Alkliproof corrosion resistant ceramic packing and producing technique

A ceramic filler, alkali-resistant technology, used in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc. Can not be used for a long time and other problems, to achieve the effects of excellent alkali corrosion resistance, low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

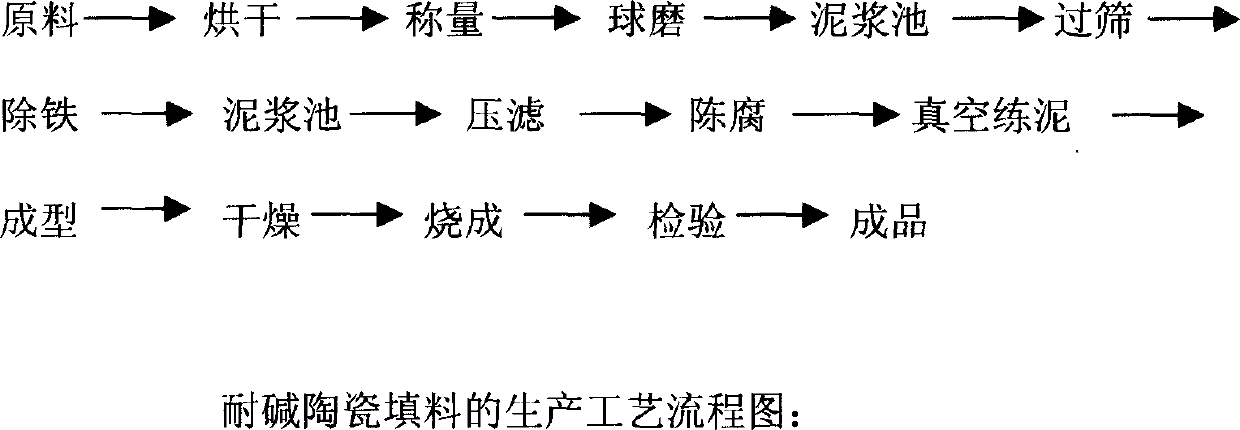

Image

Examples

Embodiment Construction

[0022] According to the above-mentioned production process, wollastonite, diopside, black talc, magnesite and clay are used as the main raw materials, according to wollastonite 20%, diopside 10%, black talc 26%, magnesite 26% clay and 18% clay weighed 2000 kg, according to the specified production process parameters, followed by ball milling, sieving, iron removal, pressure filtration, stale and vacuum mud refining and other production processes to prepare plastic clay that can be used for molding Material, select the φ25 saddle ring production mold, use a suitable vacuum extrusion molding machine to produce the φ25 saddle ring green body, after drying the green body, use 5m 3 Firing in liquefied petroleum gas edge kiln, the firing time is 10 hours, the firing temperature is controlled at 1230°C, and then naturally cooled to below 200°C to leave the kiln. After firing, the φ25 saddle ring has excellent alkali corrosion resistance. The product quality inspection results of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com