Carbon element coreless electrode

A hollow electrode and carbon technology, applied in electrical components, electric heating devices, heating through discharge, etc., can solve the problems of anti-bending, high compressive strength, low electrode resistivity, small thermal expansion coefficient, etc., and achieve high compressive strength , good air permeability and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of electrode conductive material with graphite as the main component, including the weight percentage of each component is:

[0045] The coke is needle coke with a particle size of 50mm and a weight percentage of 10%.

[0046] Graphite crushed particle size is 80mm, percentage by weight is 20%,

[0047] Anthracite graphite coal particle size is 50mm, percentage by weight is 15%,

[0048] Metallurgical graphite coke with a particle size of 50mm and a weight percentage of 20%,

[0049] Silica particle size is 0.3mm, percentage by weight is 1.8%,

[0050] Stearic acid 1%,

[0051] Calcined petroleum coke particle size is 50mm, 15%,

[0052] Modified asphalt 17.2%.

Embodiment 2

[0054] A kind of electrode conductive material with carbon as the main component, including the weight percentage of each component is:

[0055] The weight percent of each component is:

[0056] Needle coke, particle size 30mm, 8%,

[0057] Graphite crushed particle size is 50mm, 35%,

[0058] Anthracite graphite coal particle size 30mm, 15%,

[0059] Graphite coke particle size is 30mm, 12%,

[0060] Silicon oxide particle size is 0.1mm, 1.2%,

[0061] Stearic acid 1%,

[0062] Calcined petroleum coke particle size 30mm, 8%,

[0063] Modified bitumen 19.8%.

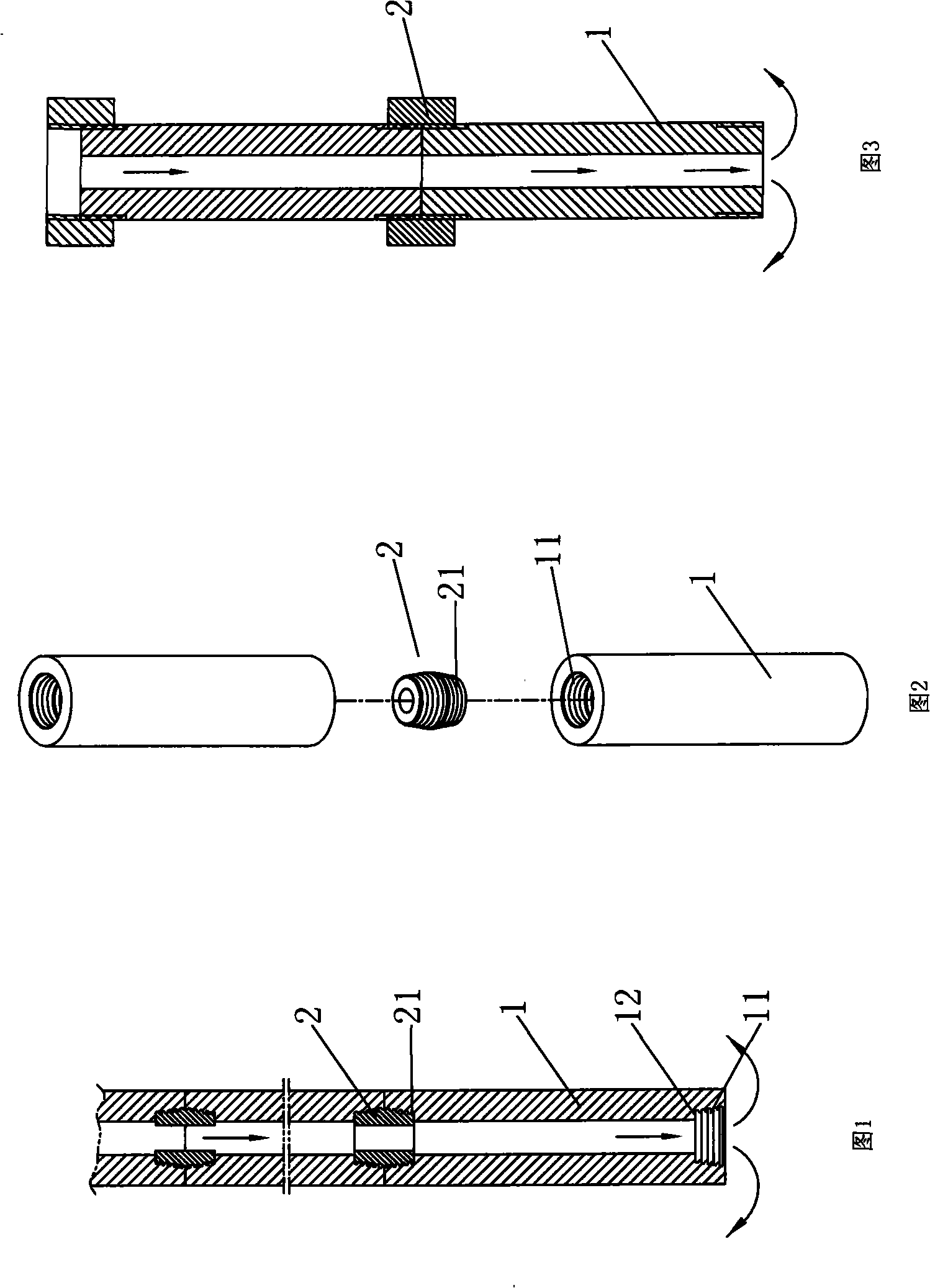

[0064] A carbon hollow electrode made of the above-mentioned electrode material includes an electrode body 1 and an electrode joint 2, as shown in FIG. The electrode joint 2 is hollow cylindrical. The upper and lower ends of the electrode body 1 have threads 11, and the electrode connector 2 is also provided with threads 21; The upper and lower ends of the electrode main body 1 have recesses 12 , the side walls ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com