Dust depressor for open storage area and preparation method thereof

A dust suppressant and storage yard technology, applied in the field of silicon-acrylic emulsion dust suppressant and its preparation, can solve the problems of affecting plant growth, VOC secondary pollution, not resistant to rain erosion, etc., and achieves good environmental safety and hydrophobicity Improvement, hardness and water erosion resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

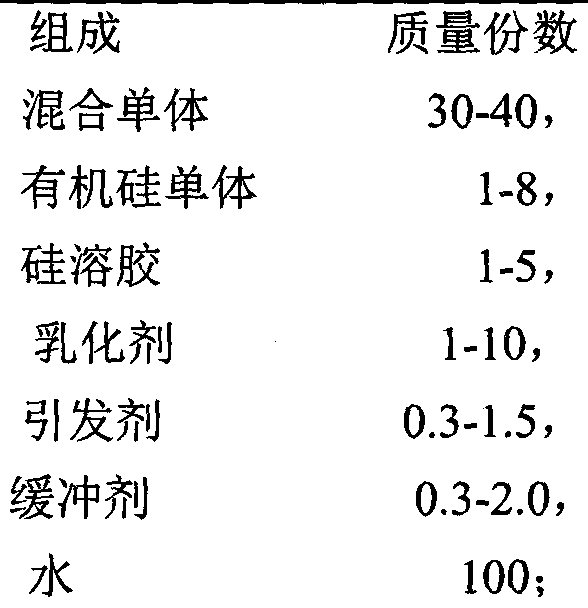

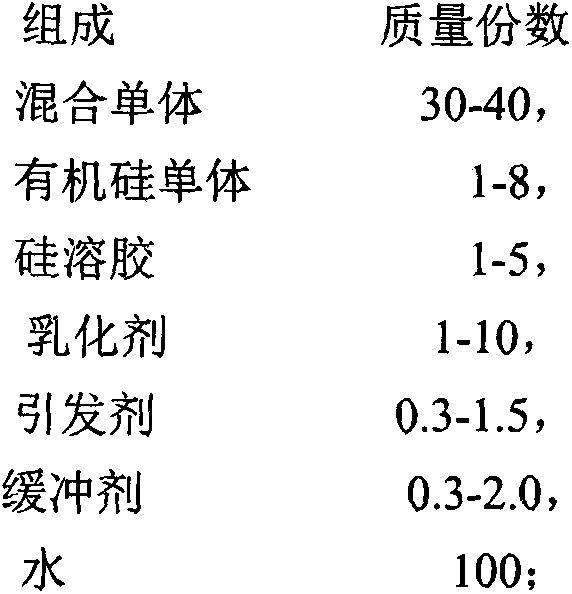

Method used

Image

Examples

Embodiment 1

[0027] Add 0.6g sodium bicarbonate, 3g silica sol, 1g emulsifier SDS, 0.5g emulsifier D-360, 1.2g emulsifier 15S-20 and 100g of distilled water, replaced with nitrogen for 30 minutes under stirring, the temperature of the water bath was raised to 80°C, and 4g of acrylic acid, 19g of butyl acrylate, 2g of triethylene glycol diacrylate, 3g of glycidyl acrylate and 5g of hydroxyethyl acrylate were added dropwise Prepared mixed monomers. During the dropwise addition of monomers, 8 g of ammonium persulfate aqueous solution with a mass concentration of 5% was added dropwise. When the mixed monomers were added dropwise to the remaining 20%, the organosilicon monomer prepared from 2.0 g of vinyltriethoxysilane and 0.8 g of γ-glycidyl etheroxypropyltrimethoxysilane was started to be added dropwise. Control the dripping progress, and the dripping was completed in 3.0 hours. After the addition of the monomers was completed, the temperature of the system was raised to 87° C. and kept fo...

Embodiment 2

[0031] Other steps are the same as in Example 1, except that the dosage of γ-glycidoxypropyltrimethoxysilane is 0 g; the dosage of silica sol is increased to 3.8 g; and the coal powder is replaced by iron ore powder.

[0032] The performance evaluation method is the same as in Example 1.

Embodiment 3

[0034] Add 0.4g sodium bicarbonate, 4.2g silica sol, 1.5g emulsifier D-828, 0.8g emulsifier D-830, 1.0g emulsifier to the reactor equipped with stirrer, thermometer, dropping funnel and nitrogen conduit F-3280, 100g of distilled water, nitrogen replacement with the help of stirring for 30 minutes, the temperature of the water bath was raised to 80°C, and the mixture of 4g of methacrylic acid, 3g of methyl methacrylate, 16g of butyl acrylate, and 2g of trimethylolpropane was added dropwise. Acrylate, 3g glycidyl acrylate and 5g hydroxypropyl acrylate mixed monomer. Meanwhile, 15 g of an aqueous solution of potassium persulfate with a mass concentration of 2.2% was added dropwise during the dropwise addition of monomers. When the mixed monomers were added dropwise to the remaining 20%, the organosilicon monomer prepared from 1.7g of vinylmethyldiethoxysilane and 1.3g of γ-methacryloxypropyltrimethoxysilane was started to be added dropwise. Control the dripping progress, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com