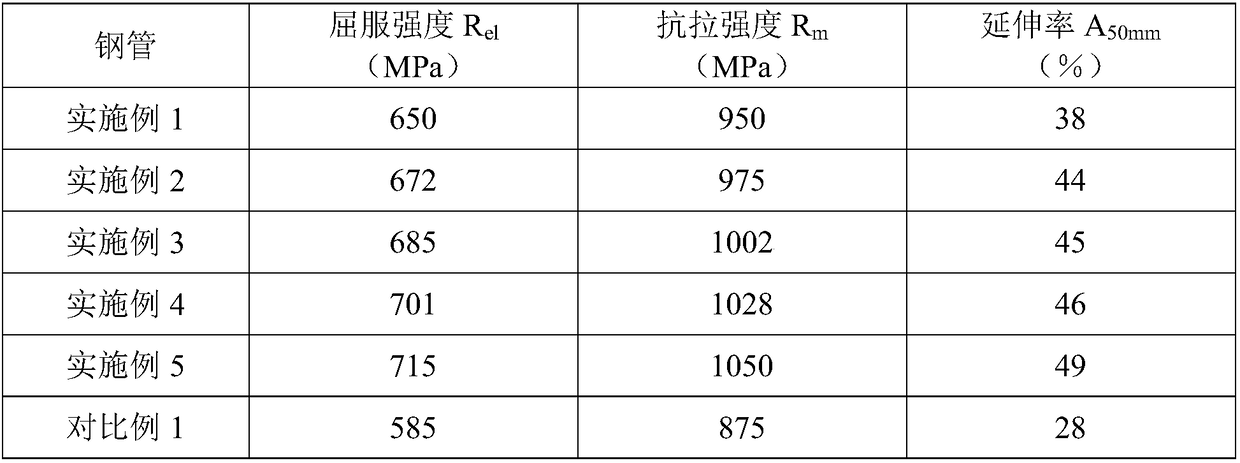

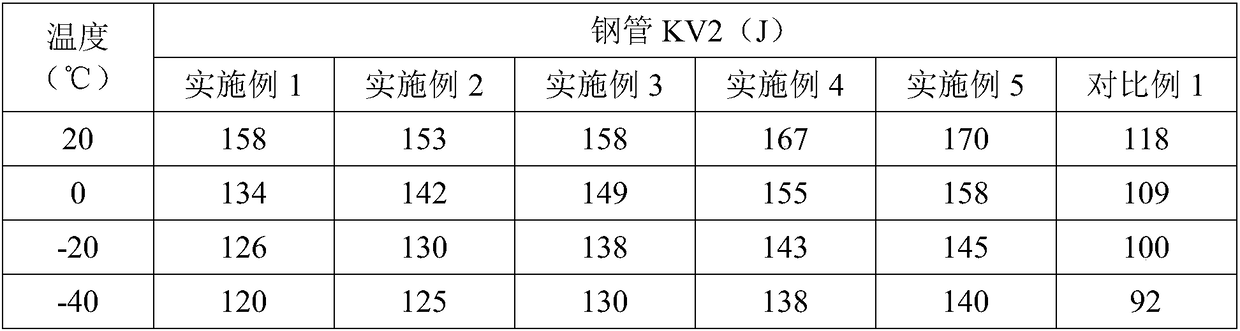

Dual-phase steel tube for low-temperature pressure vessel and preparation method of dual-phase steel tube

The invention provides a dual-phase steel tube for a low-temperature pressure vessel and a preparation method of the dual-phase steel tube. In terms of the total weight of the steel tube, the steel tube is prepared from chemical components in percentage by weight as follows: smaller than or equal to 0.03% of C, smaller than or equal to 1.0% of Si, smaller than or equal to 1.0% of Mn, smaller thanor equal to 0.010% of S, smaller than or equal to 0.025% of P, 6.0%-8.5% of Ni, 24.0%-26.0% of Cr, 3.0%-4.0% of Mo, 0.5%-1.0% of W, 0.25%-0.35% of N, smaller than or equal to 1.0% of Cu, 0.005%-0.1% of Re and the balance of Fe and inevitable impurities; the content of each component is not 0. The dual-phase steel tube for the low-temperature pressure vessel has good room temperature mechanical performance, the impact absorption energy KV2 larger than or equal to 120 J at subzero 40 DEG C or below, good low temperature resistance, excellent alkali corrosion resistance and higher hardness.

Owner:SINOPEC ENG +1

Wear-resistant alkaline-corrosion-resistant aluminum alloy

InactiveCN102876937AImprove corrosion resistanceGood alkali corrosion resistanceLithiumWear resistant

The invention discloses wear-resistant alkaline-corrosion-resistant aluminum alloy which comprises, by weight, 12-13% of silicon, 3-4.3% of magnesium, 1.2-2.7% of lithium, 0.3-0.35% of titanium, 0.4-0.6% of cobalt, 0.6-0.76% of cerium, 0.1-0.2% of ytterbium and the balance aluminum. The corrosion resistance, particularly the alkaline corrosion resistance of the aluminum alloy can be obviously improved, the corrosion rate is decreased from originally 0.027-0.03g / (m<2> h) to 0.01-0.012g / (m<2> h), and the hardness is increased from originally about 490 to about 540.

