Method for preparing zircon bricks using dense zircon aggregates

A technology of zircon bricks and zircon, which is applied in the field of refractory materials, can solve the problems of too many zircons and affect the performance of high-temperature use, and achieve the effects of high refractoriness, excellent alkali corrosion resistance, and reduced hot repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] 1. Preparation of zircon ball mill powder and dense zircon aggregate:

[0035] According to the embodiment scheme batching, use ZrO 2 ≥65% of zircon powder, add 0.6-1.2% of titanium dioxide and other sintering aids, wet grinding in grinding equipment such as ball mill or stirring mill, and grind to particle size D 50 = 1-6 micron mud. The slurry is dried or spray granulated to obtain zircon ball mill powder.

[0036] The powder is subjected to 50-200MPa isostatic pressing, semi-dry press molding, or mud casting to form a green body. After the green body is dried, use a shuttle kiln or other kilns to heat at 1400-1600°C for 10-100 hours and fire to make the bulk density > 4.0g / cm 3 aggregate body. Through crushing, sieving, and magnetic separation, dense zircon aggregates of ≤3mm or ≤5mm are produced.

[0037] The ingredients ratio and bulk density test results of the prepared dense zircon aggregate are shown in Table 1.

[0038] Table 1

[0039] raw mate...

Embodiment 4

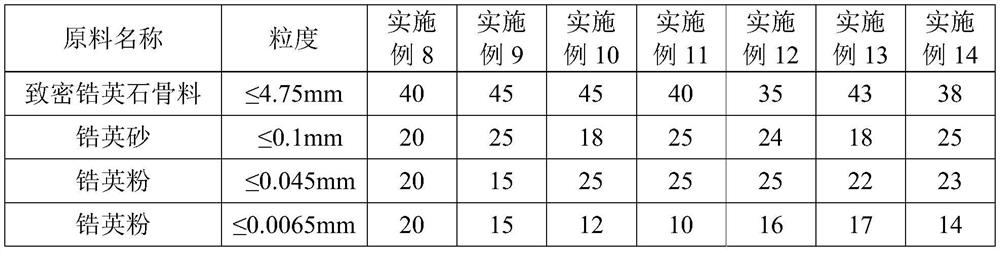

[0041]The bulk density of the aggregate obtained in Example 4 is the largest, and the dense zircon aggregate obtained in Example 4 is used to prepare zircon bricks. The specific examples are as follows:

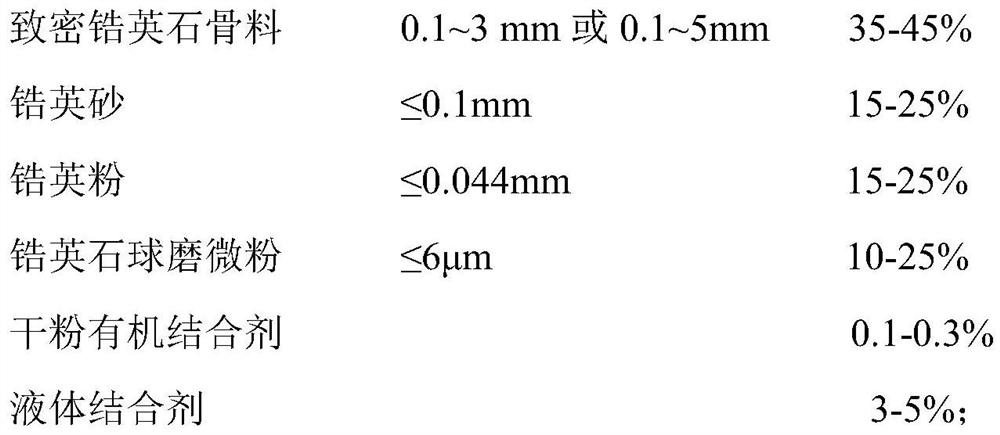

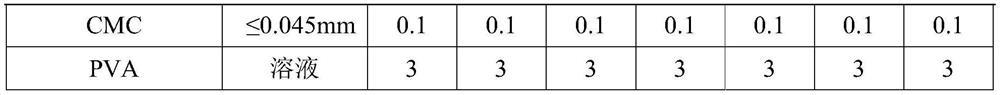

[0042] Use a wheel mill mixer for semi-dry mixing. Put 0~5mm or 0~3mm dense zircon aggregate and ≤0.1mm zircon sand into the wheel mill mixer and mix evenly; then add liquid binder and mix evenly; ≤0.044mm zircon powder, ≤6μm Zircon ball milled powder and dry powder organic binder are added to the cone mixer, mixed evenly, put into the wheel mill mixer, mixed for 10-20 minutes, and made into semi-dry mud; put into the molding silo Sleepy material 4-5 hours.

[0043] Use friction press or hydraulic press to form, forming density > 3.70g / cm 3 .

[0044] The green body is dried using a far-infrared drying box or other drying equipment at a drying temperature of 80-120°C.

[0045] Use a shuttle kiln or other firing kilns, the firing temperature is 1400-1600 °C, and the heat p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com