Nonaqueous-secondary-battery separator and nonaqueous secondary battery

A secondary battery, non-aqueous technology, applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of lower manufacturing yield, achieve improved peeling force, sufficient ion permeability, and good slitting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

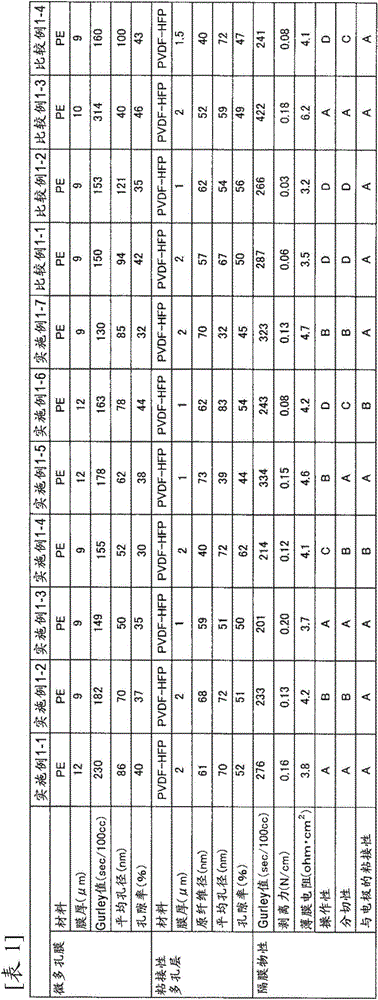

Embodiment 1-1

[0160] As the polyvinylidene fluoride-based resin, a copolymer (PVDF-HFP) of vinylidene fluoride / hexafluoropropylene=98.9 / 1.1 mol% and a weight average molecular weight of 1.95 million was used. This polyvinylidene fluoride resin was dissolved in a mixed solvent of dimethylacetamide / tripropylene glycol=75 / 25 by weight at a concentration of 5% by weight to prepare a coating liquid. It is coated on both sides of a polyethylene (PE) microporous membrane with a film thickness of 12 μm, a Gurley value of 230 seconds / 100cc, an average pore diameter of 86 nm, and a porosity of 40% in equal amounts on both sides. Acetamide / tripropylene glycol=60 / 30 / 10 weight ratio coagulation solution (30° C.) and solidified. This was washed with water and dried to obtain a separator for a non-aqueous secondary battery in which an adhesive porous layer made of a polyvinylidene fluoride resin was formed on both the front and back surfaces of the polyolefin-based microporous membrane.

[0161] Regardin...

Embodiment 1-2~1-7、 comparative example 1-1~1-3

[0163] Using the membrane shown in Table 1 as the microporous membrane, the coating conditions were adjusted, and the separators for non-aqueous secondary batteries shown in Table 1 were obtained in the same manner as in Example 1-1.

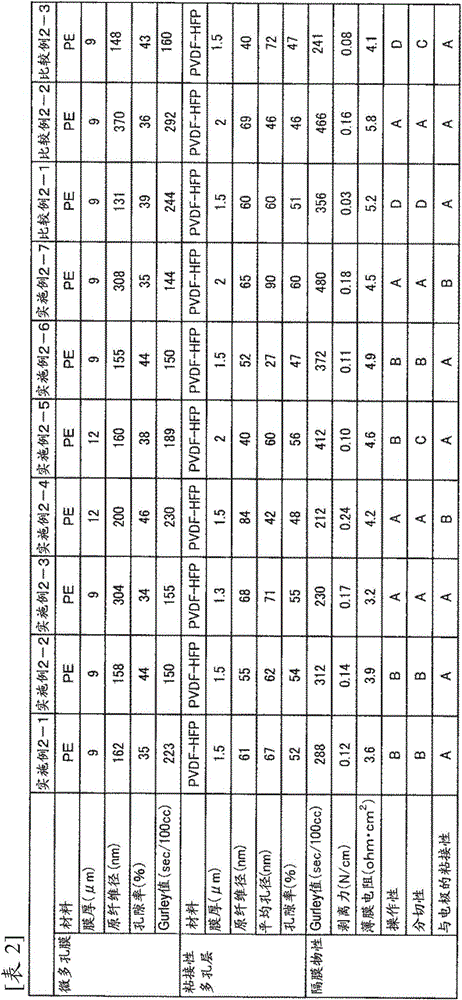

Embodiment 2-1

[0169] As the polyvinylidene fluoride-based resin, a copolymer (PVDF-HFP) of vinylidene fluoride / hexafluoropropylene=98.9 / 1.1 mol% and a weight average molecular weight of 1.95 million was used. This polyvinylidene fluoride resin was dissolved in a mixed solvent of dimethylacetamide / tripropylene glycol=75 / 25 by weight at a concentration of 5% by weight to prepare a coating liquid. It is coated on both sides of a polyethylene (PE) microporous membrane with a film thickness of 9 μm, a Gurley value of 223 seconds / 100cc, a fibril diameter of 162 nm, and a porosity of 35% in equal amounts on both sides. It was solidified in a coagulation solution (30° C.) of acetamide / tripropylene glycol=60 / 30 / 10 weight ratio. This was washed with water and dried to obtain a separator for a non-aqueous secondary battery in which an adhesive porous layer made of a polyvinylidene fluoride resin was formed on both the front and back surfaces of the polyolefin-based microporous membrane.

[0170] Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com