A kind of methacrylate modified reactive resin

A technology of methacrylate and methacrylic acid, which is applied in the direction of coatings and anti-corrosion coatings, can solve the problems of reducing the toughness and impact resistance of coatings, the poor adhesion of substrates, and affecting the film-forming quality of coatings. Ease of promoting the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

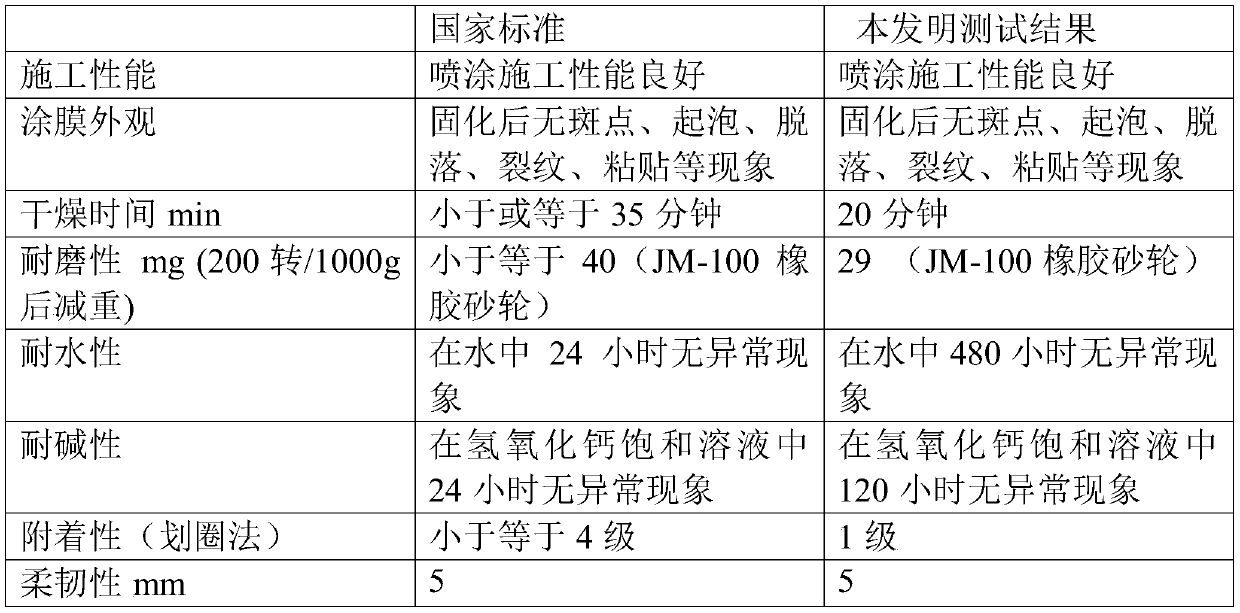

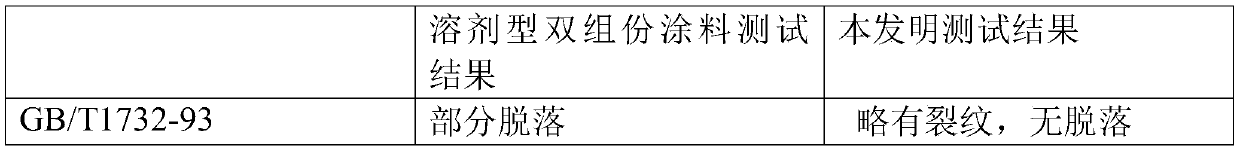

[0026] The resin of the present invention is made into a coating for road markings, and the commonly used two-component spraying equipment is used for road coating construction. That is to say, the road marking coating is formed by using the known construction technology of "cooperating in groups, spraying separately-mixing in the air-ground reaction, curing and forming a film".

[0027] The resin formulation of the present invention is divided into two groups of A and B for coordination, and the resins of A and B are made into two groups of coatings of A and B, wherein the resin of group A and the coating made contain accelerators, and the coating of group B is in the Just before spraying, add curing agent benzoyl peroxide, stir evenly and spray the two-component paint at the same time immediately, the accelerator in the A-component paint and the curing agent in the B-component paint are mixed in the air and redox reaction occurs on the ground , so that the methacrylate resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com