Preparation method for water electrolysis hydrogen production electrode material

An electrode material, a technology for electrolyzing water, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of not being able to be eliminated in time, blocking hydrogen in pores, reducing activity, etc., and achieving good pore structure characteristics, low cost, and production methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

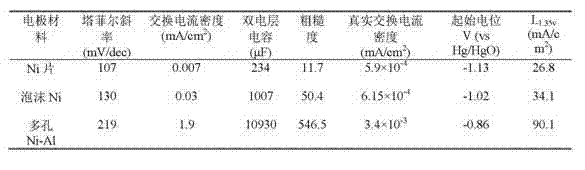

[0023] Example 1 Catalytic activity test of electrode for hydrogen production by electrolysis of water

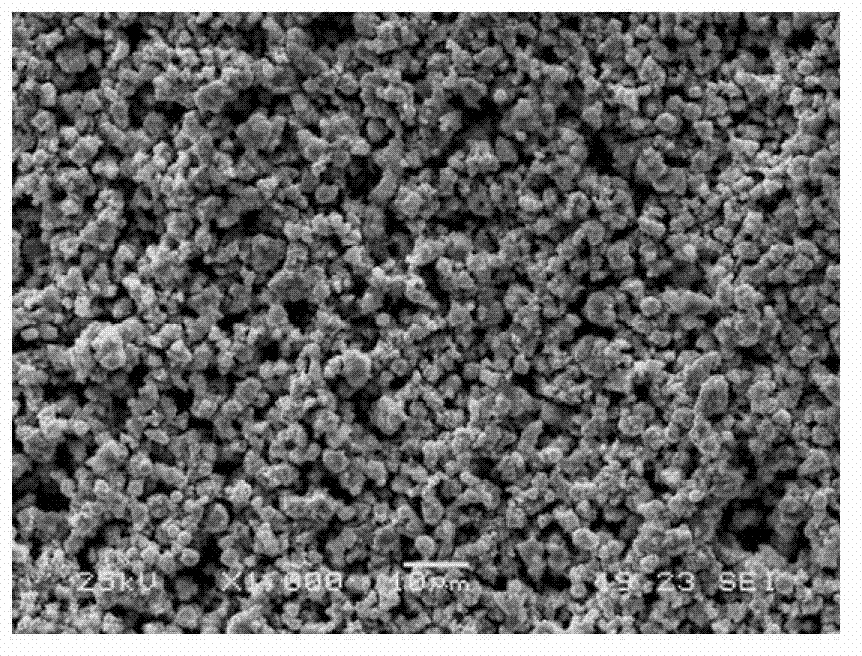

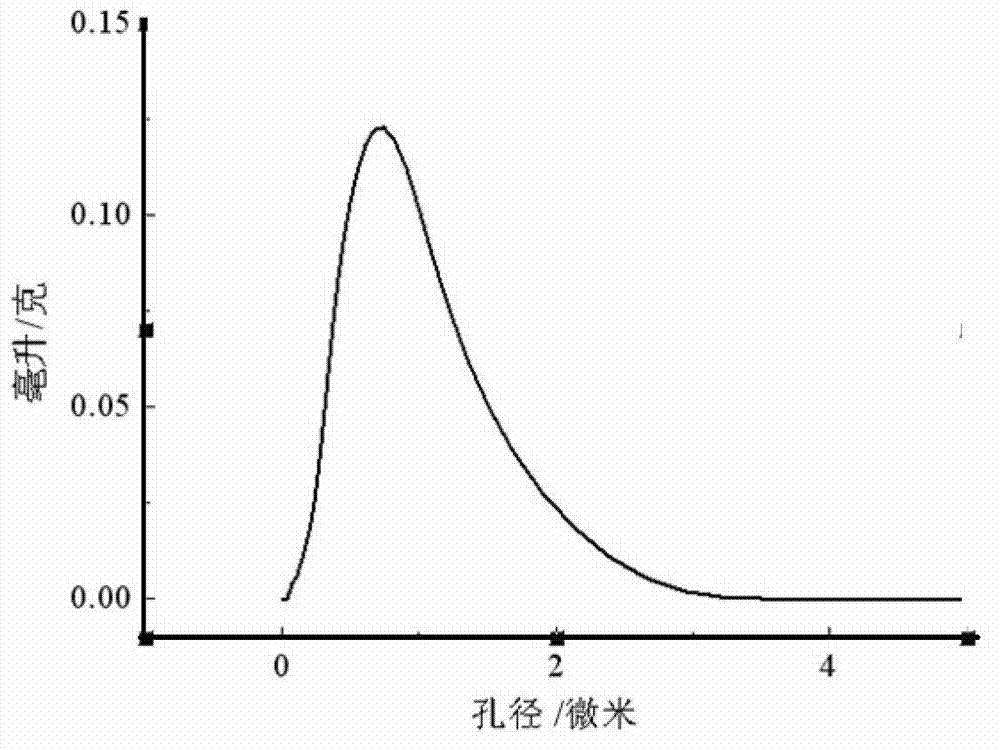

[0024] Nickel powder with an average particle size of 3 microns and aluminum powder with an average particle size of 3 microns are used to make a mixture according to the ratio of Ni powder to the total weight of Ni powder and Al powder 15wt%, and then the mixture is heated at 150MPa Under the pressure of 10 seconds, it was cold-pressed and formed into a strip-shaped green compact with a width of 6 mm, a thickness of 2 mm, and a length of 6 mm. Place the compact in a 1×10 -3 Under Pa vacuum conditions, firstly, the temperature was raised to 500°C at a heating rate of 5°C / min, and kept for 1 h; then, the temperature was raised to 900°C at a heating rate of 5°C / min, and the temperature was kept for 1 h; finally, the furnace was cooled to room temperature (25°C), That is, the electrode material for electrolyzing water for hydrogen production is obtained. The electrode wire i...

Embodiment 2

[0030] Example 2: Electrode catalytic activity test for electrolysis of water for hydrogen production

[0031] Using nickel powder with an average particle size of 8 microns and aluminum powder with an average particle size of 8 microns, the mixture is mixed according to the ratio of Ni powder to the total weight of Ni powder and Al powder 15wt%, and then the mixture is heated at 150MPa. Under the pressure of 10 seconds, it was cold-pressed and formed into a strip-shaped green compact with a width of 6 mm, a thickness of 2 mm, and a length of 6 mm. Place the compact in a 1×10 -3 Under Pa vacuum conditions, firstly, the temperature was raised to 450°C at a heating rate of 5°C / min, and kept for 1 h; then, the temperature was raised to 900°C at a heating rate of 5°C / min, and the temperature was kept for 1 h; Electrode material for hydrogen production from water electrolysis. The electrode wire is then drawn from the electrode material by spot welding. The electrode material fo...

Embodiment 3

[0032] Example 3: Electrode catalytic stability test for electrolysis of water for hydrogen production

[0033] The electrolytic water hydrogen production electrode prepared in Example 1 was tested for catalytic stability. The measurement method was cyclic voltammetry, the scanning potential range was -0.7 to -1.4V, the scanning rate was 10mV / s, and the scanning period was 500 cycles. Other conditional parameters are as follows:

[0034] The geometric area of the working electrode of the present invention is 1cm 2

[0035]

[0036] The results are shown in Table 2. It can be seen from the table that the Ni-Al porous material of the present invention has excellent catalytic stability for electrolytic hydrogen production.

[0037] Table 2 Current density values measured by cyclic voltammetry at -1.39V potential

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com