Patents

Literature

147results about How to "Good flexural resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforced aerogel composite material and preparation method thereof

The invention provides a reinforced aerogel composite material and a preparation method thereof. The reinforced aerogel composite material comprises single aerogel or two aerogels or more than two aerogels, the surfaces or block interfaces of the block aerogel are coated or bound into a whole by virtue of fiber mesh fabric-reinforced waterborne adhesive. The preparation method of the reinforced aerogel composite material comprises the following steps: (1) carrying out hydrophobic modification treatment on the surfaces; (2) carrying out hydrophilic / hydrophobic modification treatment on the surfaces; and (3) preparing the reinforced aerogel composite material: uniformly coating the surface of the block aerogel or the interface of two aerogels with waterborne adhesive and fiber mesh fabric and curing to obtain the reinforced aerogel composite material. The reinforced aerogel composite material provided by the invention has the characteristics of excellent thermal-insulation property, heat preservation property, sound insulation property, fireproof property, explosion resistance, shock absorption, energy absorption, light weight, better mechanical properties, the preparation process of the material is simple and practical and the material has wide range of applications.

Owner:NANJING WEICAI NEW ENERGY TECH

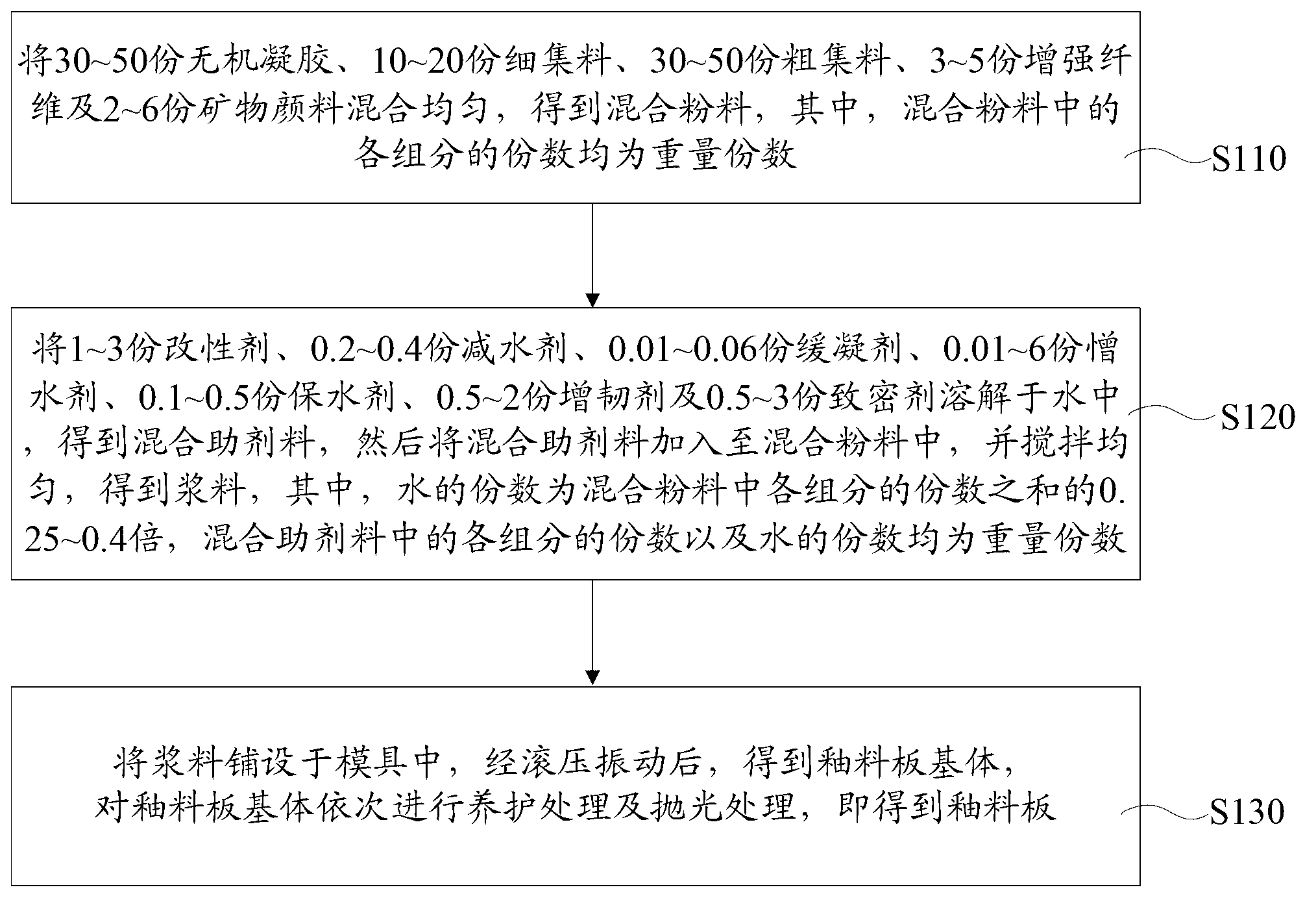

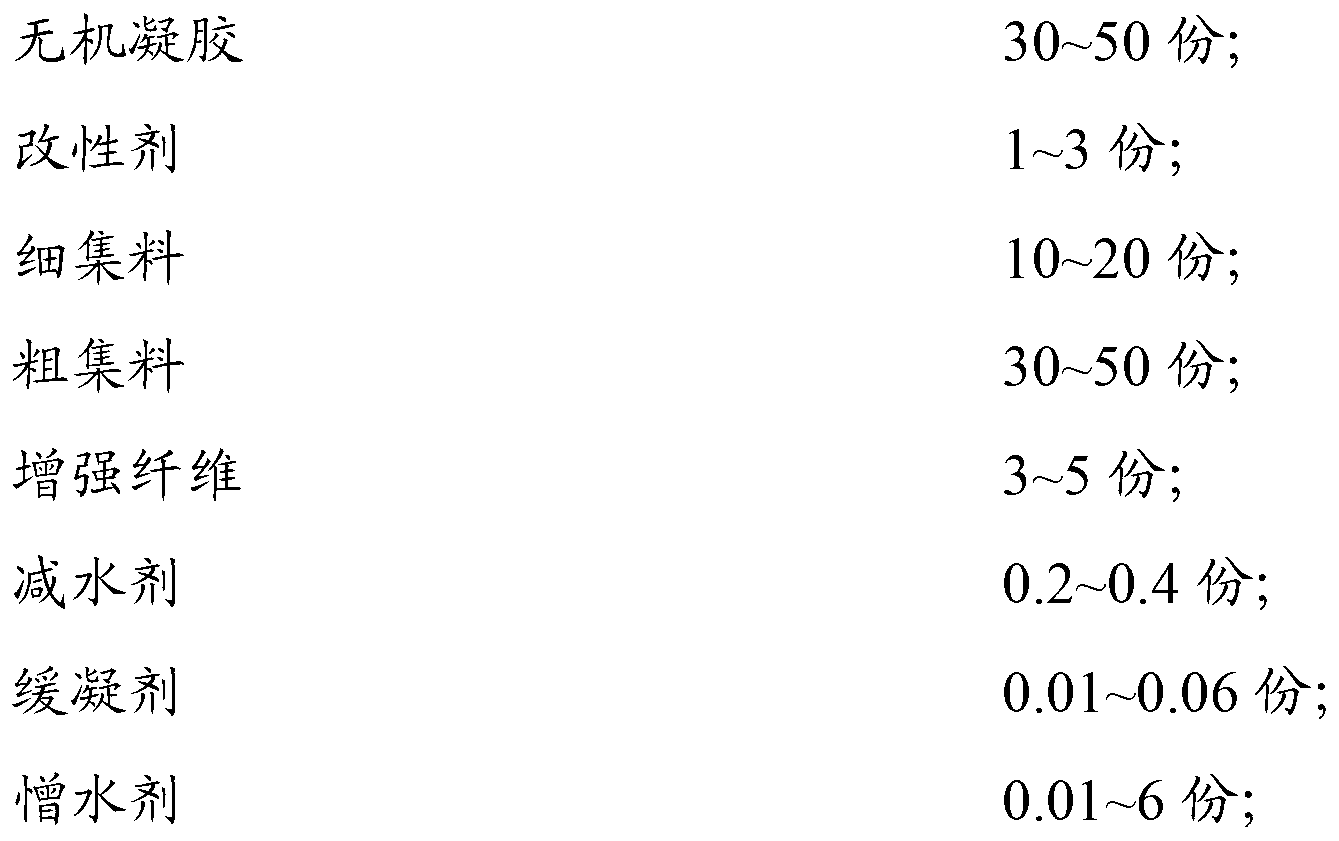

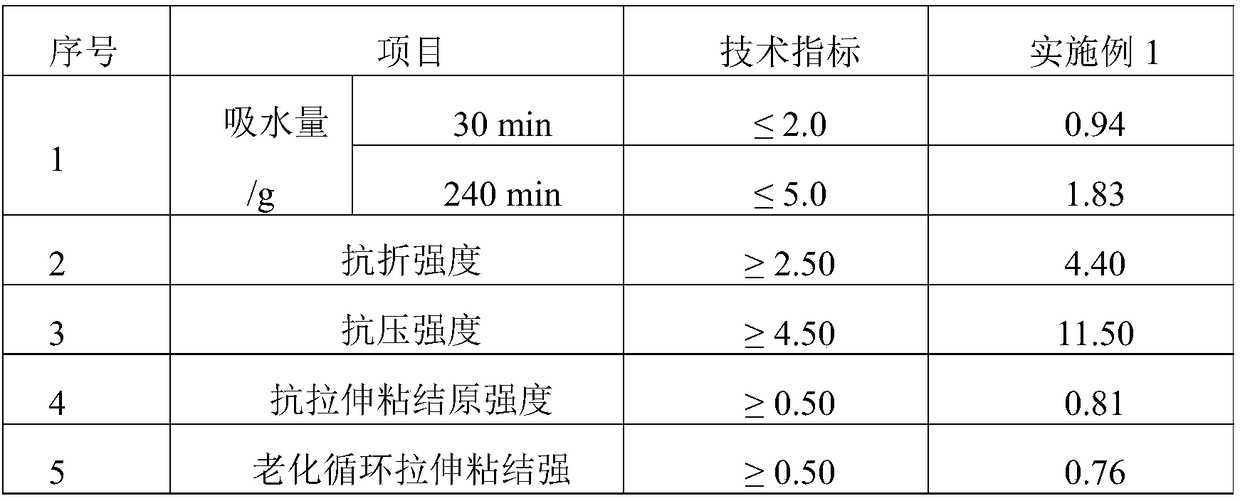

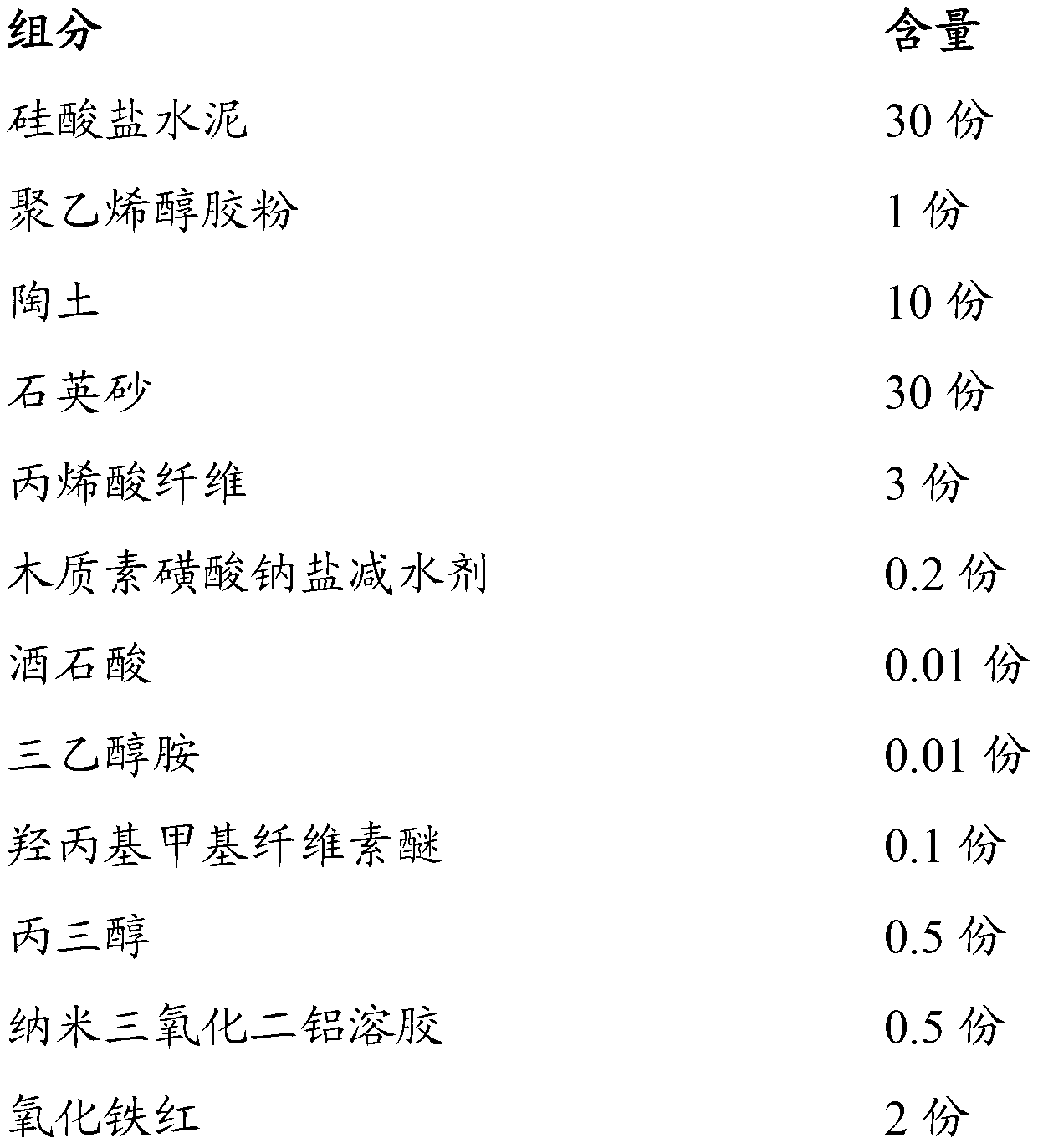

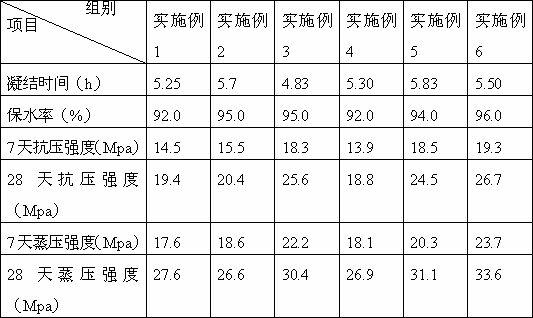

Glaze material and preparation method of glaze material plate

The invention relates to a glaze material which comprises the following components in parts by weight: 30-50 parts of inorganic gel, 1-3 parts of modifier, 10-20 parts of fine aggregate, 30-50 parts of coarse aggregate, 3-5 parts of reinforced fiber, 0.2-0.4 part of water reducer, 0.01-0.06 part of retarder, 0.01-6 parts of moisture repellent, 0.1-0.5 parts of water-retaining agent, 0.5-2 parts of flexibilizer, 0.5-3 parts of densification agent and 2-6 parts of mineral pigment. The invention also provides a preparation method of a glaze material plate. Most of the components of the glaze material are common inorganic materials, thus being low in cost, having no toxicity and radiation, having no contamination, and being environment-friendly. When in preparation of the glaze material plate by using the glaze material, the step of high temperature roasting is eliminated, the molded glaze material plate can be cured at normal temperature, and carbon emission can be greatly reduced, so that the preparation method is environment-friendly and energy-saving.

