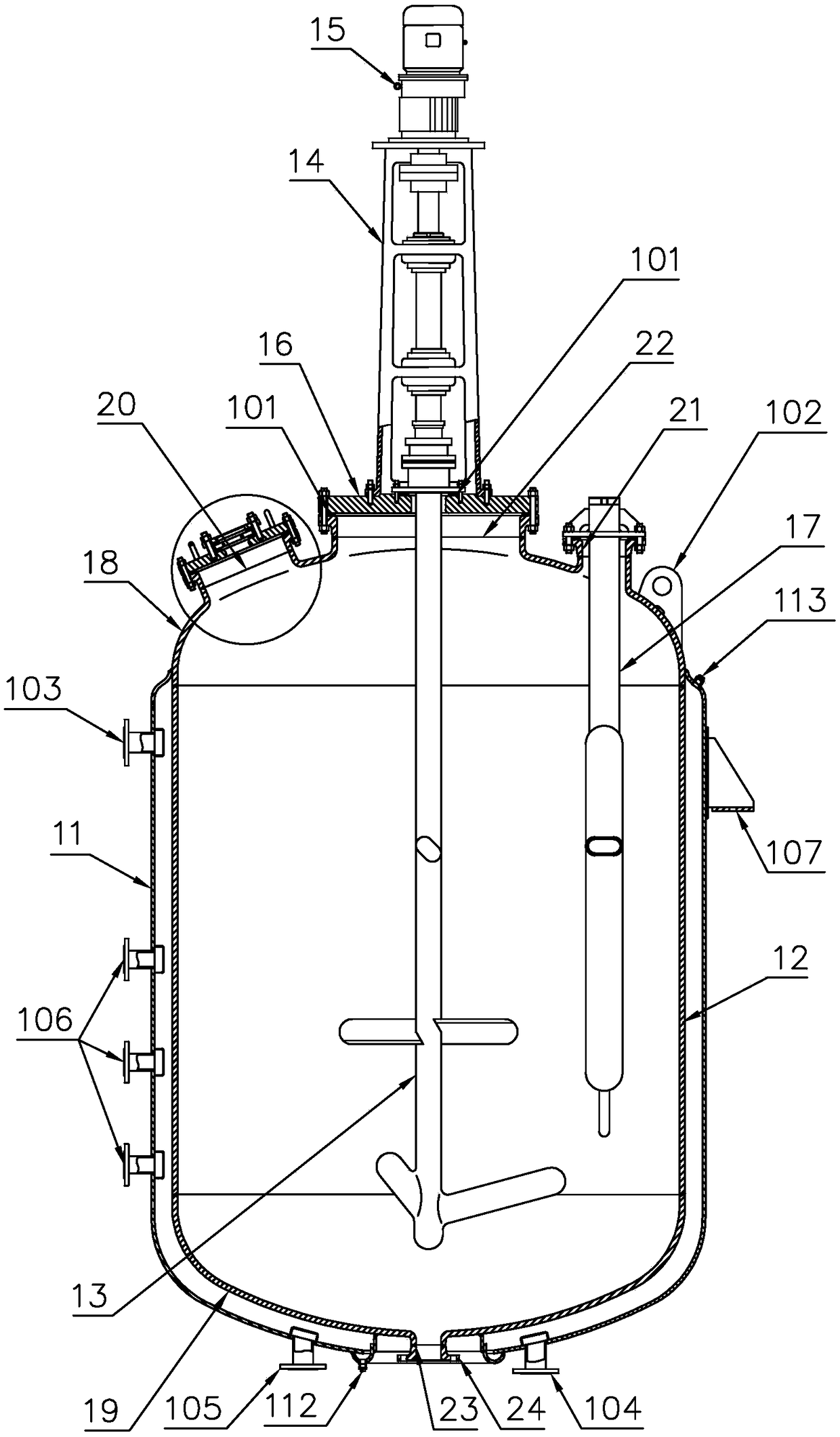

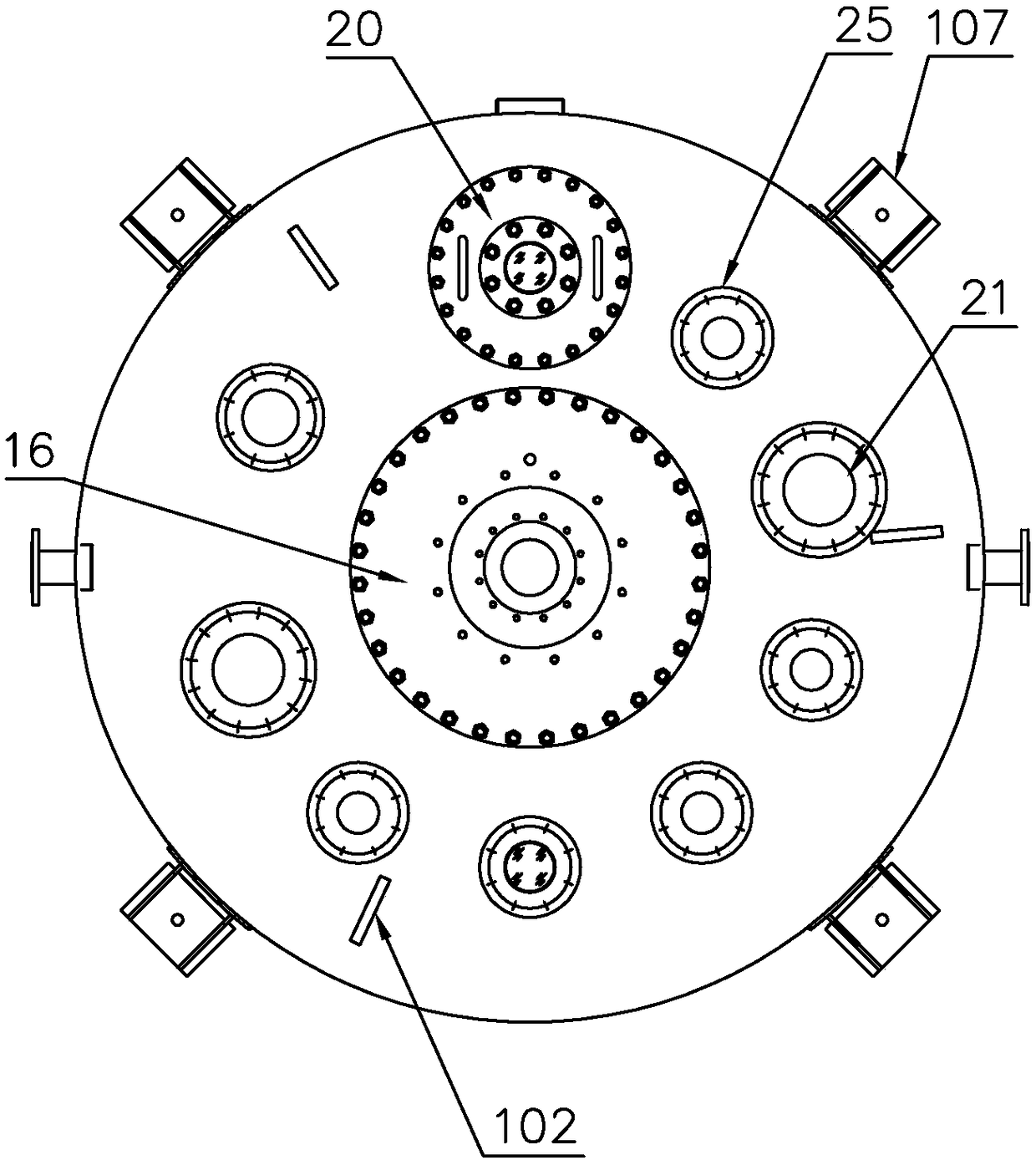

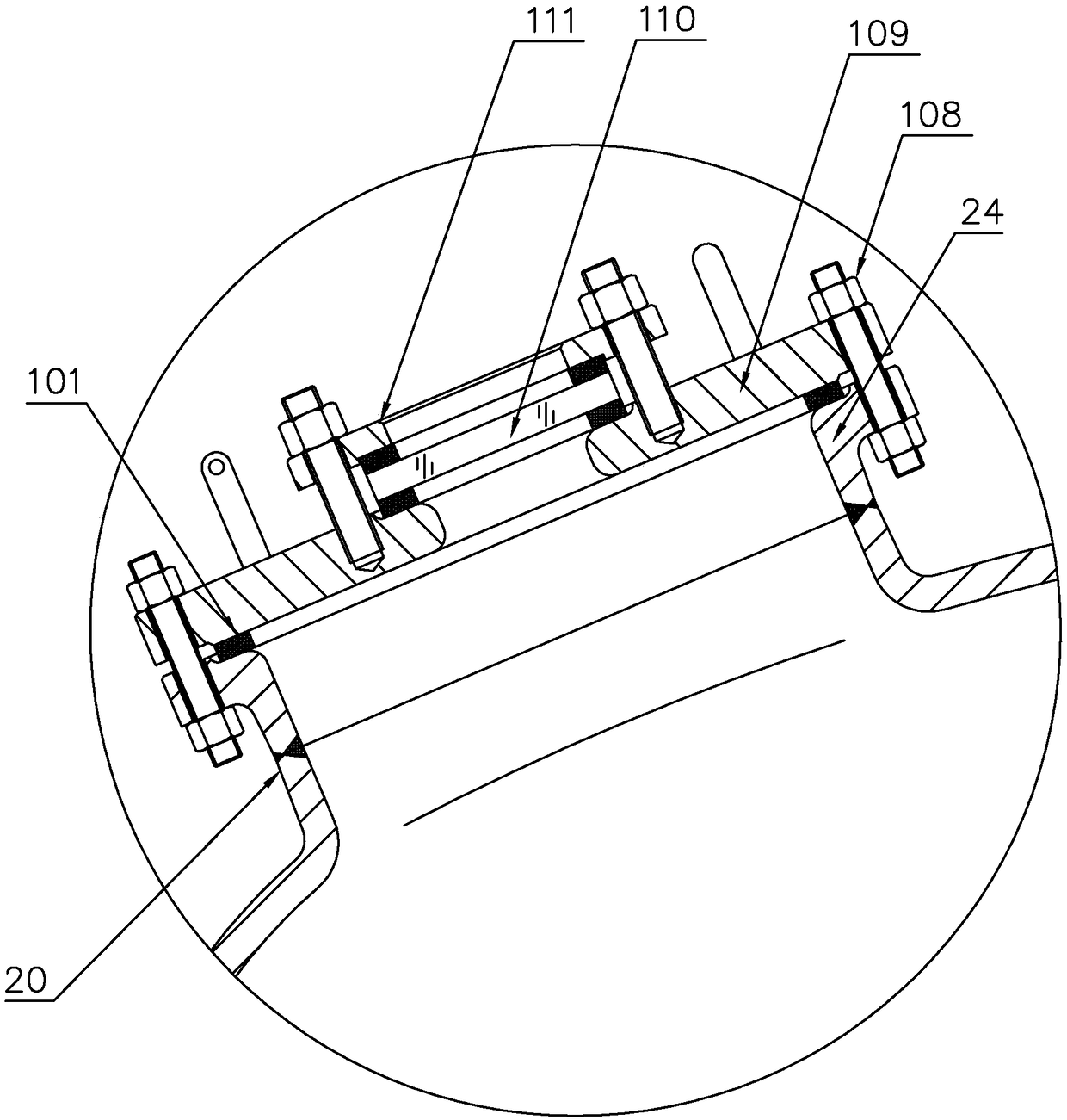

A high-strength corrosion-resistant glass-lined reactor

A corrosion-resistant and glass-lined technology, which is applied in the field of high-strength corrosion-resistant glass-lined reactors, can solve the problems of reducing fish scale cracking, general alkali corrosion resistance, and limited application range, etc., and achieves reducing fish scale cracking and excellent acid corrosion resistance The effect of increasing the resistance and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] 1) Weigh 4.8Kg of bastnaesite