High heat conductivity reinforced graphite composite material and preparation method thereof

A technology of high thermal conductivity and composite materials, applied in the field of thermally conductive composite materials, can solve problems such as weak bonding force, and achieve the effects of excellent thermal conductivity, high thermal conductivity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

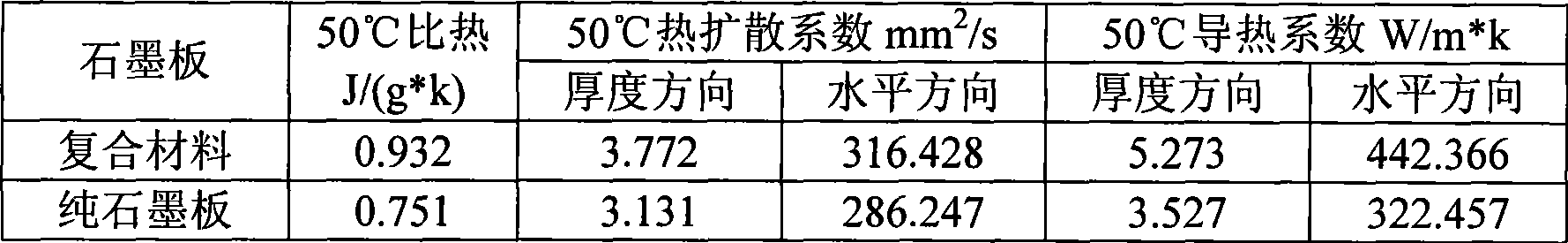

Embodiment 1

[0022] Adopt chemical method to prepare expanded graphite, the used fine natural flake graphite of this example, its particle size is 300 μ m, purity is 99.5%, and intercalation agent adopts the concentrated sulfuric acid that concentration is 98%, and addition ratio is graphite: concentrated sulfuric acid=1: 2.5 (weight ratio), the oxidizing agent adopts 35% hydrogen peroxide, and the addition ratio is graphite: hydrogen peroxide=1: 0.18 (weight ratio). Control the reaction temperature at 30-60°C, intercalation reaction for 40 minutes, then wash the intercalated product with water until the pH value is greater than 4, and then dry it at 100°C for 2 hours until the moisture content is less than 3%. Carry out high-temperature expansion treatment at high temperature to obtain expanded graphite with an expansion volume of 250ml / g.

[0023] The boron nitride used has a purity of 99.0% and a particle size of 300 μm. According to the ball-to-material ratio of 5:1, 50kg of grinding ...

Embodiment 2

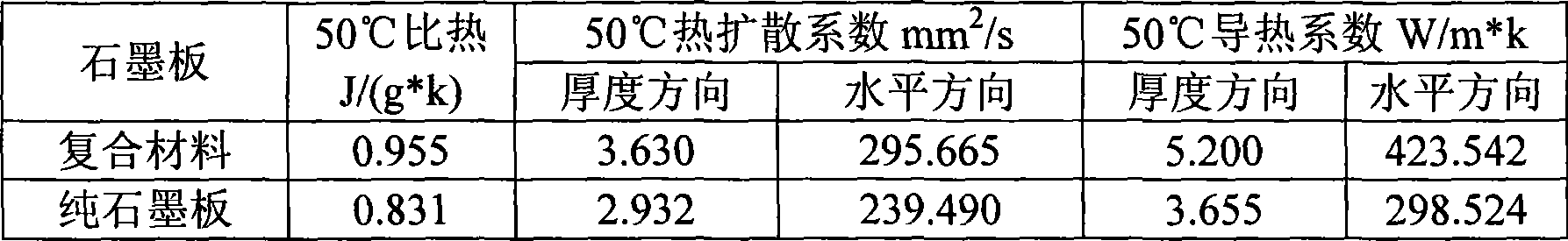

[0035] Embodiment two: adopt chemical method to prepare expanded graphite, the used fine natural flake graphite of this example, its particle size is 178 μ m, and purity is 99.5%, and intercalation agent adopts the concentrated sulfuric acid that concentration is 98%, and addition ratio is graphite: concentrated sulfuric acid=1 : 2.5 (weight ratio), the oxidizing agent adopts 35% hydrogen peroxide, and the addition ratio is graphite: hydrogen peroxide=1: 0.20 (weight ratio). Control the reaction temperature at 30-60°C, intercalation reaction for 40 minutes, then wash the intercalated product with water until the pH value is greater than 4, and then dry it at 100°C for 2 hours until the moisture content is less than 3%. Carry out high-temperature expansion treatment at low temperature to obtain expanded graphite with an expansion volume of 200ml / g.

[0036] The boron nitride used has a purity of 99.0% and a particle size of 500 μm. According to the ball-to-material ratio of 5:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com