Owner:深圳市爱思宝科技发展有限公司

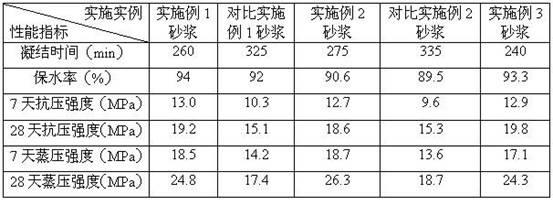

White wall veneer mortar prepared by calcium carbide slag

The invention provides a white wall veneer mortar prepared by calcium carbide slag. The mortar is prepared from the calcium carbide slag, white cement, coarse whiting, quartz sand, redispersible powder and other admixtures. The veneer mortar adopts the calcium carbide slag as a gel material, which is of great significance for reducing the environmental pollution of industrial waste residues and reducing the production cost. In addition, high-belite-sulphoaluminate cement is hydrated to generate expanded ettringite, which is beneficial to improve the crack resistance of the veneer mortar. The veneer mortar has excellent flexibility, flexural strength, compressive strength, gas permeability and the like, and is suitable for the decoration of a building wall.

Owner:BEIJING UNIV OF TECH

Insulation system with polycrystalline insulation mortar

ActiveCN101851958AEnhanced Penetration Grip InsufficientHigh compressive strengthClimate change adaptationHeat proofingHydroxypropylmethyl celluloseSodium silicate

The invention discloses an insulation system with polycrystalline insulation mortar, which belongs to the technical field of the building material. The insulation system comprises interface mortar, insulation mortar and waterproofing mortar, wherein the insulation mortar comprises the following components: cement, redispersable latex powder, cold water type polyvinyl alcohol, hydroxypropyl-methylcellulose ether, air entraining agents, sodium silicate, inorganic retarder and polystyrene particles. Compared with the prior art, the invention has the following advantages of: 1, solving the problem that the bonding strength of the inorganic cementitious material for penetration is not sufficient, and significantly improving the bonding strength and the compressive strength of the whole insulation system; 2, improving the construction property of the material and the insulation effect of the system; 3, improving the construction property and enhancing the long-term strength of the product;4, improving the waterproofing function of the system, and changing the rigidity of various kinds of polycrystalline mortar into softness, thereby improving the impact resistance, bending resistance,tensile strength, shrinkage resistance and other strain capacities of the insulation system; and 5. improving the bending resistance and the tensile strength of the material and the physical anti-cracking performance of the system.

Owner:HAIDA CONSTR GRP

Double-component polymer-cement-base waterproof mortar and preparation method thereof

