Red mud lightweight aggregate as well as preparation method and application thereof

A technology of light aggregate and mud, which is applied in the field of red mud light aggregate and its preparation, can solve the problems of polluting the ecological environment, occupying land resources, and low comprehensive utilization rate of red mud, and achieves excellent alkali corrosion resistance and improved Relative humidity, the effect of solving early shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

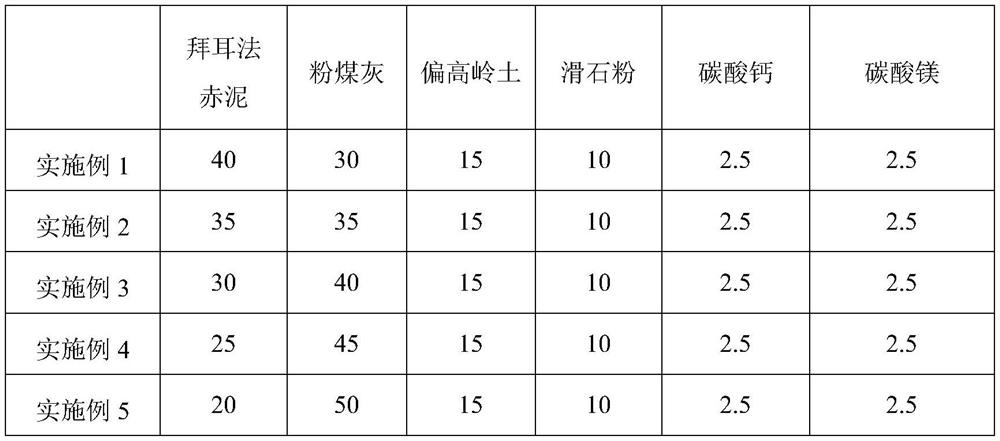

[0031] Table 1 Example 1-5 Proportion of red mud light aggregate (wt%)

[0032]

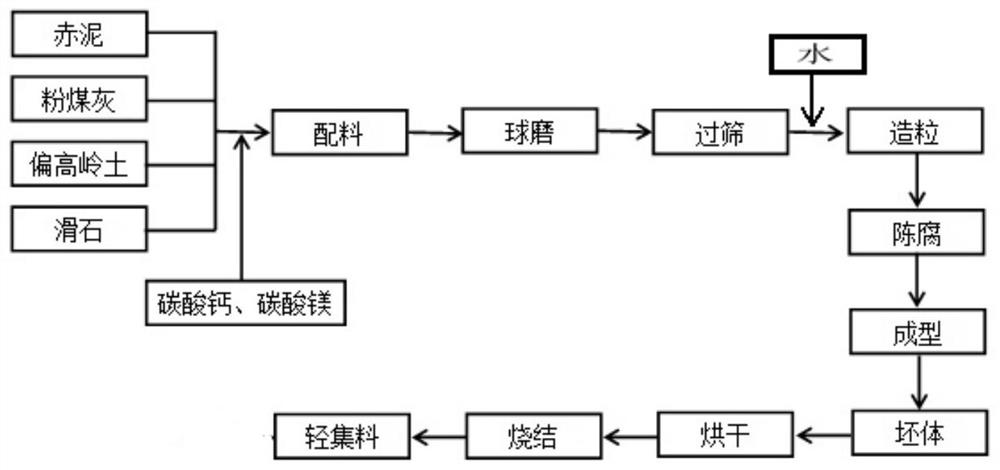

[0033] Embodiment 1-5 preparation method is as follows (technical process is as follows figure 1 shown):

[0034] (1) Take the raw materials according to the ratio described in Table 1.

[0035] (2) After mixing the raw materials by dry ball milling for 12 hours, pass through a 200-mesh sieve to obtain the mixed powder, add 8wt% tap water to granulate, mix evenly and stale for 30 hours after being isolated from the air, and use a disc ball making machine to prepare the particle size 10mm spherical body.

