Compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric and production system thereof

A technology of hot air non-woven fabric and cotton non-woven fabric, which is applied in the process of physical spunlace composite of hot air non-woven fabric (chemical fiber) and cotton spunlace non-woven fabric, hot air non-woven fabric and cotton non-woven fabric The composite method and its production system field can achieve the effect of improving high-end demand, improving comfort and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

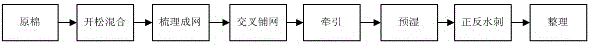

[0043] Embodiment 1 provides a composite method of air-through non-woven fabric and cotton non-woven fabric, the method comprising: the air-through non-woven fabric is used as the bottom layer, the non-woven fabric cotton web is laminated on the air-through non-woven fabric, and after pre-wetting , The finished product is obtained after the front and back spunlace compounding. Among them, the superposition of two layers of cloth needs to place the hot air non-woven fabric under the cotton non-woven fabric, because the hot air non-woven fabric has been initially formed, the surface tension of the chemical fiber is relatively large, the cloth surface is smooth, and the high-pressure water thorn flow directly hits the hot air. The non-woven fabric is not easy to penetrate, and the cotton net is not easy to pre-wet to discharge the air between the cotton layers; on the contrary, if the hot-air non-woven fabric is placed below, the high-pressure water thorn flow passes through the c...

Embodiment 2

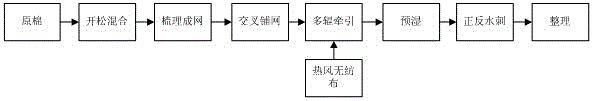

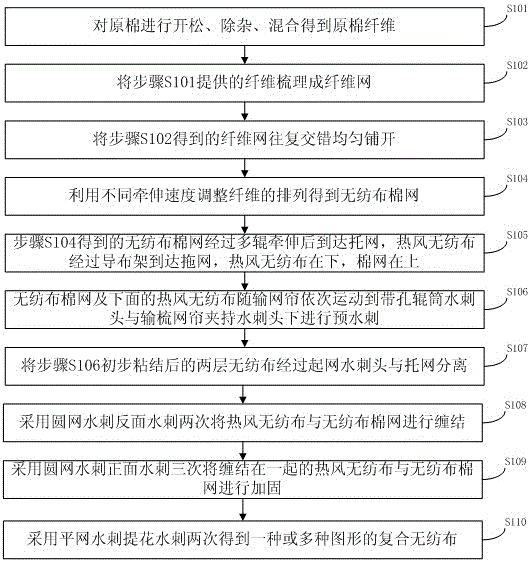

[0070] see figure 2 and 3 , embodiment two provides a kind of preparation method of jacquard composite non-woven fabric, comprises the following steps:

[0071] S101 Opening and mixing: Opening, removing impurities and mixing raw cotton to obtain raw cotton fibers.

[0072] S102 carding into a web: carding the fibers provided in step S101 into a fiber web.

[0073] S103 cross-lapping: spread the fiber web obtained in step S102 in a reciprocating and staggered manner.

[0074] S104 Multi-roller drafting: Use different drafting speeds to adjust the arrangement of fibers to obtain non-woven cotton webs.

[0075] The above-mentioned process is the same as the production method of the existing spunlace cotton non-woven fabric. If a normal spunlace process is installed afterwards, its grammage will be 25-180 grams per square meter.

[0076] S105 Lamination: The non-woven fabric cotton web obtained in step S104 reaches the support net after multi-roller drafting, and the hot-air...

Embodiment 3

[0084] Embodiment 3 provides a preparation method of plain weave composite nonwoven fabric, which is basically the same as steps S101-S110 of embodiment 2. In step S110, the jacquard roller is used as a common hydroentanglement roller to strengthen the hydroentangled nonwoven fabric. The effect of the vertical and horizontal strength of the cloth is different: it also includes: S111 Finishing: use flat net spunlace to finish the cloth surface twice (if there are missing stitches in the previous spunlace process, these two spunlace heads can to modify the fluff of the cloth surface), the spunlace pressure is the same as the finishing spunlace pressure in the production process of the existing spunlace cotton non-woven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com