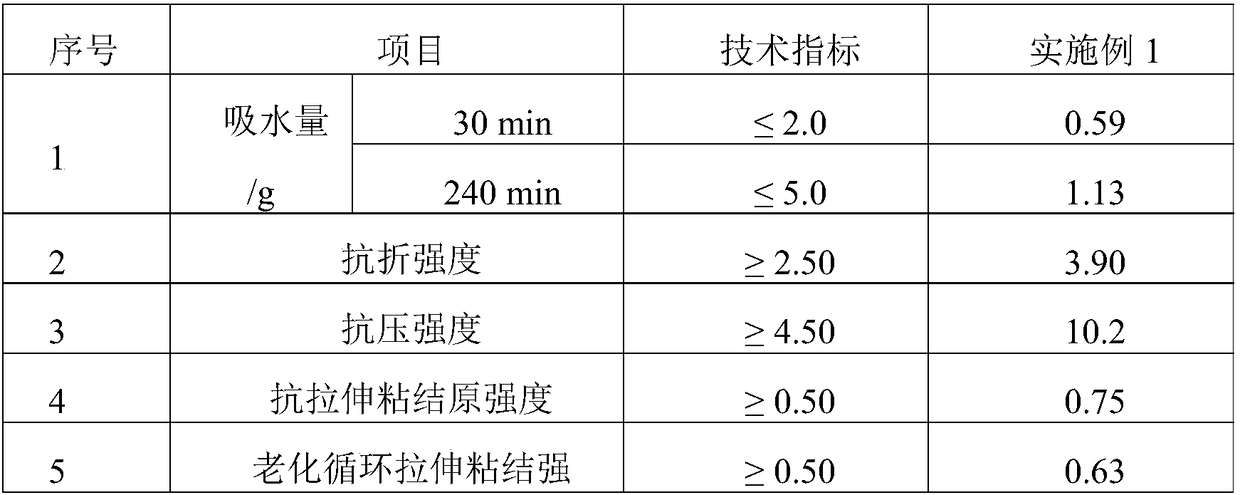

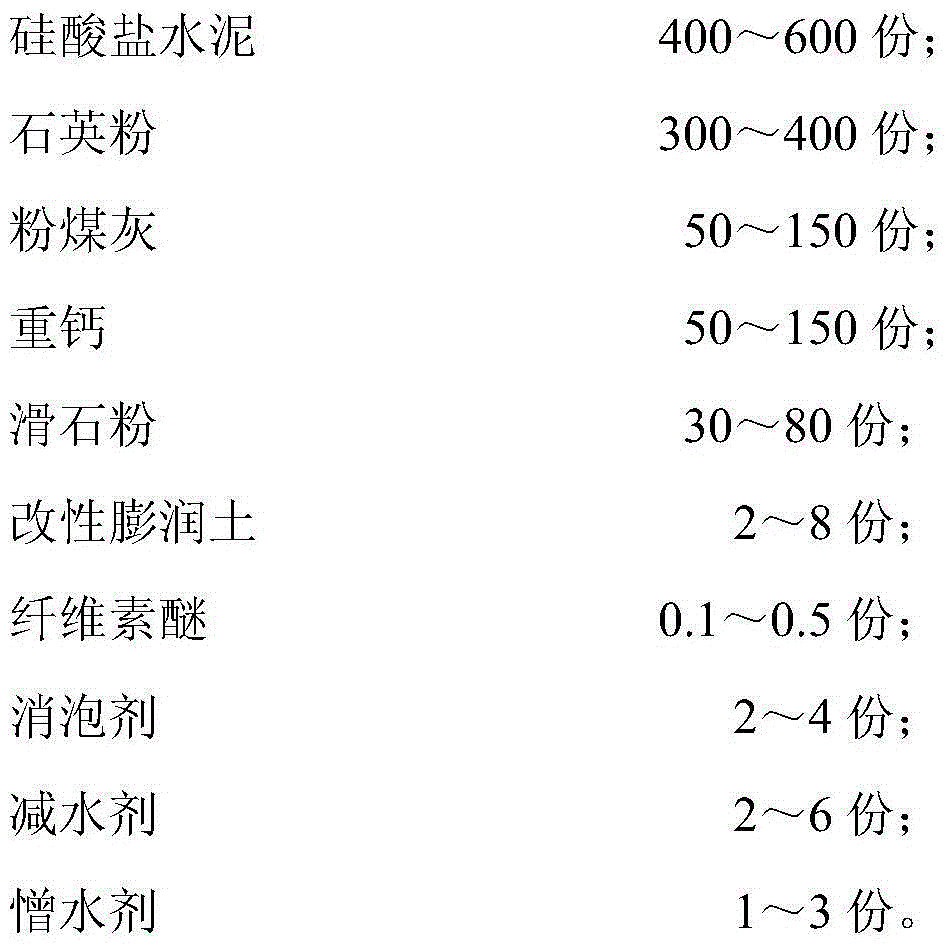

InactiveCN104909662AGood flexural resistanceImprove stress resistanceMechanical propertyDefoaming Agents

The invention discloses a double-component polymer-cement-base waterproof mortar and a preparation method thereof. The mortar comprises a liquid component and a powder component in a ratio of 1:(3.0-4.0). The liquid component comprises a VAE (vinyl acetate-ethylene) emulsion, a preservative, a defoaming agent and tap water. The powder component comprises Portland cement, quartz powder, fly ash, heavy calcium carbonate, talcum powder, modified bentonite, cellulose ether, a defoaming agent, a water reducing agent and a water repellent. The preparation method comprises the following step: mixing and stirring the liquid component and powder component. The double-component polymer-cement-base waterproof mortar has excellent physical and mechanical properties, does not do harm to the environment and human body, has excellent bending resistance, compression resistance and other physical properties, and is widely used in engineering buildings with high structural rigidity and low building deformation.