Owner:WUXI HONGCHANG HARDWARE MFG

Wear-resistant alkali corrosion-resistant aluminum alloy

ActiveCN103290274AImprove corrosion resistanceImprove alkali corrosion resistanceWear resistantManganese

The invention discloses a wear-resistant alkali corrosion-resistant aluminum alloy which consists of the following components in percentage by weight: 11-13% of silicon, 4-6% of magnesium, 0.1-0.2% of chromium, 0.2-0.4% of titanium, 0.04-0.08% of manganese, 0.1-0.15% of tungsten, 0.1-0.18% of ytterbium, 0.02-0.03% of nickel, 0.5-0.7% of zinc and the balance of aluminum. By adopting the composition, the corrosion resistance and alkali corrosion resistance of a silicon-aluminum alloy can be obviously improved, the corrosion rate is reduced to 0.001-0.0025g / (m<2>.h) from 0.027-0.03g / (m<2>.h) before, and the hardness is improved to about 590 from about 490 before.

Owner:GUANGZHOU GOLDEN ALUMINUM ALUMINUM

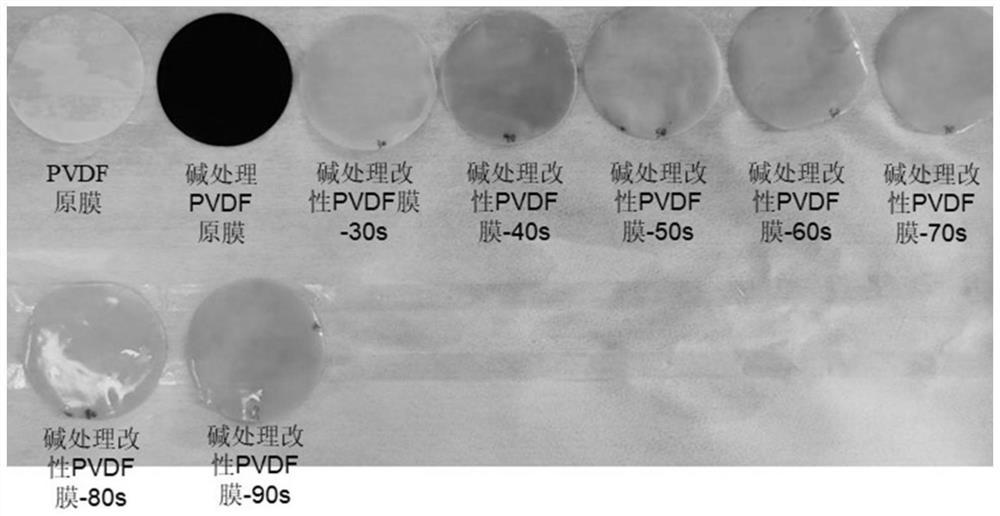

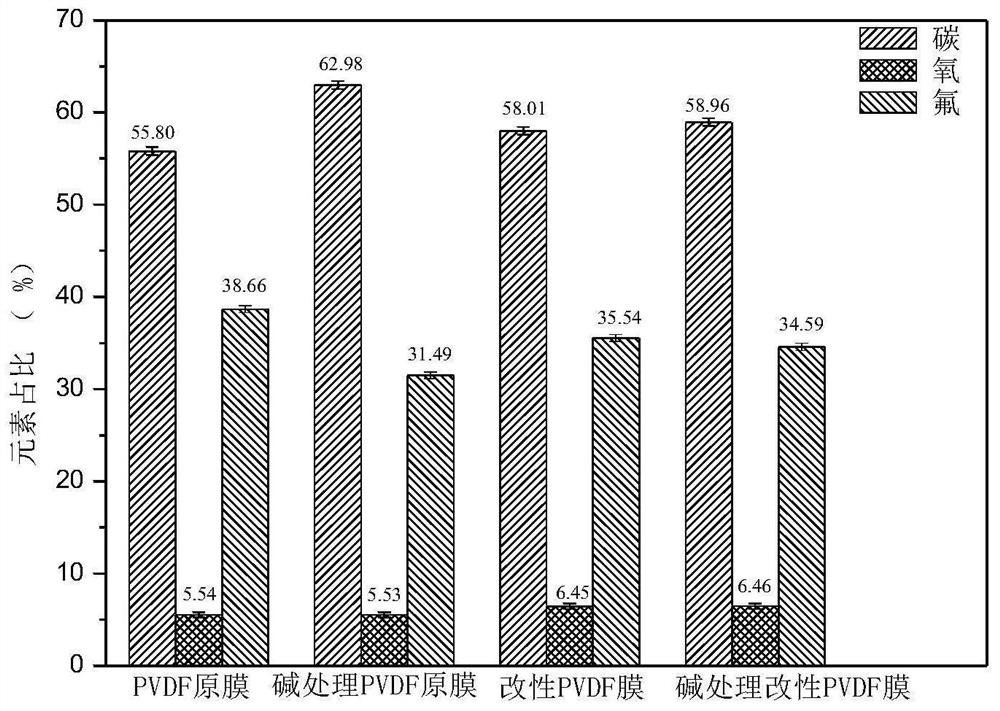

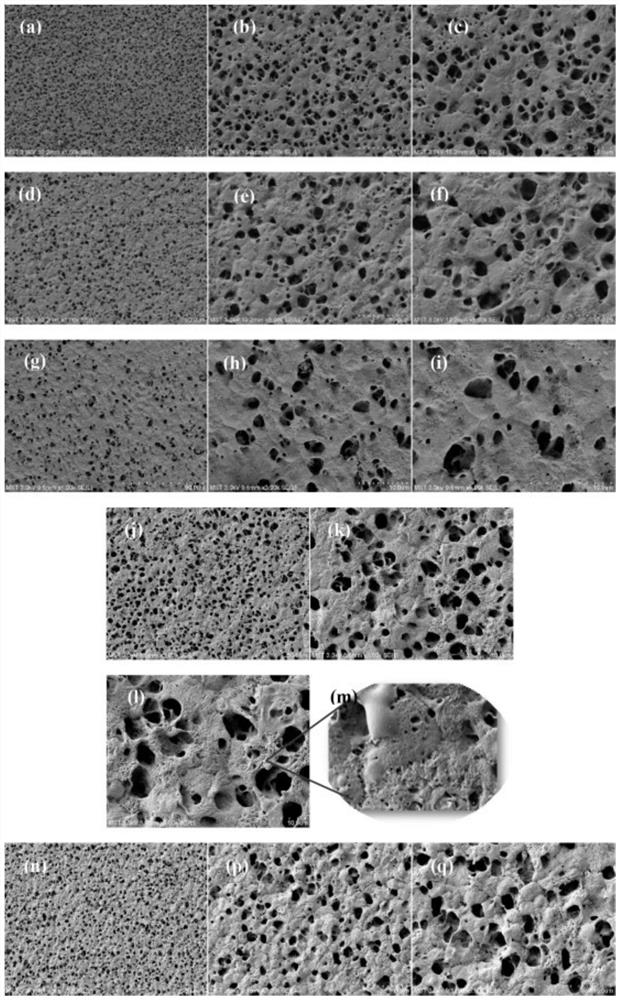

PVDF polymer separation membrane and preparation method thereof

ActiveCN112337323AHigh reuse rateLow costMembranesSemi-permeable membranesPolymer scienceFoaming agent

The invention discloses a PVDF polymer separation membrane and a preparation method thereof, and according to the method, a layer of alkyl anion compound capable of resisting alkali liquid attack is formed on the surface of a PVDF membrane material, so that the purpose of improving the alkali corrosion resistance of the PVDF membrane material is achieved. The method comprises the following steps:mixing PVDF powder, hydrophilic nano silicon dioxide and a pore-foaming agent (such as PVP, PEG and the like) solution by adopting a solution blending method, performing non-solvent induced phase separation (NIPS) to form a membrane, lightly