powder, 1.2Kg of manganese oxide, 0.6Kg of copper oxide, 3Kg of molybdenum oxide and 0.4Kg of titanium dioxide and pulverize them, heat the mixture to 140°C, stir, and keep warm for 40 minutes;

[0054] 2) Heat up to 550°C, stir and keep warm for 1h;

[0055] 3) Heat up to 900°C, stir, fill with air, sinter, cool, ball mill, pass through 80-mesh sieve to obtain a mixed adhesive.

preparation example 2

[0057] 1) Weigh 4.5Kg of bastnaesite powder, 1.4Kg of manganese oxide, 0.7Kg of copper oxide, 2.8Kg of molybdenum oxide and 0.6Kg of titanium dioxide and pulverize them. The mixture is heated to 160°C, stirred, and kept for 40 minutes;

[0058] 2) Heat up to 600°C, stir and keep warm for 1h;

[0059] 3) Heat up to 950°C, stir, fill with air, sinter, cool, ball mill, pass through 80-mesh sieve to obtain a mixed adhesive.

preparation example 3

[0061] 1) Weigh 4.6Kg of bastnaesite powder, 1.3Kg of manganese oxide, 0.4Kg of copper oxide, 3Kg of molybdenum oxide and 0.7Kg of titanium dioxide and pulverize them, heat the mixture to 130°C, stir, and keep warm for 30 minutes;

[0062] 2) Heat up to 500°C, stir and keep warm for 1h;

[0063] 3) Heat up to 1000°C, stir, fill with air, sinter, cool, ball mill, and pass through 80-mesh sieve to obtain a mixed adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com