Owner:安徽朗凯奇科技股份有限公司

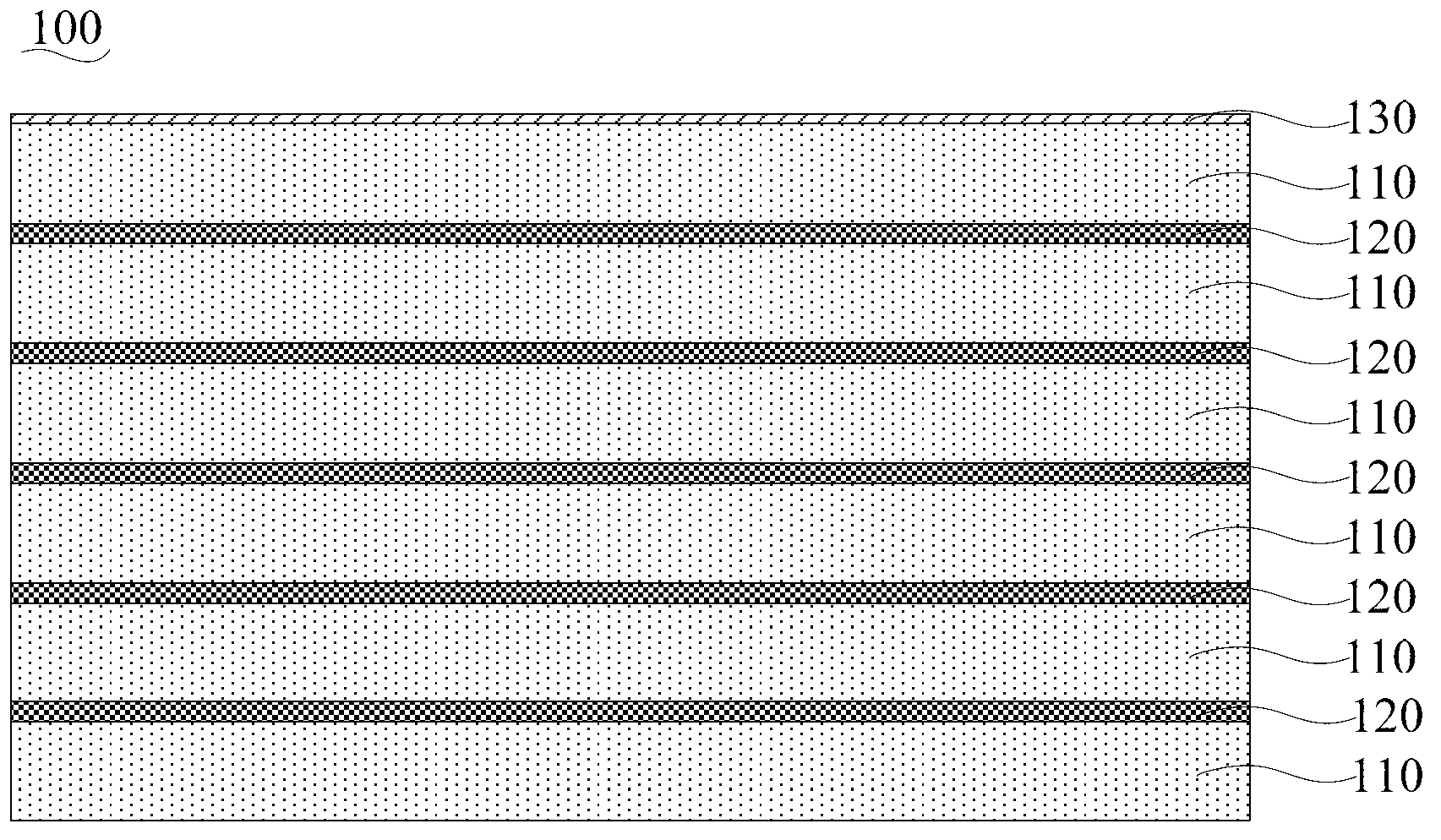

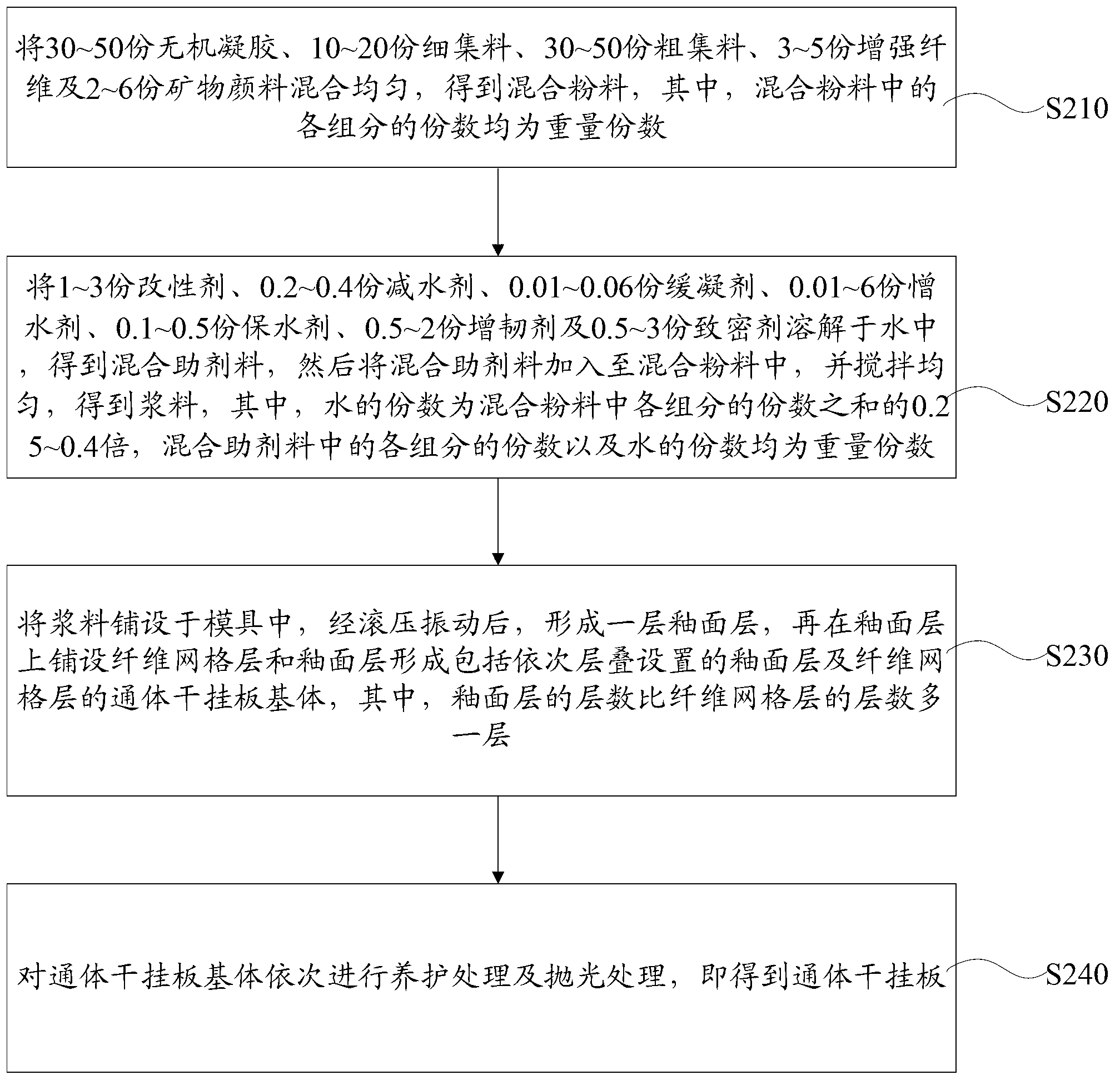

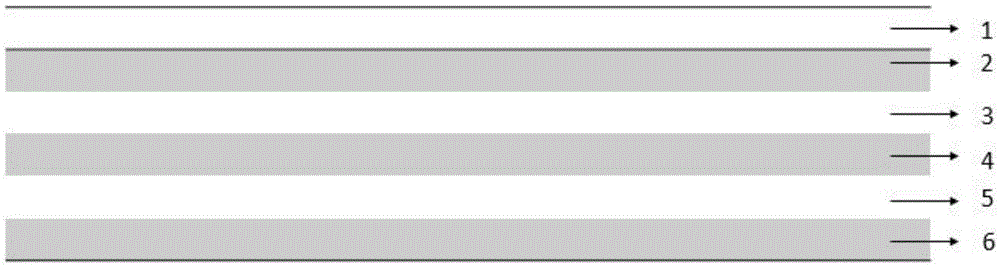

Full-body dry hanging plate and manufacturing method thereof

ActiveCN103255888AGood anti-delamination performanceExtended service lifeCovering/liningsFiberProcess conditions

The invention relates to a full-body dry hanging plate which comprises glaze layers and fiber grid layers, and the number of the glaze layers is one more than the number of the fiber grid layers. Each glaze layer comprises, by weight parts, 30-50 parts of inorganic gel, 1-3 parts of modifying agents, 10-20 parts of fine aggregate, 30-50 parts of coarse aggregate, 3-5 parts of reinforced fibers, 0.2-0.4 part of water reducer, 0.01-0.06 part of retarder, 0.01-6 parts of moisture repellent, 0.1-0.5 part of water-retaining agents, 0.5-2 parts of flexibilizer, 0.5-3 parts of densification agents and 2-6 parts of mineral pigment. The full-body dry hanging plate is good in layering resistant performance and splitting resistant performance. In addition, the invention provides a manufacturing method of the full-body dry hanging plate. The manufacturing method needs no procedure of high-temperature roasting, process conditions are relatively simple, and the full-body dry hanging plate is suitable for industrialized production.

Owner:深圳市爱思宝科技发展有限公司

Insulation system with polycrystalline anti-cracking and waterproofing mortar

InactiveCN101851960AImprove the defect of insufficient penetration gripImprove adhesionHeat proofingInsulation systemReducing agent

The invention discloses an insulation system with polycrystalline anti-cracking and waterproofing mortar, which belongs to the technical field of the building material. The insulation system comprises interface mortar, insulation mortar and waterproofing mortar, wherein the waterproofing mortar comprises the following components: cement, sand, redispersable latex powder, hydroxypropyl-methyl cellulose ether, inorganic water reducing agent, organosilicon waterproofing agent, sodium silicate and inorganic retarder. Compared with the prior art, the invention has the following advantages of: 1, solving the problem that the bonding strength of the inorganic cementitious material for penetration is not sufficient, and significantly improving the bonding strength and the compressive strength of the whole insulation system; 2, improving the construction property of the material and the insulation effect of the system; 3, improving the construction property and enhancing the long-term strength of the product; 4, improving the waterproofing function of the system, and changing the rigidity of various kinds of polycrystalline mortar into softness, thereby improving the impact resistance, bending resistance, tensile strength, shrinkage resistance and other strain capacities of the insulation system; and 5. improving the bending resistance and the tensile strength of the material and the physical anti-cracking performance of the system.

Owner:HAIDA CONSTR GRP

Dry mixed mortar

InactiveCN102126849ALight weightIncrease late strengthSolid waste managementCellulosePulverized fuel ash

Owner:UNIV OF JINAN +1

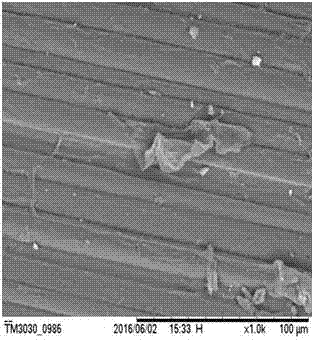

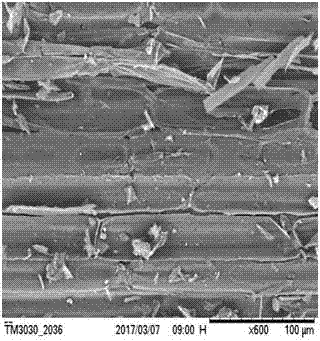

Crude polypropylene fiber for concrete and preparation method thereof

InactiveCN101629332AHigh breaking strengthIncrease elasticityFilament manufactureArtificial filament heat treatmentWater bathsPolymer science

The invention relates to a crude polypropylene fiber for concrete and a preparation method thereof. The crude polypropylene fiber comprises polypropylene, a thermotropic liquid crystal polymer being 0.1-25 percent by weight of the polypropylene, a compatilizer being 0.1-5.0 percent by weight of the polypropylene, an antioxidant being 0.1-0.5 percent by weight of the polypropylene and an ultraviolet absorption agent being 0.1-0.3 percent by weight of the polypropylene. The preparation method comprises the following steps: drying the polypropylene, the thermotropic liquid crystal polymer and other components to constant weight and then uniformly mixing the components; extruding the dried components by a spinneret plate of a double-screw extruder and then cooling an obtained extruded material in a water bath; stretching the cooled material in different stages for multiple times at a temperature being higher than the vitrification temperature of the polypropylene; spraying a conventional oil agent used for polypropylene spinning on an obtained fiber bundle and carrying out thermal shaping; and then carrying out indentation processing on the surface of the fiber. The thermotropic liquid crystal polymer strengthens the crude polypropylene fiber in the form of a microfiber so as to greatly improve the mechanical property of the crude polypropylene fiber, thereby enhancing or improving the crude polypropylene fiber to enhance the performances of anti-cracking, permeability resistance, breaking resistance, toughness, impact resistance, freezing and thawing resistance, fire resistance, bursting resistance, and the like of the concrete.

