Adhesion layer for adhesive tape as well as preparation method and application thereof

A technology of adhesive layer and tape, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc., can solve problems such as parts damage, residual glue pollution, and bonded objects loosening and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

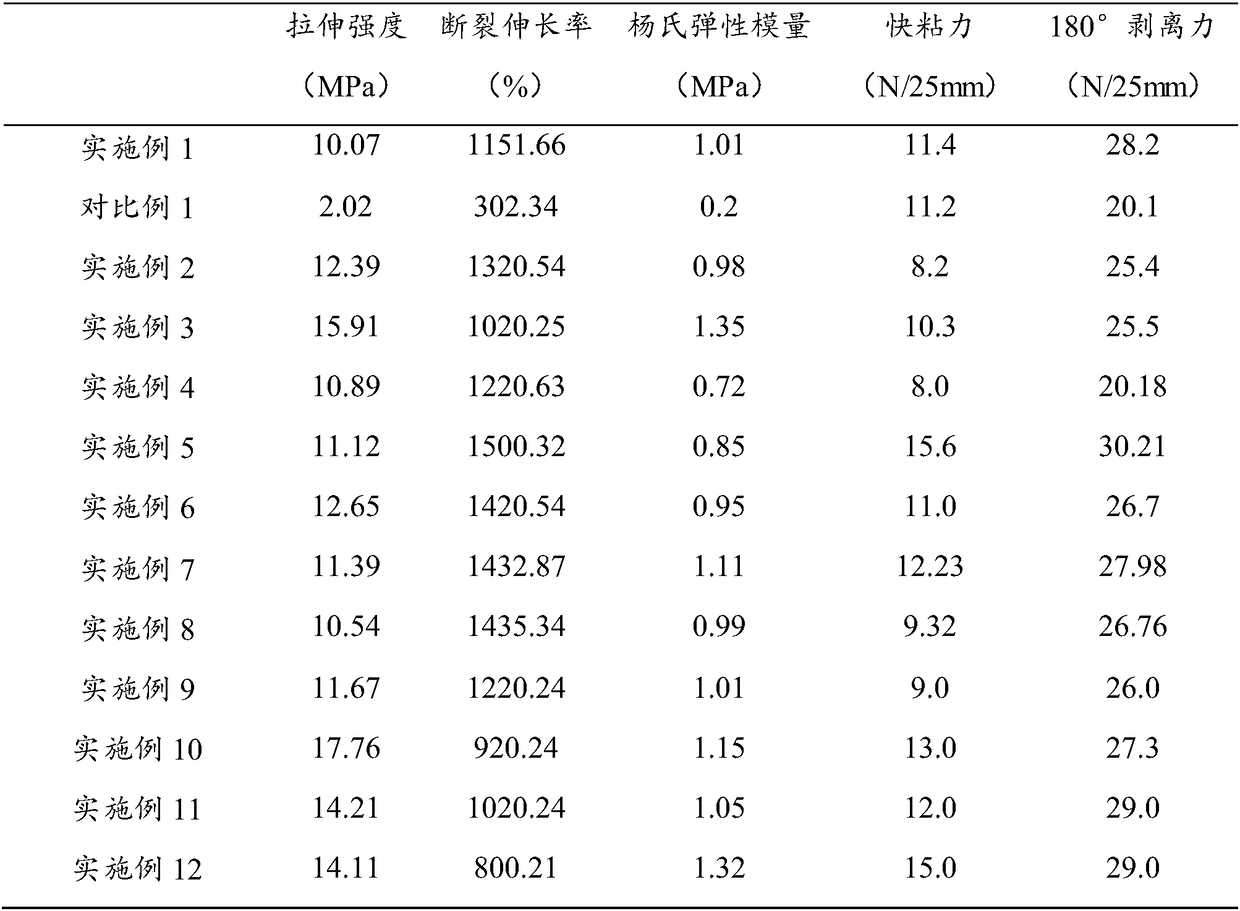

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing the adhesive layer described in the above technical solution, comprising the following steps:

[0047] a) mixing a thermoplastic elastomer and a reinforcing agent in a solvent to obtain a mixed solution; the thermoplastic elastomer is selected from the group consisting of styrene block copolymer, polyolefin block copolymer, acrylic block copolymer, polyisobutylene, thermoplastic polyurethane One or more of butyl rubber and EPDM rubber; the reinforcing agent is selected from polystyrene, polyphenylene ether, polyethylene terephthalate and polybutylene terephthalate one or more of esters;

[0048] b) sequentially adding tackifying resin, softener, antioxidant and filler to the mixed solution obtained in step a) for mixing to obtain an adhesive dispersion;

[0049] c) coating the adhesive dispersion obtained in step b) on a release film and drying to obtain an adhesive layer.

[0050] In the present invention, fi...

Embodiment 1

[0068] The substrate-free tape provided in Example 1 is composed of an adhesive layer with a thickness of 150 μm and a heavy release film and a light release film attached to the upper and lower sides of the adhesive layer respectively; The release force ratio of the heavy release film is 1:3.

[0069] The adhesive layer is prepared from raw materials comprising the following components: 40 parts by weight of styrene-butadiene-styrene block copolymer (SBS), 40 parts by weight of terpene resin, 15 parts by weight of polystyrene, 20 parts by weight of naphthenic oil, 0.5 parts by weight of phenolic antioxidant, and 2 parts by weight of titanium dioxide.

[0070] The preparation method comprises the following steps:

[0071] (1) The polystyrene of 15 parts by weight is dissolved in the toluene of 120 parts by weight, then the styrene-butadiene-styrene block copolymer (SBS) of 40 parts by weight is added and dissolved to obtain a solid content of 30%. mixed solution;

[0072] (...

Embodiment 2

[0084] The substrate-free adhesive tape provided in Example 2 is composed of an adhesive layer with a thickness of 200 μm and a heavy release film and a light release film respectively attached to the upper and lower sides of the adhesive layer; The release force ratio of the heavy release film is 1:2.5.

[0085] The adhesive layer is prepared from raw materials comprising the following components: 50 parts by weight of styrene-isoprene-styrene block copolymer (SIS), 45 parts by weight of rosin resin, 20 parts by weight of polyphenylene ether, 20 parts by weight of aromatic oil, 1 part by weight of p-phenylenediamine antioxidant, and 2 parts by weight of carbon black.

[0086] The preparation method comprises the following steps:

[0087] (1) The polyphenylene ether of 20 weight parts is dissolved in the xylene of 140 weight parts, then adds the styrene-isoprene-styrene block copolymer (SIS) of 50 weight parts and dissolves, and obtains that solid content is 30% mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com