High-temperature-resistant high-strength fireproof door panel and manufacturing method thereof

A high-strength fire door core technology, applied in the field of fire door materials, can solve the problems of foam cement boards such as easy water absorption, inability to find, and fragile bulk density, so as to improve the comprehensive performance of fire prevention, reduce the generation of smoke, and increase the specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

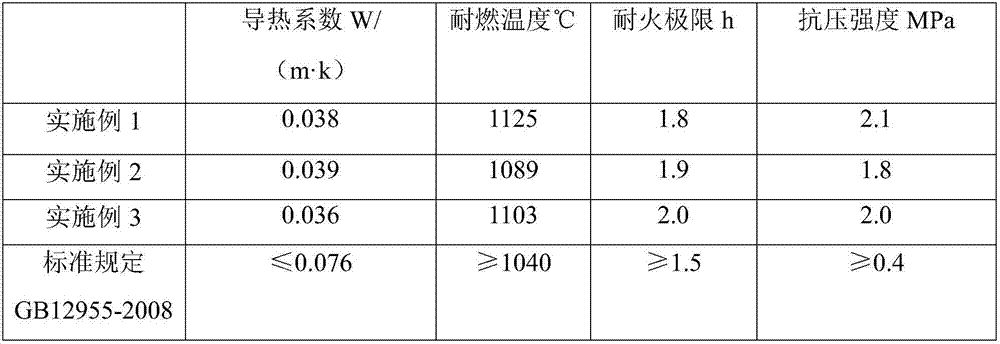

Examples

Embodiment 1

[0034] A high-temperature-resistant high-strength fireproof door core plate in this embodiment includes the following raw materials in parts by weight:

[0035] 50 parts of foaming agent, 30 parts of perlite powder, 20 parts of ore filler, 10 parts of magnesium sulfate, 14 parts of magnesium oxide, 3 parts of expandable graphite, 4 parts of zinc borate, 8 parts of calcium hydroxide, 25 parts of adhesive, 10 parts of desulfurized gypsum, 4 parts of boron oxide, 15 parts of reinforcing fiber, and 10 parts of anti-cracking fiber.

[0036] The foaming agent in this embodiment is water, bone glue, galactomannan gum, alkylphenol polyoxyethylene ether, sodium lignosulfonate synthesized by weight ratio 10:3:2:1:5 colloid foaming agent.

[0037] The ore filler in this embodiment is a mixture of calcined kaolin, bentonite, talcum powder, quartz powder and vermiculite powder in a weight ratio of 3:2:1:2:1; the calcined bentonite and kaolin are all heated at 700°C Calcining at lower tempe...

Embodiment 2

[0047] A high-temperature-resistant high-strength fireproof door core plate in this embodiment includes the following raw materials in parts by weight:

[0048] 80 parts of foaming agent, 40 parts of perlite powder, 30 parts of ore filler, 14 parts of magnesium sulfate, 18 parts of magnesium oxide, 5 parts of expandable graphite, 6 parts of zinc borate, 12 parts of calcium hydroxide, 35 parts of adhesive, 16 parts of desulfurized gypsum, 6 parts of boron oxide, 25 parts of reinforcing fiber, and 14 parts of anti-cracking fiber.

[0049] The foaming agent in this embodiment is water, bone glue, galactomannan gum, alkylphenol polyoxyethylene ether, sodium lignosulfonate synthesized by weight ratio 10:3:2:1:5 colloid foaming agent.

[0050] The ore filler in this embodiment is a mixture of calcined kaolin, bentonite, talcum powder, quartz powder and vermiculite powder in a weight ratio of 3:2:1:2:1; the calcined bentonite and kaolin are all heated at 750°C Calcining at lower te...

Embodiment 3

[0060] A high-temperature-resistant high-strength fireproof door core plate in this embodiment includes the following raw materials in parts by weight:

[0061] 65 parts of foaming agent, 35 parts of perlite powder, 25 parts of ore filler, 12 parts of magnesium sulfate, 16 parts of magnesium oxide, 4 parts of expandable graphite, 5 parts of zinc borate, 10 parts of calcium hydroxide, 30 parts of adhesive, 13 parts of desulfurized gypsum, 5 parts of boron oxide, 20 parts of reinforcing fiber, 12 parts of anti-cracking fiber.

[0062] The foaming agent in this embodiment is water, bone glue, galactomannan gum, alkylphenol polyoxyethylene ether, sodium lignosulfonate synthesized by weight ratio 10:3:2:1:5 colloid foaming agent.

[0063] The ore filler in this embodiment is a mixture of calcined kaolin, bentonite, talcum powder, quartz powder and vermiculite powder in a weight ratio of 3:2:1:2:1; the calcined bentonite and kaolin are all heated at 720°C Calcining at lower temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com