Owner:JIANGSU SUBOTE MATERIAL +1

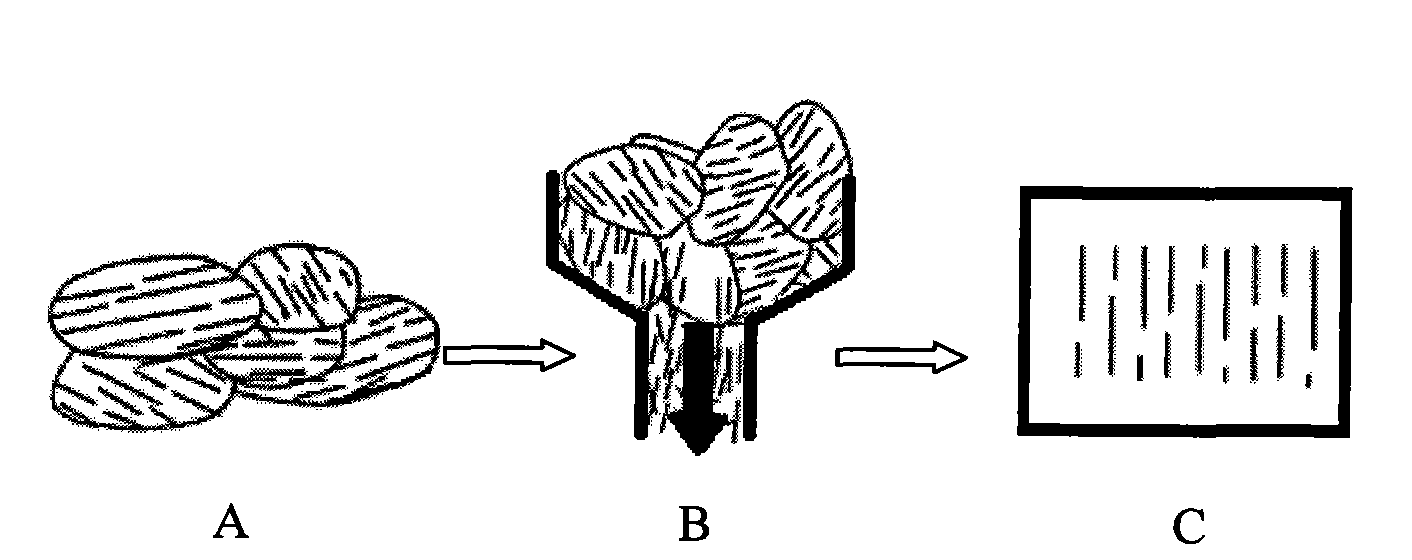

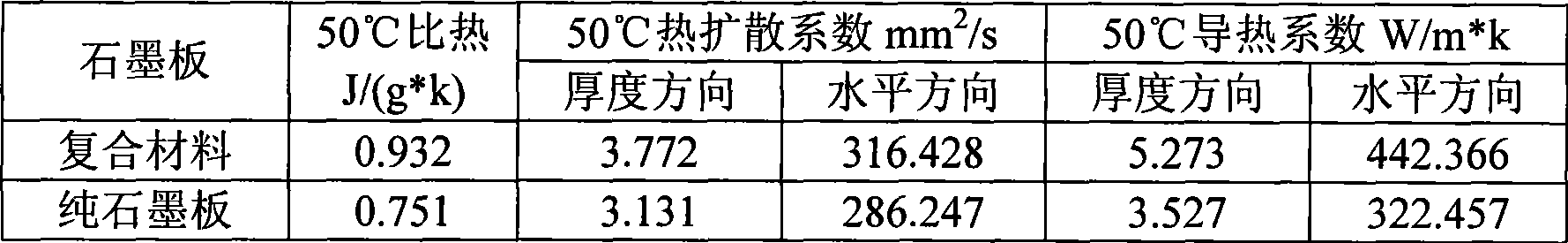

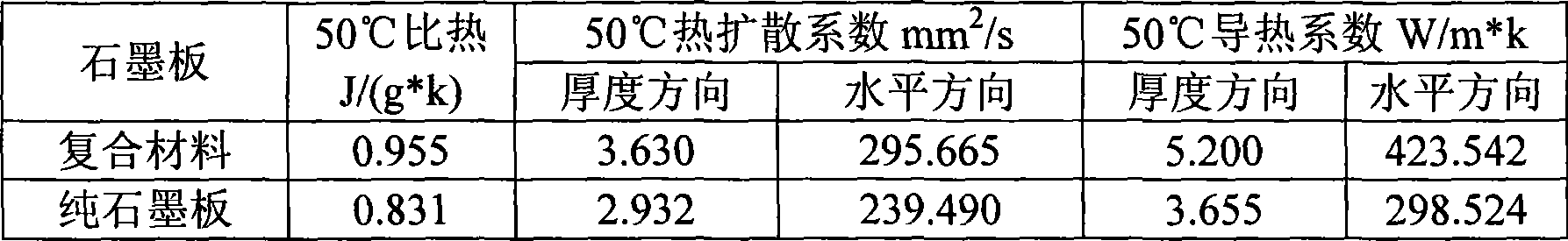

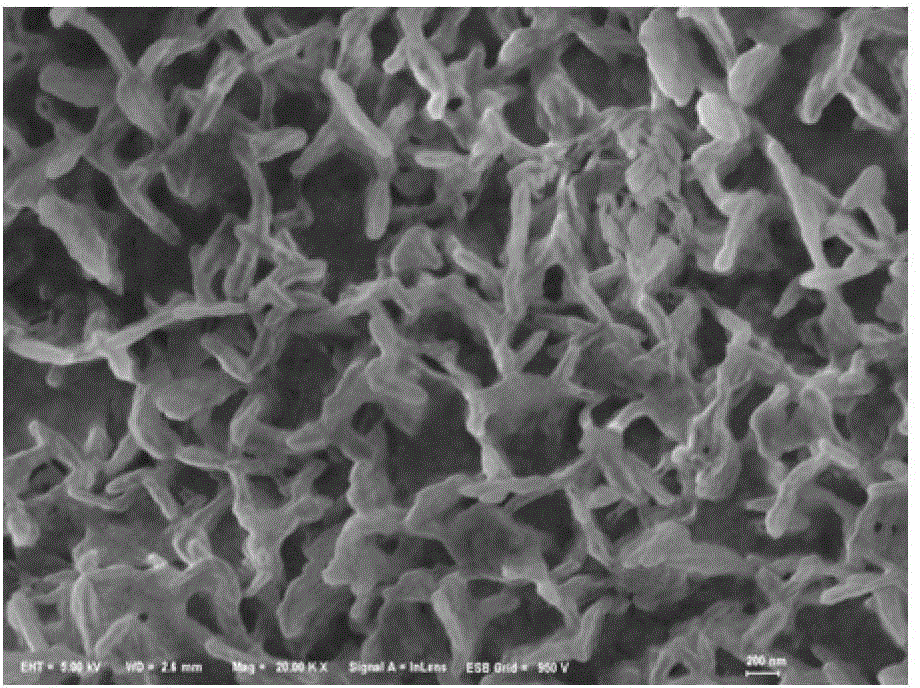

High heat conductivity reinforced graphite composite material and preparation method thereof

InactiveCN101391894AImprove thermal conductivityGood physical propertiesBoron nitrideMaterial distribution

The invention relates to a reinforced graphite composite material with high heat conductivity and a preparation method thereof; the reinforced graphite composite material with high heat conductivity is formed by expanded graphite with the weight percentage of 69.5 percent to 89.5 percent and nano boron nitride with the weight percentage of 10.5 percent to 30.5 percent. The preparation method of the reinforced graphite composite material with high heat conductivity comprises the steps: (1) intercalation is carried out to natural crystalline flake graphite; (2) a product after the intercalation is washed by water until the pH value is more than 4; (3) the product after washing is dried for 0.5 to 2 hours at the temperature of 60 to 120 DEG C; (4) high temperature swelling processing is carried out at the temperature of 800 to 1100 DEG C, and the time is not more than one minute; (5) uniform material distribution is carried out to the expanded graphite; (6) the nano boron nitride is uniformly sprayed on the expanded graphite with uniform material distribution; and (7) the reinforced graphite composite material with high heat conductivity can be obtained by prepressing and rolling of 4 to 6 times.

Owner:晟茂(青岛)先进材料有限公司

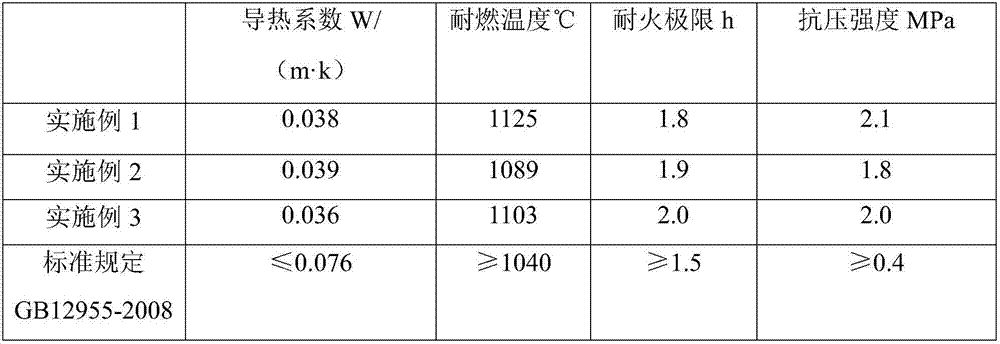

High-temperature-resistant high-strength fireproof door panel and manufacturing method thereof

The invention discloses a high-temperature-resistant high-strength fireproof door panel. The high-temperature-resistant high-strength fireproof door panel comprises the following raw materials in parts by weight: 50-80 parts of foaming agent, 30-40 parts of perlite powder, 20-30 parts of ore filler, 10-14 parts of magnesium sulfate, 14-18 parts of magnesium oxide, 3-5 parts of expansible graphite, 4-6 parts of zinc borate, 8-12 parts of calcium hydroxide, 25-35 parts of adhesive, 10-16 parts of desulfurized gypsum, 4-6 parts of boron oxide, 15-25 parts of reinforced fibers and 10-14 parts of anti-cracking fibers. The fireproof door panel disclosed by the invention has relatively good high temperature resistance and waterproof performance, is relatively strong in heat insulation and fire smoke resistance, is relatively good in mechanical performance indexes such as pressing resistance and bending resistance, is green and environmentally friendly, is light and is high in strength, and achieves the requirements of fireproof combustion and safety; and meanwhile, raw material components are safe and reliable, are harmless on environment, and are easily available, the cost is relatively low, the process is simple and clear, operation is easy and industrial production is easily realized, a practical value is higher and the application prospect is good.

Owner:合肥市旺友门窗有限公司

Polyurethane-compounded cement-based expanded-perlite heat preservation plate and preparing method thereof

InactiveCN106116328AIncrease productivityGood dimensional stabilityCeramicwarePolyurethane adhesiveWeather resistance

The invention discloses a polyurethane-compounded cement-based expanded-perlite heat preservation plate and a preparing method thereof. The polyurethane composite cement-based expanded-perlite heat preservation plate is prepared from 50-100 parts of expanded perlite, 40-90 parts of cement, 5-10 parts of two-component polyurethane adhesive, 0.1-0.5 part of coupling agent, 0.1-0.25 part of fiber, 0.1-0.5 part of reusable dispersion emulsion powder, 40-90 parts of water, 0.5-2 parts of early strength agent and 0.1-0.5 part of water reducing agent. According to the polyurethane-compounded cement-based expanded-perlite heat preservation plate and the preparing method thereof, cement mortar is modified through polyurethane, polyurethane resin and the cement are evenly dispersed into the expanded perlite, hydration of the cement and solidification of polyurethane are carried out at the same time, and the mutually-filled whole structure is formed; the expanded perlite and the polyurethane cement-based composite are combined, and the polyurethane composite cement-based expanded-perlite heat preservation plate is prepared in a compression-molding mode; the defects of the expanded perlite are effectively overcome, and meanwhile the advantages and the like of the water resistance and heat preservation performance of the polyurethane material, the low heat conductivity of the expanded perlite, the high weather resistance of concrete and the liker are used.