wiping redundant moisture on the surface of the membrane, then putting the membrane into a 5-10% anionic surfactant aqueous phase solution, and performing ultrasonic soaking for 3-5 minutes until the membrane is completely soaked; taking out and removing redundant liquid drops on the surface of the membrane, hanging and airing; putting the air-dried PVDF membrane into a 5-14% alkali-resistant resin solution, taking out the PVDF membrane after the PVDF membrane is completely soaked, lightly wiping off redundant resin on the surface of the membrane, andthen putting the membrane under an ultraviolet lamp for ultraviolet radiation curing for 30-90s, so as to obtain the alkali-resistant membrane.

Owner:NANJING UNIV OF TECH

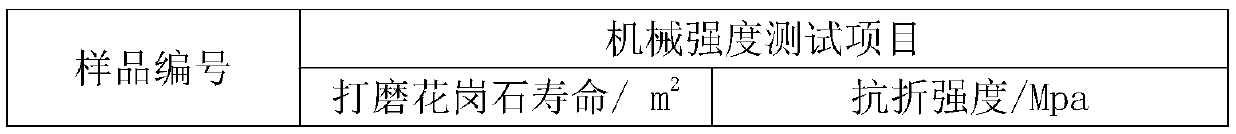

Diamond resin grinding slice material and preparation method thereof

PendingCN109735052AImprove toughnessImprove friction resistanceOther chemical processesPolymer chemistryAdhesive

The invention discloses a diamond resin grinding slice material and a preparation method thereof, and relates to the technical field of grinding materials. The technical scheme includes that the diamond resin grinding slice material comprises, in weight percent, 3-8% of diamond, 10-15% of cashew nut oil modified phenolic resin, 5-12% of stainless steel powder, 5-15% of copper fibers, 5-10% of auxiliary abrasive and the balance melamine formaldehyde resin molding powder, and the total weight percent is 100%. According to the material, the cashew nut oil modified phenolic resin and the melamineformaldehyde resin molding powder are matched to serve as an adhesive of a grinding block, the toughness of the grinding block can be improved, friction resistance is enhanced, and bending strength and abrasion resistance are further enhanced after the copper fibers are added.

