Rotary kiln lining brick, lining composite brick and manufacturing method thereof

A rotary kiln and composite brick technology, applied in the field of rotary kiln, can solve problems such as short service life, high kiln shell temperature, and large heat loss, and achieve the effects of reducing energy consumption, lowering kiln shell temperature, and increasing product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The rotary kiln lining brick in this embodiment includes: 25% bauxite, 58% M45 mullite, and 17% clay in terms of mass percentage.

[0023] In the present embodiment, by mass percent, the bauxite in the heavy layer contains 54.8% Al 2 o 3 , and 2.46% Fe 2 o 3 ; M45 mullite in the heavy layer contains 45.4% Al 2 o 3 , and 1.03% Fe 2 o 3 ; The clay in the heavy layer contains 28.3% Al 2 o 3 , and 1.43% Fe 2 o 3 .

Embodiment 2

[0024] Embodiment two: the manufacture method of rotary kiln lining brick in embodiment one, comprises the following steps:

[0025] 1) After mixing bauxite and clay, co-grind in a pulverizer;

[0026] 2) Add the powder prepared by the pulverizer and M45 mullite into the wet wheel mill for mixing;

[0027] 3) Send the mixed material obtained by mixing and milling with a wet wheel mill into a 630t press for pressing to obtain the adobe lining the rotary kiln;

[0028] 4) Put the adobe into the tunnel kiln and fire at 1410°C for 8 hours to obtain the lining brick of the rotary kiln; the lining brick of the rotary kiln includes: 25% bauxite, 58% M45 mullite stone, and 17% clay.

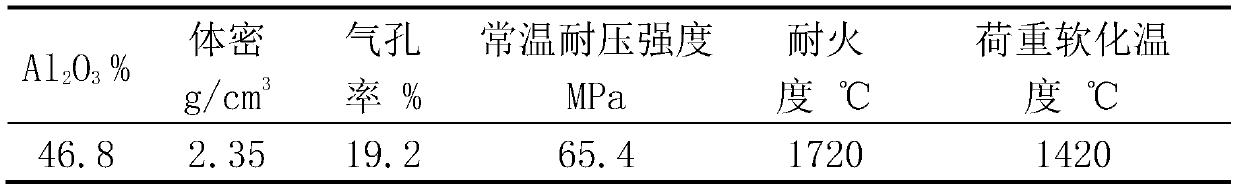

[0029] The following table is the physical and chemical parameters of the rotary kiln lining brick that adopts manufacturing method to make in the embodiment two:

[0030]

[0031] Select the LZ-75 high-alumina bricks used on the rotary kiln, the common clay bricks and the lining bricks obtained in...