Owner:ANHUI MINGYUAN NEW BUILDING MATERIAL TECH CO LTD

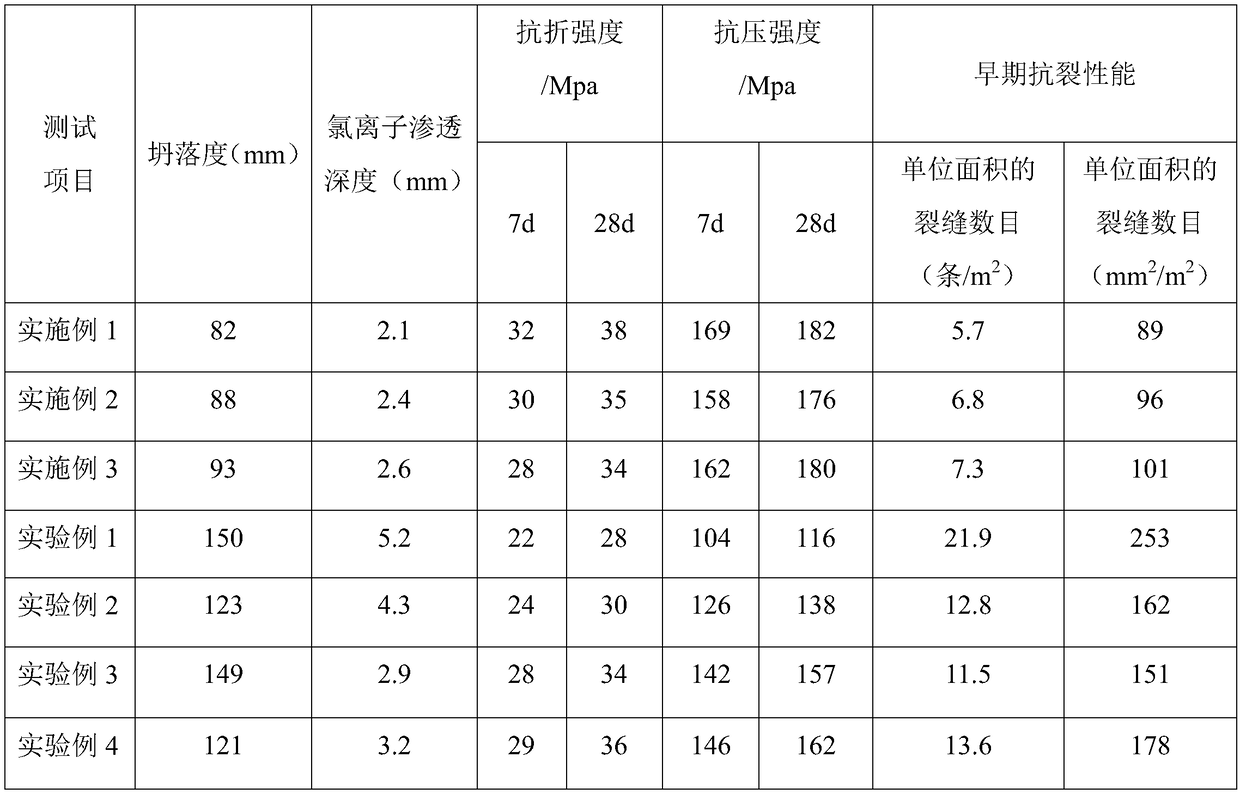

Concrete and concrete additive thereof

InactiveCN105152566AImprove toughnessHigh compressive strengthSolid waste managementCrack resistanceEmulsion

The invention discloses concrete and a concrete additive thereof and belongs to the technical field of concrete. The concrete additive comprises, by weight, 4-16 parts of coal ash, 4-10 parts of silicon dioxide powder, 4-16 parts of polypropylene fibers, 1-9 parts of calcium powder, 1-9 parts of lignin sulfonic acid calcium powder and 4-10 parts of acrylic emulsion. By the application of the concrete additive, toughness and compressive strength of the concrete can be improved, and service life can be prolonged; the concrete made by the concrete additive is good in tensile strength, fracture resistance and crack resistance, low in cost, simple in production process and applicable to scale production.

Owner:广西路佳道桥勘察设计有限公司

Preparation method of functionalized plant fiber plaster material

The invention relates to a preparation method of a functionalized plant fiber plaster material. The preparation method comprises the steps of: firstly, conducting semi-carbonization treatment to plant fiber to obtain modified plant fiber, and then evenly mixing the modified plant fiber, a plaster, a water-reducing agent, an air entraining agent, a gas-forming agent, a thickener, lime and cement, to obtain the functionalized plant fiber plaster material. The preparation method has the beneficial effects of being large in waste consumption quantity and strong in product functionality, as well as the advantages that 1) the maximum plant fiber consumption quantity can achieve 50%, thus being conductive to saving resource consumption in the production process of products; 2) after being modified, the plant fiber integrates the toughness and strong adsorbability, the porosity and specific surface area of the material can be increased, from the basic phase (plaster and semi-carbonized fiber) to the internal structure of the material all have certain humidifying and heat-preserving functions, and compared with the existing energy-saving material, the functionalized plant fiber plaster material is high in waste utilization rate, and strong in functionality, and the product can obtain good properties of fracture resistance, moisture absorption, heat preservation and the like.

Owner:WUHAN UNIV OF TECH

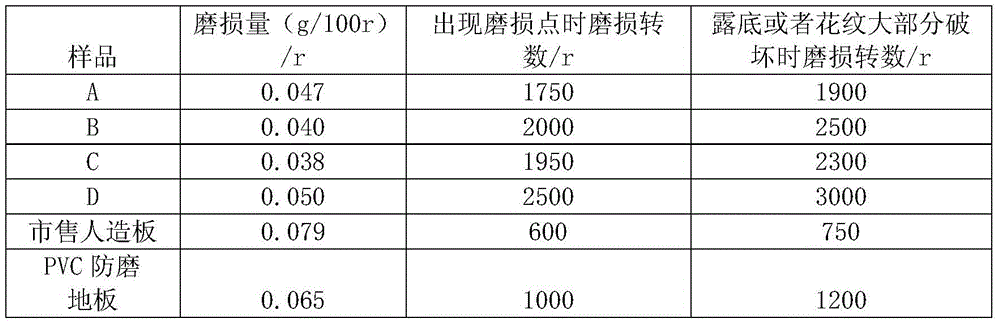

Fireproof floor and preparation method thereof

InactiveCN105421723AImprove fire performanceSimple processCovering/liningsFlooringHigh surfaceEngineering

The invention relates to a building material, in particular to a fireproof floor for a container type trailer coach and a preparation method thereof. The fireproof floor for the container type trailer coach and the preparation method thereof, provided by the invention, are simple in technological process, convenient for operation and stable in product quality. Compared with the prior art, the fireproof floor has the beneficial effects of beauty, high surface strength and good wear resistance.

Owner:张家港市盛港绿色防火建材有限公司

Environment-friendly flame-retardant fiber board and method for preparing same

ActiveCN105885459AReduce pollutionAbundant raw materialsWood working apparatusFlat articlesFiberEnvironmental resistance

The invention relates to an environment-friendly flame-retardant fiber board and a method for preparing the same. By the aid of the environment-friendly flame-retardant fiber board and the method, problems of heavy weight, high cost, poor quality and environmental friendliness and short service life of existing boards can be solved effectively. The method includes cleaning, drying and smashing waste fibers; soaking the waste fibers in NaOH solution with the mass concentration of 2% for 24 h; washing the waste fibers by the aid of clear water; dissociating the waste fibers by the aid of a fiber dissociation device at the speed of 5000 r / min; washing the waste fibers by the aid of clear water until NaOH is thoroughly washed out to obtain treated wet fibers; evenly mixing aluminum hydroxide, ammonium polyphosphate, melamine and zinc borate with one another to obtain flame retardants; mixing the treated wet fibers with the flame retardants under stirring conditions to obtain uniform board slurry; molding the board slurry in a mold and carrying out cold pressing and hot pressing to obtain the environment-friendly flame-retardant fiber board. The environment-friendly flame-retardant fiber board and the method have the advantages that raw materials for the environment-friendly flame-retardant fiber board are abundant, waste can be utilized, accordingly, resources can be saved, environmental pollution is reduced, the method is simple and is low in cost and high in efficiency, the environment-friendly flame-retardant fiber board which is a product is high in quality and long in service life, and the environment-friendly flame-retardant fiber board and the method have huge economic and social benefits.

Owner:江西中竹生物质科技有限公司

Concrete additive and concrete

The invention discloses a concrete additive and concrete, and belongs to the technical field of concrete. The concrete additive is prepared from the following raw materials in parts by weight: 6-12 parts of fly ash, 5-15 parts of silicon dioxide powder, 4-16 parts of polypropylene fiber, 4-10 parts of zeolite powder, 2-8 parts of calcium lignosulphonate powder and 5-15 parts of acrylic emulsion. The concrete additive can improve the toughness, the compressive strength and the durability of the concrete; the concrete prepared by using the concrete additive is good in tensile resistance, bending resistance and anti-cracking performance, low in price, simple in production process and low in cost, and is suitable for large-scale production.

Owner:GUILIN XINYI REFRIGERATION EQUIP

Repairing material for cement concrete structure

The invention relates to a cement concrete patching material which is prepared from mixture and water, the weight portions of the mixture include silicate cement 13-17, high efficiency water reducing agent 0.06-0.2, exciting agent 0.6-5.3, yellow sand 13-28, crushed stone 26-50, polyvinyl alcohol 0.1-0.2, fibrous material 0.4-3.3, the amount of water accounts to 5-14% of the total weight parts of the mixture.

Owner:芮志平

Silicone rubber cable sheath for aerospace

InactiveCN104788962AImprove compactnessHigh strengthRubber insulatorsInsulated cablesAcrylonitrileEPDM rubber

The invention discloses a silicone rubber cable sheath for aerospace. The silicone rubber cable sheath comprises the following raw materials by weight: 80 to 90 parts of methyl vinyl silicone rubber, 10 to 20 parts of acrylonitrile grafted EPDM rubber, 1.5 to 2.8 parts of hydrogen-containing silicone oil, 6 to 10 parts of hydroxyl silicone oil, 15 to 23 parts of fumed silica, 15 to 20 parts of fine silicon powder, 30 to 45 parts of modified magnesium oxide, 20 to 28 parts of silicon carbide, 0.5 to 1.2 parts of DCP, 1 to 1.5 parts of DCBP and 20 to 30 parts of a magnesium hydroxide / platinum complex, wherein the mass fraction of a platinum complex in the magnesium hydroxide / platinum complex is 1.2 * 10<-16>. The silicone rubber cable sheath has high tensile strength and tear strength, is flame-retardant, produces small environmental pollution and is simple to prepare.

