Centering joining tooth type coaptation plate

A technology of bone plate and tooth shape, applied in the direction of outer plate, inner bone synthesis, internal fixator, etc., to achieve the effect of enhancing anti-slip, convenient bundling and reset, and promoting the formation of callus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

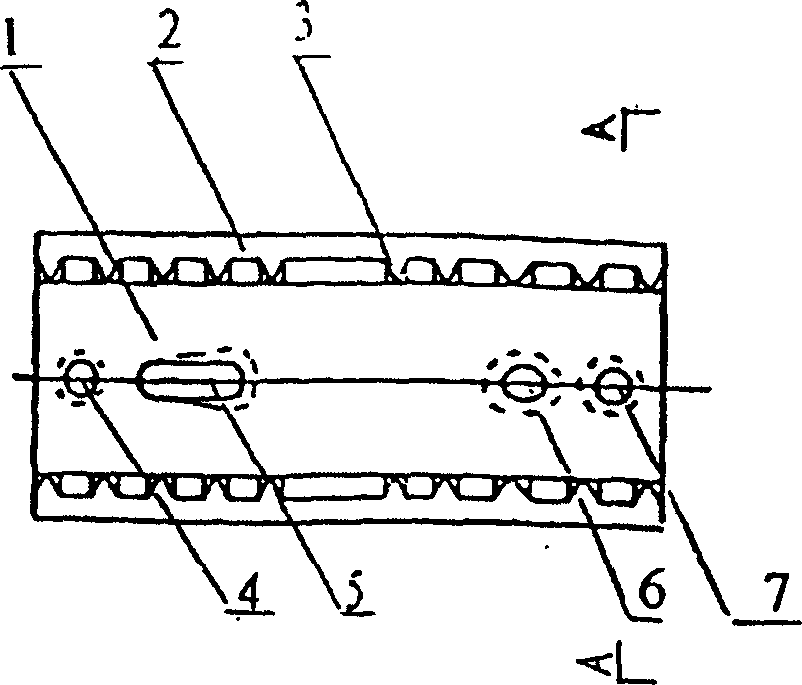

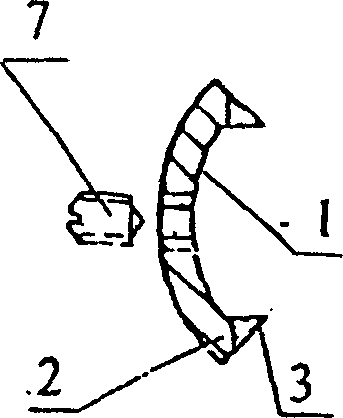

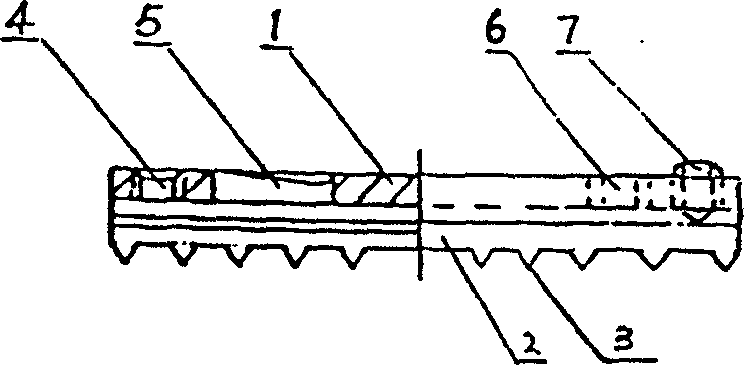

[0039] Depend on Figure 1-3 As shown, the centripetal hook-toothed bone plate includes a base plate 1 with a hook-shaped angle rib 2 with a blade tip, teeth 3 are arranged longitudinally at the blade tip of the angle rib, and there is a threaded hole 4 on the base plate 1. Close the reset adjustment hole 5, the pressure screw installation hole 6, and adjust the top screw 7.

[0040] The hook-shaped ribs 2 with blade tips are located at both ends of the concave bone-attached surface of the base plate 1 or around the outer edge of the bone plate, and at least one tooth 3 is arranged along the distance between the blade tips of the longitudinal ribs.

[0041] Depend on Figure 4 As shown, A, B are the two ends of the outer arc of the base plate 1, E, F are the two ends of the inner arc of the base plate 1, C, D are the two occlusal points of the blade tip and the bone skin, G, the bone skin of the outer diameter of the bone line, O is the bone center point. H is the centerlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com