Heat-resistant UV viscosity breaking film and preparation method thereof

A heat-resistant, mucous membrane technology, applied in adhesives, pressure-sensitive films/sheets, polymer adhesive additives, etc., can solve problems such as inability to overcome high temperature resistance of 150°C, increase production costs, reduce production efficiency, etc., to achieve enhanced High temperature resistance, improved adhesion, and optimized product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

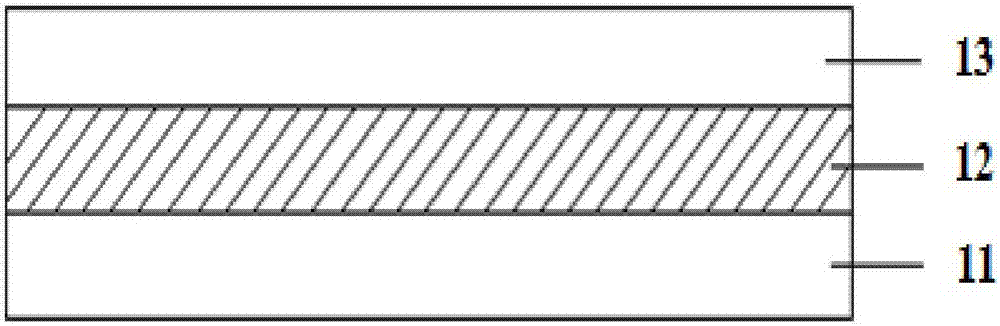

[0027] Such as figure 1 As shown, the heat-resistant UV adhesion-reducing film of this embodiment includes a corona PET substrate layer 11 , a UV-adhesion-reducing PSA layer 12 , and a PET release film layer 13 in sequence.

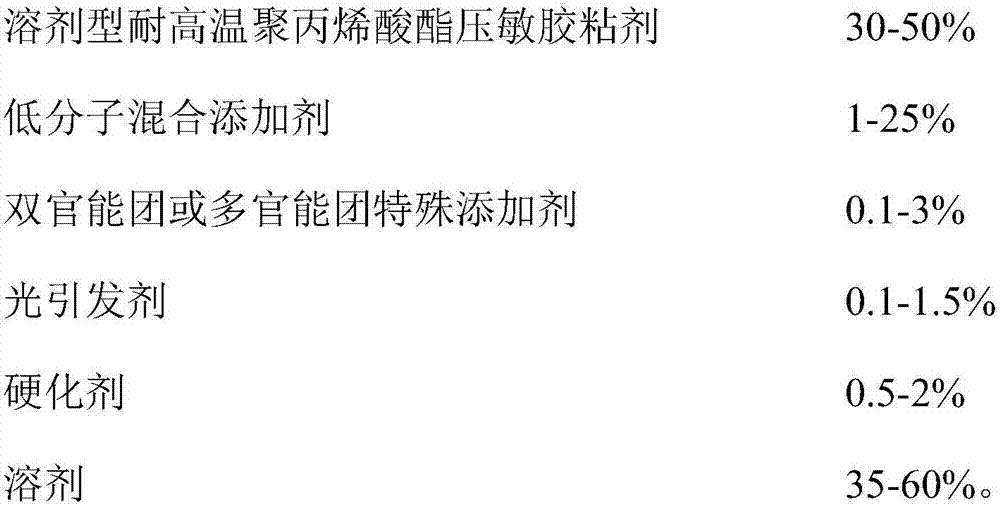

[0028] Prepare heat-resistant UV photosensitive adhesive: put 28g DR-U202 (manufactured by Changxing Chemical Co., Ltd.), 8g EM231 (manufactured by Changxing Chemical Co., Ltd.), 120g DS-203A (manufactured by Dongsheng Chemical Co., Ltd.) and 118g into a 500mL light-shielding cup Ethyl acetate, stir with disperser, then add 0.5g XY-2 (Shanghai Saikensen Material Technology Co., Ltd.), 1.9g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 4.14g while stirring in order L-45E (Nanjing Soyan Chemical), after adding, stir at 500rpm for 30min, let it stand for more than 30min to defoam naturally, and you can get heat-resistant UV photosensitive adhesive.

[0029] Coating UV photosensitive adhesive process: On the corona PET substrat...

Embodiment 2

[0031] Such as figure 1 As shown, the heat-resistant UV adhesion-reducing film of this embodiment includes a corona PET substrate layer 11 , a UV-adhesion-reducing PSA layer 12 , and a PET release film layer 13 in sequence.

[0032] Prepare heat-resistant UV photosensitive adhesive: 31g DM87A (manufactured by Double Bond Chemical Co., Ltd.), 7.5g EM231 (manufactured by Changxing Chemical Co., Ltd.), 110g DS-201A (manufactured by Dongsheng Chemical Co., Ltd.), and 125g ethyl acetate, stir evenly with a disperser, then add 0.65g XY-2 (Shanghai Saikensen Material Technology Co., Ltd.), 1.9g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 3.98g while stirring in order g L-45E (Nanjing Soken Chemical Co., Ltd.), after the addition, stir at 500rpm for 30 minutes, let it stand for more than 30 minutes to naturally defoam, and you can get a heat-resistant UV photosensitive adhesive.

[0033] Coating UV photosensitive adhesive process: On the corona PET su...

Embodiment 3

[0035] Such as figure 1 As shown, the heat-resistant UV adhesion-reducing film of this embodiment includes a corona PET substrate layer 11 , a UV-adhesion-reducing PSA layer 12 , and a PET release film layer 13 in sequence.

[0036] Prepare heat-resistant UV photosensitive adhesive: put 35g 8415 resin (manufactured by Allnex), 3g EM264 (manufactured by Changxing Chemical Co., Ltd.), 100g 1537-2 (Toyo Ink) and 130g ethyl acetate into a 500mL shading cup, Stir evenly with a disperser, then add 0.55g XY-2 (Shanghai Saikensen Material Technology Co., Ltd.), 2.0g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 3.93g L-45E ( Nanjing Soken Chemical), after the addition is completed, stir at a speed of 500rpm for 30 minutes, and let it stand for more than 30 minutes to naturally defoam, and the heat-resistant UV viscose-reducing adhesive can be obtained.

[0037]Coating UV photosensitive adhesive process: On the corona PET substrate 11, use a scraper to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com