Owner:ANHUI TIANCAI CABLE GRP

Preparation method of artificial sand

The invention relates to a method for preparing artificial sand from iron alloy slag, belonging to the field of reutilization of iron alloy slag. The method comprises the following steps: preparing iron alloy slag into sand grains of which the grain size is 0.1-5mm, modifying with an alkaline modification liquid, and drying to obtain the artificial sand, wherein the concentration of the alkaline modification liquid is 0.05-0.2wt%, and the solute comprises Ca(OH)2 and NaOH of which the weight ratio is (5-15):(2-5) as well as 0.02wt% of sodium silicate. The artificial sand can be substituted for natural bluestone sand and quartz sand, lowers the production cost of mortar, improves the economic benefit, and has the properties of small volume weight and increasing later strength; the discharge amount of the used iron alloy slag material is large, the price is low, and the treatment process is simple, thereby ensuring low investment, quick gain return and remarkable benefit; and the invention implements the comprehensive utilization of industrial waste slag, solves the problems of farmland occupation and environment pollution, and achieves the national economy development goals of constructing resource-conserving and environment-friendly society and realizing sustainable development.

Owner:UNIV OF JINAN +1

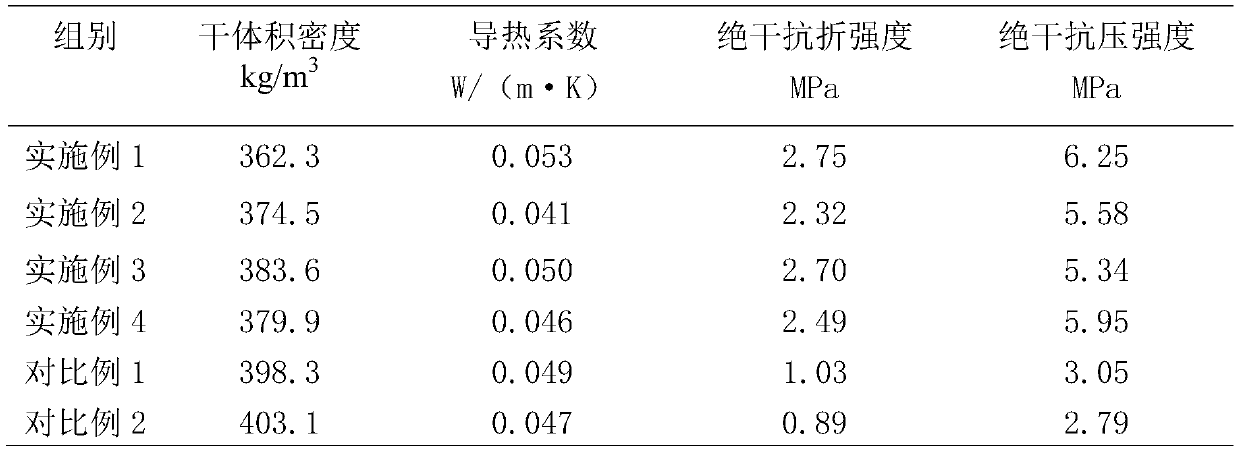

Straw compounded building material and preparation method thereof

The invention discloses a straw compounded building material and a preparation method thereof provides a novel compound building material and a preparation method thereof. The surface properties of straw can be effectively improved, and accordingly the problem that the straw and a cement base material are difficult to bond. In addition, the novel compound straw material is a green and environment-friendly resource which are rich and cheap in composition and ingredient selection, and the novel compound material having the strength properties including compression resistance, fracture resistance and freezing resistance and having very excellent thermal insulation properties can be obtained.

Owner:JILIN JIANZHU UNIVERSITY

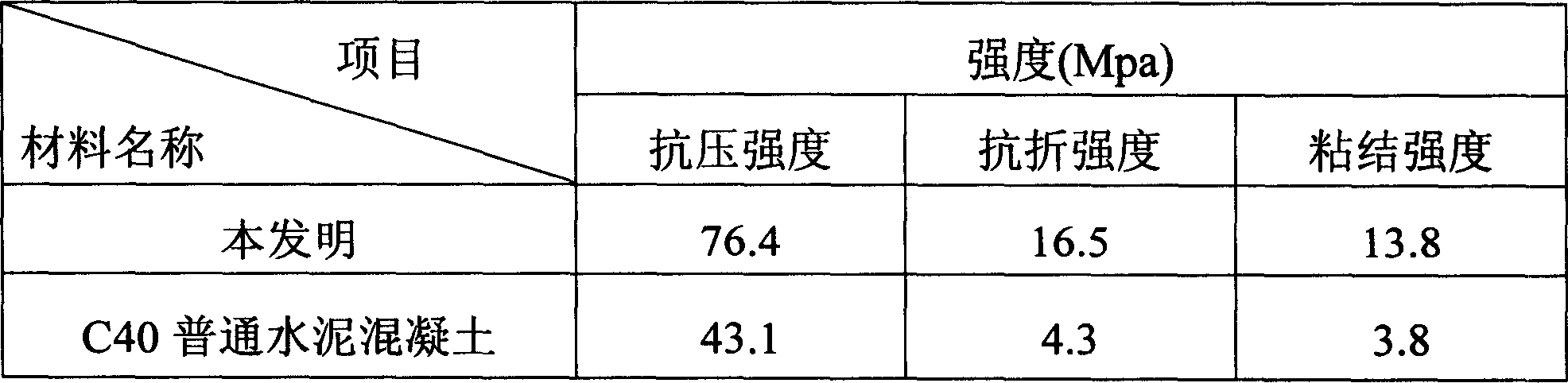

Active powder concrete applicable to road and bridge project

The invention provides active powder concrete applicable to a road and bridge project and belongs to the technical field of building materials. The active powder concrete is prepared from the following raw materials in parts by weight: 60 to 75 parts of cement, 40 to 50 parts of quartz sand, 12 to 15 parts of silicon ash, 8 to 15 parts of steel fiber, 1.5 to 2.5 parts of a polycarboxylic acid water reducer, 2 to 3 parts of an expanding agent, 4 to 6 parts of steel slag micro-powder, 1 to 1.5 parts of triethanolamine, 18 to 20 parts of water and 0.8 to 1.2 parts of a set retarder. The active powder concrete prepared by the invention has good controllability, good economical efficiency and no shrinkage or cracking, and has good bending strength and compression strength; meanwhile, the problem of high-addition-value utilization of steel slag is effectively solved, and the active powder concrete has good actual application value.

Owner:SHANDONG HUAJIAN ENG TESTING CO LTD

Gypsum-based heat insulation board and production method thereof

InactiveCN110922154ALow costGood flexural resistanceCeramic shaping apparatusCement mixing apparatusFoaming agentSlurry

The invention relates to a gypsum-based heat insulation board and a production method thereof, and belongs to the technical field of building materials. The gypsum-based heat insulation board is produced from semi-hydrated gypsum, anhydrous gypsum, a water reducing agent, a dispersing agent, a retarder, a water retaining agent, a foaming agent, a foam stabilizer and water. The production method comprises the following steps: proportionally mixing the foaming agent, the foam stabilizer and water to obtain a foaming solution, and preparing foam by using a foaming machine; uniformly mixing the above raw materials in proportion, stirring and mixing the raw materials and water in proportion, and adding the foam into the obtained slurry to obtain a mixed slurry; and injecting the mixed slurry into a mold to produce a core board, pouring a lower protective surface layer slurry into the forming mold, placing the core board on the protective surface layer slurry, preparing an upper protective surface layer, and performing hardening, demolding, and drying to obtain the heat insulation board. The semi-hydrated gypsum and the anhydrous gypsum are used as main raw materials, so that the produced gypsum-based heat insulation board has the advantages of small density, high strength, fireproof property, good heat insulation performance, non-toxicity and non-corrosivity, and the production method has the advantages of simple production process and low cost.

Owner:湖南昌迅科技环保股份有限公司

Formaldehyde-free flame-retardant plywood and preparation method thereof

InactiveCN106965269AHigh bonding strengthGood flexibilityNon-macromolecular adhesive additivesWood veneer joiningFoaming agentCombined use

The invention discloses formaldehyde-free flame-retardant plywood and a preparation method thereof. The formaldehyde-free flame-retardant plywood comprises a plate layer. The plate layer is veneer. An adhesive layer is arranged on the surface of the veneer and comprises magnesium oxide, magnesium chloride and polyvinyl alcohol. A small material is further added into the adhesive layer and is one or more kinds of a foaming agent, a dispersing agent and a modifying agent. Through combined use of the polyvinyl alcohol and the magnesium chloride and a cold pressing process, the produced plywood has extremely good physical and mechanical properties, is free of formaldehyde, flame-retardant and high in strength and has flexibility and the mothproof property.

