Al alloy film for display device

A display device, al alloy technology, applied in identification device, transportation and packaging, metal material coating process, etc., can solve problems such as large potential, and achieve the effect of improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

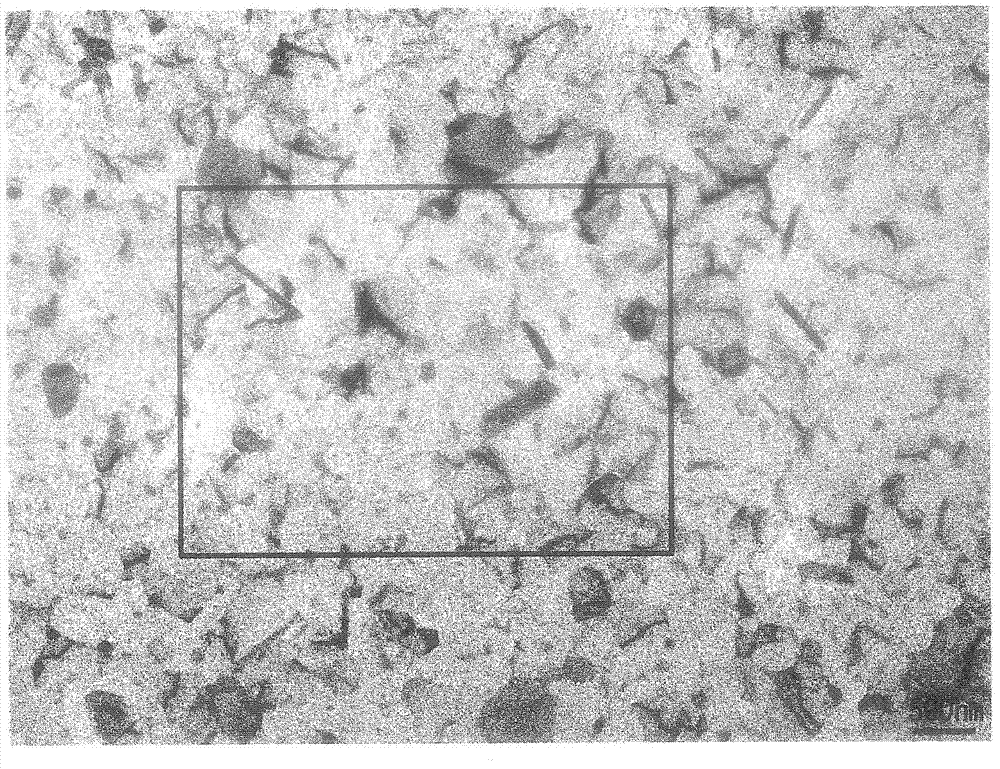

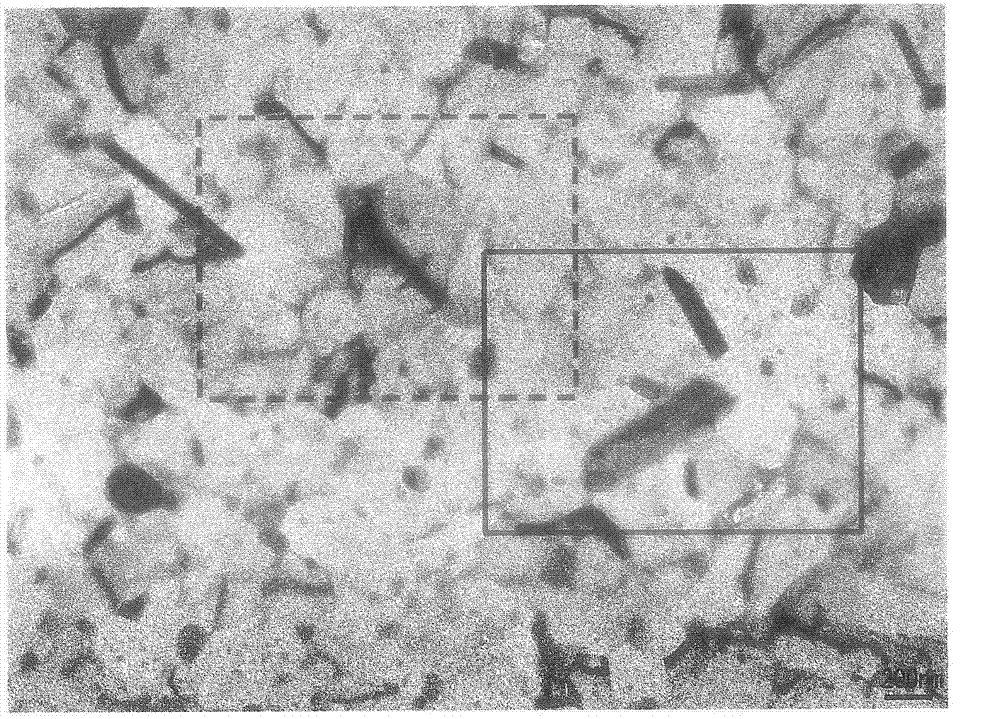

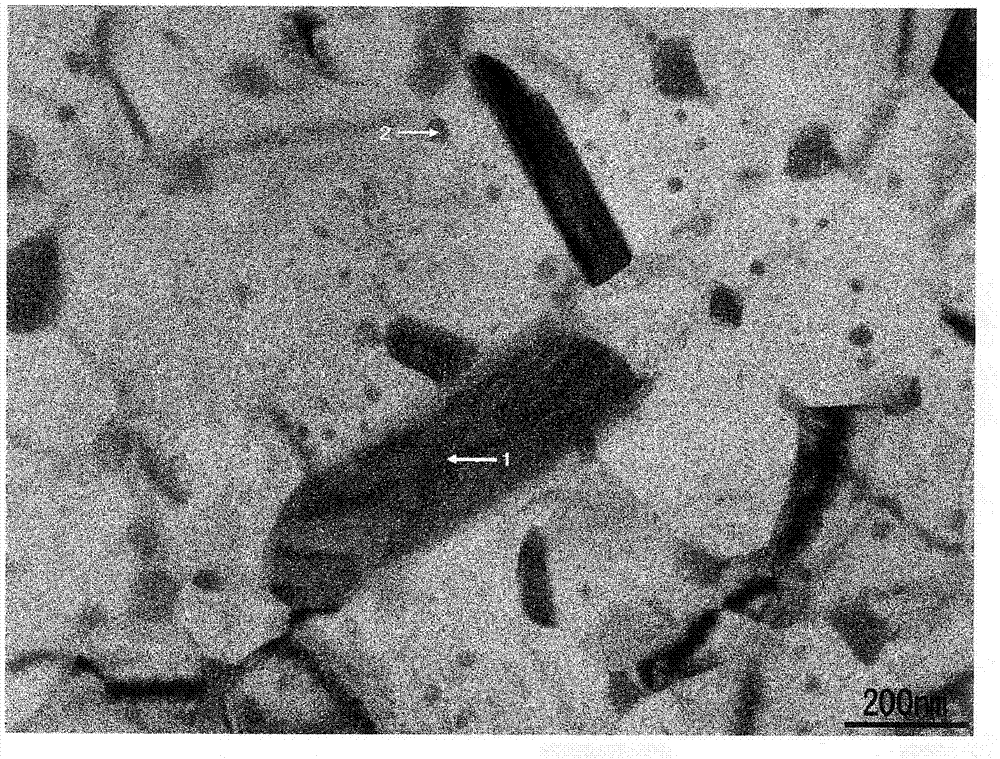

[0136] Al alloy films (film thickness=300nm) with various alloy compositions shown in Tables 1 to 7 were subjected to DC magnetron sputtering (substrate=glass substrate (Eagle2000 manufactured by Corning Corporation), atmosphere gas=argon , pressure=2mTorr, substrate temperature=25°C (room temperature)) to form a film.

[0137] In addition, in the formation of the Al alloy film of the above-mentioned various alloy composition, the Al alloy target of various composition produced by the vacuum melting method was used as a sputtering target.

[0138] In addition, the content of each alloy element in the various Al alloy films used in the examples was obtained by ICP emission analysis (inductively coupled plasma emission analysis) method.

[0139] For the Al alloy film formed as described above, high-temperature heat treatment at 450 to 600°C was performed twice, and for the Al alloy film after the high-temperature heat treatment, the heat resistance and the Al alloy film were mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com