Owner:厦门家和兴钻石工具有限公司

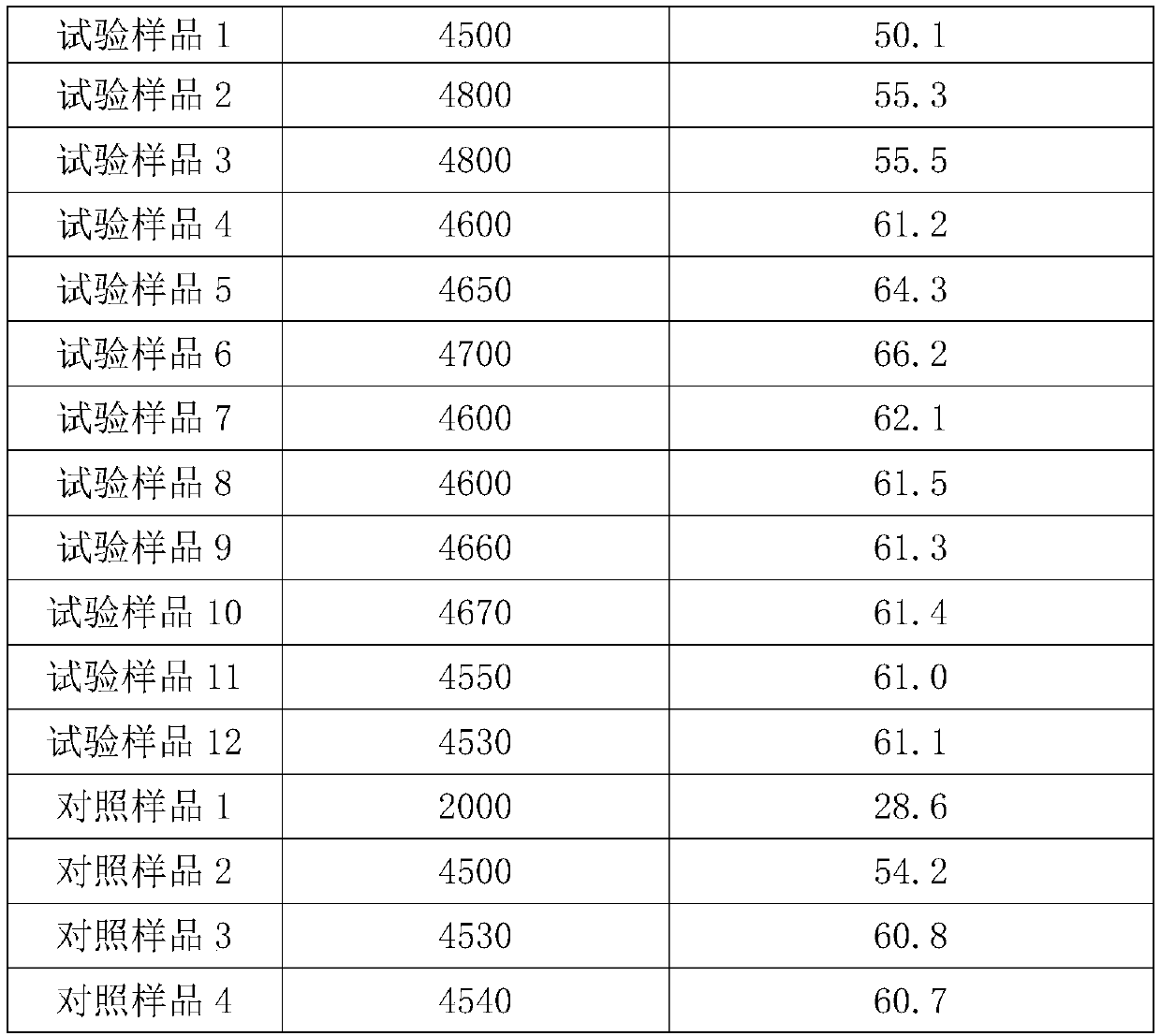

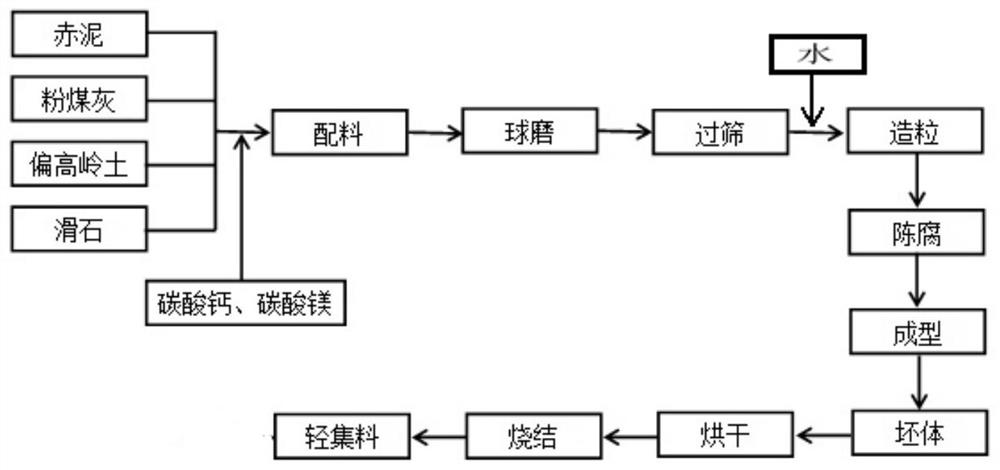

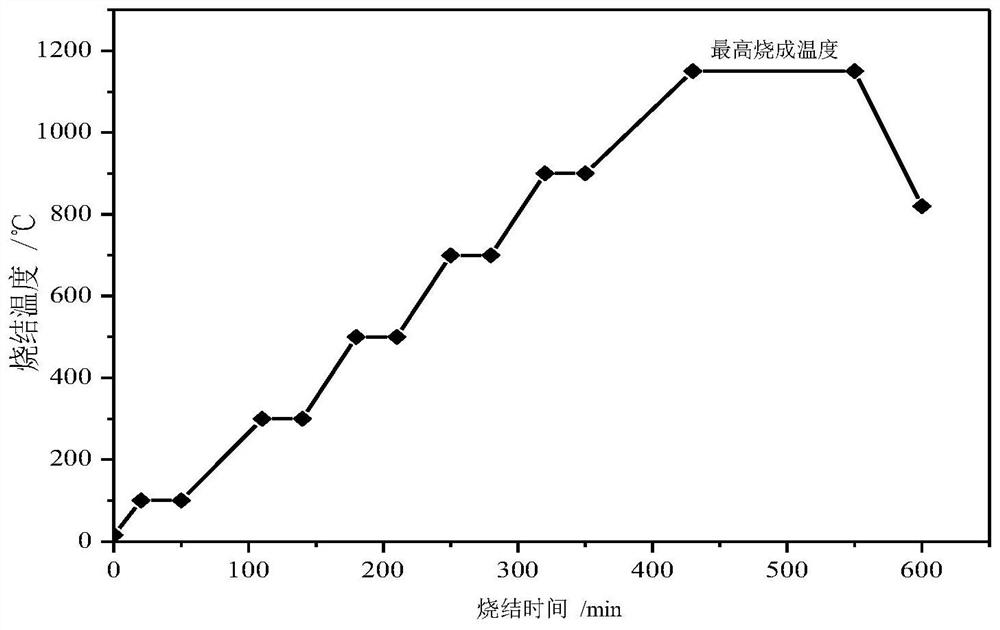

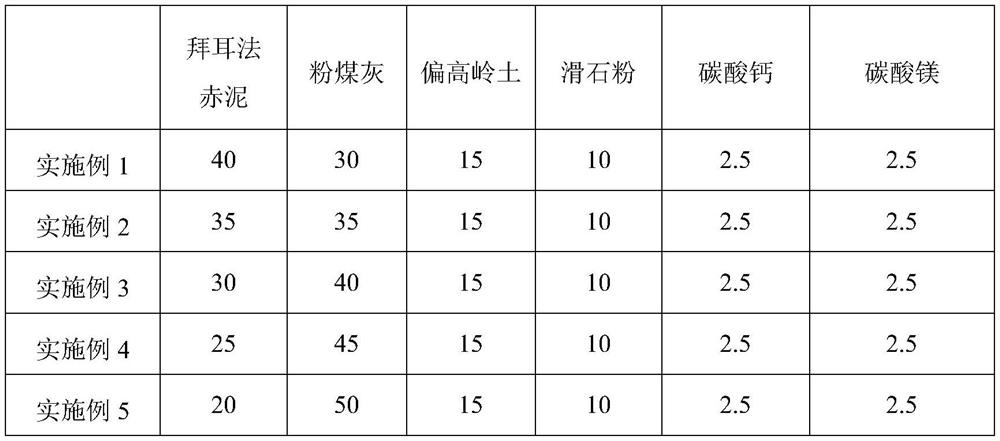

Red mud lightweight aggregate as well as preparation method and application thereof

PendingCN112062543AImprove sinterabilityGive full play to the internal maintenance effectCeramic materials productionCeramicwareRed mudKaolin clay

The invention belongs to the technical field of comprehensive utilization of solid wastes, and discloses a red mud lightweight aggregate as well as a preparation method and application thereof. According to the invention, Bayer process red mud, fly ash, metakaolin and talcum powder are used as main raw materials, calcium carbonate and magnesium carbonate are added as pore forming agents, and a proper firing process is matched to prepare the red mud lightweight aggregate with good sintering performance (the volume density is greater than or equal to 1.2. cm<-3>), medium and high mechanical strength (the cylinder compressive strength is greater than or equal to 5.5 MPa), high water absorption rate (greater than or equal to 13%) and excellent alkali corrosion resistance. The red mud lightweight aggregate not only can solve the problem of solid waste red mud treatment, but also can promote the development of light aggregate high-strength concrete, realizes the comprehensive utilization ofa large amount of industrial solid wastes, protects the environment, and has a popularization value.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Method for preparing insulating antistatic high-reflectivity waterborne coating

InactiveCN110698947AGood antibacterial and antifungal effectGood UV shielding functionElectrically-conductive paintsReflecting/signal paintsVinyl esterTriethanolamine

Owner:孙振龙

Anti-corrosion aluminum alloy