Owner:烟台市宝翔木业有限公司

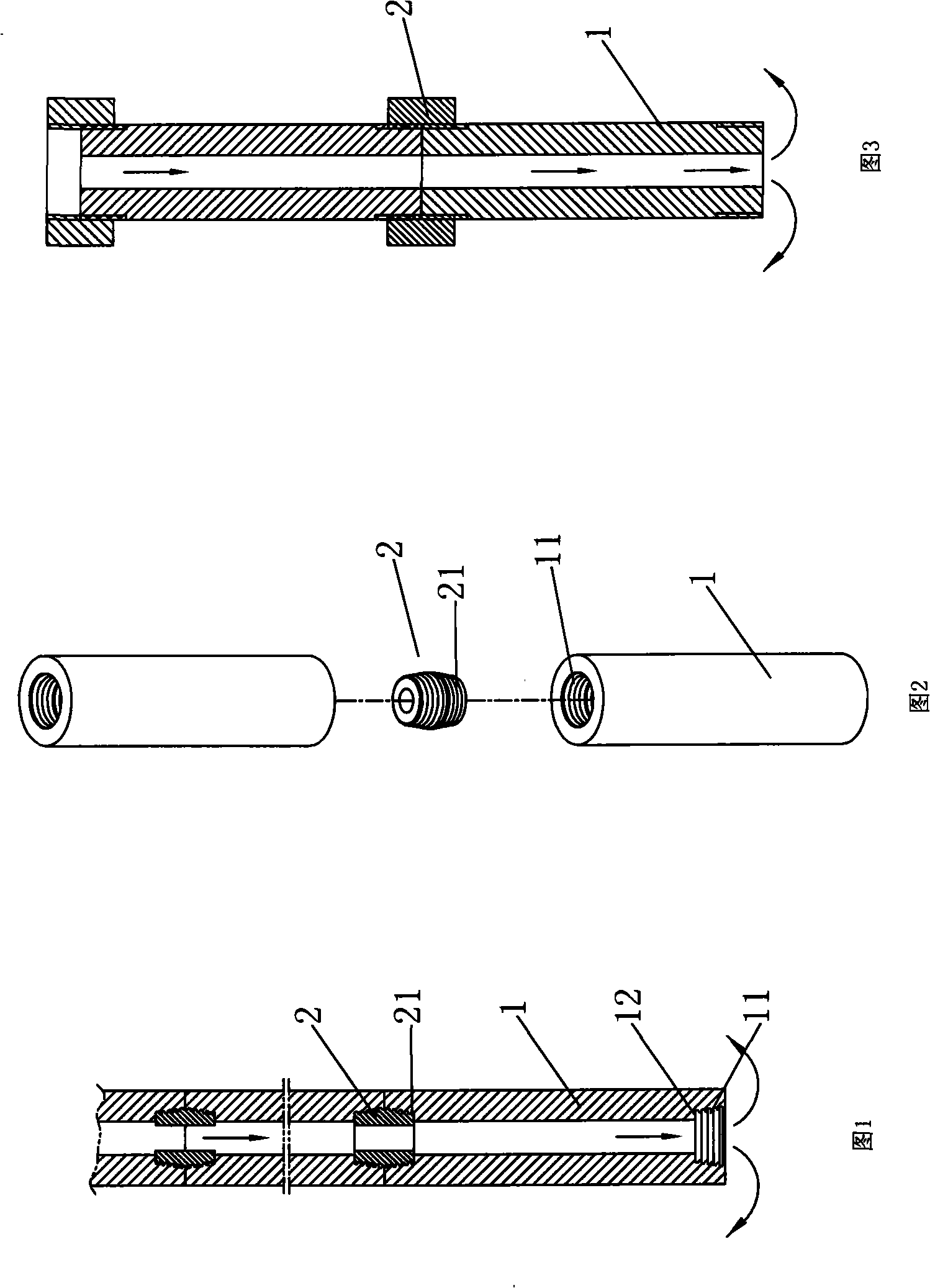

Carbon element coreless electrode

InactiveCN101282601ALow resistivityHigh bulk densityElectric discharge heatingSiliconConductive materialsHigh surface

The present invention relates to a carbon electrode material used in ferroalloy electric furnace smelting and the structure thereof. The invention provides an electrode conductive material taking carbon as the main component and provides a carbon hollow electrode comprising the electrode body and electrode nipple; the electrode body and electrode nipple are both in hollow cylinder shape; upper and lower ends of the electrode body have concave stages; side wall of the concave stage is installed with internal thread; the electrode nipple is less than the electrode body; the electrode nipple is connected with the electrode body through the external thread. Under the situation with the same carbon volume; the carbon electrode material has higher surface ratio, larger working area and larger machining area, generates higher thermal efficiency, is able to save the using amount of carbon electrode, and the carbon hollow electrode has simple and ingenious structure, little energy consumption, high heat production and high heat utilization; when the furnace is lack of carbon, the carbon electrode material blows carbon in time; and when the carbon is more, the carbon electrode material reduces the carbon and blows material in time; and the addition is simple and is able to continuously work.

Owner:北京民海艳科技有限公司

Concrete additive and concrete thereof

The invention discloses a concrete additive and concrete thereof, belonging to the technical field of concrete. The concrete additive comprises the following raw materials by weight: 5 to 15 parts of bentonite, 1 to 9 parts of silicon dioxide powder, 5 to 15 parts of polypropylene fiber, 2 to 8 parts of calcium powder, 2 to 8 parts of calcium lignosulphonate powder, 1 to 9 parts of dispersion emulsion powder and 5 to 15 parts of an acrylic emulsion. The concrete additive provided by the invention can improve toughness, compressive strength and service life of the concrete; and the concrete prepared by using the concrete additive in the invention has the advantages of good tensile, flexural and anticracking performances, low price, simple production process, low cost, and applicability to large-scale production.

Owner:广西路佳道桥勘察设计有限公司

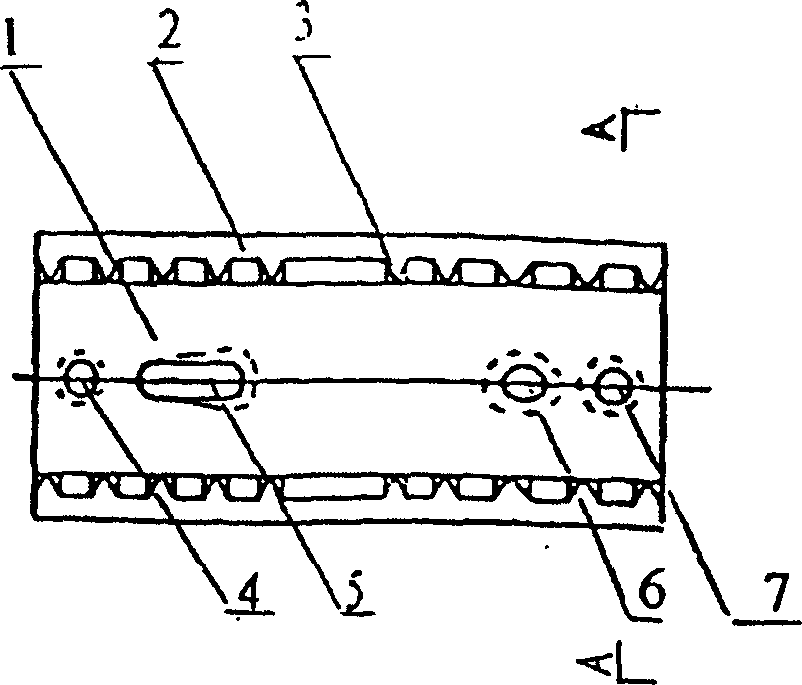

Centering joining tooth type coaptation plate

InactiveCN1686057AGood flexural resistanceImprove bending resistanceInternal osteosythesisBone platesTherapeutic effectEngineering

Owner:张荣魁 +1

Dry-scattering ground hardening agent and using method thereof

InactiveCN108975809AImprove mechanical propertiesImprove wear resistanceRoads maintainenceAlloyUltimate tensile strength

The invention belongs to the field of concrete ground hardening agents, and particularly discloses a dry-scattering ground hardening agent and an using method thereof. The dry-scattering ground hardening agent is prepared by uniformly mixing the following raw materials in parts by weight: 320 to 350 parts of cement, 15 to 20 parts of silica fume, 750 to 800 parts of copper slag and 4 to 6 parts ofa water reducing agent. The dry-scattering ground hardening agent is prepared by taking copper slag undergoing treatment and grading optimization as aggregate, so that the wear resistance, surface strength, impact resistance and oil resistance of the ground are improved greatly. Meanwhile, the problem of high aggregate cost in the conventional alloy aggregate and metal aggregate dry-scattering ground hardening agents is solved, and a novel way is provided for the efficient recycling utilization of the copper slag.

Owner:成都宏基建材股份有限公司

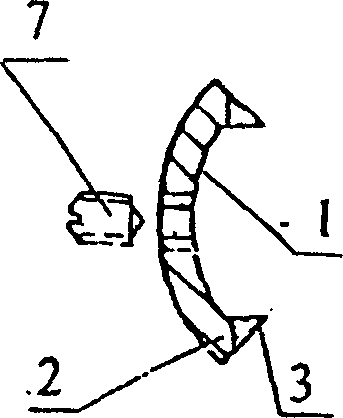

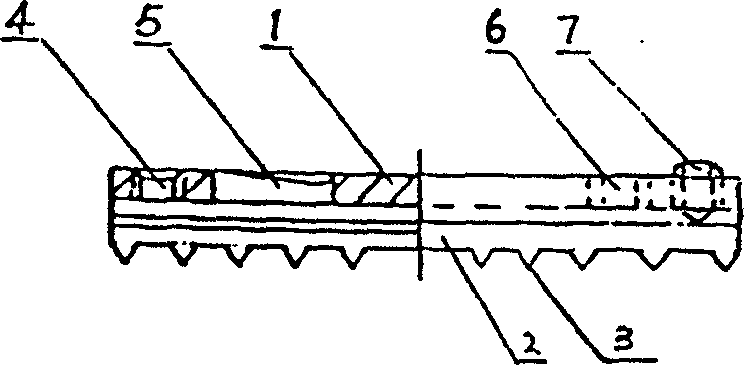

Semi-conductive polyimide film

InactiveUS20080242832A1Improve fatigue resistanceGood flexural resistanceElectrographic process apparatusThin material handlingCommon logarithmSurface resistivity

The present invention provides a semi-conductive polyimide film having: a common logarithm of a surface resistivity at 25° C. and 60% RH of 9 to 15 log Ω / square; a common logarithm of a volume resistivity of 8 to 15 log Ω·cm; a fatigue stress in accordance with a fatigue test complying with JIS K7118, upon a number of repetition being 107, of 160 MPa or more; and a number of durable bending in accordance with an MIT test complying with JIS P8115 of 2,000 times or more, and an intermediate transfer belt and an transfer transportation belt using the semi-conductive polyimide film.

Owner:NITTO DENKO CORP

Fiber restricted expansion mortar as well as dry mixture, wet mixture and preparation method of fiber restricted expansion mortar

The invention relates to the field of building materials and in particular relates to a fiber restricted expansion mortar as well as a dry mixture, wet mixture and preparation method of the fiber restricted expansion mortar. Due to the addition of a foaming agent, a CSA expanding agent, a stabilizer and polypropylene chopped fibers, mortar is subjected to a whole string of reaction processes including foaming, flowing, bubble breakage, concrete contraction, restricted expansion of an expanding agent, plasticity change caused by plasticity stability neutralizing fibers and the foaming agent andmechanical property improvement by the polypropylene chopped fibers to finally form repair mortar with high early strength development speed, volume restricted expansion, high tensile strength, highultimate tensile rate and high toughness. Due to the addition of the fibers, the tensile and crack resistance of the repair mortar are greatly improved; due to the addition of the expanding agent, themortar generates a restricted expansion effect so as to be more densely filled, the performances such as fracture resistance, tensile strength and durability of the hardened repair mortar are more excellent than those of other repairing agents, and the problem of poor restricted expansion property of the current repair mortar is solved.

Owner:河南中建西部建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com