Supersulphated cement-based glass fiber concrete

A technology of ultra-sulfate cement and glass fiber, which is applied in the field of building materials, can solve the problems of concrete toughness and splitting strength decline, and achieve the effect of high service life and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

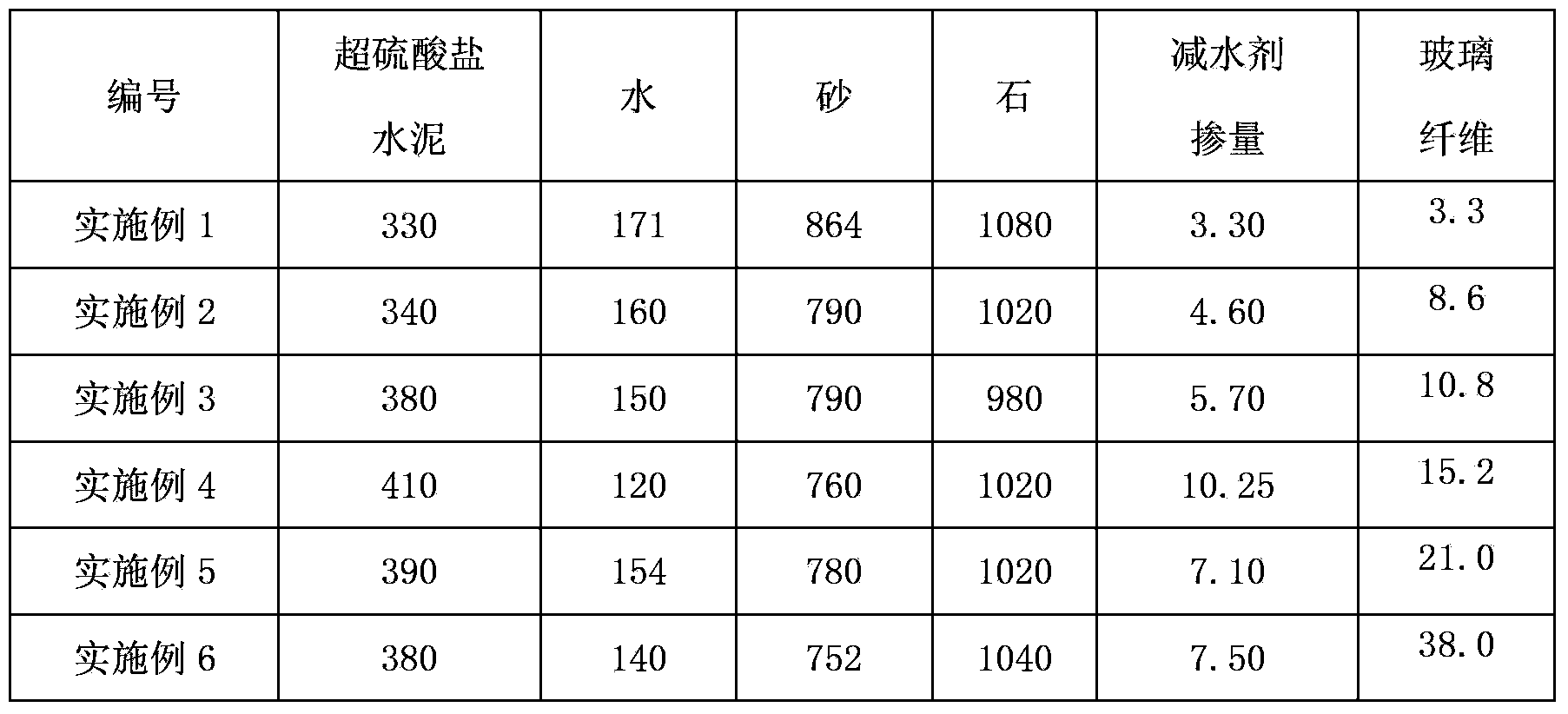

[0021] A glass fiber concrete based on super sulfate cement, its components are shown in Table 1 by parts by weight, wherein the components of super sulfate cement by parts by weight are: 90 parts of blast furnace slag, composite activator 10 parts; The components of the composite activator are calculated in parts by weight: 60 parts of desulfurized gypsum, 25 parts of cement clinker, 15 parts of sulphoaluminate cement, the Al 2 o 3 The content is 60%.

[0022] The glass fiber is medium alkali-resistant glass fiber, immersed in 10wt% sodium hydroxide solution, placed in a water bath at 100°C for 1 hour, and its weight loss after soaking in alkali is 8.12%; the diameter of the monofilament of the glass fiber is 6um , the average number of bridging oxygen ions is 3.32.

[0023] The preparation method of the above-mentioned glass fiber concrete based on super sulfate cement: (1) batching: weighing sand, stone, super sulfate cement, water, water reducing agent, and glass fiber a...

Embodiment 2

[0026] The present embodiment is based on the glass fiber concrete of super sulfate cement, and the components are shown in Table 1 by weight parts, wherein the components of the super sulfate cement are: 85 parts of blast furnace slag, composite activator 15 parts; The components of the composite activator are calculated in parts by weight: 65 parts of phosphogypsum, 20 parts of cement clinker, 15 parts of aluminate cement, the Al 2 o 3 The content is 55wt%.

[0027] The glass fiber is non-alkali-resistant glass fiber, immersed in 10wt% sodium hydroxide solution, placed in a water bath at 100°C for 1 hour, and the weight loss after soaking in alkali is 10.78%; the diameter of the monofilament of the glass fiber is 10um , The average number of bridging oxygen ions is 3.90.

[0028] The preparation method of the glass fiber concrete based on super sulfate cement in this embodiment is the same as in Example 1, and the main properties of the glass fiber concrete based on super ...

Embodiment 3

[0030] The present embodiment is based on the glass fiber concrete of super sulfate cement, and each component is counted in Table 1 by weight part, wherein the component of described super sulfate cement is counted as: blast furnace slag 82 parts, composite activator 18 parts; The components of the composite activator are calculated in parts by weight: 70 parts of fluorogypsum, 20 parts of calcium hydroxide, 10 parts of sodium aluminate, the Al of the sodium aluminate 2 o 3 The content is 62wt%.

[0031] The glass fiber is non-alkali-resistant glass fiber, immersed in 10wt% sodium hydroxide solution, placed in a water bath at 100°C for 1 hour, and its weight loss after soaking in alkali is 10.41%; the diameter of the monofilament of the glass fiber is 10 μm , The average number of bridging oxygen ions is 2.86.

[0032] The preparation method of the glass fiber concrete based on super sulfate cement in this embodiment is the same as in Example 1, and the main properties of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com