InactiveCN103290273AImprove corrosion resistanceImprove alkali corrosion resistanceManganeseTitanium

The invention discloses an anti-corrosion aluminum alloy which consists of the following components in percentage by weight: 4-6% of silicon, 3-4% of magnesium, 0.1-0.2% of chromium, 0.2-0.4% of titanium, 0.04-0.08% of manganese, 0.1-0.15% of tungsten, 0.1-0.18% of ytterbium, 0.02-0.03% of nickel, 1.5-1.7% of zinc and the balance of aluminum. According to the anti-corrosion aluminum alloy disclosed by the invention, the corrosion resistance (particularly alkali corrosion resistance) of the aluminum alloy can be obviously improved, and the corrosion rate is reduced to about 0.0005g / (m<2>.h) from 0.032-0.037g / (m<2>.h).

Owner:四川铭帝铝业有限公司

Alkliproof corrosion resistant ceramic packing and producing technique

InactiveCN100457254CWide variety of sourcesGood alkali corrosion resistanceChemical/physical/physico-chemical processesMohs scale of mineral hardnessAdhesive

An alkali corrosion resistant ceramic filler is prepared from wollastonite, diopside, black talc, magnesite, and clay as adhesive. Its advantages are low hydroscopicity, high volume density, hardness and alkali resistance.

Owner:FUJIAN JUNGIE NEW MATERIAL TECH CO LTD

Plastic for calcium plastic pipe

InactiveCN103275435AImprove liquidityGood alkali corrosion resistanceRigid pipesPolyvinyl chlorideStearate

The invention discloses plastic for calcium plastic pipe. The plastic mainly comprises the following ingredients in weight percentage: 35-55% activated chalk, 0.5-2.5% barium stearate, 0.35-1.25% lead stearate, 0.2-0.55% paraffin, and the balance of PVC resin. Through the manner, the plastic for calcium plastic pipe provided by the invention has good fluidity, and is excellent in good alkali and corrosion resistance, low in manufacture cost, good in stability, low in water absorption and good in plasticity.

