Dry-scattering ground hardening agent and using method thereof

A ground hardening and dry-scattering technology, applied in construction, roads, road repairs, etc., can solve the problem of high aggregate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

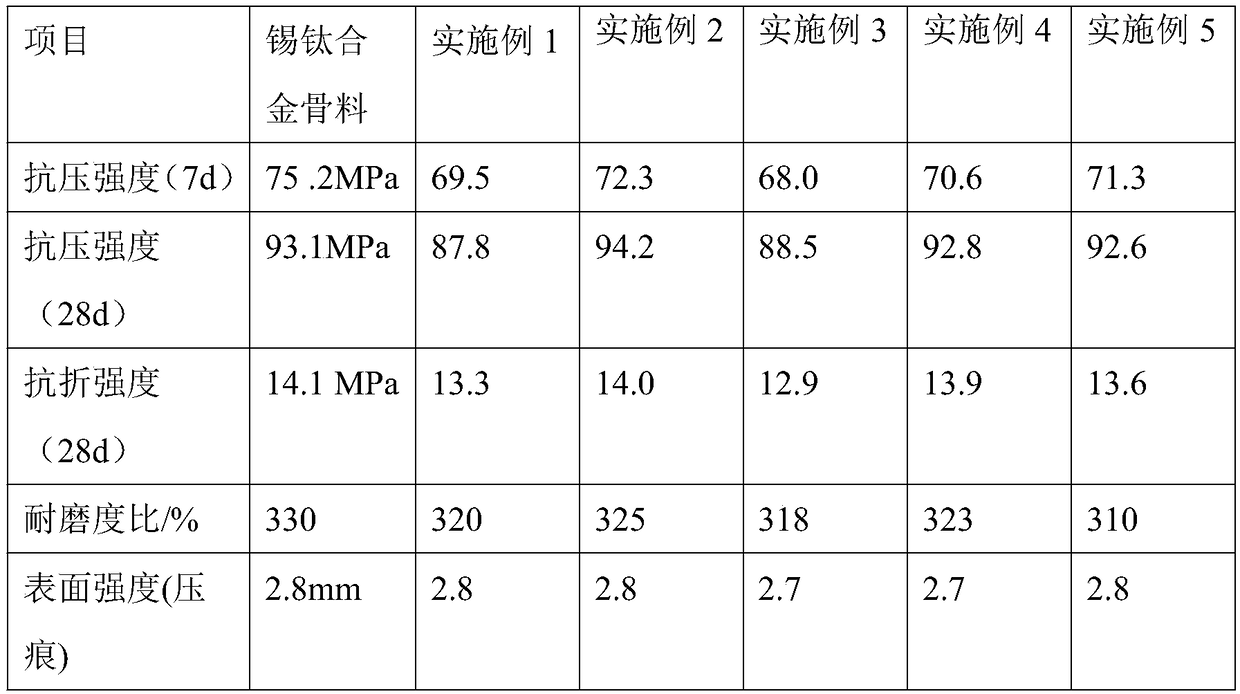

Examples

Embodiment 1

[0026] A dry-shattering ground hardener prepared by uniformly mixing the following raw materials: PO42.5R cement: 335 parts, silica fume (310kg / m 3 ): 19 parts, copper slag: 790 parts, water reducing agent (naphthalene series): 5 parts.

[0027] The copper slag is water-quenched copper slag after treatment and gradation optimization; the water-quenched copper slag is a glassy material formed by melting copper smelting slag in a water quenching pool behind the furnace.

[0028] The treatment and gradation optimization process of the above copper slag are as follows:

[0029] (1) Grinding: use a ball mill to crush the water-quenched copper slag in its original state, and the running time of the ball mill is 3 minutes;

[0030] (2) Screening and classification: Screen the crushed copper slag, retain all particles below 2.36mm, and further classify through 0.075mm, 0.15mm, 0.3mm, 0.6mm, 1.18mm sieves to obtain 0 - 0.075mm, 0.075-0.15mm, 0.15-0.3mm, 0.3-0.6mm, 0.6-1.18mm, 1.18-2....

Embodiment 2

[0039] A dry-shattering ground hardener prepared by uniformly mixing the following raw materials: PO42.5R cement: 335 parts, silica fume (310kg / m 3 ): 19 parts, copper slag: 790 parts, water reducing agent (naphthalene series): 5 parts.

[0040] The copper slag is water-quenched copper slag after treatment and gradation optimization; the water-quenched copper slag is a glassy material formed by melting copper smelting slag in a water quenching pool behind the furnace.

[0041] The treatment and gradation optimization process of the above copper slag are as follows:

[0042] (1) Grinding: use a ball mill to crush the water-quenched copper slag in the original state, and the running time of the ball mill is 5 minutes;

[0043](2) Screening and classification: Screen the crushed copper slag, retain all particles below 2.36mm, and further classify through 0.075mm, 0.15mm, 0.3mm, 0.6mm, 1.18mm sieves to obtain 0 - 0.075mm, 0.075-0.15mm, 0.15-0.3mm, 0.3-0.6mm, 0.6-1.18mm, 1.18-2.3...

Embodiment 3

[0052] A dry-shattering ground hardener prepared by uniformly mixing the following raw materials: PO42.5R cement: 335 parts, silica fume (310kg / m 3 ): 19 parts, copper slag: 790 parts, water reducing agent (naphthalene series): 5 parts.

[0053] The copper slag is water-quenched copper slag after treatment and gradation optimization; the water-quenched copper slag is a glassy material formed by melting copper smelting slag in a water quenching pool behind the furnace.

[0054] The treatment and gradation optimization process of the above copper slag are as follows:

[0055] (1) Grinding: use a ball mill to crush the water-quenched copper slag in its original state, and the running time of the ball mill is 3 minutes;

[0056] (2) Screening and classification: Screen the crushed copper slag, retain all particles below 2.36mm, and further classify through 0.075mm, 0.15mm, 0.3mm, 0.6mm, 1.18mm sieves to obtain 0 - 0.075mm, 0.075-0.15mm, 0.15-0.3mm, 0.3-0.6mm, 0.6-1.18mm, 1.18-2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com