Embodiment 3

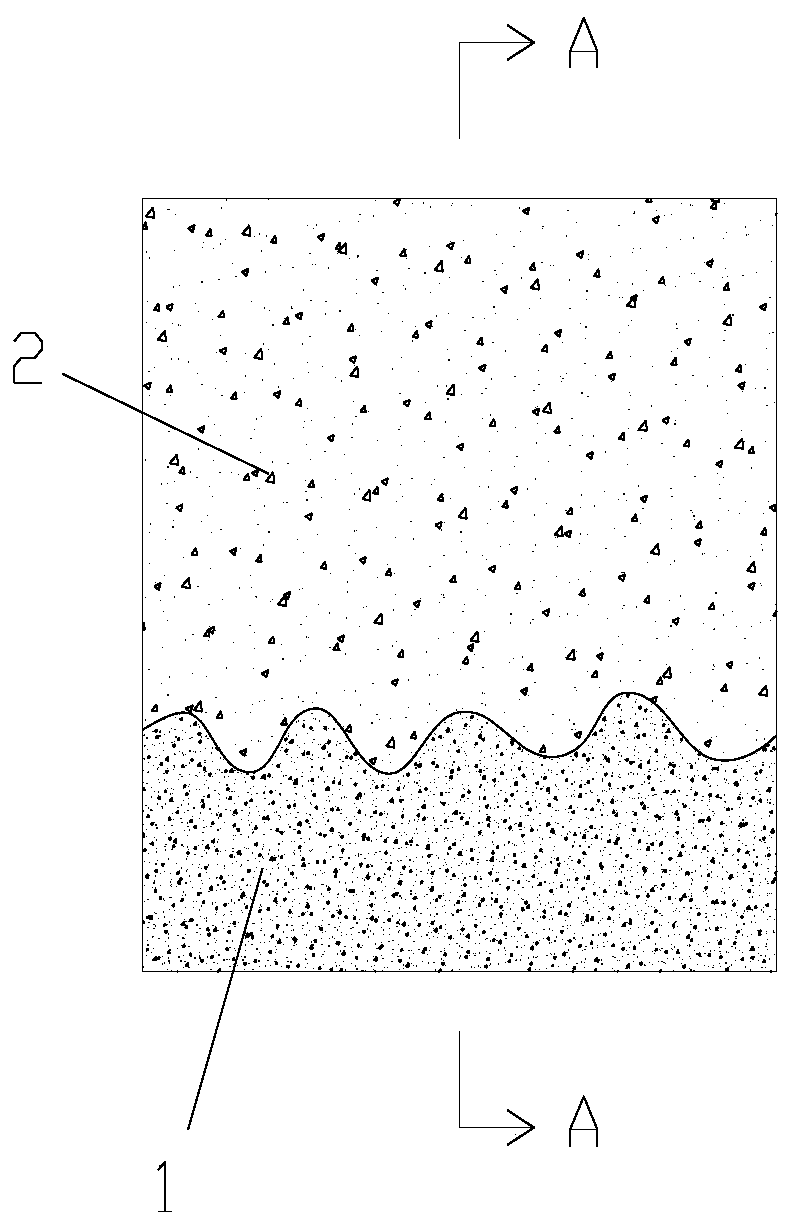

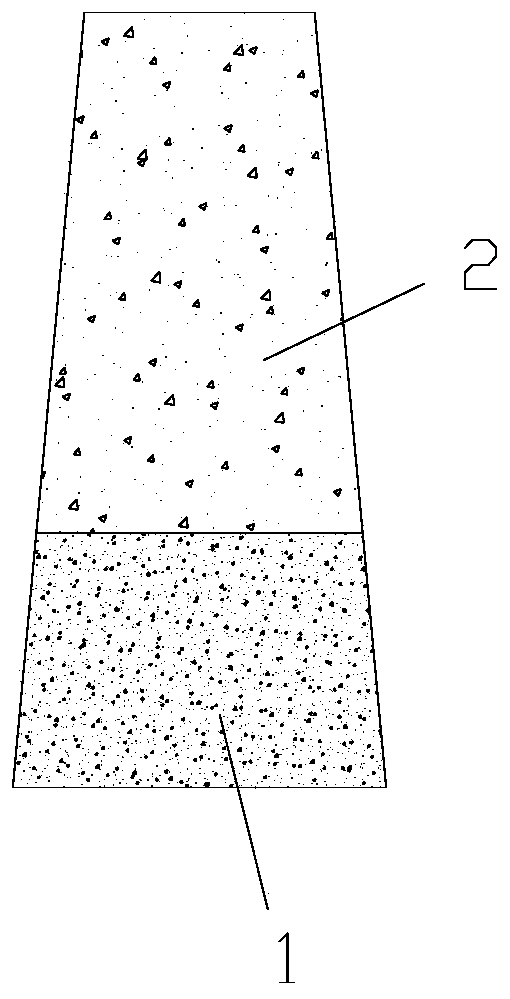

[0033] Embodiment 3: The rotary kiln lining composite brick in this embodiment includes a heavy layer 1 and a light layer 2 above the heavy layer. The heavy layer includes: bauxite 25%, M45 Mo 58% of mullite and 17% of clay, and the light layer includes 20% of floating beads, 60% of light mullite, and 20% of clay in terms of mass percentage.

[0034] In the present embodiment, by mass percent, the bauxite in the heavy layer contains 54.8% Al 2 o 3 , and 2.46% Fe 2 o 3 ; M45 mullite in the heavy layer contains 45.4% Al 2 o 3 , and 1.03% Fe 2 o 3 ; The clay in the heavy layer contains 28.3% Al 2 o 3 , and 1.43% Fe 2 o 3 .

[0035] In the present embodiment, by mass percentage, the light mullite in the light layer contains 65.8% Al 2 o 3 , 28.6% SiO 2 , and 2.3% Fe 2 o 3 ; The floating beads in the lightweight layer contain 26.8% Al 2 o 3 , 63.7% SiO 2 , and 3.5% Fe 2 o 3 .

[0036] Further, in this embodiment, the bonding surface of the heavy layer and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com