Owner:SUZHOU NEW DISTRICT TEFLON PLASTIC PRODS FACTORY

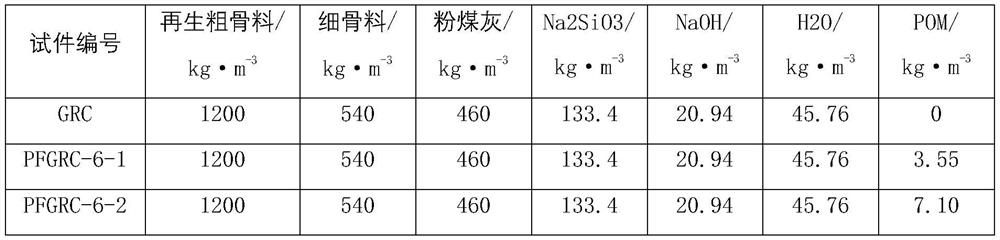

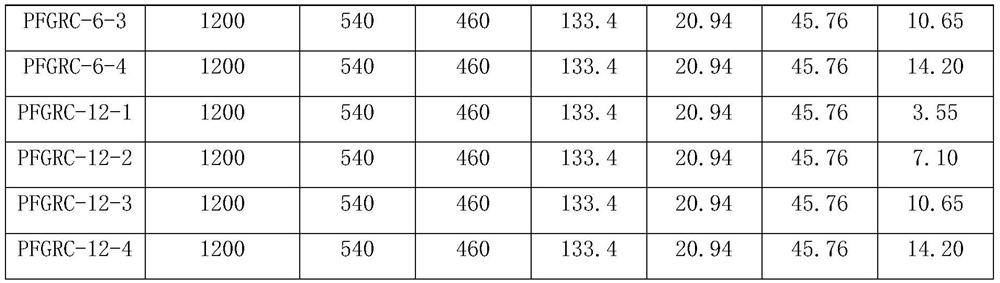

Polyformaldehyde fiber improved geopolymer recycled concrete

InactiveCN111960743AGood flexural resistanceHigh compressive strengthCement productionFiberPolyoxymethylene

The invention discloses a polyformaldehyde fiber improved geopolymer recycled concrete. Polyformaldehyde fibers with a length of 6 mm or 12 mm and a total mass ratio of 0.25%-1% are added. Through theabove scheme, polyformaldehyde fibers are doped into concrete, the reinforcing effect on the flexural strength, compressive strength and ductility of concrete is remarkable, the excellent alkali corrosion resistance of polyformaldehyde fibers can resist alkalinity in the concrete, the long-term stability of the concrete is improved, and the polyformaldehyde fibers have a very high practical valueand popularization value in the technical field of geopolymer recycled concrete.

Owner:SICHUAN UNIV

Preparation method of waterproof breathable film, waterproof breathable film and application

ActiveCN113270594APrevent leakagePrevent \"sweating\"Fuel and primary cellsCell electrodesPolymer scienceElectrical battery

The invention discloses a preparation method of a waterproof breathable film, the waterproof breathable film and application. The preparation method comprises the following steps: step 1, uniformly mixing a conductive carbon material, a heat-conducting material and a pore-forming agent, then adding PTFE emulsion, a reinforcing agent and a solvent, and stirring to obtain paste; step 2, allowing the paste obtained in the step 1 to be subjected to multiple times of roll forming to prepare a thin film; step 3, heating the film obtained in the step 2 at 180-280 DEG C for 3-5 hours; step 4, soaking the film cooled in the step 3 in clear water for 8-12 hours; and step 5, taking out the film in the step 4, and airing to obtain the waterproof breathable film. The waterproof breathable film prepared by the invention is applied to an aluminum air battery as a constituent part of an air electrode. The prepared waterproof breathable film is high in breathability, high in flexibility, good in alkali corrosion resistance and excellent in heat dissipation performance.