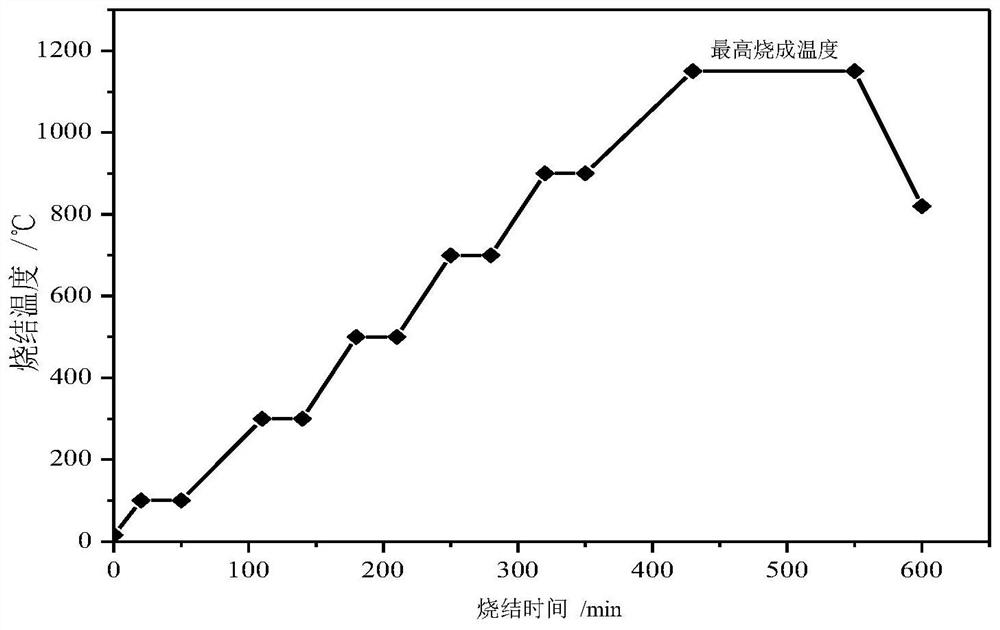

[0036] (3) Dry the green body prepared in step (2) at 92°C for 48h, then put the green body into a resistance muffle furnace, use a pressureless sintering process to sinter the light aggregate, and keep it at 1150°C for 2h, Then cool down to room temperature with the furnace to get red mud light aggregate. The specific firing process is as follows: figure 2 As shown: when the temperatur...

Embodiment 6

[0038] (1) Weigh 45% of Bayer process red mud, 20% of fly ash, 10% of metakaolin, 15% of talcum powder, 5% of calcium carbonate and 5% of magnesium carbonate.

[0039] (2) After mixing the raw materials by dry ball milling for 12 hours, pass through a 200-mesh sieve to obtain the mixed powder, add 5wt% tap water for granulation, mix well and stale for 36 hours after being isolated from the air, and use a disc ball making machine to prepare the particle size 5mm spherical body.

[0040] (3) Dry the green body prepared in step (2) at 100°C for 48h, then put the green body into a resistance muffle furnace, use the pressureless sintering process to sinter the light aggregate, and keep it at 1000°C for 2h, Then cool down to room temperature with the furnace to get red mud light aggregate. The specific firing heating process is as follows: when the temperature T≤900°C, the heating rate is 5°C / min, and the temperature is kept at 100°C, 300°C, 500°C, 700°C and 900°C for 0.5h; when th...

Embodiment 7

[0042] (1) Weigh 50% of Bayer process red mud, 21% of fly ash, 20% of metakaolin, 5% of talcum powder, 2% of calcium carbonate and 2% of magnesium carbonate.

[0043] (2) After mixing the raw materials by dry ball milling for 12 hours, pass through a 200-mesh sieve to obtain the mixed powder, add 10wt% tap water for granulation, mix well, and stale for 24 hours after being isolated from the air, and use a disc ball making machine to prepare the particle size It is a 20mm spherical blank.

[0044](3) Dry the green body prepared in step (2) at 102°C for 48h, then put the green body into a resistance muffle furnace, use a pressureless sintering process to sinter the light aggregate, and keep it at 1200°C for 2h, Then cool down to room temperature with the furnace to get red mud light aggregate. The specific firing heating process is as follows: when the temperature T≤900°C, the heating rate is 5°C / min, and the temperature is kept at 100°C, 300°C, 500°C, 700°C and 900°C for 0.5h;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com