Owner:郑州佛光发电设备股份有限公司

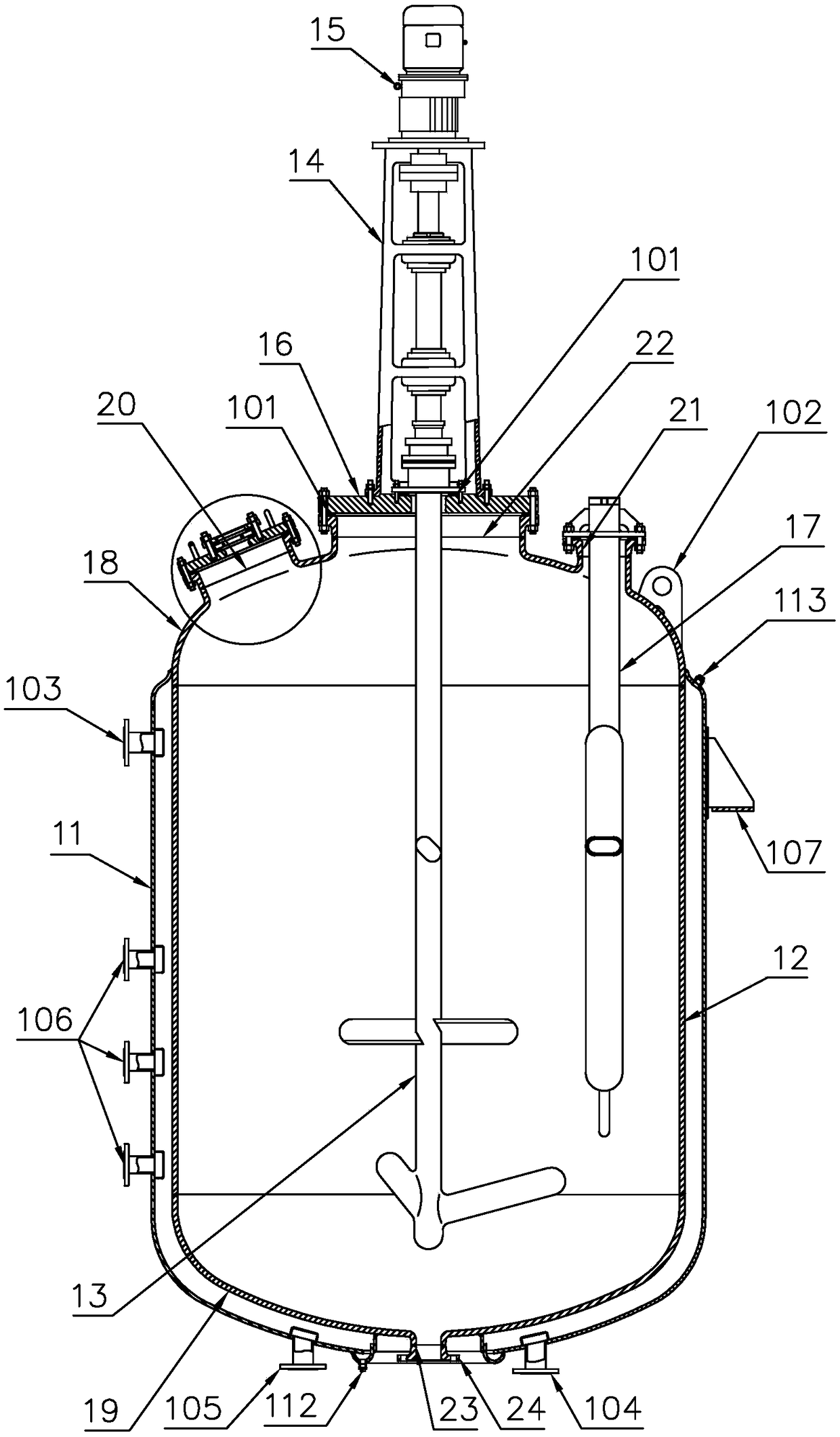

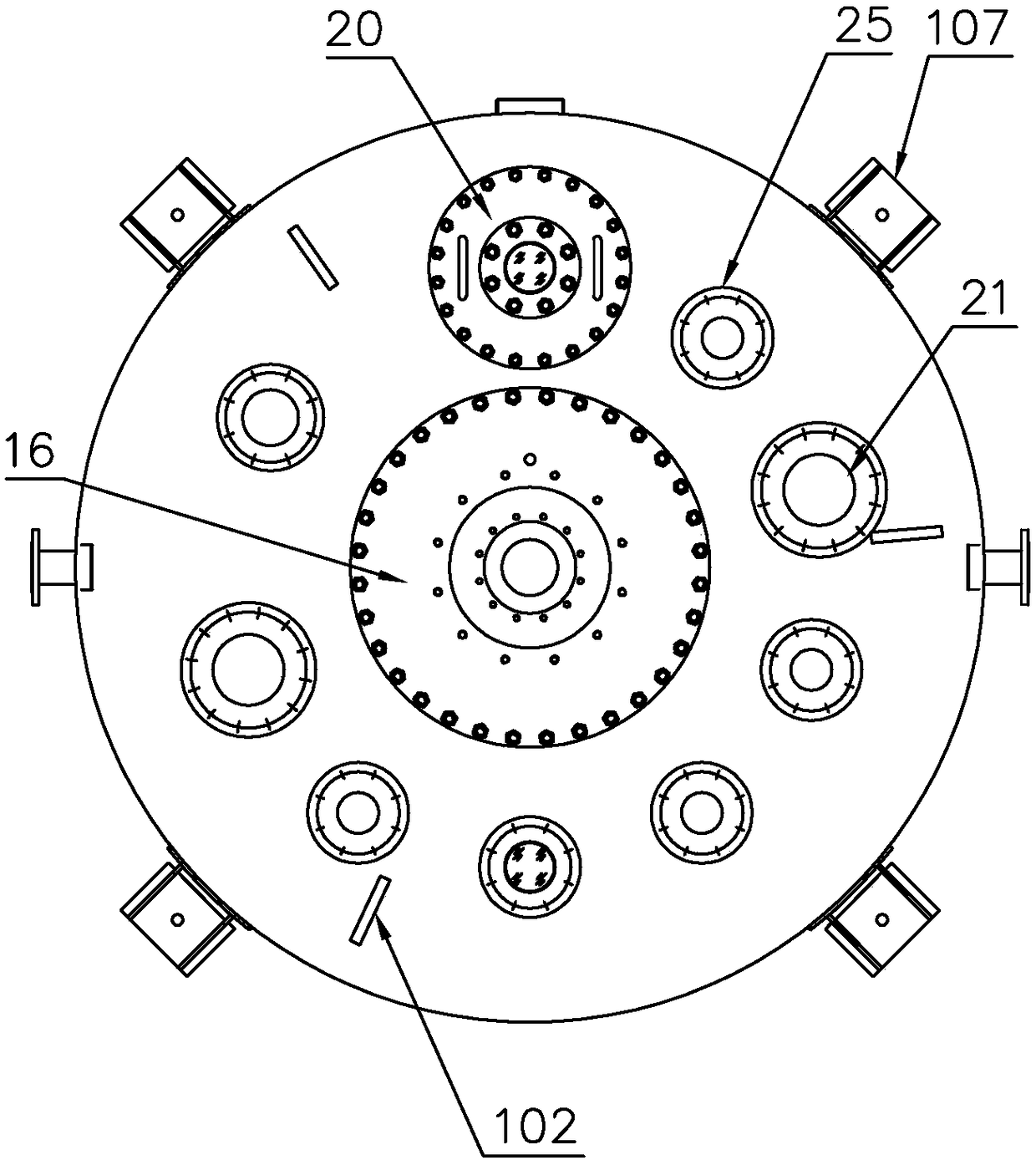

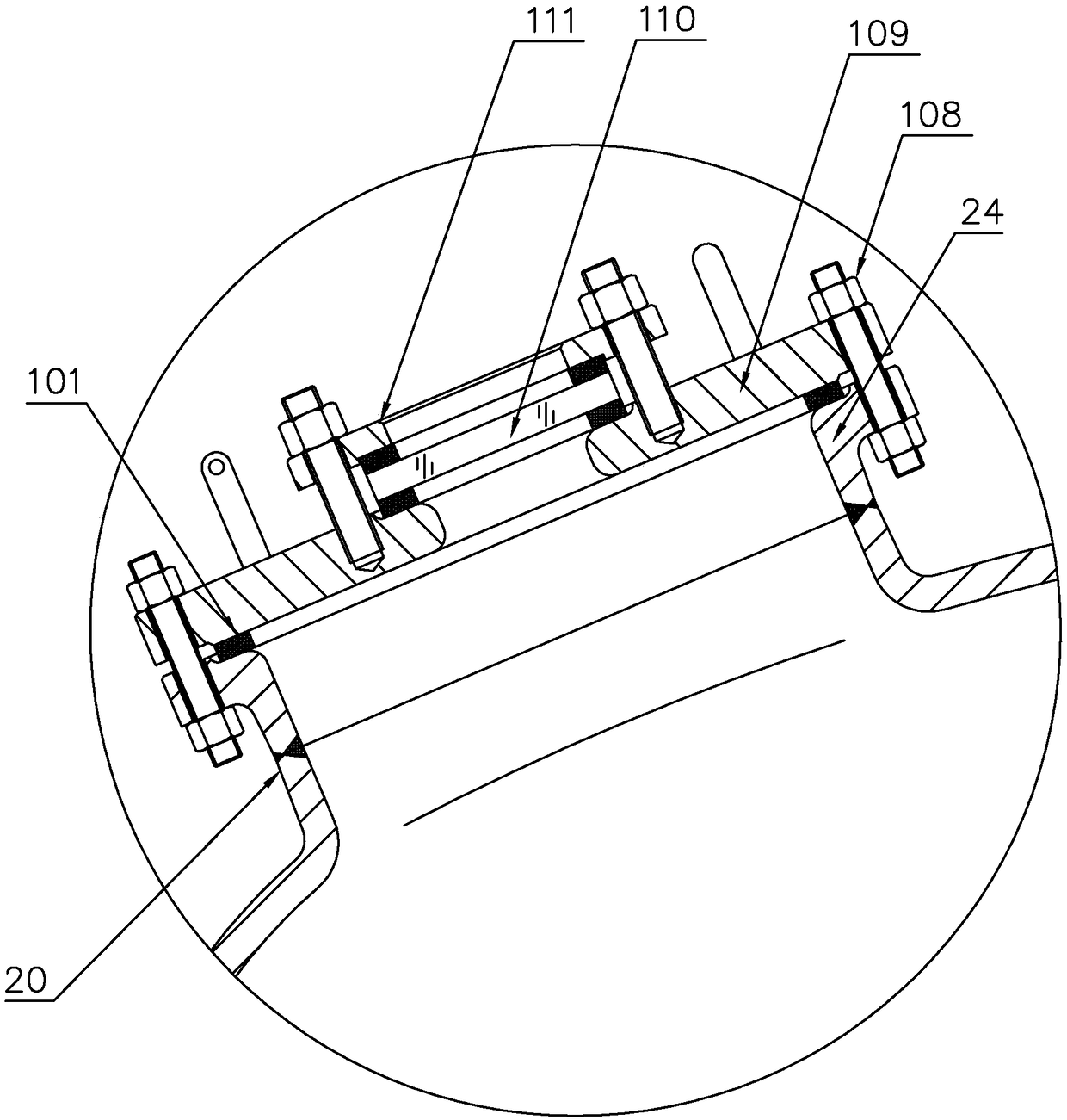

A high-strength corrosion-resistant glass-lined reactor

ActiveCN106512907BExcellent adhesionStrong lusterChemical/physical/physico-chemical stationary reactorsEngineeringHigh intensity

The invention discloses a high-strength corrosion-resistant glass-lined reactor, which comprises a jacket, a tank body, a stirrer, an upper head, a lower head, a sight glass manhole, a thermometer nozzle, a feed port, and a discharge port, wherein the jacket is arranged at the outer side of the tank body, and a plurality of mounting and positioning devices are arranged outside the jacket at equal angles; a steam inlet is formed in the upper part of the jacket, and a vent port is formed in one side of the steam inlet; a condensate water outlet is formed in the bottom of the jacket, and a high-necked flange is welded on the feed port; a high-necked flange is welded on the sight glass manhole, and a high-necked flange is welded on the thermometer nozzle; a high-necked flange is welded on the discharge port, a bottom glaze layer is arranged on the inner side wall of the tank body, and a surface glaze layer is arranged on the bottom glaze layer; bottom glaze layers are arranged on the inner side walls, end surfaces and grooves of the high-necked flanges, and surface glaze layers are arranged on the bottom glaze layers. The high-necked flanges are added for welding of openings, so that the number of punch forming opening R parts is decreased, the effective thickness of equipment is directly increased, the compressive strength is relatively improved, and the safe operation of the equipment is ensured.

Owner:临沂宏业化工设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com